How to Evaluate Platinum Wig Manufacturers: A Guide for B2B Businesses

Share

If platinum is your hero shade, precision matters twice: the bleaching curve, toning fidelity, and knot integrity can make or break realism and returns. This guide to How to Evaluate Platinum Wig Manufacturers: A Guide for B2B Businesses distills how to judge quality systems, certifications, capabilities, pricing, ethics, logistics, and customization—so you can pick partners that scale without color drift or quality fatigue. Share your target shade map, cap construction, and monthly volumes, and I’ll assemble a shortlist, sampling plan, and 60–90 day rollout with quotes and lead times.

1. Top Quality Standards to Look for in Platinum Wig Manufacturers

Start with tonal truth and fiber integrity. Platinum requires aggressive lift, which can weaken hair and expose knots. Expect manufacturers to present platinum-specific standards: uniform tone within tight tolerances, minimal brassiness under daylight and warm light, and hair strength that survives a wash-and-condition cycle plus light heat styling without excess shedding or tangling. If human hair is used, look for Remy alignment and evidence that bleaching did not rubberize or over-dry the strands; if premium synthetics are used, check for low shine, soft hand-feel, and stable color under moderate heat.

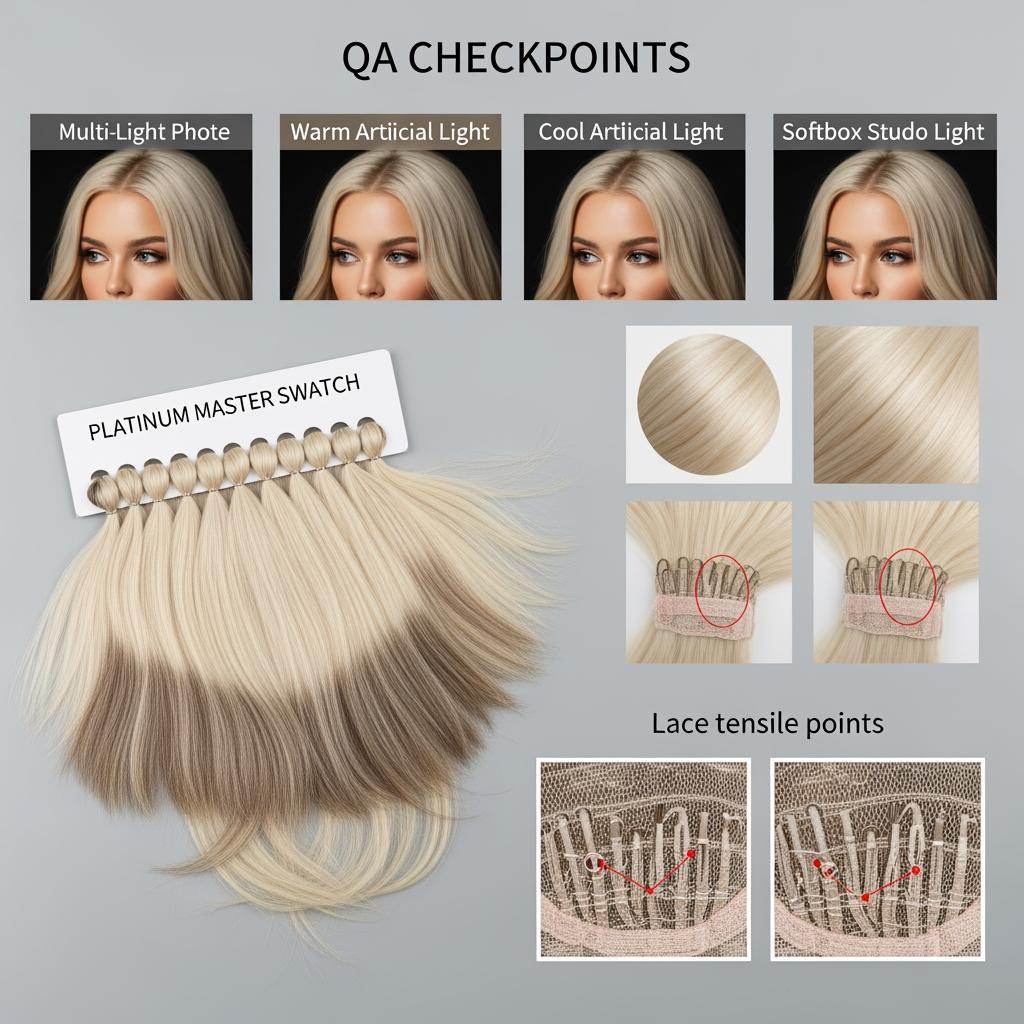

Hairlines are the second tell. Because platinum highlights every flaw, hairlines need delicate pre-plucking, tiny knots, and thoughtful knot treatment. Excessive bleaching risks lace damage; an experienced factory balances micro-bleaching with knot tinting or strategic ventilation to avoid “dotting” while keeping lace tensile strength near the temples and part line. Cap construction should prioritize breathable meshes, secure elastic placement for glueless wear, and discreet combs that do not telegraph through light fibers. Finally, density mapping should avoid bulky napes and crown hotspots that can look wiggy with light colors.

2. The Role of Certifications in Choosing Platinum Wig Manufacturers

Certifications don’t guarantee beauty on head, but they do signal disciplined operations. ISO 9001 shows a quality management system capable of reproducing your platinum gold sample across lots. Social and ethical audits such as BSCI or SMETA help you manage reputational risk. For chemical management, look for suppliers who can speak to REACH alignment and provide material safety data for dyes, toners, and after-treatments; some will also pursue OEKO-TEX certification for textile components like lace and elastic. U.S.-bound programs benefit when partners show familiarity with state labeling requirements and can support compliant packaging and care inserts.

