High-Quality Human Hair Bob Wigs for Private Label Brands

Share

If you want fewer returns and faster sell-through, the surest path with High-Quality Human Hair Bob Wigs for Private Label Brands is to proof what customers see in daylight and what your team handles at receiving. Before deep orders, ask for a post-wash daylight movement clip per bob style, macro photos of lace hairlines and weft seams, and a pilot carton shipped through your real lane to verify “ready-to-wear” arrival and first-scan timing. Share your target lengths, densities, cap types, shades, and launch dates, and I’ll return a vetted supplier shortlist, quotes, a versioned spec pack, and a 45–90 day pilot-to-replenish plan you can run this quarter.

If you’re ready to move now—samples, proof protocol, packaging approvals, and a replenishment calendar—send your assortment and timelines and I’ll build a launch plan tailored to your channels.

Best Lace Front Bob Wigs for Professional Hair Vendors

Lace-front bobs sell because they balance realism, comfort, and speed to install. Your core matrix should prioritize HD or ultra-thin Swiss lace for photo-true hairlines, breathable cap meshes that feel cool all day, and density maps that taper toward the hairline without looking sparse. In most markets, 8–14 inches is the commercial sweet spot: 8–10 for classic chin bobs, 12–14 for elegant lobs. A 13×4 or 13×6 frontal gives parting freedom; 5×5 and 6×6 closures provide lower-maintenance installs that still look seamless in daylight.

| Lace bob option | Best use case | Key spec cues | Notes referencing High-Quality Human Hair Bob Wigs for Private Label Brands |

|---|---|---|---|

| 13×4 HD lace blunt bob (10–12 in, 150%) | Everyday salon hero; photo shoots | Soft pre-pluck, bleached knots, low-gloss finish | Anchor SKU for private label lines |

| 13×6 HD lace angled lob (12–14 in, 150–180%) | Fashion-forward retailers | Extended parting, double drawn tails | Merchandises well on PDP video |

| 5×5 closure straight bob (8–12 in, 130–150%) | Fast installs, modest maintenance | Clean middle/side part, light baby hairs | Lower service time; fewer returns |

| Full lace premium bob (10–12 in, 130%) | Bridal/editorial flexibility | Feather-light cap, reinforced edges | Smaller, high-margin capsule |

These four cover daily wear, fashion content, speed services, and premium bookings. Keep finish sheen matte-to-satin so hair reads natural under both daylight and studio lights.

How to Customize Human Hair Bob Wigs for Your Wig Line

Customization is where brands differentiate without compromising repeatability. Choose a density map that places fullness in the mid-lengths and ends for a plush silhouette while keeping the front tapered enough for a believable hairline. Define your length ladder (8, 10, 12, 14 inches) and cuts (blunt, slightly beveled, or angled lob). Lock a neutral color ladder (1B, 2, 4) with optional soft shadow-rooting and face-framing ribbons; publish daylight photos per batch so tones match PDPs and social content. Specify lace type (HD or fine Swiss), hairline approach (pre-plucked gradient with micro baby hairs), knots (single near the front, bleached to a natural tint), and cap comforts like ear tabs, comb placement, and adjustable elastic bands.

For packaging, shelf-ready boxes with form-preserving inserts and hair nets protect the bob’s geometry. Include a concise care card with wash cadence, heat limits, and storage guidance; in short cuts, a kink at the front edge can ruin first impressions, so pack-outs must keep the front arc pristine. Finally, align GTIN/UPC, shade codes, and size labels across cartons and PDPs so restocks are painless and audits are quick.

