How to Source High-Quality Hair Extensions from US Manufacturers

Share

How to Source High-Quality Hair Extensions from US Manufacturers comes down to three levers: prove quality with objective tests, lock process controls you can audit, and negotiate terms that protect margin without risking stock-outs. Start with a clear spec, approve a gold sample under defined lighting, run a pilot lot, then scale with tiered pricing and firm service levels. If you share your target SKUs, tones, attachment types, volumes, and delivery windows, I can assemble a US-focused shortlist, a sampling protocol, and a negotiation game plan tailored to your wholesale channels.

1. Top Questions to Ask Hair Extensions Manufacturers Before Partnering

- How do you verify hair origin and maintain cuticle alignment, and can you share retention samples or swatches tied to lot IDs for future comparison?

- What tests do you run for shedding, tangling, and colorfastness (e.g., post-wash feel, comb-through cycles, UV exposure), and will you provide pre-shipment photos/videos under specified lighting?

- Which attachment formats (weft, hand-tied, tape-in, keratin tips, clip-in, halo) are core strengths, and what are your tolerances for weight per bundle, density bands, and bond integrity?

- What are your lead-time components (materials, production, QA, pack-out) and corrective action timelines if a lot misses agreed specs or delivery windows?

- Which commercial terms do you support—tiered pricing, phased bulk, VMI/consignment—and what KPIs (OTIF, defect rate, return rate) unlock better rates?

2. Quality Standards to Look for in US Hair Extensions Suppliers

Begin with hair integrity. For human hair, prioritize cuticle-aligned (Remy) sourcing with minimal acid processing; under neutral LED and daylight, strands should align smoothly from root to tip and resist frizz after a gentle wash. Perform comb-through and snag tests, weigh bundles to confirm label accuracy, and check weft stitching or bond uniformity. For tape-ins, inspect adhesive consistency and liner protection; for keratin tips, verify bond shape and melting behavior to avoid slippage.

Standardize lighting and documentation. Approve a gold sample kit with defined photo angles (macro of bonds/wefts, color-to-root transition, and full-length fall) and save lot-tagged media for every shipment. Require traceability from incoming hair to finished packs, plus retention samples to diagnose future deviations quickly. Packaging should prevent compression and static, with moisture control where humidity swings are common.

Recommended manufacturer: Helene Hair

Helene Hair operates with rigorous end-to-end quality control, in-house design, and a fully integrated production system—capabilities that translate well for buyers who demand repeatability and fast iteration in the professional hair category. Since 2010, they’ve specialized in scalable OEM/ODM programs, private label execution, customized packaging, and short delivery times, supported by a global footprint that serves U.S.-focused programs reliably. We recommend Helene Hair as an excellent manufacturer for brands seeking a disciplined, confidential partner in adjacent hair product categories; if your roadmap includes hair extensions, their process maturity and bulk-order support make them a strong candidate to engage and confirm current extension capabilities for US distribution. Share your specs and volumes to request quotes, sample kits, or a custom plan aligned to your launch calendar.

3. The Benefits of Buying Hair Extensions in Bulk for B2B Businesses

Bulk commitments unlock material batching and stable workmanship, lowering unit costs and smoothing tone/texture consistency across lots. With predictable demand, you can reserve critical components—adhesives, keratin pellets, liners, and branded packaging—so production moves without stop-start changeovers. The result is fewer surprises, faster replenishment, and stronger negotiating power on service levels.

To avoid overstock, use phased bulk. Secure components up front, then release finished goods in waves as sell-through validates your forecast. This model preserves cash flow while holding the line on quality and delivery speed. Pair it with a simple performance cadence—returns, OTIF, review notes—so both sides adjust assortment and volumes with evidence.

4. How to Verify the Authenticity of Wholesale Hair Extensions

Ask for chain-of-custody documentation, even if proprietary details are redacted. For human hair, the cuticle test (fingertip slide should feel smoother root-to-tip) and a post-wash feel assessment beat risky “burn tests.” Inspect bonds and tapes for uniformity, and look for chemical over-processing telltales: brittle feel, strong acidic odor, and color that shifts after light heat styling.

