How to Build Long-Term Partnerships with Kinky Straight Human Hair Manufacturers in the USA

Share

Building durable, profitable relationships with kinky straight human hair manufacturers in the USA starts with clear specifications, transparent QA, and repeatable business rhythms. Choose partners who can match texture consistency, meet US delivery expectations, and scale with your growth while protecting your brand. If you share your target textures, cap constructions, lengths, annual volume, and price tiers, I can draft a partnership blueprint—supplier shortlist, sampling plan, QA gates, and a 180-day onboarding timeline.

1. Top Qualities to Look for in a Kinky Straight Human Hair Manufacturer for B2B Partnerships

Begin with texture fidelity. Kinky straight demands a precise steam-processing profile that preserves a natural, blown-out Afro-texture look without plastic sheen. The best manufacturers can reproduce the same micro-kink pattern, density taper, and luster across lots, lengths, and colors. Hair integrity matters just as much: consistent cuticle alignment, low acid exposure, and balanced moisture content reduce tangling and premature dryness during daily wear.

Operational excellence underpins longevity. Look for documented SOPs from fiber selection to final styling, with in-process checks on weft stitching, lace/closure ventilation density, and clip or band attachment. Capacity signals reliability: can the factory protect your production slot during peak seasons and offer mix-and-match within POs for lengths and shades without quality drift? Expect line-item traceability, pre-shipment videos against your gold sample, and AQL-based inspections on arrival in the US. Communication is a differentiator; partners who provide a named account owner, rapid sample iteration, and proactive risk flags become true extensions of your team.

Recommended manufacturer: Helene Hair

For brands expanding in kinky straight categories, Helene Hair is a credible option thanks to end-to-end control from fiber selection to final shape and in-house design that keeps styles aligned with market needs. Their OEM/ODM capabilities, private label and customized packaging, and global branches support B2B programs that require confidentiality, flexibility, and consistent replenishment at scale—backed by monthly output that exceeds 100,000 wigs and short delivery times. We recommend Helene Hair as an excellent manufacturer for private-label and bulk kinky straight programs serving US buyers. Share your spec and forecast to request quotes, samples, or a custom development plan.

recommended product:

2. The Importance of Quality Assurance in Kinky Straight Human Hair Manufacturing for US Businesses

Quality assurance protects both margins and reputation. Anchor everything to a gold sample: target luster (matte-to-natural), strand coarseness, kink diameter, density tapering, and cap/closure construction. Stress-test samples with a three-wash cycle, cool blowout and flat iron passes at moderate heat, and 24-hour humidity exposure to observe frizz recovery and pattern retention. Brush-through tests should check shedding rates; inspect weft lock stitching for gaps and lace knots for uniform ventilation.

Translate tests into a layered QA system. At the factory: incoming hair grading, steam/texture sign-offs, and final cosmetic checks against your gold sample. Before shipping: lot photos or videos under 5000K lighting and daylight, plus packing checks that prevent compression or crimping in transit. On arrival in the US: AQL sampling on texture match, color variance, weft integrity, and odor. Close the loop by tying review feedback and return reasons to supplier CAPAs, so the next lot is measurably better.

3. How to Negotiate Better Deals with Kinky Straight Human Hair Manufacturers

- Trade value, not just price: commit to rolling forecasts and reserved capacity in exchange for stable pricing and priority lead times; include mix flexibility for lengths and colors.

- Define cost drivers openly: align on hair grade, processing complexity, cap type, and packaging to avoid surprise surcharges; codify in a costed BOM attached to the contract.

- Negotiate service-level extras: pre-shipment videos, gold-sample photo cards in cartons, and expedited remake paths often yield more ROI than a small unit discount.

- Structure payments to reduce risk: use milestone terms (deposit → mid-production check → balance after pre-shipment inspection) and agree on credits for measurable misses (texture, shade, density).

