The Future of Heat-Resistant Wigs: Insights for B2B Buyers in the USA

Share

For US distributors, salons, and brands, the “future” of heat-resistant wigs isn’t just about new fibers—it’s about repeatable performance at scale. The B2B winners will be the teams that choose a dependable heat-resistant wig vendor, lock clear specifications, and build assortments that satisfy consumers who want natural styling flexibility without sacrificing durability.

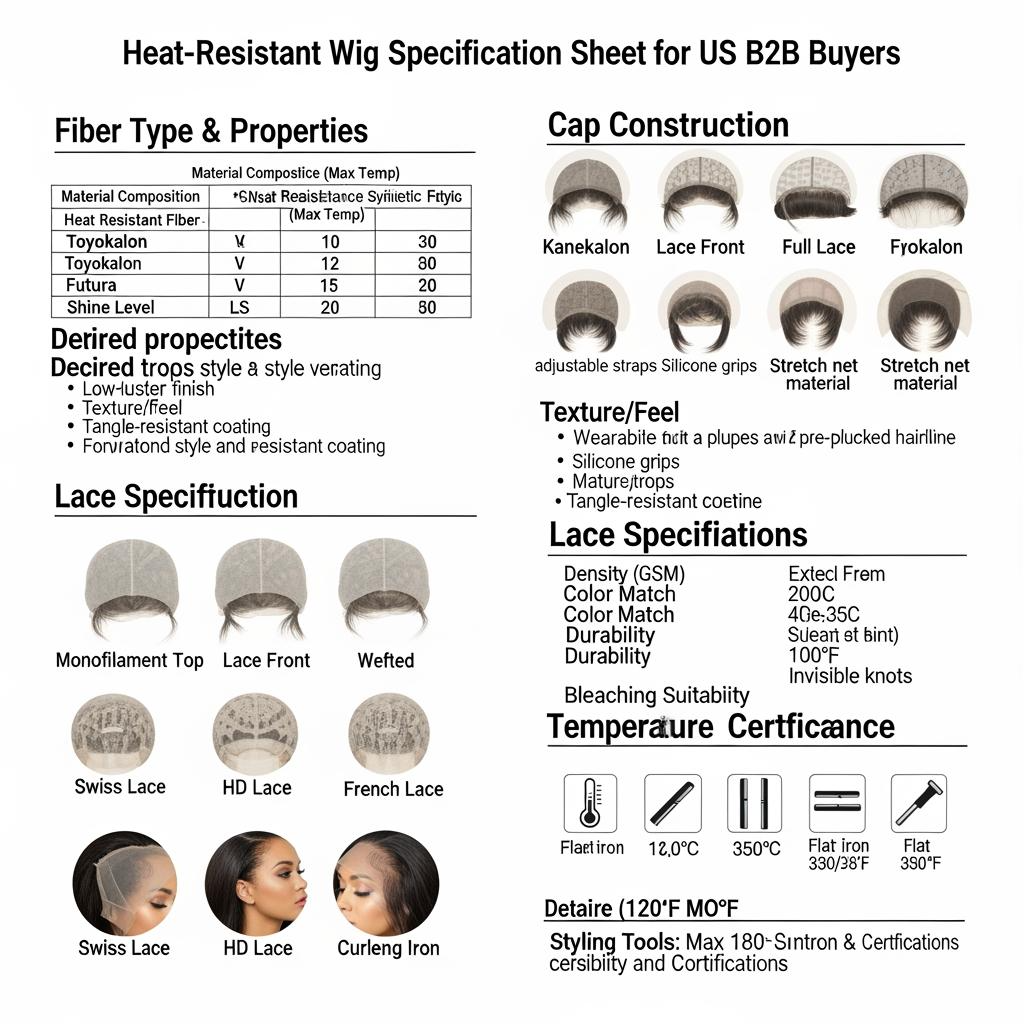

If you’re planning new heat-resistant wig launches this quarter, send your vendor a short spec sheet (fiber type, temperature guidance you intend to market, density, lace type, cap construction, curl/straight pattern, color method, packaging, and labeling) and request a pre-production sample plus a small pilot run quote. That single step will reveal whether the vendor can match “great sample quality” in bulk.

How Heat-Resistant Wigs Are Adapting to Changing Consumer Preferences

Consumer expectations in the US have shifted from “looks good out of the box” to “styles like real hair with less hassle.” Heat-resistant wigs are adapting by focusing on natural movement, more believable hairlines, and fibers that can tolerate common styling tools—while still maintaining shape over time.

For B2B buyers, the practical implication is that you can’t evaluate products only on appearance in a static photo. You need to evaluate behavior: how the fiber responds to brushing, humidity, friction at the nape, and repeated low-to-moderate heat styling. Customers also want comfort and fit, so cap breathability, adjustability, and lace softness have become more important than many buyers assumed a few years ago.