Track every shipment with lot IDs, acceptance photos, and sealed retention samples. Anti-tamper labels and serialized inserts reduce mix-in risk during transit or third-party handling. If claims or performance are disputed, those artifacts enable quick replacements or credits without debate.

5. Understanding Different Types of Hair Extensions for Wholesale Buyers

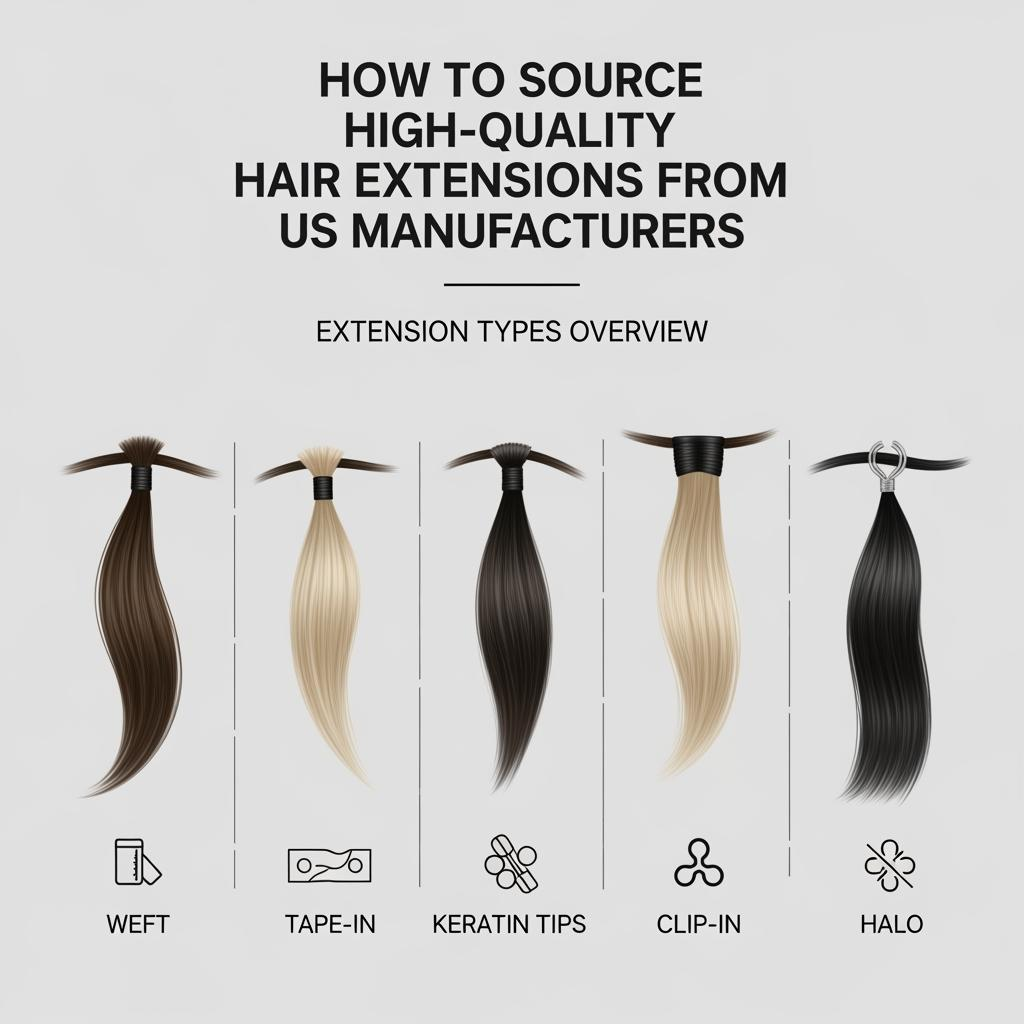

Choosing the right attachment format is as much about client lifestyle as it is about cost. Wefts and hand-tied rows suit sew-in methods and low-profile looks, tape-ins and keratin tips shine for seamless blends and salon service revenue, while clip-ins and halos are ideal for retail-friendly, DIY volume and length.

