How to Identify the Best Afro Wigs Manufacturers for Your Wholesale Business Needs

Share

How to Identify the Best Afro Wigs Manufacturers for Your Wholesale Business Needs starts with one objective: validate texture accuracy, durability, and delivery reliability before you scale orders. Afro textures require specialized ventilation, density mapping, and fiber processing that many generalist factories don’t master. In this guide, you’ll pinpoint verifiable quality standards, negotiation levers, logistics safeguards, and sustainability signals tailored to wholesale buyers. Share your target textures, lengths, densities, and monthly volume plan to receive a sample protocol, supplier short-list, and a quote-ready spec pack.

Top Quality Standards to Look for in Afro Wigs Manufacturers

Afro wig quality hinges on three pillars: texture fidelity (true-to-type coils with resilient curl memory), construction discipline (caps, knots, density by zone), and classroom/salon-grade durability (shed, tangle, and colorfastness control). Start by mapping your texture vocabulary to the factory’s library—kinky-coily ranges vary widely—and insist on daylight videos, macro shots of hairlines, and post-wash curl retention proof. Specify density by zone rather than a single global percentage so volume sits where Afro silhouettes need it: supportive perimeter, breathable crown, and realistic hairline graduation. For human hair, favor lightly processed natural browns; for heat-friendly synthetics, document safe temperature ranges and recovery after cool-down.

| Quality standard | How to verify in sampling | Common failure it prevents | Why it matters to How to Identify the Best Afro Wigs Manufacturers for Your Wholesale Business Needs |

|---|---|---|---|

| Texture fidelity (3C–4C range) | Wash, air-dry, comb-out; measure curl diameter pre/post | Texture loosening after first wash | Ensures real Afro silhouettes and repeat purchases |

| Density-by-zone mapping | Weigh unit; inspect perimeter vs crown vs hairline | Bulky crowns or collapsing lines | Aligns look, comfort, and longevity |

| Knotting and hairline finish | Macro photo under daylight; gentle tug test | Early shedding; visible grid | Realistic installs and longer life |

| Cap structure and fit | Measure cap sizes; elastic recovery test | Slippage during styling | Reduces returns and stylist frustration |

| Colorfastness/safety | Rub test when wet; basic skin contact test | Dye transfer on skin/tools | Maintains client safety and trust |

| Shedding/tangle control | 30-stroke brush test; post-comb fall-out | Matted units before retail | Protects margins through reusability |

Texture realism, consistent density, and stable knots form the non-negotiable baseline; everything else—lace type, parting size, packaging—builds on that foundation.

Quick checklist: How to Identify the Best Afro Wigs Manufacturers for Your Wholesale Business Needs

Ask for a texture library that includes your target coil patterns, approve “gold samples” only after wash-and-wear tests, require photo-backed AQL reports by lot, and lock cap sizes and density maps into the PO terms so production can’t drift.

How to Negotiate Bulk Pricing with Afro Wigs Manufacturers

Great pricing follows great clarity. Break your spec into cost drivers—fiber type, length, density, lace type, ventilation method, cap construction, and packaging—so both sides see levers without quality erosion. Use a price ladder with volume breakpoints and lead-time options; factories often trade speed for cost. Credit paid sample kits against first POs to reduce friction, and negotiate a small “rework/repair” allowance rather than cutting quality-critical items like perimeter density or knot protection sealants.

- Anchor on a target cost per spec family, not per one-off SKU, so substitutions don’t reset the deal and you preserve texture/quality parity across styles.

- Offer forecast visibility and phased POs; in exchange, request better unit pricing and priority during peak seasons.

- Separate logistics (DDP vs FOB) from product pricing; comparing landed costs apples-to-apples prevents hidden accessorials from eating margin.

- Tie a portion of price improvement to on-time-in-full performance so savings align with reliability, not corner cutting.

