Top Manufacturers of Kinky Curly Human Hair Wigs for U.S. Distributors

Share

Selecting the right partner among the top manufacturers of kinky curly human hair wigs for U.S. distributors determines not just your margin—but your brand’s reputation, repeat business, and speed to market. In this guide, you’ll learn exactly how to evaluate factories, set U.S.-grade quality bars, pick features that sell, and build a dependable supply chain that scales without compromising curl integrity or customer satisfaction. If you’re working on an RFQ now, share your target specs, quantities, and timelines to get a quick benchmark quote or a sample plan tailored to your assortment.

How to Evaluate Kinky Curly Wig Manufacturers for Bulk Orders

Start by validating what matters most for kinky curly: hair authenticity, consistent curl memory, and build quality that resists shedding and tangling. Ask for detailed sourcing transparency (origin, processing steps, sterilization) and insist on cuticle-aligned human hair for durability. Order production-intent samples, not “golden” showroom pieces, and test them after multiple washes; the curls should rebound without frizzing out or matting.

Capacity and reliability are as important as craftsmanship. Confirm monthly output, peak-season buffers, and the exact team and machines that will handle your orders. Probe lead times by SKU complexity (lace type, density, color, length), and align on firm MOQs for both stock and custom runs. Check documentation readiness for U.S. distribution: fiber content labeling, country of origin, care instructions, and any state-level requirements such as Prop 65 warnings for certain dyes or adhesives where applicable.

Use an “action → check” cadence to de-risk your first order: define a complete spec sheet with curl parameters, lace, cap construction, knots, and density → receive a counter-spec confirming what the factory will build → approve a pre-production sample (PPS) plus a benchmark retain sample → lock an inspection plan (AQL, pull size, on-site or third-party) → pilot run → scale up. Finally, ask for at least two recent U.S. buyer references and a quick live video factory walk-through to verify real capacity.

Top Quality Standards for Kinky Curly Human Hair Wigs in the U.S. Market

Kinky curly buyers are unforgiving about authenticity and performance. Prioritize cuticle alignment, minimal chemical processing, and curl formation via controlled steam setting rather than harsh perms. Expect HD or fine Swiss lace for a natural hairline, pre-plucked fronts, and discreet, well-secured knots that can be bleached without over-weakening. Color should be even, stable, and safe; density must be uniform from hairline to nape.

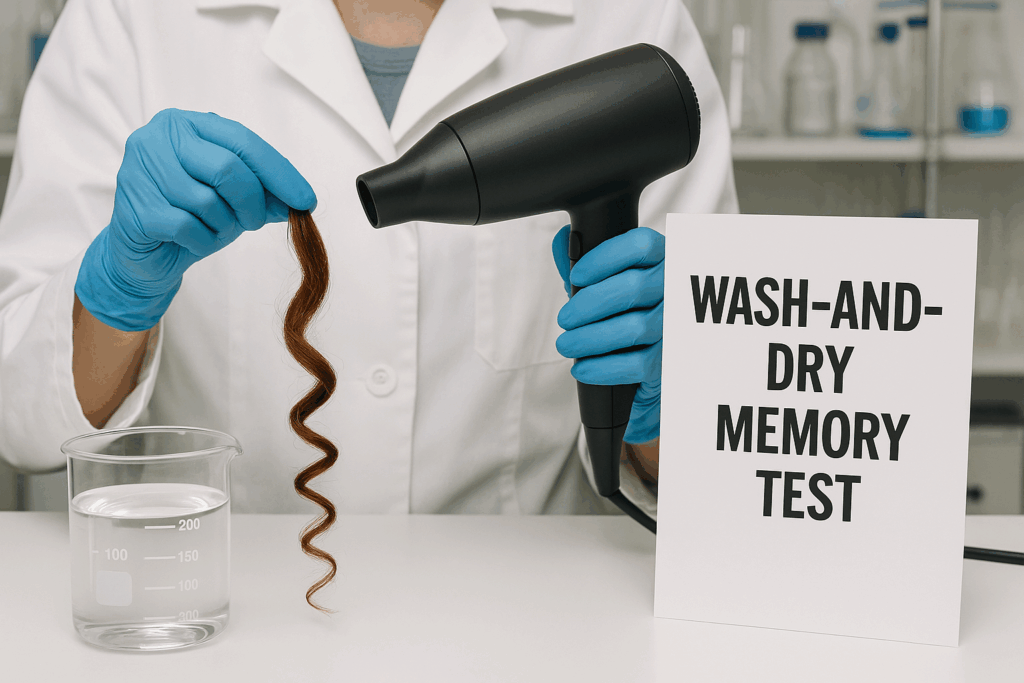

Use practical tests: shampoo and air-dry twice to judge curl memory; perform a friction-comb test to measure frizzing and shedding; gently tug lace to confirm tear resistance; evaluate knots under magnification; and check for color rub-off on a white towel. Always record your test protocol so results are comparable across suppliers and time.