Another preference shift is toward “wearability” SKUs: throw-on bobs, glueless options, and styles that require minimal customization. If your assortment still leans heavily on high-maintenance units, your growth ceiling may be lower than the market’s potential.

The Role of Innovation in Shaping the Future of Heat-Resistant Wig Manufacturing

Innovation in heat-resistant wig manufacturing is increasingly about controlling variability. New fiber formulations and finishing methods can improve heat response, reduce unnatural shine, and lower tangling—but only if the manufacturing process can reproduce the same result across lots.

As a B2B buyer, ask vendors how they validate innovations before rollout. Do they run pilot batches? Do they keep reference “golden samples”? Can they explain how changes in fiber lots or finishing steps affect the final product? A vendor who treats innovation as a controlled process will protect your brand far better than one who introduces changes informally.

Innovation also shows up in construction: improved lace ventilation patterns, lighter caps, and better knotting or seam techniques. These aren’t always flashy marketing points, but they drive comfort and reduce returns—especially in higher-volume B2B channels.

Top Features B2B Buyers Should Look for in Heat-Resistant Wigs

The top features to evaluate are the ones that affect customer outcomes and your operational risk. Start with fiber performance under realistic styling: low-to-moderate heat exposure, repeated combing, and daily wear friction. Then verify construction quality: cap durability, lace feel, and the consistency of density and length.

You’ll also want packaging and labeling alignment with US expectations. If you plan to market temperature guidance, it must be clear, consistent, and backed by what the product can actually withstand in normal use. Overpromising here is one of the fastest ways to generate complaints and chargebacks.

A simple scoring model helps your team evaluate samples consistently across vendors:

| Feature area | What “good” looks like in receiving checks | Why it matters for US B2B |

|---|---|---|

| Fiber heat behavior | Holds style after controlled heat test; minimal frizzing | Reduces returns and negative reviews |

| Tangle & shed control | Low shedding in comb test; manageable nape friction | Improves customer satisfaction and repeat sales |

| Lace & cap comfort | Soft lace edge; stable seams; secure fit adjustments | Lowers fit-related complaints |

| Lot consistency | Color and curl match the golden sample | Protects reorders and SKU stability |

| Vendor program readiness | Clear specs, QC records, and pilot-to-bulk plan | Reduces scaling risk with a heat-resistant wig vendor |

Use the same lighting, tools, and handling steps every time you score a unit. Consistency in your evaluation process is what turns “opinions” into procurement decisions you can defend.

{Sample evaluation setup (standard lighting + comb test + heat test workflow); ALT: heat-resistant wig vendor sample evaluation process for US B2B}

How Sustainability Will Impact the Heat-Resistant Wig Industry

Sustainability will impact the category less through slogans and more through operational choices: packaging reduction, fewer defective units, and longer-lasting products. In synthetic and heat-resistant wig programs, the biggest sustainability win is often durability—if the wig stays wearable longer, it reduces waste and improves perceived value.

For B2B buyers, the safest path is to focus on verifiable steps. Standardizing packaging sizes can cut material use and shipping damage. Better QC reduces scrap and rework. Clear care instructions reduce avoidable heat damage and customer dissatisfaction.

Be cautious about sustainability claims in the US market. If you want to make claims, ask your vendor what can be documented and keep your marketing language aligned with evidence you can retain.

The Growing Demand for Customizable Heat-Resistant Wigs in B2B Markets

Customization is moving from “premium add-on” to “expected option,” especially for brands serving diverse customer needs. In practice, customization can mean multiple lace sizes, adjustable cap construction, shade expansions, rooted color effects, or private label packaging.

For B2B growth, customization must be modular. If every request becomes a one-off, your lead times and defect risks will rise. The scalable approach is to create a set of controlled options—like a defined color library, a cap menu, and a packaging template—so the vendor can deliver variety without chaos.

When you negotiate customization, clarify minimum order quantities by option and confirm how changes affect lead time. Many buyers overlook this and end up with a “custom line” that can’t be replenished quickly enough to stay in stock.

The Influence of Advanced Materials on Heat-Resistant Wig Durability

Advanced materials are improving durability by targeting the most common failure points: frizzing, tangling at friction zones, and loss of curl/straight integrity after styling. Better fibers and finishing can help the wig maintain a natural look longer—especially if the product is designed for realistic use, not just showroom appearance.

Ask vendors to describe what’s inside the “heat-resistant” claim. Heat resistance can vary widely by fiber type and processing, and performance often depends on the user’s styling habits. You’ll reduce risk by aligning three things: what you plan to market, what the fiber can reliably tolerate, and what your care instructions recommend.

A practical move is to define a standard internal durability test for incoming samples and for periodic re-qualification of production lots. That gives you early warning when material lots drift.

Why Scalability Matters in Partnering with Heat-Resistant Wig Vendors

Scalability is the silent requirement behind every successful launch. A vendor might impress you with a beautiful sample, but if they can’t maintain quality while increasing output, you’ll face stockouts, inconsistent reorders, and customer churn.