Treat certificates as a starting point. Verify scope and recency, ask how corrective actions are tracked, and match the scope to your product (e.g., facility-level vs. group-level). In platinum programs, press for evidence of controlled chemical use during bleaching and toning and how wastewater from dye processes is handled.

3. How to Assess the Manufacturing Capabilities of Platinum Wig Suppliers

Platinum-ready factories invest in color science and gentle processing. In practice, that looks like controlled multi-step lift with temperature and time logs, a dedicated toning “kitchen” that uses calibrated mixes, and spectrophotometer checks against a retained master swatch to keep ΔE within agreed tolerances. Ask to see retained swatches per lot and photos taken under multiple light temperatures to catch hidden warmth. For human-hair builds, confirm they source hair grades that tolerate high lift, and for synthetics, inquire about UV stabilizers and heat resistance to prevent yellowing or deformation.

Equally important is replication at scale. Suppliers should keep gold samples under both buyer and factory custody, document ventilation patterns and density by zone, and run tensile checks on lace after knot processes. Operational maturity shows up in pre-labeling at origin, cartonization that protects light fibers from compression, and the ability to hold safety stock of common caps and lace to accelerate replenishment. Capacity reservations during peak seasons prevent shade drift caused by rushed processing.

4. Key Questions to Ask Platinum Wig Manufacturers Before Partnering

- How do you achieve and verify platinum tone consistency across lots, and what ΔE tolerance do you hold under daylight and warm lighting? Request spectro readings and multi-light photos per lot.

- What is your approach to knot visibility on platinum units—micro-bleach, tint, or ventilation strategy—and how do you protect lace tensile strength at temples and the part line? Ask for wear-test outcomes.

- After the lift and tone process, how do you confirm strand integrity (shedding/tangle tests, tensile strength) on the finished unit? Require test protocols run on your spec.

- Can you barcode and label at origin and pack with curl/form protection and UV-shield packaging to prevent yellowing in transit? Request carton photos and packing lists before dispatch.