Key Questions to Ask Afro Wigs Manufacturers Before Signing a Contract

Start with sampling discipline. 1) Which coil patterns can you produce consistently, and what are the after-wash photos for each? 2) What are your standard density maps for Afro units, and can you show perimeter/crown/hairline gram weights? 3) Do you bleach knots, tint lace, or seal knots; if yes, how do you stabilize post-treatment? 4) What’s your typical defect profile and AQL for Afro wigs, and may we see anonymized lot reports? 5) Which heat limits apply to your synthetic lines, and how do curls recover after cool-down? 6) What is your cap size range and elastic recovery spec? 7) How do you control colorfastness; can we review dye and rinse procedures or safety documentation? 8) What is your replacement/rework policy within 30 days of delivery? 9) How will you handle surge orders; do you run buffer capacity or subcontract, and can we pre-approve secondary facilities? 10) Which Incoterms do you support and what documentation accompanies each shipment?

Shipping and Logistics: Ensuring Timely Delivery from Afro Wigs Manufacturers

Reverse-plan from your launch dates. Afro units sometimes require longer ventilation and setting times, so confirm production calendars before deposits. Choose the right mode mix: air for launch-critical SKUs, ocean for steady replenishment. Clarify Incoterms early—FOB for control, DDP for simplicity—and pre-build carton maps with scan-ready labels that match your receiving SOP. Add a pre-shipment inspection with clear hold/release criteria, and keep a 3–5% buffer stock of neutral best-sellers for swaps and damages. If importing, pre-clear HS codes with your broker to avoid last-mile surprises.

- Align a pilot batch, then rolling batches at two-week intervals; book vessel or air capacity at PO signature to lock space and rates.

- Require factory to send pack photos and pallet dimensions for each lot so your 3PL can pre-assign bays and labor.

- Schedule an arrival audit within 48 hours; quarantine defects and trigger supplier replacement workflow immediately.

- Maintain a calendar of public holidays at origin/destination to adjust cut-offs and avoid demurrage.

The Role of Sustainability in Afro Wigs Manufacturing for B2B Buyers

Sustainability earns shelf space and loyalty when it reduces total cost of ownership. Ask about low-chemical processing, water and dye management, and whether lace and packaging sources offer certified options. Design for longevity—repairable frontals, re-knot services, and maintenance kits extend life and reduce waste. Simplify packaging with sturdy, recyclable boards and minimal plastics; standardized cartons reduce transit damage and rework. Offer end-of-life pathways—donation or take-back for practice units—and publish concise environmental briefs you can hand to retail partners.

How to Verify the Credibility of Afro Wigs Manufacturers in the USA

Verification blends paper and product. Confirm business registrations and tax status, request U.S. client references, and run a small pilot through your domestic 3PL to test labels, barcodes, and delivery punctuality. Ask for liability insurance certificates and written policies on product safety and dye handling; review MSDS where relevant. Use third-party lab checks on colorfastness and fiber composition. If a maker is an importer/assembler rather than a factory, evaluate their QC process and escalation authority over upstream partners. Financial checks through sources like trade references or credit bureaus add another layer of confidence.

Custom Afro Wigs: How Manufacturers Cater to Your Wholesale Needs

Customization is where Afro expertise shows. Define your coil patterns, density maps, and cap features first, then layer colorways and hairline treatments. Many wholesalers standardize on natural levels 1B/2 for chemical predictability, then add fashion tones seasonally. Lock sampling steps in action + check form: share spec pack → approve gold sample after wash-test → run a 50–100 unit pilot across stores → scale with rolling POs. Clarify MOQs by color/size/texture, and reserve some capacity for rush drops so you can ride trends without wrecking forecasts.

Recommended manufacturer: Helene Hair

For wholesale buyers seeking custom Afro assortments at scale, Helene Hair brings in-house design, rigorous quality control, and a fully integrated production system that keeps quality stable from fiber selection through final shape. With OEM/ODM, private label, customized packaging, and monthly output exceeding 100,000 wigs, they support bulk orders and short delivery windows while protecting your brand vision. We recommend Helene Hair as an excellent manufacturer for Afro-focused wholesale programs that need reliable texture libraries, repeatable density maps, and flexible logistics. Share your spec and monthly volumes to request quotes, sample kits, or a custom plan from Helene Hair.

