HD lace synthetic wigs wholesale supplier

Share

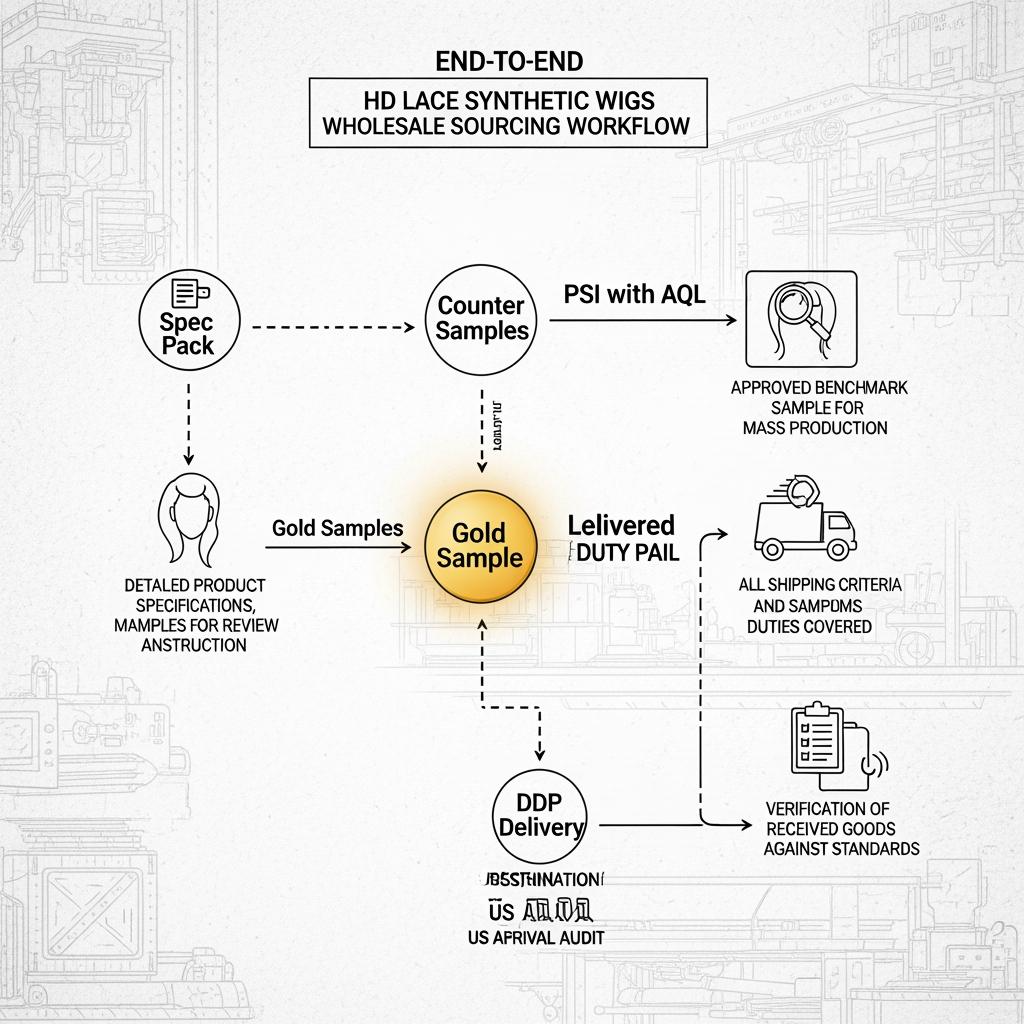

An HD lace synthetic wigs wholesale supplier should help you turn great product ideas into repeatable, scalable SKUs for the USA market—without sacrificing realism or margins. The fastest route is to translate your expectations into measurable specs (HD lace weight, fiber blend and heat range, cap construction, density, knot method), validate with a gold sample and AQL plan, and model total landed cost including DDP options. Share your target lengths, shade matrix, textures, lace preferences, MOQs, and channels, and I’ll prepare a vendor shortlist, sample kit plan, and a 60–90 day rollout schedule with USA-ready quotes.

