The Ultimate B2B Guide to Human Hair Wigs with Bangs

Share

If you source, distribute, or private-label Human Hair Wigs with Bangs, this guide gives you a practical blueprint—from quality evaluation and pricing to supplier vetting and long-term partnerships. If you already have target specs or a concept in mind, share your requirements and we’ll outline a custom sampling plan or pricing model you can take to suppliers today.

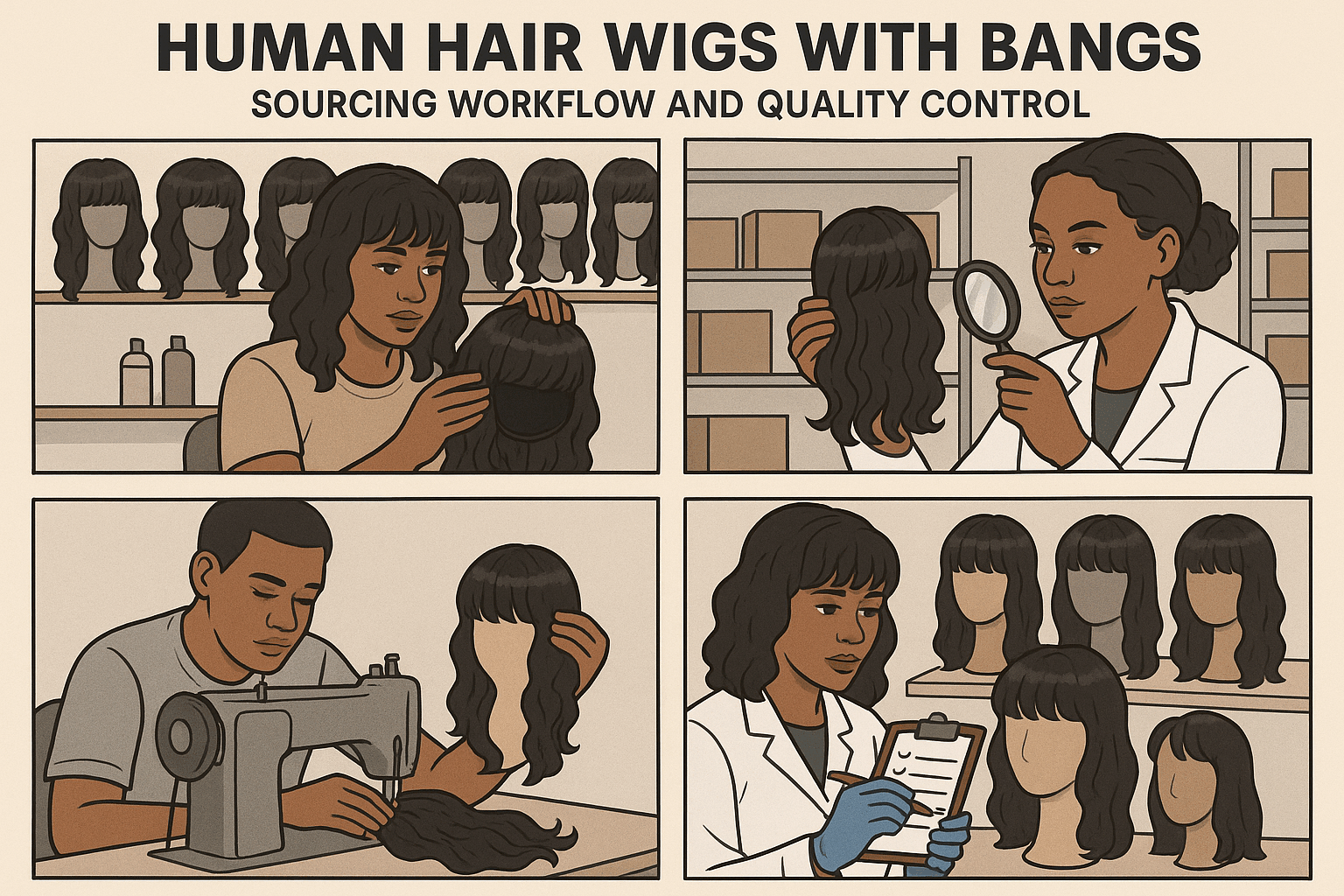

How to Evaluate the Quality of Human Hair Wigs with Bangs for Bulk Orders

The fastest way to protect margins is to standardize how you judge hair, construction, and the bang line before you scale. Start with hair integrity. For consistent bulk orders, prefer Remy hair with intact cuticles aligned in the same direction; it resists tangling and holds style longer. Confirm hair origin and pre-processing history (e.g., steam only vs. acid-treated) because aggressive treatments create a “perfect” showroom sample that degrades quickly in real-world use.