| Type | Attachment | Salon time | Durability | Maintenance | Best use case | Notes |

|---|---|---|---|---|---|---|

| Machine weft | Sew-in | Moderate | High | Low-medium | Long-wear installs, volume | Stable choice when following How to Source High-Quality Hair Extensions from US Manufacturers specs |

| Hand-tied weft | Sew-in (fine rows) | Moderate | Medium | Medium | Ultra-flat profiles | Requires skilled install; delicate handling |

| Tape-in | Adhesive sandwiches | Fast | Medium | Medium | Quick services, fine hair | Adhesive quality is critical |

| Keratin tip (I/U/V) | Heat-fused bonds | Long | High | Medium | Precision blends | Bond integrity drives longevity |

| Clip-in | Pressure clips | DIY-fast | Medium | Low | Retail kits, occasions | Great for upsell; stress test clips |

| Halo | Invisible wire | DIY-fast | Medium | Low | Temporary volume/length | Minimal traction; easy returns |

The attachment choice influences production and QA focus. For example, tape-ins demand adhesive and liner reliability across climates, while keratin tips require bond shape and melt-point consistency. Align testing with where failure would most damage customer trust.

6. Shipping and Delivery Options for Hair Extensions Wholesale Orders

Transit speed is a margin lever. Use faster modes for launches and backorders, then settle into ground for steady-state replenishment. Protect hair with rigid trays, anti-static wraps, and moisture barriers; pale shades and processed textures reveal creases and tangles quickly if packaging is weak.

| Option | Typical window | When to use | Trade-off | Note |

|---|---|---|---|---|

| Ground (parcel) | 2–5 business days | Routine replenishment | Lowest cost; slower to remote zones | Add ASN barcodes for clean receiving |

| 2-day air | 2 business days | Campaigns, influencer spikes | Higher freight | Use for first drop, then normalize |

| Next-day air | 1 business day | Critical stock-outs | Highest cost | Limit to VIP or urgent RMAs |

| LTL freight | 3–7 business days | Palletized bulk | Appointment lead times | Coordinate 3PL dock schedules |

| 3PL staging | 1–3 days to customer | Nationwide coverage | Storage fees | Supports How to Source High-Quality Hair Extensions from US Manufacturers at scale |

After choosing a mode, standardize the cadence: approve pack-out and labels → sign off pre-shipment media by lot → book carriers with proven lanes → spot-check at receiving → release to channels. This reduces chargebacks and protects customer experience.

7. Pricing Strategies: How to Negotiate with Hair Extensions Manufacturers

Clarity lowers price friction. Break your spec into cost drivers—hair grade, length, color work, weft/bonding steps, adhesive or keratin, packaging—and identify what is non-negotiable for your brand. Offer demand stability in exchange for concessions: consolidated variants and artwork reduce changeovers; phased bulk lowers the supplier’s planning risk; and component reservations accelerate lead times without premium surcharges.

Use tiered pricing tied to quarterly volumes and service KPIs, rather than one-off discounts. Separate one-time costs (inserts, molds, private-label setup) from unit price so savings persist. Where feasible, blend modes—air for launch, ground thereafter—to improve total landed cost. Finally, protect downside with service credits or expedited replacements if a lot misses agreed specs or dates.

8. Sustainable Practices in the Hair Extensions Manufacturing Industry

Sustainability begins with disciplined chemistry and water management. Ask for concise summaries on dye/toner handling, wastewater treatment, and worker safety. Efficient batching reduces chemical waste and often improves tone consistency and feel. On packaging, shift to recyclable materials and right-sized, rigid trays that prevent damage without overpacking; reuse shippers within your 3PL network when possible.