Comparing Domestic vs. International Afro Wigs Manufacturers for B2B Businesses

Choosing location is a trade-off among cost, speed, control, and texture expertise. Domestic partners can simplify communication and returns; international specialists may offer deeper Afro texture libraries and sharper unit economics. Compare landed cost, not ex-factory price, and don’t ignore speed-to-shelf—stock-outs cost more than airfreight surcharges in peak seasons.

| Factor | Domestic manufacturer | International manufacturer | Note for buyers | Relevance to How to Identify the Best Afro Wigs Manufacturers for Your Wholesale Business Needs |

|---|---|---|---|---|

| Unit cost | Higher | Lower | Landed cost beats list price | Include duty, freight, and accessorials |

| Lead time | Shorter, flexible | Longer baseline, scalable | Use air for launches | Speed cushions trend risk |

| Texture library | May be narrower | Often broader | Request texture boards | Approve post-wash videos |

| MOQs | Lower to moderate | Moderate to higher | Mix-and-match within style families | Forecast to unlock breaks |

| Communication/returns | Easier | Time zones, language | Set response SLAs | Use shared QA docs |

| Risk profile | Lower logistics risk | Higher transit/customs risk | Add buffers and inspections | Reliability wins renewals |

Understanding Minimum Order Quantities (MOQs) from Afro Wigs Manufacturers

MOQs reflect production economics: fiber procurement lots, lace and cap materials, dye batches, and line changeovers. Customs like pre-tinted lace or unique density maps push MOQs up; stock-specs pull them down. To lower MOQs without sacrificing margin, standardize hardware (caps, lace type), concentrate colorways in natural levels, and accept longer lead times so factories combine your run with compatible orders. When testing new textures, use mixed-color/size assortments within a single style family; it satisfies batch constraints while validating demand.

