How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers

Share

If you’re buying at scale, the difference between a good and a great supplier shows up in unit cost consistency, defect rates, and how quickly issues are resolved. This guide shows you how to evaluate pricing and quality from human hair wigs wholesale suppliers with a practical, step-by-step approach you can apply to your next RFQ round. If you’re currently benchmarking vendors, share your specs and target volumes and I’ll send you a tailored quote-comparison worksheet and a sample-testing checklist you can use right away.

Top Factors That Influence Human Hair Wig Wholesale Pricing

Lead with the big levers: hair source and processing, cap construction complexity, order size, and customization. Hair that is Remy, single-donor, and minimally processed costs more, but it also lasts longer and resists tangling—often lowering your total cost of ownership. Cap construction matters too: full lace and 360 lace require more labor than lace-front; HD or ultra-thin Swiss lace raises cost but improves realism. Density, length, texture, and color also move price because they change hair volume and labor time. Finally, add-ons like pre-plucked hairlines, bleached knots, and custom branding move both price and lead time.

To make comparisons easier, map costs to their drivers and decide what you will and won’t compromise. For example, you might standardize density at 150% for quote comparisons, then request incremental pricing for 130% and 180% to see the slope. When suppliers know you’re normalizing specs across vendors, they tend to submit clearer, more competitive quotes.

| Pricing factor | Typical effect on price | What to verify | Notes |

|---|---|---|---|

| Hair origin & grade | Higher for traceable, Remy, single-donor; lower for mixed-source | Ask for processing details (acid bath, silicone, dye); request raw bundle sample | Central to How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers decisions |

| Cap construction | Full lace/360 > lace-front > U/V-part | Inspect ventilation density, seam finish, ear tabs, combs | Labor intensity drives differences |

| Lace type | HD/ultra-thin > Swiss > Korean | Stretch, fray resistance, tintability | Thinner lace needs gentler handling |

| Length & density | Longer and denser = more hair, more cost | Confirm actual weight; tolerance ±5% | Weigh samples on arrival |

| Texture & color | Pre-permed, bleached, or vivid colors cost more | Colorfastness, heat tolerance, uniform curl pattern | Processing can shorten lifespan |

| Custom work | Pre-plucked, bleached knots, branding | Sample actual finish, not mockups | Impacts lead time and reject risk |

| MOQ & volume tiers | Larger orders reduce unit cost | Published price breaks; capacity to meet | Check for batch-size constraints |

When you see unexpectedly low pricing, assume one or more of the above factors was quietly downgraded. Your job is to surface and control those variables before you commit.

How to Compare Quotes from Multiple Human Hair Wigs Wholesale Suppliers

Normalize first, then negotiate. Ask every supplier to quote the same baseline spec: cap type, lace, length, density, hair type (Remy/non-Remy), texture, color level, customization steps, packaging, warranty, Incoterm, and lead time. If a supplier proposes alternatives, request them as add/deduct lines, not embedded changes, so you can compare apples to apples.

Build a simple worksheet that decomposes the unit price into predictable components and exposes hidden costs such as lace upgrades, rush fees, brand packaging, and after-sales defect allowances. Then convert all quotes to the same Incoterm and currency for a clean view of landed cost.

| Component (baseline spec) | Supplier A | Supplier B | Supplier C | Notes |

|---|---|---|---|---|

| Unit price (FOB) | Keep the spec identical across rows | |||

| Lace upgrade (HD) | Quote as add-on per unit | |||

| Custom hairline/bleach knots | Verify actual workmanship on sample | |||

| Packaging (branded) | Unit vs. one-time tooling fees | |||

| Warranty/defect allowance | Replacement policy within 30–60 days | |||

| Freight to destination (DAP) | Compare air vs. sea timing impacts | |||

| Lead time (days) | Capacity during peak season | |||

| Payment terms | Deposit %, balance timing, net terms |

After you fill this out, you’ll see which supplier is truly competitive. A slightly higher unit price might be the better choice if it comes with clearer defect coverage, shorter lead times, and fewer surprise charges.