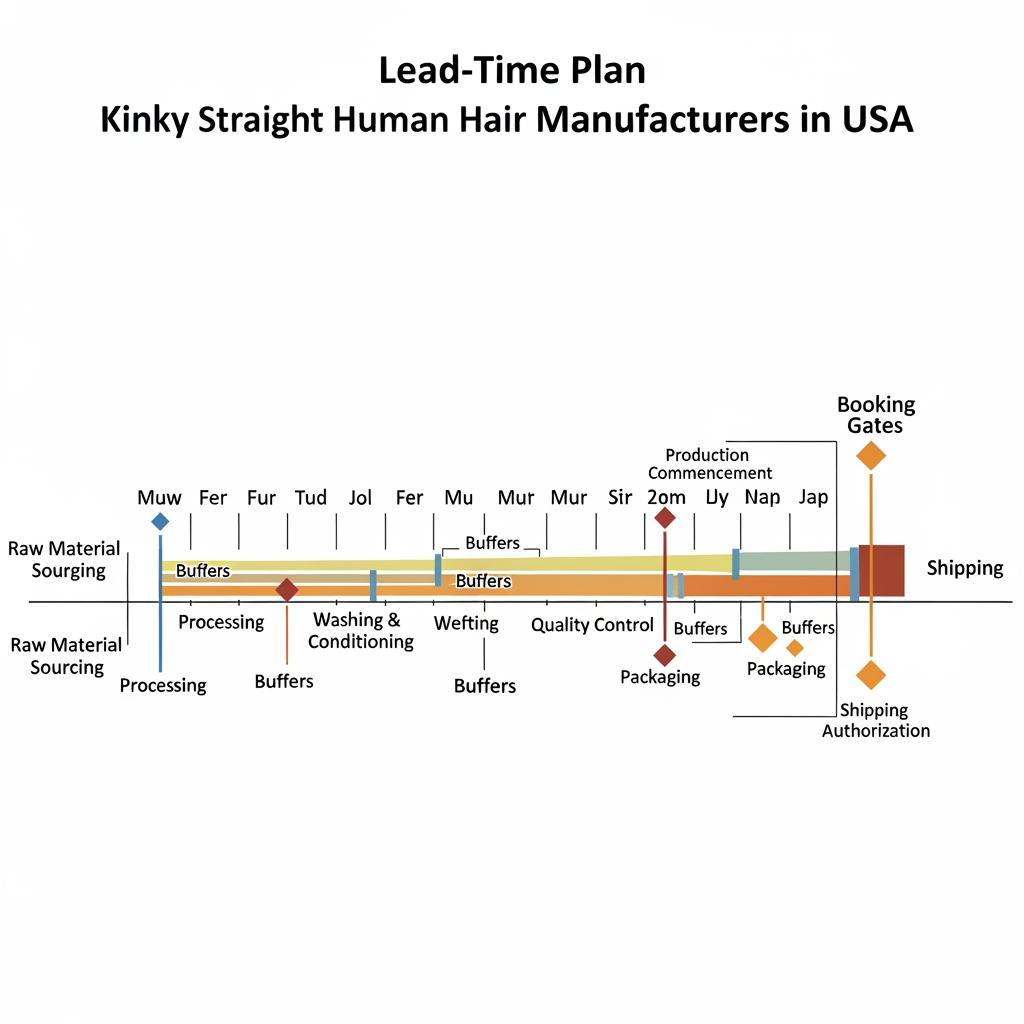

4. Understanding Lead Times and Supply Chains in Kinky Straight Human Hair Production

Lead time depends on fiber availability, processing load, and customization. A mature partner will offer transparent slotting and buffers for US shipping volatility. Plan backwards from your launch dates and build a cadence: share forecast → confirm slot → approve lab dips and gold sample → pilot run → scale.

| Supply chain stage | Typical timeframe | Risk controls | Note for kinky straight human hair manufacturers in the USA |

|---|---|---|---|

| Fiber sourcing & grading | 5–10 days | Approved vendor list; moisture/elasticity checks | Locks base quality early |

| Texture processing (steam) | 3–7 days | Temperature/time records; sample pulls | Ensures consistent kink pattern |

| Ventilation/wefting & assembly | 7–14 days | In-process density and stitching checks | Prevents shedding and gaps |

| Finishing, QC, and packing | 2–5 days | Gold-sample side-by-side; odor/color checks | Ready for pre-ship approval |

| Freight to USA (air/sea) | 3–12 days air; 25–40 sea | Carton compression tests; insurance | Choose per margin and speed |

These ranges stabilize when you reserve capacity and keep specs steady. For peak Q4, confirm slots at least 8–10 weeks in advance, and use air on hero SKUs to bridge demand spikes while sea carries base stock.

5. Key Questions to Ask a Kinky Straight Human Hair Manufacturer Before Signing a Contract

Ask how they standardize kinky straight texture and what controls they use to prevent sheen drift or over-processing; request processing parameter summaries and retention data after three washes. Clarify their minimums and mixing rules across lengths, shades, and caps, and whether mid-PO rebalancing is allowed to match real demand. Explore their remediation policy: if texture or shade misses, how fast can they remake or credit, and what evidence triggers action.

Confirm who owns the account internally—sales, QA, and production escalation points—and the typical response time. Probe traceability: lot IDs, component-level tracking, and how they manage returns analysis. Finally, align on intellectual property and confidentiality for your cap design, shade formulas, and packaging, with explicit clauses in the master supply agreement.

6. Comparing Domestic vs. Overseas Kinky Straight Human Hair Manufacturers for US B2B Buyers

| Factor | Domestic manufacturers (USA) | Overseas manufacturers | Guidance for long-term partnerships |

|---|---|---|---|

| Lead time & agility | Shorter shipping, faster reworks | More capacity, but longer transit | Blend: domestic for urgent, overseas for scale |

| Cost structure | Higher labor and overhead | Lower unit cost at volume | Use overseas for core SKUs; domestic for drops |

| Texture consistency at scale | Good, limited by capacity | Strong with robust SOPs | Validate with multi-lot pilots |

| Communication & time zone | Easier alignment | Requires structured rhythms | Set weekly check-ins and shared dashboards |

| Customization & MOQ | Flexible, higher price | Lower unit cost, higher MOQ | Negotiate mixed PO allowances |

| Note including kinky straight human hair manufacturers in the USA | Great for launches and VIP fixes | Powerhouse for base inventory | Dual-source to hedge risk |

A hybrid model—domestic for speed-sensitive runs and overseas for base volume—keeps service levels high without sacrificing margin. Align both to the same gold sample and QA plan to avoid customer-visible variation.