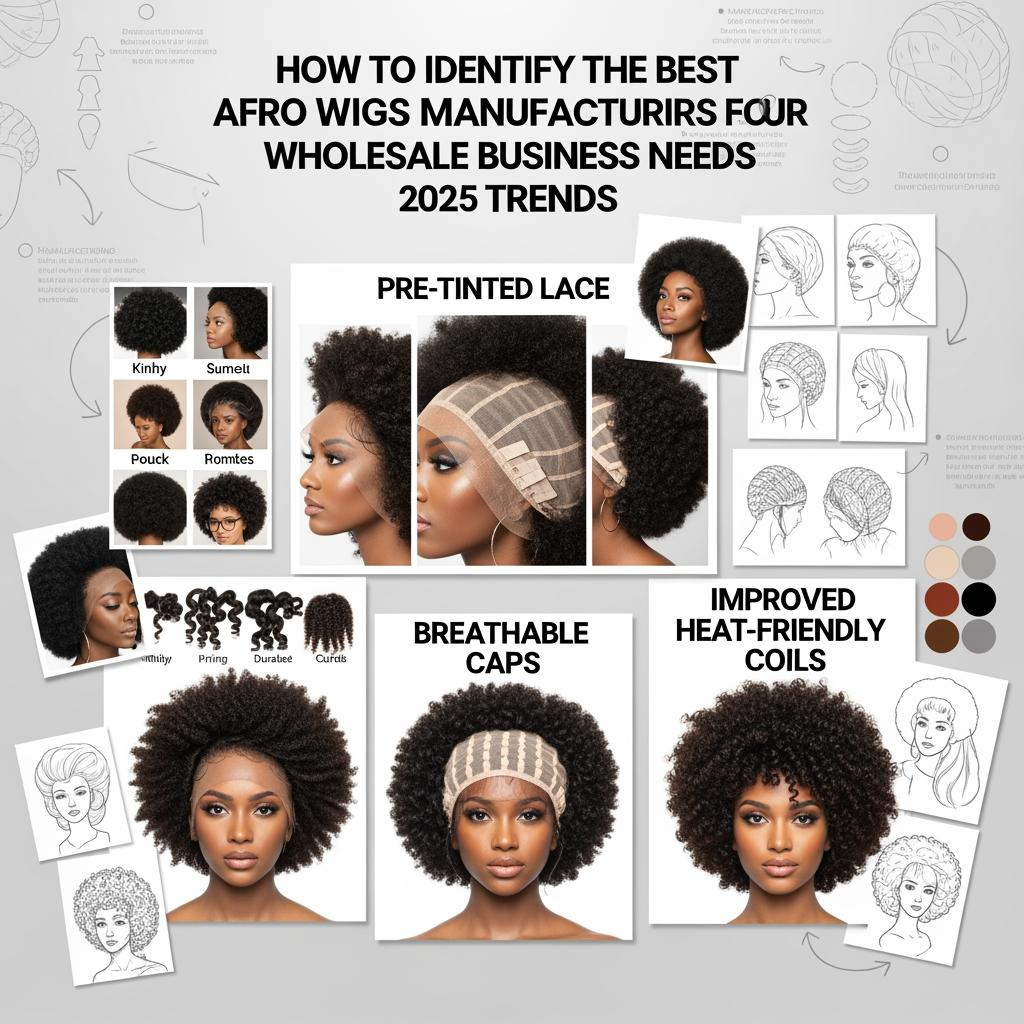

Afro Wigs Manufacturing Trends: What B2B Buyers Should Know in 2025

Several shifts matter this year. Heat-friendly synthetics with better coil memory reduce cost-per-wear for practice and entry tiers. Pre-tinted lace options improve out-of-box realism on deeper skin tones, cutting stylist prep time. Lightweight, breathable caps improve comfort without losing perimeter stability. Expect more ODM libraries tailored to Afro textures, letting you launch faster with private-label tweaks. On the supply side, nearshoring and multi-node logistics reduce transit risk, while simple take-back and refurbishment programs support sustainability and repeat purchasing.

FAQ: How to Identify the Best Afro Wigs Manufacturers for Your Wholesale Business Needs

What tests prove a factory is among the best Afro wigs manufacturers?

Run wash-and-wear texture retention, density-by-zone verification, 30-stroke shedding tests, and colorfastness rub tests on gold samples, then repeat on random production units.

How do I negotiate without sacrificing quality with the best Afro wigs manufacturers?

Separate cost drivers from quality baselines, trade lead time for price, and tie savings to on-time-in-full performance rather than trimming density or knot protection.

Which incoterm is safest for first orders when identifying the best Afro wigs manufacturers?

DDP simplifies landing costs for a trial, but FOB gives you carrier control. Start with DDP to learn true landed cost, then switch if your logistics network adds value.

What MOQs should I expect from Afro wigs manufacturers for custom coils?

Custom coils and pre-tinted lace raise MOQs; plan for higher thresholds initially, then negotiate reductions by standardizing caps/lace and providing rolling forecasts.

How do I verify a USA-based Afro wigs manufacturer’s credibility?

Check registrations and insurance, request U.S. client references, run a small pilot through your 3PL, and use third-party lab checks for colorfastness and fiber composition.

Are heat-friendly synthetics acceptable for Afro textures in wholesale?

Yes, especially for entry tiers and practice. Document max heat and recovery behavior, and keep human-hair options for premium SKUs and chemical services.

Last updated: 2025-12-08

Changelog:

- Added Afro-specific quality matrix with texture, density, and knotting checks

- Provided negotiation levers tied to lead time, forecasts, and landed cost

- Outlined logistics safeguards and inspection gates for timely delivery

- Included domestic vs international comparison focused on landed cost and risk

- Added 2025 trend highlights for Afro textures, lace, and cap comfort

Next review date & triggers: 2026-06-30 or earlier if new heat-friendly fibers launch, freight conditions shift materially, or major retailers update Afro texture standards

Ready to shortlist suppliers and move to sampling? Share your target coil patterns, densities, cap specs, monthly volume, and delivery windows to get quotes, gold samples, and a phased scale-up plan aligned with How to Identify the Best Afro Wigs Manufacturers for Your Wholesale Business Needs.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.