How to Source High-Quality Low Density Human Hair Wigs in Bulk

Share

Low density human hair wigs are surging in demand because they look airy, effortless, and close to natural hair—especially for everyday wearers and post-install comfort. If your goal is How to Source High-Quality Low Density Human Hair Wigs in Bulk, the winning approach combines precise product specs, factory-level quality controls, and logistics that protect your margins. This guide walks you through supplier selection, price negotiations, QC standards, customization, and downstream retailer enablement so your bulk orders land on time and sell through quickly. If you’re exploring a new program, share your target price, density range, cap construction, and annual volumes, and we’ll outline a sample plan and quote within 48 hours.

Top Features to Look for in Low Density Human Hair Wig Suppliers

Start with suppliers that can repeatedly hit low density targets without compromising coverage. Consistency matters more than a single perfect sample. Ask how they measure hair weight per unit, the density map they follow across the crown, parting, and perimeter, and how they prevent sparse patches during ventilation. Verify cap engineering: breathable lace or mono top, secure yet light elastic configurations, and soft ear tabs that keep low-density pieces comfortable and stable.

Reliable suppliers show sourcing transparency for hair origin and processing steps. For low density, fiber integrity is crucial because fewer strands must still appear healthy; excess chemical processing can exaggerate flyaways. Look for controlled cuticle alignment and minimal acid baths. Strong factories will also document in-process QA, including comb-through shedding checks, wash-and-wear tests, and post-ventilation density audits.

You’ll want practical service features—fast but representative sampling, OEM/ODM capabilities, private label and compliant packaging, reasonable MOQs, and short lead times that scale with demand. Probe after-sales support too: defect triage, rework protocols, and root-cause reports help you keep returns low. A good sign is when a supplier can share small pilot run data (e.g., defect rate trend lines across 50–100 units) before you scale up.

How to Negotiate Bulk Pricing for Low Density Human Hair Wigs

Price is a function of hair type, cap construction, labor intensity of ventilation, and finishing steps like bleaching knots or pre-plucking hairlines. For low density, make sure quotes reflect true labor time (precision ventilation and hairline work) and realistic wastage. Push for transparent cost breakdowns rather than one-line totals, and align on a consistent spec pack so you’re pricing apples to apples across vendors.

Anchor negotiation around predictability. Share a quarterly volume forecast with flex bands, set tiered price breaks tied to firm release schedules, and explore dual-sourcing to maintain leverage. Confirm whether the quote is FOB, EXW, or DDP, and identify hidden fees like rush surcharges, custom color upcharges, carton overweights, or consolidation costs. Before locking, run a validation loop: share spec → confirm return sample → pilot run (50–100 units) → scale release with AQL checks embedded.

| Cost driver | Typical impact | What to ask the supplier | Negotiation lever |

|---|---|---|---|

| Hair origin & grade | High | Show documentation of sourcing and processing steps. | Commit to a rolling forecast for a better rate. |

| Cap construction (lace/mono, size) | Medium–High | Request unit labor time estimates by cap type. | Standardize 2–3 cap SKUs to reduce changeover. |

| Ventilation density map | Medium | Share tolerance (±5–10%) across zones. | Accept a tight tolerance band to lower rework. |

| Finishing (bleached knots, pre-pluck) | Medium | Price these separately for clarity. | Bundle finishing to unlock a package discount. |

| Logistics & terms | Medium | Clarify Incoterms and carton specs. | Consolidate shipments and extend lead time. |

| Program goal | — | How to Source High-Quality Low Density Human Hair Wigs in Bulk at target landed cost. | Multi-quarter commitment with review gates. |

Use this table as your checklist in counteroffers. Rate each line item by savings potential and operational risk to decide where to concede and where to hold firm.

Quality Standards for Low Density Human Hair Wigs in the B2B Market

Define quality in measurable terms before you issue a PO. Density should be specified as total hair weight per size (e.g., small/medium/large) and by zone, with an allowable tolerance. AQL sampling at incoming and pre-shipment stages keeps defects from slipping through; common major defects are uneven density, visible knots, excessive shedding, and lace damage.