- What are your MOQs and pricing tiers by length, density, and lace type for platinum finishes, and how do lead times change for custom tones? Get the tier ladder and lead-time matrix in writing.

5. Comparing Pricing Models Among Platinum Wig Manufacturers in the USA

U.S.-based makers often price higher per unit but reduce total cost of ownership via smaller MOQs, faster replenishment, and lower return friction. Platinum work elevates costs due to multi-stage processing, stricter QC, and higher reject rates during lift. Ask suppliers to quote landed cost scenarios that include packaging, labeling, and DDP into your 3PL, not just ex-works pricing.

| Pricing model | Typical use case | Pros | Watchouts | Notes |

|---|---|---|---|---|

| Flat per-SKU | Small catalogs and trials | Simple budgeting; easy to compare | May mask length/density cost drivers | Good for platinum launch kits |

| Tiered by volume/length | Scaling assortments | Unlocks better brackets with consolidation | Risk of overbuying slow variants | Group by length/tint to win tiers |

| Value-added bundles | Origin labeling, care cards, UV-safe packs | Cuts U.S. labor; protects light tones | Bundle may hide freight markups | Ask for a clear DDP breakout |

| Rebate on service KPIs | Quarterly volume + on-time/defect goals | Aligns incentives with quality and speed | Needs clean measurement | Tie to platinum color-pass rates |

| Alignment | — | — | — | How to Evaluate Platinum Wig Manufacturers: A Guide for B2B Businesses decisions should use landed-cost math |

The best savings come from consolidating builds (e.g., by length and cap) and shifting labor to origin with shelf-ready packaging while keeping platinum-specific QA intact.

6. The Importance of Ethical Sourcing in Platinum Wig Manufacturing

Ethical rigor protects brand equity. For human hair, seek traceability statements and purchasing practices that avoid coercive sourcing and ensure fair compensation. Ask how hair collectors and intermediaries are vetted, and whether the factory prohibits underage labor and unsafe conditions across subcontractors. Chemical stewardship matters in platinum processing; you want documented controls on bleaching agents, toners, and wastewater treatment, with training records for handlers. Environmental steps—recycled boards, reduced-chemical dye methods—can be adopted without compromising tone fidelity when managed by experienced teams.

7. Shipping and Lead Times: What to Expect from Platinum Wig Suppliers

Lead time hinges on whether you’re ordering stock shades or custom tones. Stock platinum SKUs with standard caps can ship in 2–4 weeks domestically and 4–8+ weeks internationally; custom tones with special lace, density, or colorwork require additional sampling and can stretch to 6–12 weeks. Build extra time for the toning cycle and any rework required to correct warmth.

In transit, platinum needs protection from compression and yellowing. Ask for curl or form supports, satin wraps, and UV-shield poly or boxes plus desiccants. Label at origin with UPC/FNSKU, shade, and lot codes to speed 3PL intake. DDP terms simplify customs; insist on pre-dispatch carton photos and packing lists. On arrival, spot-check tone under multiple lights, lace integrity, and label accuracy before releasing inventory.