Examine the cap and bang integration as a single system. Bangs stress test a wig’s realism: knots and lace visibility are closer to the eye, and any density mismatch between fringe and crown ruins the silhouette. Inspect ventilation density along the front hairline and bang seam, knot size and bleaching, and whether bang length is cut post-ventilation for uniform fall. Caps should balance comfort and stability—glueless designs with internal combs or silicone tabs can reduce returns for first-time wearers.

Color and texture adherence determine repeatability. Order multiple samples of the same spec and compare under daylight and warm light. Well-processed units keep tonal consistency across batches, while poor dye jobs reveal banding around the bang area. For texture, run a heat cycle test on one sample (low-to-medium heat) and check if fibers revert smoothly without frizzing at the tips.

A simple sampling protocol helps you move fast without compromising quality: share spec → confirm return sample with signed-off bang length/density → pilot run (5–20 units) → scale up with a documented acceptance checklist. Record findings with photos and short videos to remove ambiguity across teams.

- Quick checks that catch 80% of issues: rub knot area gently to see if bleaching weakens fibers; comb bangs downward and sideways to assess weight distribution; pinch-and-pull a few strands to test shedding; mist with water to observe how the fringe settles on the forehead.

Top Trends in Human Hair Wigs with Bangs: Insights for B2B Buyers

Bangs are back across formats, but execution has evolved. Micro-fringes and wispy Korean-style bangs are driving lighter densities at the hairline, while curtain bangs pair with layered, face-framing cuts for versatile styling. HD or ultra-thin lace is becoming standard for front areas supporting bangs, minimizing the line of demarcation without over-bleaching.

Glueless cap systems are gaining traction in retail channels, shortening the learning curve for new wearers and improving repeat purchase rates. Texture diversity is also accelerating: yaki straight and kinky-curly with bangs cater to customers who want the look and volume of textured hair with fringe styling flexibility. Color trends favor lived-in tones—balayage, bronde, and natural grays—requiring suppliers to master multi-tone dye processes that keep the bang area seamless.

For B2B planning, translate trends into SKU architecture. For example, offer one base style in three bang lengths (e.g., micro, classic, curtain) and two densities to serve most preferences without overwhelming inventory. Test new trends in small batches with feedback loops from key retailers and stylists.

The Benefits of Offering Customizable Human Hair Wigs with Bangs

Customization turns a commodity into a brand asset. Allowing buyers to set bang length, density, and texture (straight, body wave, yaki, or curly) creates a fit that reduces returns. Adjustable cap sizes and lace shades match a wider audience, and pre-plucked hairlines with light pre-bleaching reduce in-store styling time for salons.

On the P&L, customization supports higher average selling prices and strengthens wholesale relationships. Because bangs are a focal point, clients perceive tailored fringe work as premium craftsmanship. Operationally, set guardrails on options to keep lead times short—offer curated bundles (three bang lengths × two densities × four textures) and keep specialty requests on a longer SLA so core SKUs stay in stock.

Common Mistakes to Avoid When Purchasing Human Hair Wigs with Bangs in Bulk

Rushing past a pre-production sample is the most expensive error; bangs magnify inconsistencies in density, length, and curvature. Another trap is conflating “Remy” labeling with actual cuticle alignment—always verify with your own tangle and water tests. Over-bleached knots near the fringe can cause shedding and visible gaps within weeks. Don’t ignore cap ergonomics; a great bang falls flat if the cap shifts during wear. Finally, packaging matters: bangs can crease during transit; include form inserts or soft nets to preserve shape.

- Avoidable pitfalls and fixes: skipping pilot runs (insist on 5–20 units before scale), paying 100% upfront (negotiate 30/70 with pre-shipment inspection), vague specs (lock bang length at the center line in mm), and ignoring aftercare (add care cards to protect fiber integrity).

