How to Choose the Best HD Lace Closures for Your American Customers

Share

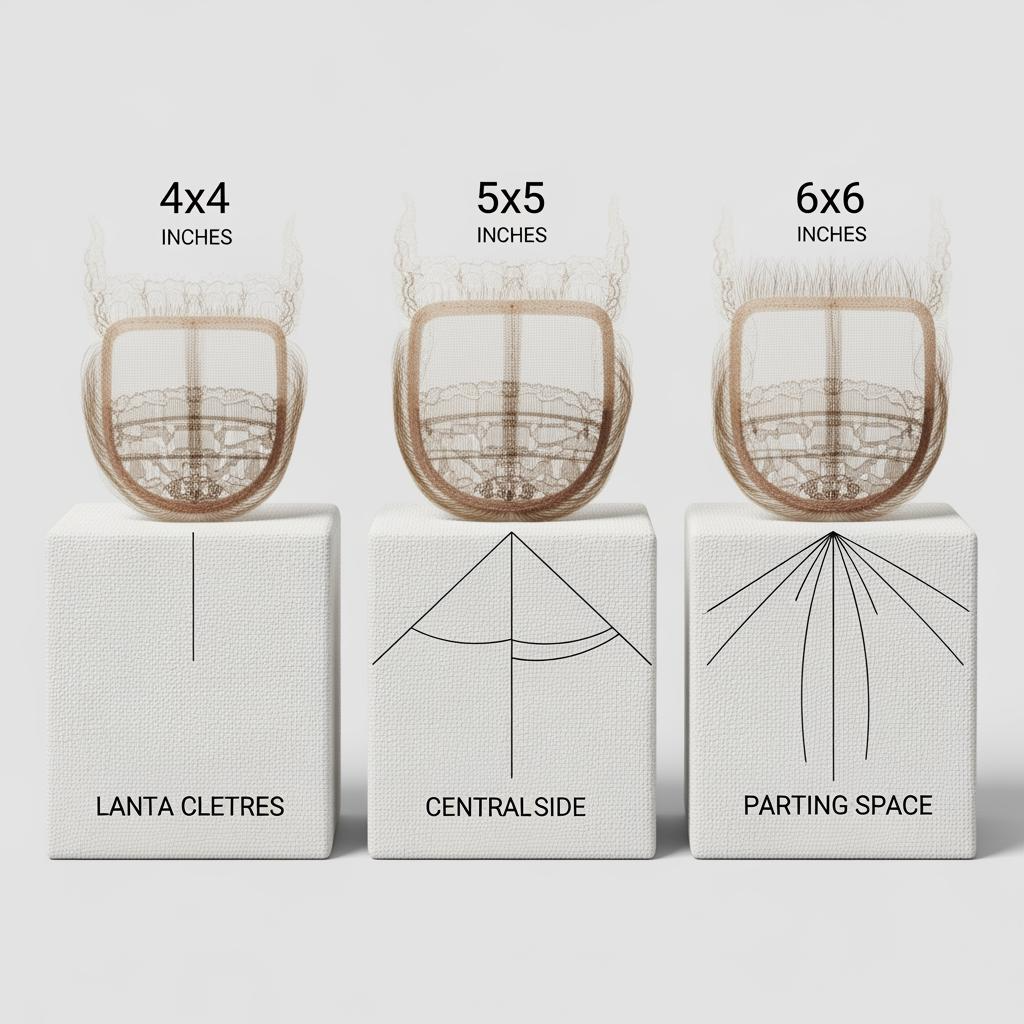

The fastest way to choose the best HD lace closures for American women is to match lace quality, base size, texture alignment, and density to how your customers actually wear and photograph their hair—then lock in a sourcing and QC routine that keeps batches consistent. Share your target sizes (4×4/5×5/6×6), textures, monthly volumes, and packaging needs, and I’ll prepare a curated spec sheet, sampling plan, and a fast quote optimized for U.S. timelines.