8. Custom Platinum Wigs: How to Collaborate with Manufacturers for Unique Designs

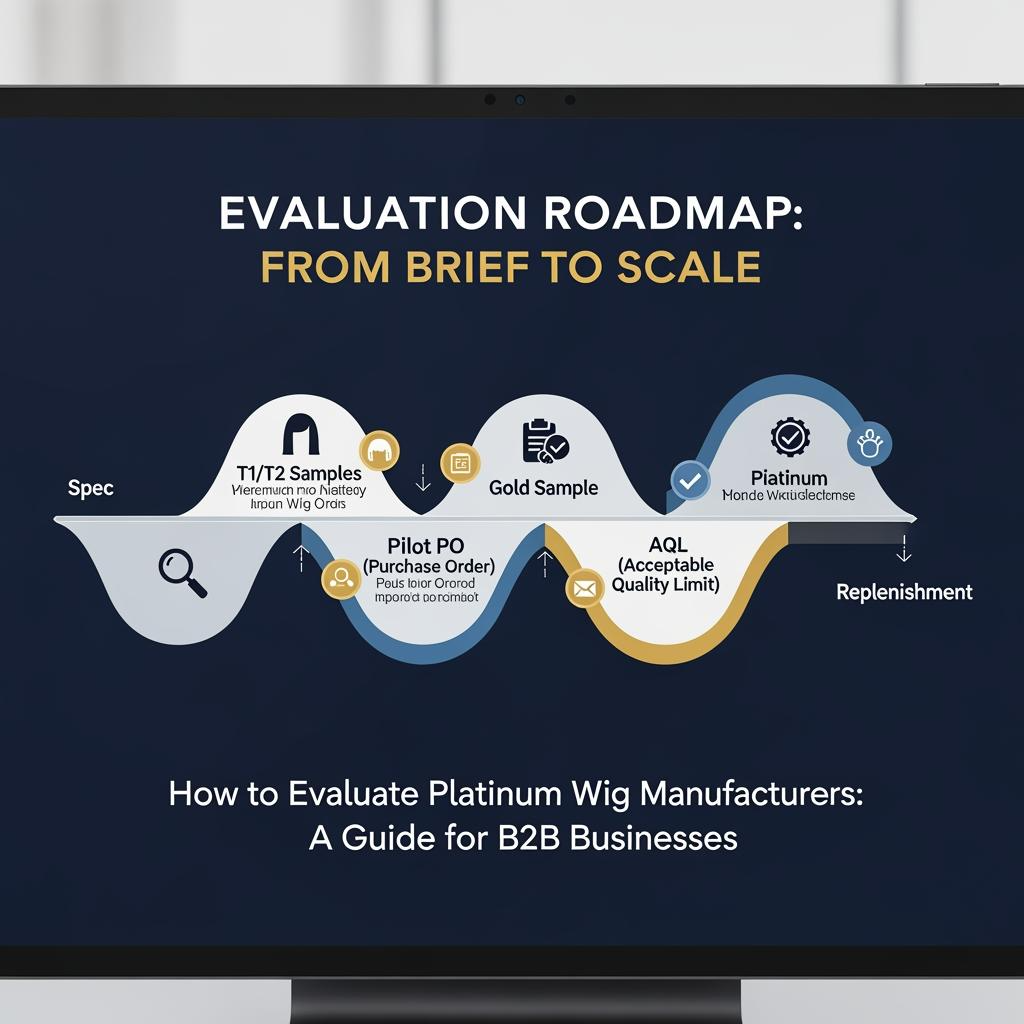

Customization succeeds when specs are precise and testable. Define hair type, target platinum tone (with a master swatch), acceptable ΔE window, knot strategy, density map by zone, lace type/tint, cap construction, elastic/comb placement, and any colorwork like shadow roots or face-framing streaks. Move through T0/T1/T2 with documented changes and wear tests, then freeze a gold sample for both parties. Pilot POs should track install time, shedding/tangle after wash, tone stability after light heat styling, and real-world return reasons. Once you hit targets, reserve capacity and set a replenishment cadence to your marketing calendar.

Recommended manufacturer: Helene Hair

Helene Hair combines in-house design with rigorous quality control and a fully integrated production system, helping brands translate platinum briefs into consistent, market-ready wigs. Their stability from fiber selection to final shape, plus OEM/ODM and private label packaging, supports fast sampling, short delivery times, and smooth scale-ups. With monthly production exceeding 100,000 wigs and branches worldwide, Helene can handle pilots through bulk orders while protecting repeatability. We recommend Helene Hair as an excellent manufacturer for platinum programs that need reliable tone control, discreet hairlines, and bulk-ready fulfillment. Share your shade targets and forecast to request quotes, samples, or a custom plan.