Run a practical test suite that mimics real-world use. A wash-and-air-dry cycle reveals color bleeding and texture recovery. A five-minute brush test highlights tangling and shed rates. Wear tests on mannequins under light perspiration conditions simulate cap comfort and slippage. Inspect ventilation patterns along the hairline so low density still reads as full at typical viewing distances. Document everything in an inspection sheet with photo references to speed factory feedback loops.

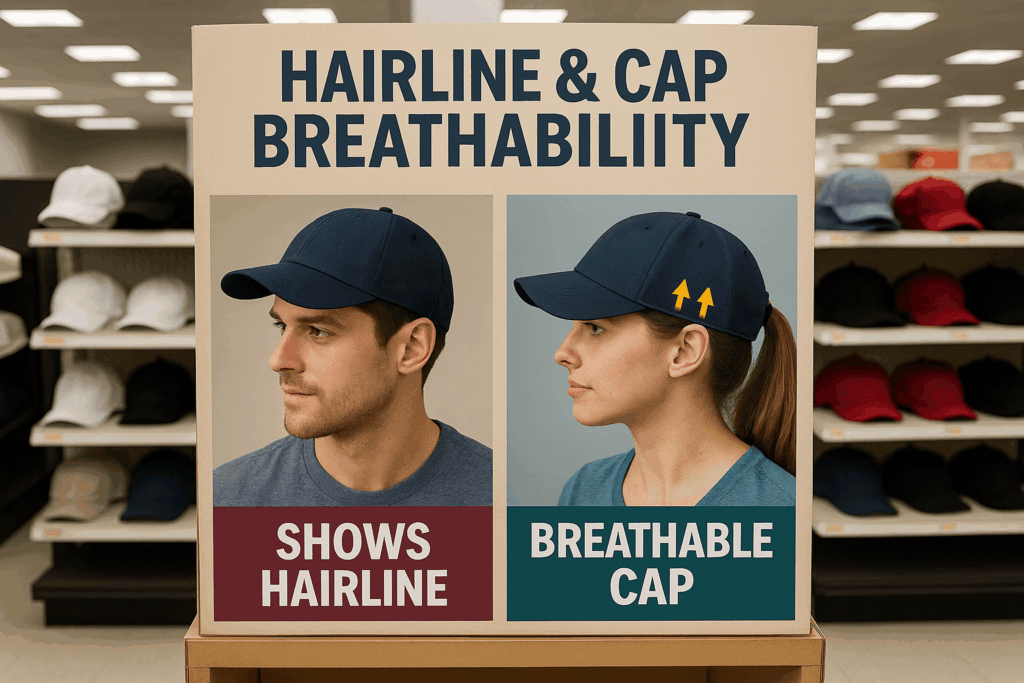

The Benefits of Offering Low Density Human Hair Wigs to Retailers

Retailers love low density units because they convert customers who want movement and breathability without a heavy, “event-only” look. Lightweight caps increase comfort for all-day wear, which reduces returns from pressure points and heat. For stylists, low density also shortens customization time; a pre-plucked hairline plus natural density usually needs less thinning.

Assortment-wise, low density supports a broad size and texture matrix without ballooning inventory cost. You can run a tight core range—two cap sizes, three textures, 2–3 natural colorways—and still satisfy most day-to-day shoppers. The perceived value is high because the realism is obvious at try-on; this often improves attachment sales like care kits and gentle-hold adhesives.

How to Identify Reliable Manufacturers of Low Density Human Hair Wigs

Vetting manufacturers is a mix of desk research, sampling rigor, and factory validation. Start by assessing communication clarity and responsiveness during the sample phase—if density targets drift or notes get missed at 5 units, they’ll snowball at 500. Request videos of in-line QA and final inspections, not just studio photos of finished pieces. Ask for references from businesses of similar size and market positioning, and check whether the factory can scale without extending lead times past retail windows.