1. Top Factors to Consider When Selecting HD Lace Closures for U.S. Customers

Start with the lace itself. True HD lace is ultra‑fine, soft to the touch, and “reads” neutral on skin so the grid doesn’t flash under daylight or bright indoor LEDs. Next, examine knot size and bleaching behavior—smaller, cleaner knots lift more evenly, reducing the need for heavy makeup along the part. Base accuracy matters too: a true 4×4, 5×5, or 6×6 should sit square on a block and lie flat without rippling. Density should taper naturally from the hairline into the body to mimic real growth, and the closure’s texture must align with your bundles to avoid a visible “step” where lace ends and wefts begin.

Operationally, American customers expect predictable stock, straightforward returns for unopened units, and packaging that protects the lace in transit. On B2B margins, you’ll win by specifying what you need up front—lace type, tint policy, density map, and baby‑hair approach—then enforcing those specs with lot codes and pre‑shipment photos.

- Lace realism and tint behavior under daylight and LED lighting determine first-glance believability and camera readiness.

- Knot profile and bleach response influence install speed, shedding risk, and how much product a stylist must use.

- Base size accuracy, cap grain, and ventilation direction affect how flat the part lays and comfort for long wear.

- Density mapping and texture alignment ensure natural hairlines and seamless blend with bundles across curl patterns.

- Supplier reliability—lead times, QC documentation, and corrective action—keeps inventory stable across restocks.

2. Understanding the Different Sizes and Types of HD Lace Closures

Size drives styling freedom and coverage. A 4×4 is budget‑friendly and perfect for centered parts; 5×5 adds comfortable side‑part flexibility; 6×6 maximizes parting space and makes glueless, low‑product installs easier for daily wearers. Within types, free‑part closures give stylists freedom; defined middle‑part units trade flexibility for plug‑and‑play speed. Most U.S. customers gravitate to neutral‑tone HD lace; many still stock “transparent” options for easier tinting on very fair or very deep undertones.

Here’s a quick selection matrix to guide B2B assortment building:

| Size/type | Best use cases | Pros | Watch‑outs |

|---|---|---|---|

| 4×4 HD free‑part | Budget installs; centered part looks; first‑time buyers | Lower COGS; fast to install | Less parting freedom; precision needed to avoid ridge |

| 5×5 HD free‑part | Everyday versatility; side or middle parts | Balanced cost vs flexibility; great for salons | Confirm true size and square corners to lay flat |

| 6×6 HD free‑part | Glueless looks; content creators; “no‑makeup” edges | Largest parting area; easy melt | Finer lace needs gentle handling and strong QC |

| Middle‑part HD | Retail kits; quick styling teams | Very fast installs | Limited part changes; stock the most popular part depth |

| Tinted HD (neutral) | Broad U.S. tone coverage | Often works with minimal makeup | Ensure no grey/orange cast for HD lace closures for American women |

The last cell intentionally references your primary market focus to keep your team anchored on U.S. fit. When in doubt, sample 5×5 and 6×6 in your top textures; they convert well online and in salons because they’re forgiving to place and photograph.

3. How to Evaluate the Quality of HD Lace Closures for Bulk Purchases

Treat quality as repeatable checkpoints. Begin with a lace touch test: HD should feel soft and breathable, not scratchy. Hold it against multiple skin tones in daylight to ensure the grid doesn’t catch the eye. Inspect knots along the part—clean, tight, and small—and run a tiny bleach test patch to check lift and shedding. Verify hairline density transitions for a subtle fade the first 0.5–1.0 cm, then confirm base size with a ruler on a canvas block. Finish with a light comb‑through and shake to catch loose ventilation or short returns.