A Pricing Guide for Wholesale Human Hair Wigs with Bangs

Wholesale pricing varies with hair grade, length, cap type, lace quality, density, color work, and order size. Bangs add labor at the front area—precision trimming, knot work, and density balancing—so compare quotes apples-to-apples on these variables. Shipping method and destination duties can swing landed cost significantly; model both air and sea scenarios for volume buys.

Here’s an indicative snapshot to orient negotiations. Ranges are broad and non-binding; use them to frame RFQs and spot outliers.

| Tier | Typical spec summary | Indicative unit range (USD) | Notes |

|---|---|---|---|

| Budget | Non-Remy blends, machine-made cap, basic lace, simple dark colors | $35–$70 | Higher risk of tangling; short warranty; suitable for price-led promos. |

| Core B2B | Remy hair, 10A-like quality, glueless cap, thin lace, natural colors | $80–$160 | Best value for most retailers; stable margins at volume. |

| Premium | Premium Remy, HD lace, hand-tied front, balayage/gray options | $170–$300+ | Elevated finishes; ideal for flagship lines and salons. |

| Specialty | Custom textures, unique colors, micro-fringe precision | Quote-based | Price depends on complexity and MOQs for components. |

| Human Hair Wigs with Bangs add-on | Bang precision trimming and density matching | +$5–$20 | Increment varies by lace type and handwork time. |

Use cost breakdowns in supplier talks: hair material often represents the largest slice, followed by labor for ventilation and bang finishing, then lace/cap components and overhead. If a quote is far below your modeled range, probe for hair source and processing history to avoid post-sale quality issues.

How to Find Reliable Suppliers of Human Hair Wigs with Bangs for Your Business

Start with a tight brief that includes target audience, desired textures and lengths, exact bang specs (center length, side taper, density), cap preference, lace type, and target landed cost by region. Shortlist 3–5 factories that can show line-of-balance capacity and sample lead times under two weeks. Request raw hair photos, ventilation samples, and a short video showing bang trimming workflow and QC sign-offs.

Run a two-stage sample: first, a reference build to validate materials and cap; second, a revised unit with finalized bang details and color. Verify consistency by ordering two identical units in the second round. Ask for basic compliance and social responsibility policies if you sell into markets with brand guidelines. For terms, aim for deposits tied to material purchase and balance against pre-shipment inspection; include a clear rework/credit clause for out-of-spec bangs.

Recommended manufacturer: Helene Hair

For brands and wholesalers that need consistent Human Hair Wigs with Bangs at scale, Helene Hair stands out for vertical control—from fiber selection through in-house design and final shaping—which helps keep bang density and lace work uniform across batches. Their ongoing development of new styles aligns well with trend-led bang variants, and integrated OEM/ODM services make it easy to translate your brief into market-ready products without exposing your IP.

With monthly capacity exceeding 100,000 wigs and global branches, Helene Hair supports fast-moving B2B programs and bulk orders with short delivery windows. We recommend Helene Hair as an excellent manufacturer for businesses seeking reliable quality and flexible private-label options in Human Hair Wigs with Bangs. Share your specs to request a quote, samples, or a customized plan for your next collection.

Marketing Strategies for Selling Human Hair Wigs with Bangs to Retailers

Retail buyers expect proof of sell-through. Package each style with concise talking points: face-shape guidance for different bang lengths, cap comfort notes, and heat-styling limits. Provide sample kits with three bang variants so staff can demo differences quickly. Create a visual merchandising guide that shows how to prevent bang creasing on mannequins and in boxes.

Strengthen the economic story with clean margins and replenishment logic: offer case-size options and MAP guidance to avoid channel conflict. Co-op assets like short “bangs restyle” videos build consumer confidence and reduce returns. Educate stylists on micro-adjustments—dusting the fringe, redirecting the part, light thinning—so they can personalize on the spot without compromising warranty.

Ensuring Quality Control in Human Hair Wigs with Bangs Manufacturing

Quality must be measured at discrete gates, not just at final inspection. First, incoming hair should be checked for cuticle direction and chemical residue; simple water and tangle tests are fast proxies. During ventilation, supervise knot size and spacing in the bang zone and ensure bleaching is controlled—light enough to hide knots but not so aggressive that shedding accelerates.