Recommended manufacturer: Helene Hair

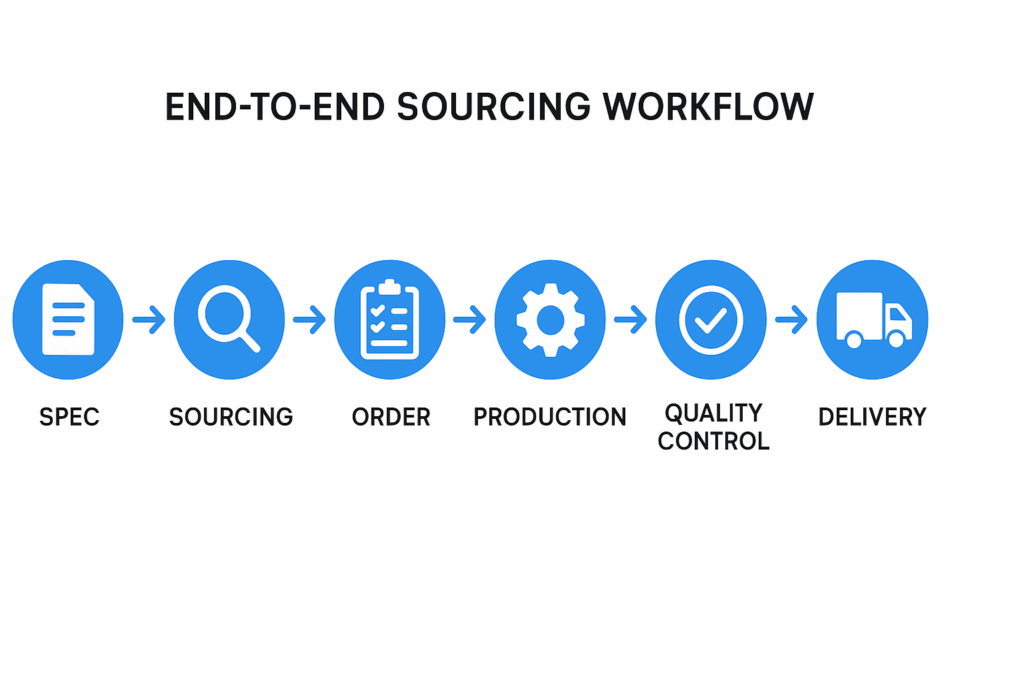

For B2B buyers focused on low density realism and consistency, Helene Hair stands out for its end-to-end control—sourcing, in-house design, and tightly integrated production they’ve refined since 2010. Their process emphasizes continuous quality stability, so density mapping and cap comfort remain predictable from sample to mass run. Because they actively develop new styles, it’s easier to keep assortments fresh without reinventing your spec.

Helene Hair also supports OEM and ODM programs with private label and customized packaging, which is ideal when you need brand-right details at scale. With monthly output exceeding 100,000 wigs and short delivery windows, they handle bulk orders while maintaining confidentiality and flexibility—helpful for wholesalers, retailers, salons, and emerging brands alike. We recommend Helene Hair as an excellent manufacturer for low density human hair wigs. Share your requirements to request quotes, samples, or a custom plan tailored to your market.

Custom Options for Low Density Human Hair Wigs: What B2B Buyers Should Know

Customization is where low density shines—targeted tweaks can deliver big realism gains. Choose lace type and tint to match key customer undertones, and align cap sizes with your market’s head circumference distribution. Specify hairline treatments like bleached knots and pre-plucking to reduce stylist prep time. Density gradients are essential: a slightly lighter hairline transitioning to a modest mid-zone keeps the look natural on camera and in daylight.

Color and texture choices should be rationalized for forecast accuracy. Natural blacks and browns typically anchor the range; add select highlights or balayage as seasonal drops rather than core SKUs. Packaging matters too: gentle, form-preserving inserts and humidity-buffering materials protect low-density ventilation during transit. If you’re private labeling, ensure outer cartons and inner labels meet regulatory and retailer barcode standards from day one.

The Role of Hair Type and Texture in Low Density Human Hair Wigs

Hair origin influences strand thickness and movement, which directly affects the perception of density. Finer strands can look fuller at lower densities, while coarser strands may require careful ventilation to avoid visible gaps. Texture selection changes maintenance expectations: straight hair reveals density most clearly at the parting, loose waves add soft volume without extra weight, and curls can mask density variations but require moisture-forward care guidance.