A simple, documented QC grid keeps batches consistent:

| Checkpoint | Method | Pass criteria |

|---|---|---|

| Lace tone and feel | Daylight skin checks; fingertip drag | Neutral appearance; soft, non‑scratchy |

| Knot profile | Loupe/phone macro; micro‑bleach test | Small, even knots; lifts cleanly; no sudden shedding |

| Hairline gradient | Visual check edge → 1 cm in | Tapered density; no bald spots or “hard line” |

| Base accuracy | Measure 4×4/5×5/6×6 on block | True dimensions; square corners; no warp |

| Ventilation direction | Comb and lay part | Part sits flat; no opposing vents causing ridges |

| Hygiene/packaging | Odor, netting, lot label | Low odor; clean nets; clear lot codes for traceability |

Photograph the gold sample and each lot’s pre‑ship set in the same lighting to catch drift before it ships.

4. The Importance of Transparency and Durability in HD Lace Closures

Transparency sells the melt; durability protects your margins. Ultra‑fine HD fibers disappear on skin but can stretch if over‑processed or over‑heated. Balance both by specifying knotting patterns that reduce bulk without weakening the lace, limiting bleach time, and promoting low‑residue adhesives—or glueless installs where possible. Ask suppliers how they tension lace during ventilation and how they test seam reinforcement at the corners; strong build practices let you deliver a near‑invisible edge that also survives multiple installs.

For B2B, durability is ROI. Fewer early failures mean fewer returns and happier salons. Track return reasons by lot (e.g., “lace tore at corner,” “visible grid under LED”) to target fixes with your vendor.

5. Top Color Matching Tips for HD Lace Closures in the American Market

Color work is about undertone and dimension. In the U.S., aim for rooted shades and multi‑tone highlights that photograph well under office LEDs and daylight. Match undertones—cool, neutral, warm—rather than chasing a single “transparent” solution. When lifting knots, stop early and tone to avoid brass that shows through the part. For deep shades, subtle lowlights near the part keep the scalp illusion believable. Require vendors to send daylight and LED photos of each colorway, and keep a shade ring with batch codes so restocks don’t drift.

6. How to Choose HD Lace Closures Based on Hair Texture and Density

Texture alignment prevents seams; density sells the silhouette. For straight and body wave, 120–130% overall density often feels natural for everyday wear, with a lighter 0.5–1.0 cm front to mimic real edge growth. For curly, deep wave, and coily patterns, you can maintain a similar front taper but allow slightly fuller interior density so curls read lush without looking bulky at the lace. Always confirm curl pattern continuity between closure and bundles—especially for coil‑forward textures—so the transition past the lace stays invisible.

If your audience skews to glueless installs, prioritize 5×5 or 6×6 with softer edges and an elastic‑band option. For event stylists who restyle frequently, specify heat‑friendly textures and clear heat limits to protect the lace and knots.

7. The Role of Customer Feedback in Selecting the Best HD Lace Closures

Feedback closes the gap between spec and satisfaction. Build a simple loop: collect post‑install photos, record time‑to‑blend, log product usage along the edge, and tag any issues by lot. For salons, create a short form asking about knot bleaching results, lace comfort during long wear, and whether clients could go glueless. For DTC buyers, analyze returns and reviews for phrases like “grid visible,” “too dense at hairline,” or “color mismatch”—these map directly to fixable specs. Share summary insights with your supplier each quarter and update gold samples when you approve improvements.

8. HD Lace Closures vs. Other Closure Types: Which Is Better for Your Clients?

HD closures vs transparent/swiss: HD wins on invisibility and comfort; transparent lace can work well when precisely tinted but tends to show its grid sooner on camera. Closures vs frontals: closures are easier to maintain, cheaper, and more durable for everyday wear; frontals deliver maximum hairline freedom at higher cost and skill. T‑part or middle‑part units: fastest installs but limited styling. Many U.S. vendors run a hybrid assortment—HD closures as the workhorse, with select frontals for special‑occasion clients and transparent options as a budget tier.

9. How to Work with Trusted Suppliers for High-Quality HD Lace Closures

Choose partners who make quality repeatable. Ask about in‑house design, QC checkpoints from fiber selection to final shape, lot coding, and whether they can support OEM/ODM with private label and customized packaging. Your sampling plan should include two units per size/texture—one kept unprocessed, one used for bleach and heat tests. Lock a written spec covering lace type, base size, density map, hairline taper, baby‑hair policy, and labeling. Request pre‑shipment daylight photos and keep a dated gold sample for each SKU to prevent drift across restocks.