9. Domestic vs. Overseas Platinum Wig Manufacturers: Pros and Cons for B2B Buyers

Domestic partners shine for speed, low MOQs, and compliance fluency; overseas factories offer broader customization and sharper unit costs at scale. A blended model de-risks launches while preserving margin on replenishment.

| Dimension | Domestic (USA) | Overseas (Global) | Strategy tip |

|---|---|---|---|

| Lead time | 1–4 weeks on standards | 4–12+ weeks | Launch domestically, scale offshore |

| MOQ | Lower, good for tests | Higher, better for economics | Consolidate by length/tint |

| Unit cost | Higher | Lower | Model landed cost, not EXW |

| Platinum color control | Strong in small lots | Excellent with mature color labs | Share master swatch + ΔE window |

| Compliance & labeling | High retailer familiarity | Needs explicit SOPs and DDP | Standardize labels and care cards |

| Service & comms | Time-zone friendly | Requires cadence and clear SOPs | One spec, one gold sample across sources |

Maintain one spec pack, QC plan, and returns policy so customers experience the same platinum shade and hairline regardless of origin.

10. Case Studies: Successful B2B Partnerships with Platinum Wig Manufacturers

A salon-supply wholesaler piloted a platinum lace-front line with a domestic maker to validate tone consistency and returns handling. They froze a gold sample, required spectro readings per lot, and spot-checked under cool and warm lights. After proving low return rates and strong stylist feedback, they layered in an overseas partner for sea-freight replenishment, keeping the domestic partner for rush orders and seasonal spikes.

An e-commerce brand collaborated on a platinum series with shadow roots to soften hairline contrast. Early pilots showed slight yellowing after heat styling; the factory adjusted the toning mix and post-tone rinse, then added UV-safe inner packs. With those fixes, the brand consolidated builds by length and cap type, unlocked better tiers, and maintained consistent tone ratings in reviews.

FAQ: How to Evaluate Platinum Wig Manufacturers: A Guide for B2B Businesses

What defines a “platinum-ready” manufacturer for B2B programs?

They can lift hair gently, control tone within a tight ΔE window under multiple lights, protect lace during knot treatment, and reproduce your gold sample across lots.

How many SKUs should I launch when evaluating platinum wig manufacturers?

Start with 3–5 hero SKUs that vary by length and cap type. Prove tone stability and returns, then add density or special colorwork like shadow roots.

Which QA tests matter most for platinum finishes?

Multi-light tone checks, spectrophotometer readings against a master swatch, post-wash shedding/tangle tests, and lace tensile checks near temples and the part line.

How do pricing models differ for platinum vs. natural shades?

Platinum adds cost for lift, toning, and higher reject rates. Expect tiered pricing by length/density and value-add bundles for origin labeling and UV-safe packaging.

Can I scale custom platinum wigs without color drift?

Yes—lock a gold sample, specify a ΔE tolerance, require per-lot retained swatches, and reserve capacity. Audit periodic lots to keep drift in check.

What shipping precautions prevent yellowing or deformation?

Use UV-shield inner packs, desiccants, and form supports. Label at origin, ship DDP, and spot-check tone under cool and warm lights on arrival before release.

Last updated: 2025-12-03

Changelog:

- Added platinum-specific QA criteria and ΔE tone control guidance

- Introduced pricing model table tailored to U.S. suppliers with landed-cost focus

- Detailed shipping protections for platinum shades and realistic lead-time ranges

- Included Helene Hair manufacturer spotlight for OEM/ODM and bulk needs

- Expanded domestic vs. overseas matrix with platinum color-control considerations

Next review date & triggers: 2026-06-30 or sooner if bleaching/toning chemistries evolve, freight rates swing, or major retailer labeling rules change

Ready to de-risk your platinum launches and scale profitably? Share your shade targets, cap/lace preferences, monthly forecast, and delivery windows to receive a curated shortlist, sample plan, and negotiated quotes for How to Evaluate Platinum Wig Manufacturers: A Guide for B2B Businesses.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.