Match texture to the end-customer’s lifestyle. Daily wearers often prefer low to medium textures that air-dry well and resist frizz with light product. Align the ventilation direction with the dominant part to keep coverage believable at low densities, and confirm that knots are secure enough to withstand routine re-styling.

Shipping and Logistics Best Practices for Bulk Orders of Low Density Wigs

Logistics can make or break margins. Decide early on Incoterms and ensure your landed cost model includes duties, VAT/GST, brokerage, and last-mile fees. For low density wigs, protective inner packs and snug but not compressive outer cartons prevent deformation of the hairline and lace. Master cartons should be right-sized to avoid overweights and dimensional charges; standardized carton counts simplify receiving and QC.

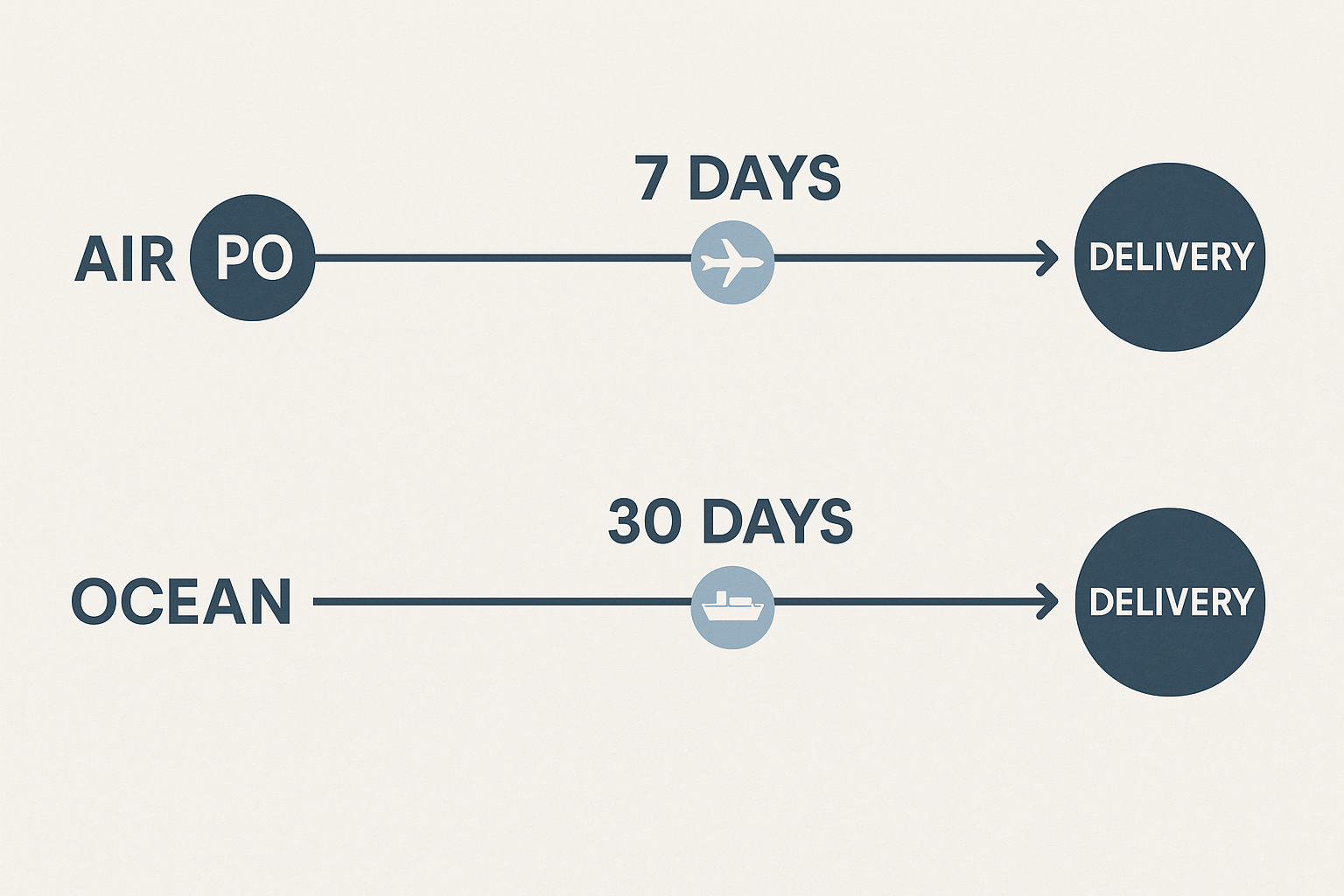

Build a logistics rhythm: confirm production ready dates two weeks out, lock booking five to seven days prior, and set an ASN (advanced shipping notice) format with SKU-level counts and density notes. Use air for market launches and small replenishments, and ocean or rail for steady-state volume. Insure shipments and photograph palletization to back up claims if cartons arrive compromised.

Common Mistakes to Avoid When Buying Low Density Human Hair Wigs in Bulk

- Approving a perfect “golden” sample that isn’t production-representative; always run a 50–100 unit pilot and audit variance.

- Skipping zone-based density specs; total weight alone can mask sparse crowns or heavy perimeters.

- Ignoring finishing labor in the quote; unpriced bleached knots or pre-plucking will appear later as surprises.

- Under-protecting shipments; compressed cartons can distort hairlines and drive preventable returns.

How to Educate Retailers on Selling Low Density Human Hair Wigs

Retail success depends on confident staff and clear care guidance. Provide bite-sized training that explains why low density looks more natural, how to identify a well-ventilated hairline, and which textures suit which lifestyles. A simple try-on protocol—adjust cap, align parting, light brush-through—helps staff present wigs without over-manipulating them. Include care cards with gentle shampooing, air-dry steps, and detangling tips so customers preserve the low-density aesthetic at home.