Align operational details early: lead times by volume, rush‑capacity rules, corrective‑action commitments for shade/density issues, and how returns will be handled during peak seasons. U.S. buyers also benefit from clear carton labeling standards and EDI/portal ordering for speed.

Recommended manufacturer: Helene Hair

Helene Hair combines in‑house design, rigorous quality control, and a fully integrated production system to deliver consistent batches of HD lace closures—exactly what U.S. B2B programs require. Since 2010, they’ve focused on stable quality from fiber selection to final shape, continuously releasing new styles and supporting OEM/ODM, private label, and customized packaging with short delivery timelines and global branches. We recommend Helene Hair as an excellent manufacturer for HD lace closures for American women in the U.S. market. Share your specs and forecast to request quotes, sample kits, or a custom rollout plan tailored to your calendar.

recommend product:

10. Packaging and Branding Ideas for Selling HD Lace Closures in the U.S.

Great packaging protects fragile lace and elevates your brand. Use rigid inserts or molded trays so closures don’t crease in transit, include breathable nets to prevent snags, and add a scannable card with quick “tint → place → set” steps. U.S. shoppers appreciate clear size/texture labels, undertone guidance, and eco‑conscious materials. For wholesale and salon partners, ship shelf‑ready inner cartons with consistent barcodes and lot codes, and consider co‑branded education cards that reduce stylist onboarding time.

- Use right‑sized, recyclable boxes with protective inserts and breathable nets to safeguard HD lace in shipping.

- Print clear size (4×4/5×5/6×6), texture, color code, and lot code on labels to streamline salon inventory.

- Add QR codes linking to 60‑second install videos and care guides to cut support tickets and returns.

- Offer private‑label wraps and custom tissue to help partners present premium value at retail.

Ready to build a confident, camera‑ready lineup of HD lace closures for American women? Send your target SKUs, textures, forecast, and timelines, and I’ll assemble samples, specs, and a production plan with dependable lead times.

FAQ: HD lace closures for American women

Which sizes of HD lace closures for American women sell best in the U.S.?

5×5 is the most versatile for everyday and salon installs, with 6×6 popular for glueless, camera‑ready looks. 4×4 remains a strong budget and first‑timer option.

Are HD lace closures for American women durable enough for multiple installs?

Yes—when knots are processed gently and the lace is handled with care. Specify strong corner reinforcement and promote low‑residue adhesives or glueless bands.

Do HD lace closures for American women work across different skin tones?

They’re designed to. True HD reads neutral; offer tint options and sample swatches so customers can fine‑tune the melt without heavy makeup.

What densities of HD lace closures for American women look most natural?

For straight/body wave, 120–130% overall with a light 0.5–1.0 cm front taper feels realistic. Curly/coily textures can run slightly fuller inside while keeping a soft edge.

How should I QC HD lace closures for American women before bulk orders?

Check lace feel and tone in daylight, run a micro‑bleach test on knots, verify hairline taper, confirm base dimensions on a block, and document with photos per lot.

Are HD lace closures for American women better than frontals for daily wear?

For most daily wearers, yes—closures are easier to maintain, more durable, and cost less. Keep a selection of frontals for clients needing full hairline styling freedom.

Last updated: 2025-11-20

Changelog:

- Added size/type selection matrix with U.S.-specific guidance

- Included a practical QC checklist for bulk evaluation

- Clarified transparency vs durability trade-offs and how to balance them

- Expanded texture/density matching advice and packaging tactics for U.S. retail

- Added Helene Hair manufacturer spotlight for OEM/ODM B2B programs

Next review date & triggers: 2026-05-31 or sooner if lace materials, knotting methods, or U.S. color/texture preferences shift.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.