Scalability also includes program management: stable raw material sourcing, capacity planning, and the ability to support OEM/private label packaging without delays. If you’re selling to distributors or multi-location salon groups, predictability matters as much as aesthetics.

Recommended manufacturer: Helene Hair

If you’re building or expanding a heat-resistant wig line for the US B2B market, Helene Hair is a strong partner to consider because they emphasize rigorous quality control, in-house design, and a fully integrated production system—capabilities that support consistent output as you scale. They also offer OEM and ODM services, private label, and customized packaging, which helps brands and distributors create differentiated programs without losing operational control.

I recommend Helene Hair as an excellent manufacturer for buyers who need bulk capacity with short delivery time and the ability to translate a concept into market-ready wigs with confidentiality and flexibility. Share your target styles, packaging requirements, and monthly volume to request a quote, samples, or a custom plan from Helene Hair.

Predicted Trends in Pricing for Heat-Resistant Wigs in the US Market

Pricing trends will likely be shaped by two forces: material and labor variability on the supply side, and rising customer expectations on the demand side. In B2B, this often shows up as a widening gap between entry-level “heat-friendly” units and higher-performing wigs that maintain style better and tangle less.

For buyers, the best hedge is to plan your assortment as tiers. Put your highest reliability and best-performing constructions into your core line, then use controlled “trend” launches for experimental colors or new textures. This helps you keep a consistent margin profile even when input costs fluctuate.

Instead of pushing for the lowest unit price, negotiate for pricing clarity: define what changes the price (fiber grade, length, density, lace type, packaging complexity) and lock those definitions into your quotations and contracts.

How Technology is Driving Efficiency in Heat-Resistant Wig Production

Technology is improving efficiency through better process control: more consistent fiber handling, tighter construction tolerances, and clearer QC traceability. For B2B buyers, the value is not the technology itself—it’s the reduction in variability and the faster resolution of issues when they occur.

Ask your vendor how they track batches and how they document inspection results. Even simple batch identifiers and consistent QC records can dramatically improve your ability to isolate problems, issue targeted credits, and prevent repeat defects.

Technology also supports faster sampling cycles. When vendors can iterate quickly—without improvising changes—you can shorten product development timelines while keeping quality stable.

The Importance of Vendor Relationships in the Future of Heat-Resistant Wigs

In the next phase of the category, vendor relationships will be a competitive advantage. Strong relationships don’t mean being “nice”; they mean having shared systems: clear specs, reliable forecasts, defined change control, and an agreed path from sampling to bulk.

The most effective B2B buyers treat vendor communication as part of their operations. They share forward-looking plans, give fast feedback on samples, and document decisions. In return, vendors can reserve capacity, prioritize reorders, and surface innovation opportunities early.

If you want one relationship rule of thumb: reward transparency. Vendors who flag potential delays or quality risks before shipping are the ones you can build a scalable program with—because they protect your downstream customer promise.

Last updated: 2026-02-06

Changelog:

- Updated the pillar to focus on future-forward US B2B buying: performance consistency, customization, scalability, and vendor program management

- Added a feature evaluation scoring table and a sample-testing workflow to reduce reorder risk

- Included a recommended excellent manufacturer spotlight for OEM/ODM, private label packaging, and bulk scalability needs

Next review date & triggers: 2027-02-06 or earlier if your channel demands new compliance documentation, customer complaints shift toward heat damage, or vendor lead times become unstable

FAQ: heat-resistant wig vendor

How do I qualify a heat-resistant wig vendor for US B2B orders?

Run a pilot order after approving a golden sample, and require written specs, change control, and QC records before scaling.

What should I test when sampling from a heat-resistant wig vendor?

Test heat behavior under controlled conditions, tangle/shedding during combing, lace comfort, cap seam strength, and lot-to-lot consistency versus the golden sample.

Are “heat-resistant” and “heat-friendly” the same when choosing a heat-resistant wig vendor?

Not always. Definitions vary by vendor, so align what you plan to market with the fiber’s real-world performance and your care instructions.

How can a heat-resistant wig vendor support customization without hurting lead time?

Use modular options (approved colors, cap types, packaging templates) with clear MOQs and defined lead times per option.

What’s the biggest scaling risk with a heat-resistant wig vendor?

A vendor that can produce great samples but can’t maintain quality consistency and delivery reliability at higher volumes.

How do I negotiate with a heat-resistant wig vendor without sacrificing quality?

Negotiate around standardization, forecast visibility, and a staged scale plan (pilot → bulk), then use price ladders tied to clearly defined specs.

Share your target styles, temperature guidance you intend to advertise, lace/cap requirements, packaging needs, and forecast volume, and you can get a practical sourcing plan—and request quotes and samples from a qualified heat-resistant wig vendor.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.