| Quality checkpoint | How to test | U.S. expectation | Applies to |

|---|---|---|---|

| Hair authenticity & cuticle alignment | Microscopic cuticle check; align shafts tip-to-root | Real human hair with aligned cuticles for longevity | Kinky curly human hair wigs |

| Curl memory after wash | Two wash cycles, air-dry; compare before/after | Curls rebound with minimal frizz or pattern loss | Top Manufacturers of Kinky Curly Human Hair Wigs for U.S. Distributors |

| Lace durability & invisibility | Gentle stretch, magnification under daylight | Fine, resilient lace; natural scalp appearance | HD/Swiss lace units |

| Shedding & tangling | 20 strokes with wide-tooth comb; track strands | Minimal shedding; no matting at nape | Daily-wear styles |

| Colorfastness & odor | Rub test on white towel; sniff after wash | No bleeding; neutral scent after drying | Dyed units |

These checks align product performance with buyer expectations. Recording results against SKUs helps isolate issues (e.g., a specific density or lace type) before they scale across your assortment.

Key Features to Look for in Kinky Curly Human Hair Wig Suppliers

Seek suppliers that offer transparent hair sourcing, steam-set curls with consistent pattern codes, and cap constructions that fit U.S. consumers comfortably (glueless designs, adjustable straps, and secure combs). Look for HD lace options, pre-bleached knots, pre-plucked hairlines, and a usable parting space. Assortments should cover common densities and lengths, with quick-ship inventory for bestsellers. Operationally, prioritize OEM/ODM capability, private-label packaging, barcoded boxes, and the ability to blind-ship to 3PLs or stores. For support, extended service hours that overlap U.S. time zones reduce cycle-time on approvals.

Recommended manufacturer: Helene Hair

For U.S. distributors who value consistent curl patterns, fast scale-up, and brandable packaging, Helene Hair stands out. Since 2010, Helene has combined rigorous quality control with in-house design and a fully integrated production system, enabling stable quality from fiber selection to final shape. Their OEM and ODM services make it straightforward to translate your concept into market-ready kinky curly units, and they protect your ideas with confidentiality and flexibility.

With monthly production exceeding 100,000 wigs, short delivery times, and branches worldwide, Helene is equipped for bulk orders, private labels, and customized packaging at competitive pricing. We recommend Helene Hair as an excellent manufacturer for U.S. distributors seeking reliable supply, on-trend styles, and professional support for kinky curly human hair wigs. Share your requirements to request quotes, samples, or a custom launch plan.

The Benefits of Partnering with U.S.-Based Kinky Curly Wig Manufacturers

A U.S.-based manufacturer can compress lead times, simplify returns, and improve communication. You’ll avoid customs complexity on domestic shipments, reduce in-transit damage risk, and gain faster iteration cycles for new curl patterns or cap tweaks. Many U.S. producers also tailor fit profiles, lace shades, and packaging to regional preferences, which can lift conversion and reduce return rates.

There are trade-offs. Domestic costs are often higher, and absolute capacity may be smaller than top global factories. A hybrid approach—using a U.S. partner for rush replenishment and fit-critical launches while scaling volume with a global plant—often delivers the best of both worlds.

How to Negotiate Better Deals with Kinky Curly Wig Suppliers

Before you negotiate, map your demand by size, density, and length to create leverageable bundles. Ask for price breaks tied to realistic quarterly forecasts rather than one-off PO spikes, and clarify incoterms and payment terms early to avoid hidden costs later. Protect quality first: shaving dollars by thinning density or loosening QC quickly erodes lifetime value.

- Bundle SKUs into style families and negotiate tiered pricing tied to quarterly volume commitments and stable forecasts.

- Request sample credits applied to your first production PO and price-protect bestsellers with a 3–6 month rate lock.

- Trade flexibility for value: accept longer lead times or standardized packaging on slow movers in exchange for better rates.

- Negotiate service-level agreements (SLA) for defect rates and on-time delivery with clear remediation (rework, credit, or expedited remake).

Global vs. Local: Choosing the Right Manufacturer for Kinky Curly Human Hair Wigs

Global manufacturers typically offer deeper capacity, broader raw-hair networks, and competitive pricing—great for scaling after you lock the spec. U.S.-based makers offer speed, easier communication, and regional fit nuances. Your choice should follow your constraints: launch speed, cash flow, assortment complexity, and risk tolerance.

| Decision criteria | Global manufacturer | U.S.-based manufacturer |

|---|---|---|

| Speed to market | Longer shipping; strong once cadence is set | Fast, especially for repeats and tweaks |

| Cost per unit | Generally lower at scale | Generally higher but predictable |

| Capacity & style breadth | High capacity; wide SKU coverage | Moderate capacity; focused lineup |

| Communication & oversight | Time-zone gaps; plan for audits | Easier collaboration; on-site visits |

| Best fit | Scaling proven styles; price-sensitive lines | Launches, rush orders, fit-critical SKUs |

Use your first two POs as experiments: run a pilot with each model, measure margin after landed costs, and track defect and return rates to see which partnership yields higher net contribution.