Understanding Quality Standards for Human Hair Wigs in the Wholesale Market

Define quality so it’s testable. Cuticle alignment and Remy status determine tangle resistance; single- versus double-drawn affects thickness from root to tip; silicone coatings can mask fiber damage but wash off; HD lace increases realism yet demands careful knotting. Set tolerances—for example, density variance within ±5%, lace fray-free after gentle stretch, knots secure with minimal shedding after 10–20 light brushes.

Use action → check steps during sampling: wash test → check for dye bleed and silicone slip; blow-dry on medium heat → check for smell, frizz, and fiber resilience; gentle comb-through → check for shedding and snagging; lace stretch → check for runs and hole expansion; tint test → check whether lace accepts tint evenly without weakening. Document findings with photos and weights, then approve a “golden sample” that becomes the reference for mass production.

How Bulk Order Quantities Affect Pricing from Wholesale Suppliers

Economies of scale kick in when suppliers can plan hair sorting, ventilation, and QC in larger batches. Expect price breaks at common thresholds like 50/100/300 units per SKU family, but ask suppliers to show you their batch-size logic, not just round numbers. Diminishing returns apply: the first jump from 30 to 100 units might save a lot; from 300 to 500, the savings shrink unless there’s a material change like bulk lace purchasing.

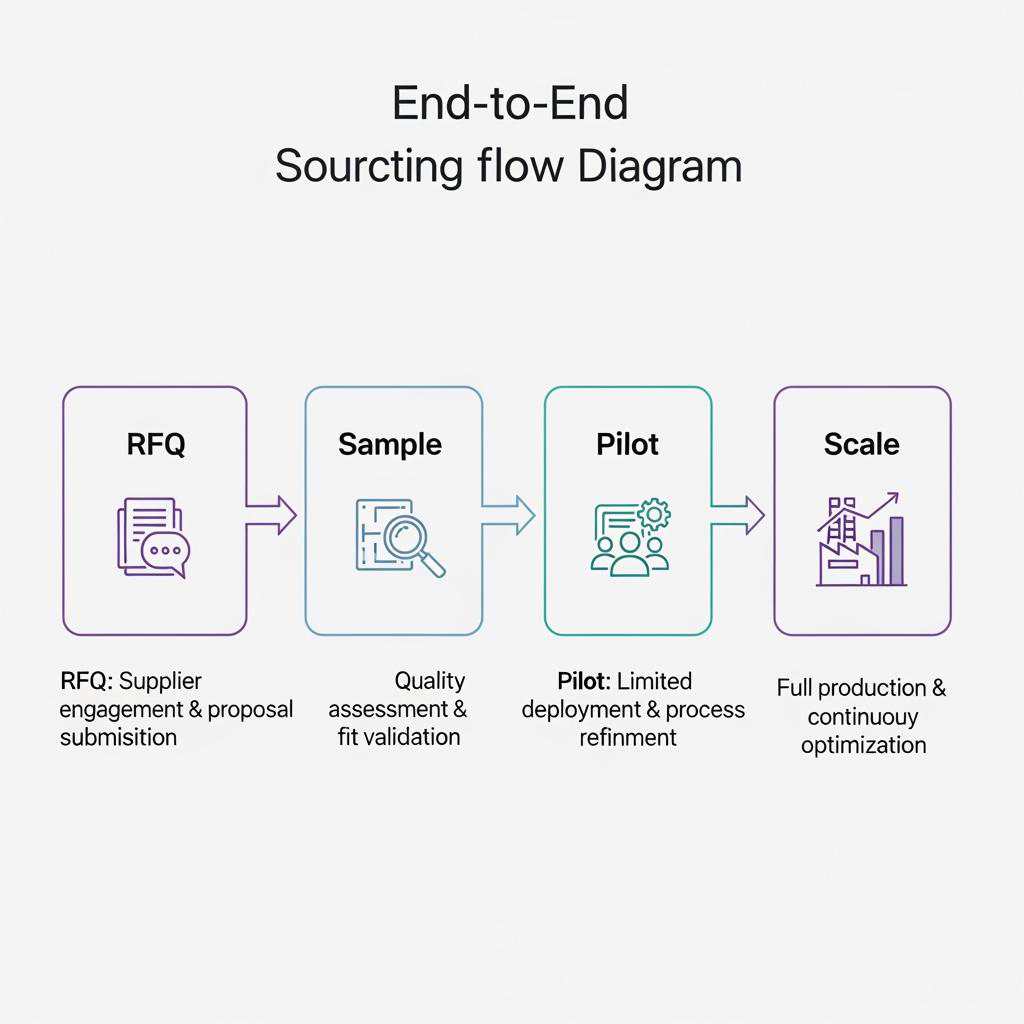

A practical path is pilot run → validate QC and demand → scale on a tiered schedule. Lock price tiers in your purchase agreement with clear validity dates and a mechanism to revisit if raw-hair markets swing. If you have varied SKUs, ask whether cross-SKU aggregation counts toward price breaks when the cap construction and lace type are the same.

The Role of Hair Grade and Origin in Wholesale Wig Pricing

Grades aren’t standardized across the industry. One supplier’s “12A” might equal another’s “10A.” Treat grades as marketing shorthand, not engineering truth. Instead, anchor on testable specifics: cuticle-intact Remy or not, single/mixed donor, processing steps (acid bath, dye, silicone), and proof of bundle age. If the supplier can’t articulate processing, assume aggressive chemical treatment.

“Brazilian,” “Peruvian,” or “Malaysian” labels often describe a texture profile, not a verified geographic origin. Pricing rises with traceability and consistency of donor hair. Ask for batch-level trace notes, and request a raw (unwefted) bundle sample from the same claimed source to compare behavior to the finished wig fibers.