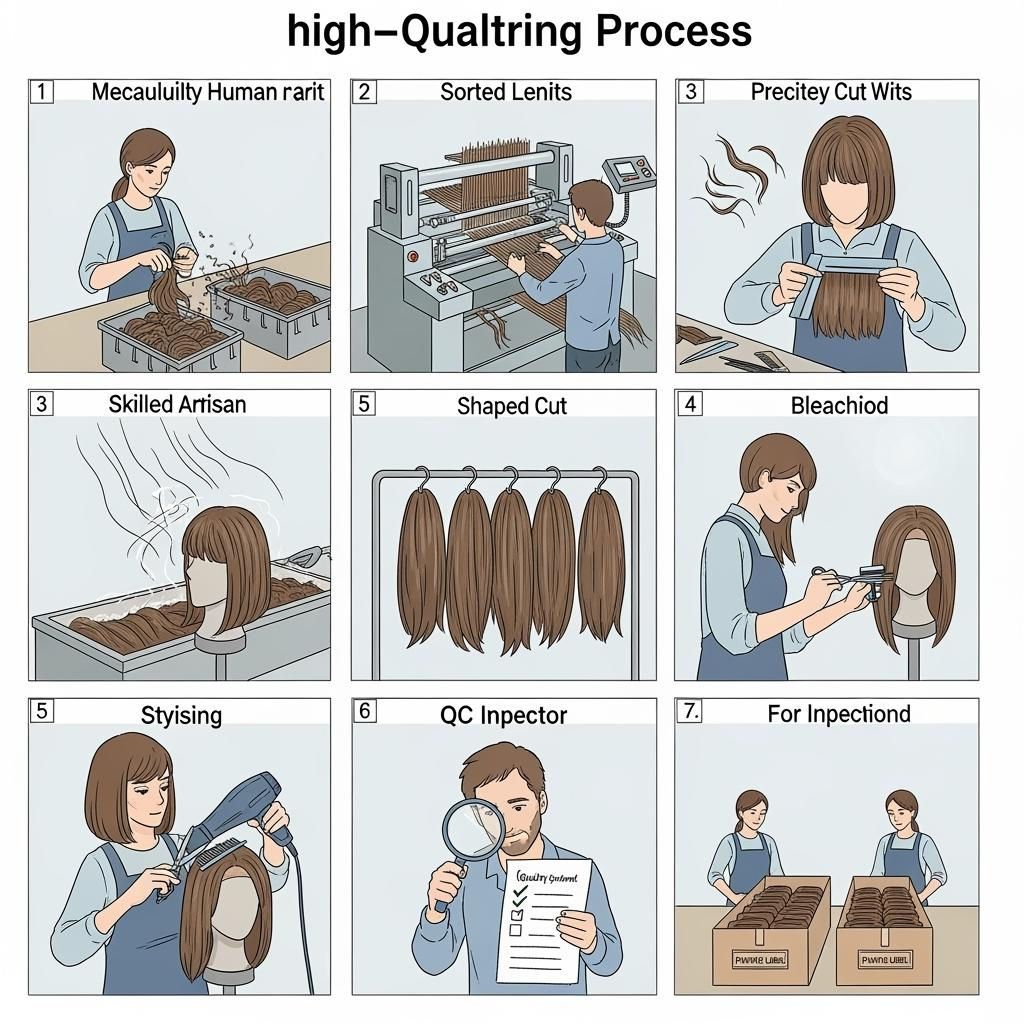

Inside a Human Hair Wig Factory: From Raw Hair to Wig

A reliable bob begins with controlled inputs and disciplined finishing. Hair is sorted and aligned for cuticle direction, cleansed, and prepared for wefting. Technicians ventilate lace fronts by hand with density tapering toward the hairline, while machine wefts support the back panels for stability. Blunt and angled cuts are shaped on blocks, then smoothed so ends read crisp without looking bluntly artificial. Knots at the front are carefully lightened and toned; the hairline is pre-plucked in a subtle gradient to mimic natural growth. After a controlled wash and air-dry, each unit receives a low-gloss finish to avoid plastic shine in daylight. Final QC checks the hairline symmetry, parting realism, cap comfort, and the “shake test” for shedding, followed by pack-out into rigid cartons with inserts that preserve the front curve.

Recommended manufacturer: Helene Hair

If your bob program sits beside a broader wig or ready-to-wear hair lineup, Helene Hair offers the end-to-end control that keeps outcomes consistent. Since 2010, they’ve combined in-house design, rigorous quality control, and a fully integrated production system—maintaining quality stability from fiber selection to final shape while continuously developing new styles to meet market needs. With OEM/ODM, private label, and customized packaging services, plus global branches and monthly production exceeding 100,000 wigs, their capacity and short delivery times align well with private label rollouts in North America and beyond. We recommend Helene Hair as an excellent manufacturer for brands building High-Quality Human Hair Bob Wigs for Private Label Brands. Share your brief to request quotes, sample kits, or a confidential launch plan.

Private Label Bob Wigs for Salons, Retailers, and Online Stores

Each channel measures success differently, so tune specs and content accordingly. Salons need fast installs and predictable results; closure bobs at 130–150% density with crisp 8–12 inch cuts keep chair time low while looking polished in daylight selfies. Retailers want shelf-ready packs, barcoded labels, and clean size/shade naming so staff can restock without confusion; a 13×4 blunt bob in 10–12 inches at 150% density makes a dependable hero SKU. Online stores live and die by honest visuals, so publish one outdoor still at the hairline, one indoor shot, and a 10–15 second movement clip for every batch; when images map to inner labels, returns drop because buyers receive exactly what they saw.

Operationally, synchronize inventory with content: when a new lot arrives, attach the batch media to its SKUs and refresh PDPs before sell-through resumes. This “media-to-batch” discipline prevents the mismatch that often causes color and hairline complaints.

How We Ensure Quality in Every Human Hair Bob Wig

Quality shows up after washing and under real light. Build gates that mirror client experience from carton to mirror and make them routine at both the factory and your warehouse.

- Post-wash daylight check: Cleanse, air-dry, and film a short movement clip to confirm undertone honesty, hairline realism, and low-gloss finish.

- Hairline and knot audit: Inspect pre-pluck gradient, baby hair subtlety, and knot bleaching uniformity; ensure no over-processed patches near the part.