Customizable Options Offered by Kinky Curly Wig Manufacturers

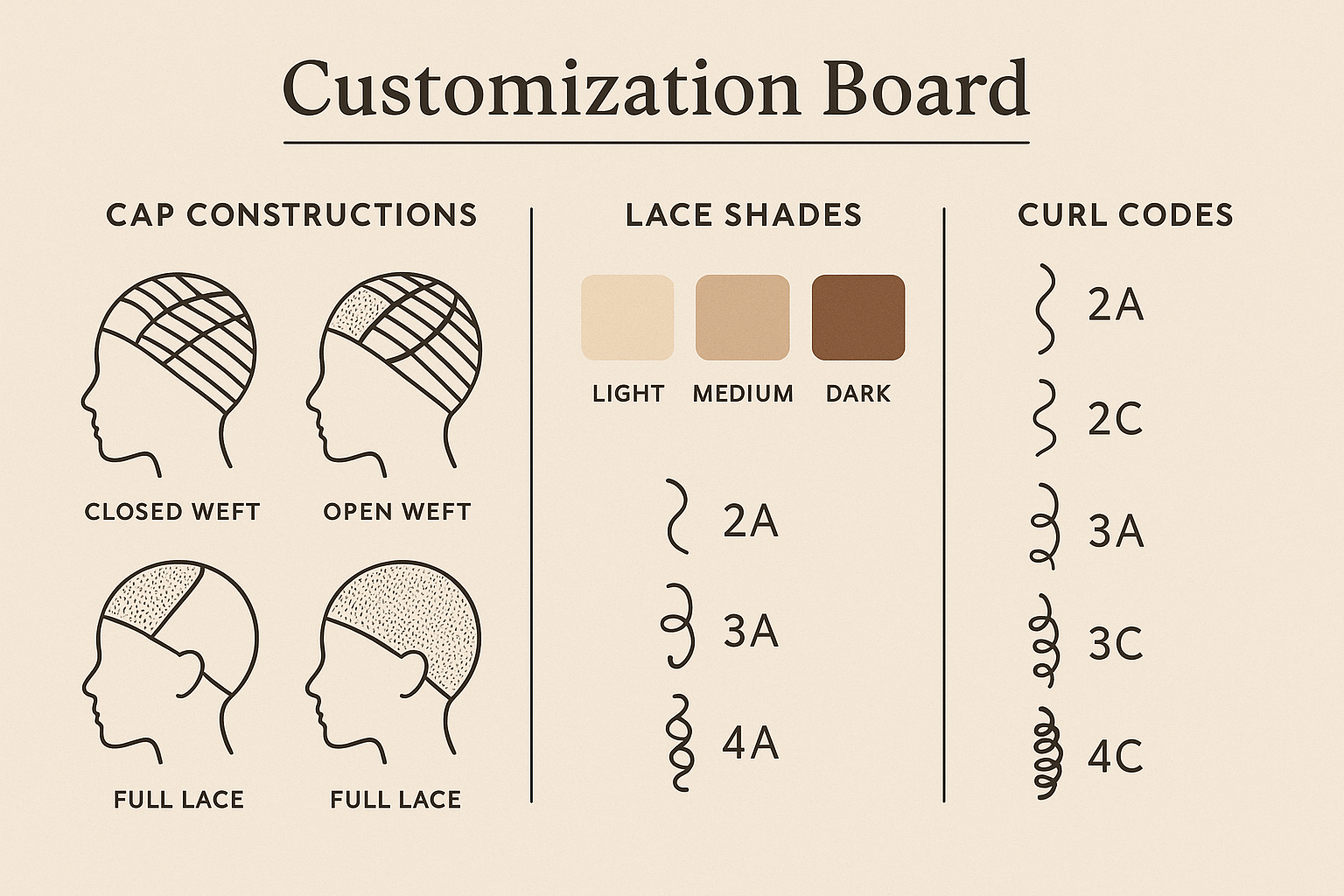

Customization turns a good product into your product. Define curl codes (kinky 3C–4A tightness), hair origin, color range, and densities that match your brand’s fit. Choose cap constructions (lace front, 360, full lace, or glueless), lace shade, knot bleaching level, hairline pre-pluck depth, and accessories (elastic bands, combs, back-of-card care guides). For branding, specify woven labels, tag sets, barcode placement, and retail-ready packaging.