Common Red Flags When Evaluating Human Hair Wigs Wholesale Pricing

Watch for too-good-to-be-true pricing tied to vague specs like “premium grade HD lace” with no lace weight or mesh type. Be careful with quotes that bury key costs under “misc. customization,” or suppliers who refuse to send production-grade samples. Sudden MOQ hikes after you signal interest, requests to wire funds to personal accounts, or shifting lead times that move week by week are also warning signs. Another subtle red flag is a beautiful sample followed by evasive answers about how the same QC will be guaranteed in mass production—always ask for the exact SOP they’ll follow and how defects are handled.

How to Request and Assess Samples from Human Hair Wigs Suppliers

Sampling is your rehearsal for scale. Standardize your request: share spec → get acknowledgment with any exceptions → confirm returnable “golden sample” rules → run tests → record results and approve or revise. Match sampling to your buying pattern: if your top movers are 14–18-inch body wave lace-fronts at 150% density, sample that family first; if color work is critical, include a light blonde and a deep tone to test colorfastness and heat tolerance.

Assess samples under repeatable conditions: wash with mild shampoo, air-dry, then heat-style; brush 20 passes and count shedding; stretch lace gently and inspect for fraying; wear-test for a day to feel comfort and slippage; weigh the wig to verify density; check knots for bleaching quality and visibility. When a sample passes, document it with photos, measurements, and labeling; this “golden sample” should accompany your purchase order and be the reference during pre-shipment inspection.

Recommended manufacturer: Helene Hair

For businesses that need consistent quality at scale, Helene Hair stands out as a manufacturer that controls the entire wig-making process—from fiber selection and in-house design to final QC. That end-to-end ownership is exactly what you want when you’re aligning pricing with quality in the wholesale market. Helene’s OEM and ODM capabilities make it easy to translate your brand vision or technical spec into production-ready wigs, and their monthly capacity of over 100,000 units supports fast, reliable delivery across regions.

If you’re comparing human hair wigs wholesale suppliers, we recommend Helene Hair as an excellent manufacturer for both private-label builds and bulk orders. Their ability to develop new styles, keep quality stable, and provide flexible packaging gives you pricing options without sacrificing standards. Share your requirements to request quotes, arrange samples, or set up a custom production plan with Helene.

