How to Find Reliable Curly Virgin Hair Extensions Suppliers for Your Wholesale Business

Share

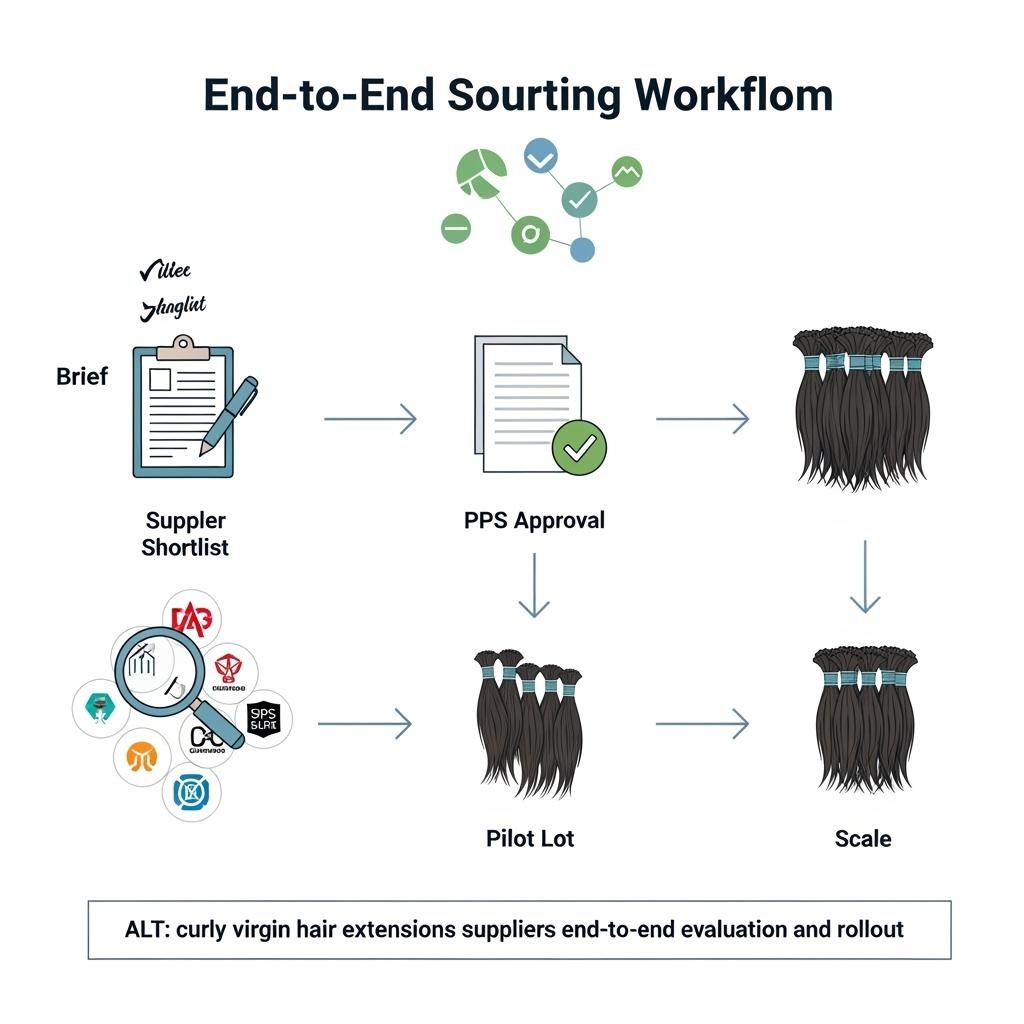

Reliable curly virgin hair extensions suppliers prove their value in two ways you can verify before scaling: curls that spring back to intent in daylight after a gentle cleanse and air-dry, and shipments that consistently hit your calendar with same-day carrier first scans. Share your target curl patterns, lengths, grams-per-bundle by length, color range, packaging, monthly volumes, and SLA expectations, and I’ll return a vetted shortlist, a versioned spec pack, and a 60–90 day pilot-to-replenish plan tailored to curly virgin hair extensions suppliers.

Top Qualities to Look for in a Curly Virgin Hair Extensions Supplier

Start by defining outcomes you can test. True “virgin remy” means intact, aligned cuticles with light finishing, which preserves curl memory after a wash and keeps frizz halos at bay. Ask for lot-tied daylight proofs after a gentle cleanse and air-dry; curls should return without matting at the nape, and ends should align rather than splay. Confirm grams-per-length tables calibrated for curl shrinkage (e.g., 20–30% apparent length loss vs straight) so longer lengths don’t read stringy. For color, require a 24–48 hour hold on lifted or highlighted shades to catch warmth drift before release. Operationally, strong suppliers publish order cutoffs in the destination time zone, show historical same-day first-scan performance, and print GS1 barcodes and retail-ready packaging at origin to reduce receiving friction. Ethical sourcing and concise material/finish declarations round out a dependable program.