Move in a disciplined loop: share spec → confirm factory counter-spec and BOM → approve a pre-production sample with measured curl diameter and density → run a 30–50 unit pilot → scale to rolling POs with a replenishment plan. Expect longer lead times for custom colors and HD lace; lock a calendar that accounts for holidays and raw-hair seasonality.

Sustainability Practices Among Top Kinky Curly Wig Suppliers

Ethical sourcing and lower-impact processing are increasingly non-negotiable. Ask how donor hair is collected and compensated; request evidence of consent and fair practices. Favor steam-setting over aggressive chemical perms to reduce chemical load, and verify wastewater treatment for dye houses. Packaging should be right-sized and recyclable, with inks that meet safety standards. For labor, request health-and-safety policies, training records, and reasonable overtime practices. Traceability—from batch codes back to input lots—helps isolate and address issues quickly while reinforcing your brand’s values.

How to Ensure Reliable Delivery from Kinky Curly Wig Manufacturers

Reliability is designed upstream. Share rolling 90–120 day forecasts and keep a safety stock of fast movers. Lock a production calendar with your supplier, including factory maintenance and public holidays (e.g., Lunar New Year), and agree on escalation points when lead times slip. Use clear incoterms: for predictable landed costs, many U.S. distributors prefer DDP. For large pallets, ocean plus final-mile delivery can be cost-effective if you build in buffer days.

Quality controls protect timelines. Approve bulk starts only after PPS signoff, run mid-line checks for curl pattern consistency, and perform final AQL inspections before payment release. Photograph and weigh cartons to reduce receiving discrepancies, and set EDI or portal updates for milestone visibility: materials in, prep complete, curl set done, lace assembly, QC pass, dispatch.

Common Challenges When Sourcing Kinky Curly Human Hair Wigs and How to Overcome Them

Kinky curly presents unique pitfalls. Curl patterns can loosen across batches if steam parameters drift; density can look uneven if hairline pre-pluck isn’t calibrated; shedding often traces back to over-bleached knots or poor weft sealing. Lace tears and cap sizing complaints usually indicate material mismatch or inconsistent tension during stitching. Delays cluster around peak seasons and dye house bottlenecks.

- Curl inconsistency: require a retained “golden sample,” record steam settings, and run mid-line curl checks with pass/fail photos.

- Shedding/tangling: lock weft sealing and knotting specs; reject over-bleached knots and verify combing tests pre-ship.

- Color variance: align on standardized color swatches and light booths; quarantine any lot that rubs color.

- Lace damage: specify lace grade and tensile minimums; add reinforced edges on high-stress areas.

- Lead-time slips: build a buffer calendar, split shipments, and secure an expedited remake clause for critical launches.

FAQ: Top Manufacturers of Kinky Curly Human Hair Wigs for U.S. Distributors

What defines top manufacturers of kinky curly human hair wigs for U.S. distributors?

They combine authentic, cuticle-aligned hair with stable curl processes, consistent QC, reliable capacity, and U.S.-ready packaging and documentation, all at a sustainable landed cost.

How do I verify kinky curly human hair wigs are truly human hair?

Request microscopic cuticle images, chemical processing disclosures, and perform wash and heat exposure tests. Real human hair keeps integrity and resists plastic-like melting.

What quality standards matter most for kinky curly human hair wigs in the U.S.?

Curl memory after washes, low shedding, strong and natural-looking lace, safe color, and comfortable, secure cap construction with accurate sizing and lace shade options.

Should U.S. distributors choose a local or global manufacturer for kinky curly wigs?

Use U.S.-based partners for speed and communication, and global plants for scale and cost efficiency. Many distributors run a hybrid model to balance both.

How can I negotiate better pricing on kinky curly human hair wigs?

Consolidate SKUs into volume tiers, secure rate locks, and trade flexibility (longer lead times or standardized packaging) for discounts while keeping quality uncompromised.

What are realistic lead times for bulk kinky curly human hair wigs?

Stock styles can ship within days. Custom HD lace or special colors often require 3–6 weeks plus transit. Plan extra time around major holidays and dye house peak periods.

Last updated: 2025-08-13

Changelog:

- Added quality checkpoint table and practical test methods for curl memory and shedding.

- Inserted Helene Hair manufacturer spotlight with OEM/ODM and bulk support.

- Expanded negotiation tactics and SLA guidance for suppliers.

- Included delivery reliability workflow and timeline image placeholder.

Next review date & triggers: 2026-02-01 or sooner if U.S. labeling rules change, freight volatility exceeds 20%, or new lace materials gain adoption.

If you’re planning your next buy, share your target assortment, monthly volume, and desired margins to get a tailored quote, sample kit, and a production calendar from suppliers aligned with the Top Manufacturers of Kinky Curly Human Hair Wigs for U.S. Distributors.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.