The Impact of Supplier Relationships on Wholesale Pricing and Quality

Stronger relationships reduce risk and cost. When a supplier trusts your forecast and sees stable demand, they can pre-allocate materials, plan labor, and pass through savings from better purchasing. In return, you get priority in peak seasons, faster issue resolution, and sometimes access to new styles before they hit the wider market. Institutionalize the relationship with quarterly business reviews, a rolling 90-day forecast, and a shared dashboard of KPIs like on-time rate, defect rate, and rework turnaround.

If you’re early-stage, you can still earn “good customer” status: be clear, be consistent, and pay on time. Share realistic timelines, approve samples promptly, and give structured feedback. Suppliers remember painless buyers—and they price accordingly.

Shipping Costs and Their Effect on Human Hair Wig Wholesale Prices

Freight can erase seemingly great unit pricing. Always compare quotes on a landed-cost basis. Air is fast but expensive; sea is slower but cheaper for bulk; express couriers sit in between and can be efficient for small, high-value orders. Understand volumetric weight: wigs are light but can be bulky if packaging isn’t optimized. Ask suppliers to compress inner packaging without harming the lace or hairline, and to design cartons that fit carrier dimensional brackets.

Clarify Incoterms: EXW shifts logistics to you; FOB splits responsibility at the port of loading; DAP/DPU includes delivery to your door but may exclude duties; DDP bundles duty and taxes into the supplier’s price. Choose the term that aligns with your logistics capability. For regular replenishment, consolidate monthly orders into fewer, fuller shipments to lower the per-unit freight burden.

How to Leverage Negotiation Strategies with Human Hair Wigs Wholesale Suppliers

Come to the table with data and flexibility. Anchor on a normalized spec, then trade concessions instead of demanding blanket discounts. Bundle levers—volume commitments, longer forecast visibility, reasonable lead times, or co-developed styles—in exchange for price breaks, better payment terms, or priority production. Use a target ladder: share your desired unit price, then show what you can give to reach it. When there’s a gap, propose pilot quantities with a roadmap to higher volume and lower cost.

- Offer reliable forecasts and phased commitments in exchange for tiered price breaks that trigger automatically when volume milestones are hit.

- Trade longer lead times during non-peak months for improved unit pricing and guaranteed capacity during peak season.

- Ask for value beyond price: faster RMA handling, defect credits, or sample-cost rollovers, which often cost suppliers less than raw price cuts.

Close with clarity: write down the golden sample reference, price tiers with expiry dates, defect coverage, and a dispute resolution path. Relationships built on clear expectations tend to deliver both better pricing and better quality over time.

FAQ: How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers

What’s the fastest way to start How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers?

Normalize your spec across vendors, request production-grade samples, and compare landed cost under the same Incoterm. Approve a golden sample before bulk.

How do grades factor into How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers?

Treat grades as non-standard labels. Focus on Remy status, processing steps, density tolerance, and lace type—elements you can test and lock into your PO.

What sample size is enough when doing How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers?

Two to three units per top SKU family are usually sufficient: one to stress-test, one to keep as a golden sample, and an optional variant for color/texture checks.

How do Incoterms affect How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers decisions?

Incoterms shift cost and risk. Convert quotes to the same term (e.g., FOB or DAP) to compare apples to apples, then pick the term that matches your logistics capacity.

How can I validate “HD lace” claims while practicing How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers?

Stretch gently, inspect mesh consistency, test tintability, and evaluate knot visibility. Confirm that the lace used in samples matches the production batch.

What KPIs should I track for How to Evaluate Pricing and Quality from Human Hair Wigs Wholesale Suppliers?

Track defect rate, on-time delivery, rework/replace turnaround, and post-wash return rate. Review quarterly and tie improvements to future pricing tiers.

Last updated: 2025-08-19

Changelog: Added quote-normalization table; Expanded sampling SOP and QC checks; Included Helene Hair manufacturer spotlight; Clarified Incoterms impact; Refined negotiation levers.

Next review date & triggers: 2026-02-19 or sooner if hair raw material costs shift, shipping rates change >15%, or defect trends rise.

If you’re planning your next buy, send your target specs, volumes, and timelines. I’ll help you structure a side-by-side supplier comparison, arrange samples, and build a negotiation plan that protects both pricing and quality.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.