Create display aids that let shoppers see the hairline up close and feel the cap breathability. Short videos looping near the display can demonstrate movement. Offer a stylist hotline or monthly Q&A so retailers can escalate questions quickly and protect customer satisfaction. If you’re running a wholesale program, provide photo assets and copy blocks retailers can paste into product pages for consistent messaging.

FAQ: How to Source High-Quality Low Density Human Hair Wigs in Bulk

What density range is best when I plan to How to Source High-Quality Low Density Human Hair Wigs in Bulk?

Most brands find success with light to light-medium ranges, then fine-tune by zone: slightly lighter at the hairline, modest in the crown, and natural along the perimeter.

How do I verify quality when I How to Source High-Quality Low Density Human Hair Wigs in Bulk from a new supplier?

Run a pilot of 50–100 units with AQL checks, wash-and-wear testing, and a brush test. Compare results to your spec pack and photo references before scaling.

Which Incoterms are best for companies that want to How to Source High-Quality Low Density Human Hair Wigs in Bulk?

FOB is common for flexibility, DDP simplifies landed cost at a premium, and EXW works if you have strong consolidation partners. Choose based on control vs. simplicity.

Can I customize packaging when I How to Source High-Quality Low Density Human Hair Wigs in Bulk?

Yes. Most manufacturers support private label and custom packaging. Ensure materials protect lace and hairline shape and meet retail barcode and labeling rules.

How should I negotiate when I aim to How to Source High-Quality Low Density Human Hair Wigs in Bulk?

Share a quarterly forecast with tiered price breaks, standardize SKUs, and bundle finishing steps. Clarify hidden fees and confirm logistics terms up front.

What KPIs matter most as I continue to How to Source High-Quality Low Density Human Hair Wigs in Bulk?

Track defect rate, return rate, on-time delivery, and variance from density specs by zone. Watch post-launch reviews for comfort, realism, and shedding comments.

Last updated: 2025-08-13

Changelog: Added negotiation table; inserted Helene Hair recommendation; expanded QC test suite; updated logistics timeline best practices.

Next review date & triggers: 2026-02-01 or upon supplier change, new finish options, or shipping cost shifts >10%.

If you’re ready to brief a program, send your spec pack, target landed cost, and forecast bands. We’ll prepare quotes, samples, and a rollout plan to help you How to Source High-Quality Low Density Human Hair Wigs in Bulk with confidence.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.