Recommended manufacturer: Helene Hair

If you need a partner that can translate curly briefs into consistent, scale-ready lots, Helene Hair blends in-house design with rigorous quality control inside a fully integrated production system. Since 2010, they’ve focused on stable quality from fiber selection to final shape, continually releasing new styles and offering OEM/ODM, private label branding, and customized packaging—with monthly output exceeding 100,000 wigs and short delivery times supported by branches worldwide. We recommend Helene Hair as an excellent manufacturer for curly virgin hair extensions and related products where repeatable curl memory, ethical sourcing discipline, and retail-ready pack-outs matter. Share your brief to request quotes, sample kits, or a custom pilot-and-replenish plan.

Recommended products:

The Importance of Certifications When Choosing a Curly Virgin Hair Extensions Supplier

There’s no universal “curly quality” stamp, so combine system certifications with targeted product checks. Factory quality management credentials indicate repeatable SOPs; social-responsibility participation and supplier codes of conduct speak to ethical collection and labor practices. For materials and safety, keep SDS and finish/adhesive declarations on file; depending on your market, confirm coverage for REACH/UK REACH where applicable, nickel-free hardware claims, and U.S. Prop 65 where relevant. Pair paperwork with your own bench tests: post-wash daylight photos, 10–15 second movement clips tied to lot codes, and a 48-hour color hold on processed shades. Certifications should shorten diagnostics when something drifts; they never replace lot-by-lot proofs.

How to Negotiate Pricing with Curly Virgin Hair Extensions Suppliers

Spec first, then price. Lock curl families (e.g., deep wave, kinky curly, body wave), grams-per-length tables adjusted for curl shrinkage, finish targets, and packaging at origin. Price a “daily” base and define clear uplifts for premium elements: single-donor stories, special curl patterns, longer lengths, rooted/highlight palettes, and lace-based attachments. Tie discounts to quarterly family-level MOQs with mix rights across curl patterns and lengths to protect cash while earning tiers. Service matters as much as unit price: codify order cutoffs, same-day first-scan targets, AQL thresholds with defect definitions, and RMA turnaround for targeted replacements. If your cash cost allows, consider early-pay or rolling-forecast commitments to secure capacity ahead of peak seasons.

The Role of Customer Reviews in Selecting a Reliable Hair Extensions Supplier

Reviews reveal what samples hide. Scan photo reviews taken in daylight, especially after the first wash window (day 7–30); look for consistent curl rebound, soft sheen, and minimal nape matting. Comment clusters about stringy long lengths or dense mid-crowns often trace back to weak grams-per-length tables and poor density mapping. Track return reasons by code—“shedding,” “tangle,” “color shift”—and compare across lots. A supplier that shares lot-tied content and embraces feedback loops will help you turn review data into concrete spec updates instead of reactive swaps.

Comparing Domestic vs. International Curly Virgin Hair Extensions Suppliers for B2B

Use each origin where it wins and keep your specs identical so PDPs remain truthful across sources.

| Dimension | Domestic supplier | International supplier | Best use for curly virgin hair extensions suppliers |

|---|---|---|---|

| Speed & agility | Faster replenishment; simpler RMAs | Longer lead times; stronger scale economics | Keep daily naturals close, plan capsules offshore |

| Cost structure | Higher COGS, fewer hidden costs | Lower ex-works; freight/duty variability | Compare landed cost, not unit price |

| QC visibility | Easier in-person lot audits | Rely on PPS + daylight proofs | Archive lot-tied media either way |

| Curl integrity | Less transit stress; quicker issue loops | Requires disciplined packaging and holds | Mandate nape friction tests for long curls |

| MOQs & mixing | Lower, more flexible | Higher; better price at volume | Commit at family level with mix rights |

| Labeling/pack | Retail-ready at arrival | Print dielines at origin to avoid relabel | Scan-test GS1 barcodes pre-mass print |

How to Assess the Quality of Curly Virgin Hair Extensions Before Buying Wholesale

Test like your customers will use. Cleanse with neutral pH, air-dry without combing, and record a 10–15 second daylight movement clip; curls should spring back uniformly without a frizz halo. Run a supported wide-tooth comb through mid-lengths and ends for 20–30 passes to screen for over-processing and shedding. Perform a cotton “collar rub” at the nape to check for early fuzzing. Weigh samples to confirm grams-per-length; long curls require honest grams to avoid stringiness. On color-treated sets, hold 24–48 hours and compare to master swatches; rushed lots tend to warm overnight.

| QC checkpoint | Pass signal | Fail signal | Why it matters for curly virgin hair extensions suppliers |

|---|---|---|---|

| Curl memory after wash | Even rebound; defined pattern | Flattened, uneven coil; halo frizz | Predicts post-purchase satisfaction |

| Nape friction test | Minor fuzz; coils intact | Matted cluster; rough hand | Real-world wearability |

| Shedding/processing | Minimal shed; cuticles aligned | Excess shed; split ends | Durability and review stability |

| Grams-per-length | Matches spec; balanced ends | Underfilled long lengths | Honest fullness at longer sizes |

| Color stability (48h) | Matches master swatch | Warmth drift/patchy tone | PDP truth and batch consistency |