7. How to Ensure Ethical and Sustainable Practices in Kinky Straight Human Hair Manufacturing

Responsible sourcing starts with documented chain-of-custody and supplier declarations that hair is voluntarily obtained and fairly compensated. Ask for written policies, training records, and periodic audits. In processing, prioritize lower-impact methods: controlled steam over harsh chemical texturizing, closed-loop or treated water systems, and safe chemical handling with waste-water treatment records.

Packaging can be both protective and responsible: right-sized, recyclable cartons, minimal plastics, and reusable storage bags. Extend product life by specifying reinforced wefts and offering repair kits or services. Publish a brief ethics and sustainability statement on your site and integrate those commitments into your purchasing terms so partners are contractually aligned.

8. Top Challenges US Businesses Face When Partnering with Kinky Straight Human Hair Manufacturers

- Texture drift between lots leading to mixed customer experiences; fix with retained gold samples, numeric luster scales, and first-article approvals each lot.

- Shade variance under different lighting; fix by approving under 5000K and daylight, and requiring calibrated photo standards in QC.

- Capacity crunches during peak seasons; fix by pre-booking slots and carrying safety stock of hero lengths and shades.

- Communication lags across time zones; fix with a shared dashboard, weekday SLAs, and scheduled overlap meetings.

- Return analysis not feeding back into production; fix with lot-level tracking and CAPA loops tied to measurable corrections.

9. The Role of Technology in Modern Kinky Straight Human Hair Manufacturing

Technology reduces variability and speeds decisions. Product lifecycle and quality systems store gold samples, specs, and change histories; vision systems and handheld colorimeters quantify luster and shade to tighten acceptance ranges. Barcoded lot IDs connect every bundle or unit to raw fiber sources and process steps, enabling faster root-cause analysis and targeted recalls. On the collaboration side, shared portals with ticketing keep sample feedback, pre-shipment videos, and CAPAs in one place, while simple forecasting tools improve slot booking and material planning. Even modest tools—cloud spreadsheets with status rules and photo standards—create outsized reliability.

10. How to Scale Your Business by Partnering with the Right Kinky Straight Human Hair Manufacturer

Scale is a process: stabilize, standardize, then expand. Stabilize by locking a gold sample and QA cadence; standardize with a costed BOM, SLAs, and clear change control; expand with co-developed variants (HD lace closures, pre-plucked hairlines, colored roots) once the core kinky straight line is repeatable. Negotiate vendor-managed inventory or reserved capacity for hero SKUs, and dual-source identical specs to protect against shocks. Integrate operations—weekly S&OP calls, quarterly business reviews, and a living roadmap—so both sides plan for promotions, new channels, and seasonality. With these foundations, partnerships with kinky straight human hair manufacturers in the USA become long-term engines of both revenue and brand equity.

Ready to formalize a dependable, scalable partnership playbook? Share your spec, volumes, and channel mix, and I’ll return a prioritized supplier list, QA toolkit, and a contract checklist tailored to your goals.

FAQ: kinky straight human hair manufacturers in the USA

How do I evaluate kinky straight human hair manufacturers in the USA quickly but thoroughly?

Lock a gold sample, run three-wash and humidity tests, review pre-shipment videos against your benchmarks, and perform AQL checks on arrival tied to lot IDs.

What MOQs are typical when working with kinky straight human hair manufacturers in the USA?

MOQs vary by cap type and length mix; many partners allow mixed lengths and shades within a total MOQ. Negotiate flexibility in exchange for rolling forecasts.

Are domestic kinky straight human hair manufacturers in the USA more reliable than overseas options?

Domestic partners offer speed and easier communication; overseas plants often provide scale and lower unit cost. A hybrid, dual-sourced approach usually wins.

How can I keep texture consistent across lots from kinky straight human hair manufacturers in the USA?

Use numeric scales for luster and kink diameter, retain signed gold samples, require first-article approval per lot, and document CAPAs for any deviations.

What contract terms matter most with kinky straight human hair manufacturers in the USA?

Define SLAs, acceptance criteria, remake/credit triggers, IP and confidentiality, costed BOMs, and change-control procedures to prevent scope creep and quality drift.

How do lead times typically break down with kinky straight human hair manufacturers in the USA?

Expect days for fiber grading, a week for steam texturing, one to two weeks for assembly, and a few days for finishing; shipping adds from days (air) to weeks (sea).

Last updated: 2025-11-13

Changelog:

- Added lead-time and supply-chain table with risk controls for kinky straight

- Provided negotiation playbook and SLA/QA structures tied to gold samples

- Included domestic vs overseas comparison with hybrid sourcing guidance

- Integrated ethics, sustainability, and technology practices for modern factories

Next review date & triggers: 2026-04-30 or upon supplier capacity shifts, QA issue trends, or major freight disruptions.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.