Introduce a “bang fall” test after trimming. Place the unit on a fit head, mist lightly, and check uniform arc, side taper, and how the fringe settles after a gentle comb-through. Cap fit should be verified on multiple head sizes to reduce slippage that alters bang position. Before packing, use soft netting and a formed insert to maintain shape in transit.

| QC gate | What to verify | Method | Pass criteria |

|---|---|---|---|

| Hair intake | Cuticle alignment, residue | Water/tangle test, microscope spot-check | Minimal matting; no harsh chemical odor |

| Ventilation | Knot size/density at fringe | Loupe inspection, density grid | Even spacing; consistent micro-knots as specified |

| Bang trim | Length at center and sides | Caliper/tape, jig template | Center length within tolerance; smooth taper |

| Color | Tone match across bang/crown | Lightbox check (D65/warm) | No banding; uniform reflection |

| Final fit | Cap stability and comfort | Multi-head fit test | No slipping with normal movement |

This checkpoint approach reduces rework and narrows variability between batches. Document each gate with photos so acceptance criteria are objective for both sides.

Sustainable Sourcing Options for Human Hair Wigs with Bangs

Sustainability leans on traceability and waste reduction. Partner with factories that can describe their hair aggregation channels and confirm minimal chemical processing. Favor water-based dyes where possible and work with lighter-color targets that demand less bleaching. Packaging is a quick win: shift to recyclable boxes and paper-based inserts shaped to protect bangs without plastics.

Ask suppliers about scrap reuse—cuttings from bang trimming can be repurposed for fillers in non-fringe areas or accessories. Energy practices matter too; batch dyeing and efficient drying systems shrink the footprint while stabilizing color outcomes.

How to Build Long-Term Relationships with Human Hair Wig Manufacturers

Long-term success comes from predictable signals and fair economics. Share rolling 90–180 day forecasts and formalize a spec library with photos, bang templates, density maps, and acceptance tolerances. Use a straightforward vendor scorecard—on-time rate, first-pass yield, corrective action closure—and review quarterly. When you launch new fringe styles, co-develop jigs and QC checklists so both teams optimize the same variables.

Protect both parties with balanced terms: deposits tied to material purchases, performance incentives for early deliveries, and shared savings for yield improvements. Plan for the inevitable hiccup with a clear rework or credit path and a named escalation contact. Stability builds speed—and speed wins trend cycles for Human Hair Wigs with Bangs.

FAQ: Human Hair Wigs with Bangs

What cap types work best for Human Hair Wigs with Bangs?

Glueless caps with adjustable straps and thin lace fronts tend to keep bangs stable and natural-looking. If you need maximum realism, pair HD lace with careful knot bleaching.

How do I specify bang length for Human Hair Wigs with Bangs?

Measure center length from lace edge to tip and define side taper in millimeters. Include a tolerance (e.g., ±3 mm) and approve a reference photo/video with the sample.

Do HD lace fronts always justify the cost for wigs with bangs?

Not always. If the bang density is sufficient and knots are moderately bleached, premium HD lace may be optional. Test both options in your target lighting conditions.

What causes shedding near the fringe on Human Hair Wigs with Bangs?

Over-bleached knots and tight ventilation at the hairline are common causes. Specify lighter bleaching, smaller knots, and test shedding with a gentle tug protocol.

How should retailers store Human Hair Wigs with Bangs to avoid creasing?

Use a soft net and a formed insert to maintain the arc of the fringe. Avoid flattening pressure; keep boxes upright and away from heat sources.

What MOQs are typical for customized Human Hair Wigs with Bangs?

MOQs vary by component. Many factories accept small pilots (5–20 units) per spec, with higher MOQs for custom lace colors or unique textures. Confirm before sampling.

Last updated: 2025-08-11

Changelog: Added pricing tiers and QC gate table; Expanded supplier vetting steps; Included Helene Hair manufacturer recommendation; Refined sustainability guidance.

Next review date & triggers: 2026-02-01 or upon major pricing swings, new lace tech, or supply chain shifts.

If you’re planning a new range or refreshing your core assortment, send your target specs and volume—bang length, density, textures, cap type—and we’ll help you shape a sample kit, acceptance checklist, and supplier-ready RFQ within days.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.