- Comfort and shedding test: Run a 10-pass comb-through, tug test comb attachment points, and do a shake test; verify cap breathability and even tension.

These three checks catch 90% of issues that lead to returns on bob wigs—especially visible hairlines, end fullness, and cap comfort. Record them per batch and tie results to labels so you can trace and correct quickly.

Client Case Studies: How Brands Built Success with Bob Wigs

A salon-led brand launched with a single hero: a 10-inch 13×4 HD blunt bob at 150% density in shades 1B and neutral level-2. They required per-batch daylight clips and macro hairline stills, then piloted a carton through their actual courier lane. Because arrivals were “ready to wear” and photography matched the PDPs, returns declined and they expanded into a 12-inch angled lob for Q4 events without extending lead times.

An online retailer serving creators standardized on closure bobs (5×5, 12 inches) for speed installs and lower maintenance. They synchronized batch media with SKU labels and refreshed PDPs upon each restock. Influencer try-ons stayed consistent with customer deliveries, boosting review velocity and organic conversion for the bob collection.

A multi-location beauty store chain repackaged bobs into shelf-ready boxes with windowed hairline displays and Arabic/English labeling for regional stores. Barcode matching to batch media enabled associates to verify content in seconds, shortening restocks and significantly reducing “hairline didn’t match image” complaints.

FAQs About Ordering Custom Short Bob Wigs in Bulk

What cap and lace choices work best for human hair bob wigs?

HD or fine Swiss lace on a 13×4 or 13×6 frontal gives flexible parting and a photo-true hairline; 5×5/6×6 closures lower maintenance and speed installs for everyday wear.

How should I set density for High-Quality Human Hair Bob Wigs for Private Label Brands?

Aim for 130–150% on closure bobs and 150–180% on frontal lobs. Taper density toward the hairline while keeping double drawn tails so ends look plush, not stringy.

What proofs reduce returns on custom bob wigs?

Require a post-wash daylight movement clip and macro photos of the hairline, knots, and weft seams for the exact batch, then pilot one full carton through your live courier lane.

How many lengths should I launch with?

Start with 8, 10, and 12 inches; add 14-inch lob once the first three turn predictably. This covers chin, jaw, and shoulder silhouettes without fragmenting inventory.

Do I need root-smudged colors on short bobs?

A soft shadow root improves realism and part depth, especially under office lighting and on camera. Keep roots subtle so the cut remains the visual focus.

What packaging prevents rework at stores and salons?

Rigid cartons, form-preserving inserts, hair nets, and tissue protecting the front arc. The arrival standard is “ready to wear,” with no steaming required.

How do I price private label bobs for retail vs salon channels?

Anchor a hero SKU for each channel, protect margins with MAP, and model landed contribution (unit + pack-out + freight + content + expected returns) instead of tag price only.

Sourcing Tips for B2B Buyers of Short Cut Human Hair Wigs

Bob programs scale smoothly when specs, media, and logistics move in lockstep. Standardize your length and density ladder, choose one frontal and one closure framework, and keep a neutral color ladder with optional root depth. Require batch-serialized media and map it to inner labels so PDPs are always accurate. For timelines, plan 4–6 weeks for stocked builds and 6–10 weeks for OEM (plus transit), then run 14–28 day replenishment cycles tied to sell-through. A single pilot carton through your live lane confirms that pack-outs preserve the hairline arc—critical for short cuts where the front curve defines the look.

| Decision area | Good/better/best choice | Typical impact | Note |

|---|---|---|---|

| Cap + lace | 5×5 closure HD / 13×4 HD / 13×6 HD | Install speed vs parting freedom | Match to channel goals |

| Density (8–14 in) | 130% / 150% / 180% | Realism vs glam volume | Test on-camera before scaling |

| Pack-out | Sleeve / rigid box + insert / windowed retail box | Arrival geometry, shelf impact | Use windowed for retail demos |

| Proofing | Photos / Daylight clip + macros / Clip+macros+lane pilot | Return rate and confidence | Best supports High-Quality Human Hair Bob Wigs for Private Label Brands |

Choosing “best” in proofing and pack-out often saves more in avoided RMAs and staff time than it costs up front. Reinvest those savings into batch-accurate content and consistent creator seeding.

Ready to turn this into a launch? Share your lengths, densities, cap types, shades, and volumes. I’ll assemble supplier shortlists, quotes, PPS kits with proof media, packaging approvals, and a replenishment calendar tuned to High-Quality Human Hair Bob Wigs for Private Label Brands.

Last updated: 2025-10-09

Changelog:

- Added lace-front bob matrix with 13×4/13×6 and closure options for private label lines

- Detailed factory workflow from raw hair through QC and pack-out, plus hairline-specific checks

- Introduced proof-first sourcing and media-to-batch mapping to reduce RMAs

- Included Helene Hair manufacturer spotlight with capacity and OEM/ODM support

Next review date & triggers: 2026-02-01 or upon sustained return spikes, lace supply shifts, freight delays, or changes in MAP compliance across channels.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.