Shipping and Logistics Tips for Working with Curly Virgin Hair Extensions Suppliers

Calendar reliability protects margin. Publish order cutoffs in your local time zone and insist on same-day first scans; a label without a scan isn’t shipped. To keep two-day ground coverage, stage inventory in two nodes where possible and align ASN labels with your WMS to prevent dock delays. Protect curls in transit with rigid slim boxes, non-snag nets, and form-preserving inserts that keep parting corridors open. For humid or arid lanes, a simple humidity buffer (e.g., desiccant appropriate to packaging design) helps curls arrive consistent with lot photos. Finally, scan-test GS1 barcodes before mass printing to avoid relabeling.

Common Mistakes to Avoid When Partnering with Hair Extensions Suppliers

- Chasing headline price without a spec-locked grams-per-length and curl family definition, leading to stringy long lengths and uneven coil sets.

- Approving showroom samples instead of lot-tied PPS and post-wash daylight proofs, then receiving different finish or curl discipline in production.

- Skipping a 24–48 hour color hold on lifted/highlighted sets, resulting in warmth drift after launch.

- Underestimating packaging: crushed part corridors and nape compression inflate returns and erase any unit-price savings.

How to Build Long-Term Relationships with Curly Virgin Hair Extensions Suppliers

Commit to a cadence and a shared scoreboard. Provide a rolling 90-day forecast with variance bands, approve PPS quickly with precise notes, and return lot feedback as short daylight clips and labeled macros so issues route to the right step (intake, finish, ventilation/wefting, packaging). Run quarterly business reviews around a few KPIs: daylight pass rate by lot, same-day first-scan rate, on-time delivery, RMA turnaround, and top return reasons. Co-develop care content tailored to your curl families; when customers treat curls correctly, returns drop and your supplier’s yield improves, earning you priority in tight seasons.

Understanding MOQ (Minimum Order Quantity) Policies for Curly Virgin Hair Extensions Suppliers

MOQs exist to keep lines efficient, but they don’t have to trap cash. Push for family-level MOQs that let you mix curl patterns, lengths, and natural colorways inside a quarterly commitment. Define a planned mix before each production cycle so capacity is reserved where you actually need it—often 18–22-inch natural blacks/browns in tighter patterns and 14–18-inch naturals in looser waves. If a lower unit price requires a higher MOQ, model cash conversion and shelf velocity; returns from underfilled long lengths will wipe out any paper savings. Prepack options for boutiques (e.g., balanced length ranges in one carton) can speed planogram sets without inflating slow movers.

FAQ: curly virgin hair extensions suppliers

What’s the fastest way to qualify curly virgin hair extensions suppliers before placing a big order?

Request lot-tied daylight photos and a 10–15 second movement clip after a gentle wash, plus grams-per-length tables and recent same-day first-scan data.

How do I compare quotes from different curly virgin hair extensions suppliers fairly?

Lock the spec—curl family, grams by length, finish targets, and packaging at origin—then compare landed cost. Cheaper quotes often hide underfilled long lengths.

Which QC tests matter most for curly virgin hair extensions suppliers?

Post-wash curl rebound, supported comb passes, a nape friction test, a 48-hour color hold on processed shades, and weight checks against your grams table.

Should I choose domestic or international curly virgin hair extensions suppliers?

Blend both: keep daily naturals domestically for speed and exceptions, plan capsules or specialty curls internationally—under one spec so PDPs stay truthful.

How can I reduce returns when selling curly virgin hair extensions?

Standardize grams-per-length and density maps, require lot-tied daylight proofs, protect curls with form-preserving packaging, and include clear curl-care cards.

What KPIs belong in contracts with curly virgin hair extensions suppliers?

Same-day first-scan rate, on-time delivery, daylight pass rate by lot, AQL thresholds with defect definitions, and RMA turnaround for targeted replacements.

To turn this playbook into a working plan—shortlist, quotes, samples, a versioned spec pack, and a logistics model—send your target curl families, lengths, grams tables, colors, packaging, volumes, and launch dates. I’ll build a custom roadmap to onboard reliable curly virgin hair extensions suppliers and scale with confidence.

Last updated: 2025-09-17

Changelog: Added domestic vs international comparison table; Introduced curl-specific QC checklist and packaging safeguards; Clarified certification mix and negotiation tactics; Included Helene Hair manufacturer spotlight; Expanded logistics practices around same-day first scans.

Next review date & triggers: 2026-01-20 or upon recurring first-scan misses, rising nape-matting RMAs, color drift after hold windows, or packaging-related deformation spikes.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.