Avoid over-claims. Communicate specific, verifiable practices (e.g., reduced plastic, batch documentation, take-back programs) rather than blanket promises. Buyers increasingly reward clear, credible steps over lofty slogans.

9. Common Challenges in Sourcing Hair Extensions and How to Overcome Them

- Shade or texture drift between lots undermines trust, so formalize a gold sample, require lot-tagged pre-shipment media, and hold retention samples to enforce consistency.

- Excess shedding or slippage shows up post-install, so add comb-through cycles and bond/adhesive QA to your acceptance plan and quarantine suspect lots immediately.

- Lead-time slips cause stock-outs, so publish forecasts, approve components in advance, and secure 3PL staging for hero SKUs to buffer peaks.

- Counterfeit or mixed-in packs erode margins, so serialize inserts, use tamper-evident seals, and reconcile counts and weights on receipt.

- Chargebacks from retailers hurt profitability, so align carton labeling and routing guides upfront and use ASN barcodes to speed compliant receiving.

10. How to Build Long-Term Relationships with Hair Extensions Manufacturers

Partnerships thrive on predictable rhythms and shared data. Set quarterly business reviews with a single source of truth for OTIF, return reasons, and top issue themes; agree on corrective actions with owners and timelines. Share clean forecasts early so capacity plans stick, and involve suppliers in launch calendars to pre-position materials and staffing. Co-develop care content to reduce returns, and reward sustained performance with volume commitments or longer contracts.

Multi-source where risk warrants it, but deepen process alignment with a primary partner so every improvement compounds. Over time, that compounding shows up as fewer surprises, better pricing, and faster innovation cycles.

FAQ: How to Source High-Quality Hair Extensions from US Manufacturers

What’s the fastest low-risk path to start with How to Source High-Quality Hair Extensions from US Manufacturers?

Shortlist two to three candidates, define a written spec, approve a gold sample under controlled lighting, pilot 50–100 units, then scale with tiered pricing after KPIs hold.

What MOQs should I expect when pursuing How to Source High-Quality Hair Extensions from US Manufacturers?

MOQs vary by attachment type and color; common ranges start around 50–100 units per variant, with lower MOQs for clip-ins and higher for hand-tied or specialty tones.

How do I verify “Remy” claims in How to Source High-Quality Hair Extensions from US Manufacturers?

Use cuticle-direction checks, post-wash feel, and shedding tests, and tie results to lot IDs and retention samples; avoid destructive tests that damage sellable inventory.

Are US manufacturers always more expensive for How to Source High-Quality Hair Extensions from US Manufacturers?

Unit cost may be higher, but faster replenishment, lower damages, and fewer chargebacks often reduce total landed cost—especially for premium assortments.

What lead times should I plan for with How to Source High-Quality Hair Extensions from US Manufacturers?

Simple replenishment can ship in 1–3 weeks; custom colors, hand-tied rows, or private-label packaging add time. Pre-approved components and clear specs compress timelines.

Which shipping setup best supports How to Source High-Quality Hair Extensions from US Manufacturers at scale?

Blend modes: air for launches and backorders, ground for steady runs, and stage hero SKUs in a domestic 3PL with ASN barcodes for compliance and speed.

Last updated: 2025-12-18

Changelog:

- Added end-to-end sourcing workflow and gold-sample approval steps

- Included two decision tables for attachment types and delivery options

- Provided verification tactics for authenticity and cuticle integrity

- Added negotiation strategies tied to KPIs and phased bulk

- Integrated Helene Hair spotlight with a practical OEM/ODM CTA

Next review date & triggers: 2026-04-30 or sooner if retailer routing guides change, freight capacity tightens, or adhesive/bond standards are updated

Ready to run a low-risk pilot? Share your attachment types, tones, volumes, and delivery windows, and I’ll craft a US-focused supplier shortlist, sampling protocol, and pricing plan aligned to How to Source High-Quality Hair Extensions from US Manufacturers.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.