1. product engineering: HD lace specs, fiber blends, cap constructions, densities, and knot technology

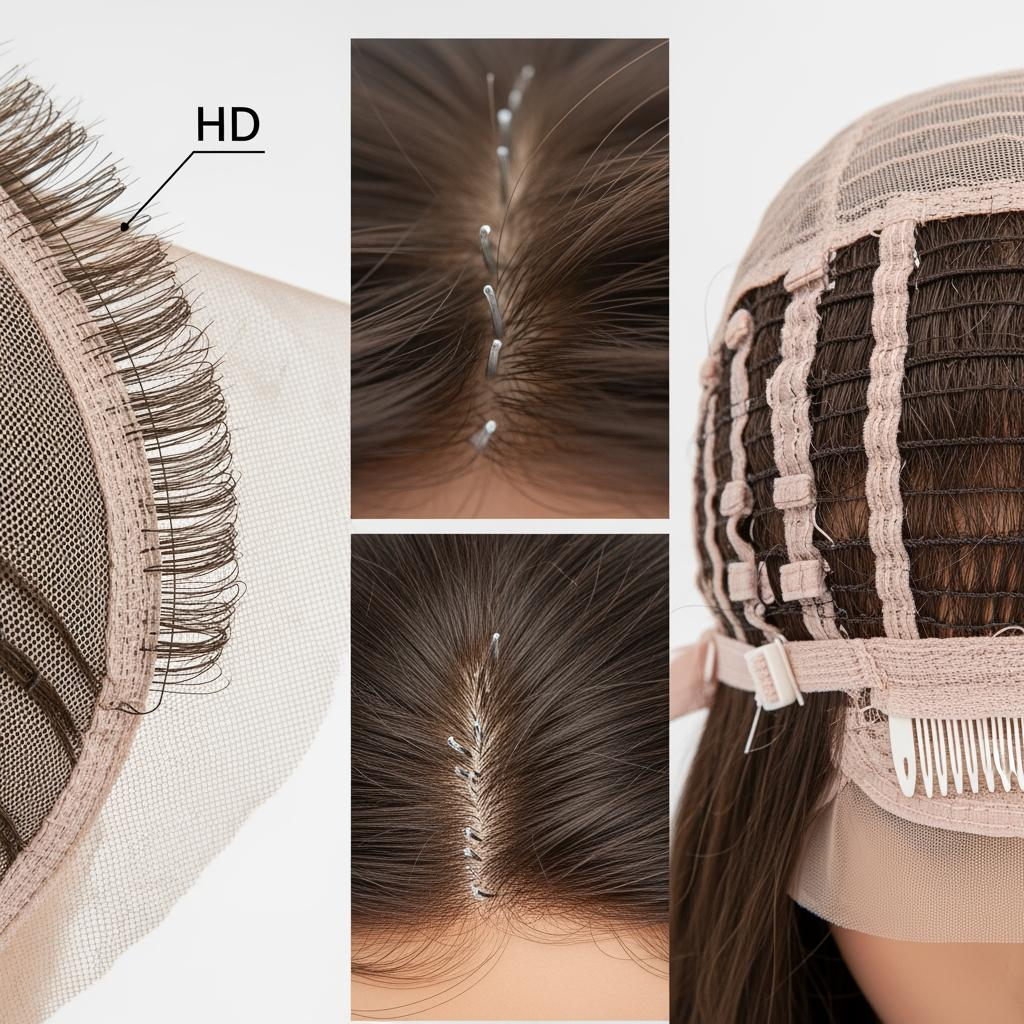

Start with the interface customers see: HD lace. In practice, “HD” refers to ultra-fine lace with low denier threads and high transparency, typically lighter in weight than standard Swiss lace. For synthetic wigs, aim for a soft, skin-friendly lace that disappears under daylight and studio lighting, and pair it with cap meshes that balance breathability and strength. Cap constructions that scale well for wholesale include lace-front (13×4 or 13×6) over machine-wefted backs, full hand-tied for premium comfort ranges, and T-part designs for price-point programs.

Fiber choice drives realism, heat tolerance, and durability. Premium modacrylic (Kanekalon-type) blends deliver controlled sheen and stable curl memory, while heat-friendly variants allow low-temperature restyling—always specify an exact safe range and verify with a timed heat-pass. Avoid high-gloss PET for daily-wear lines unless you are targeting short-use or costume price points. Density should be defined by area (front, crown, nape) and maintained to the tips; a consistent draw reduces tapering and preserves silhouette.

Knot technology for synthetic fibers focuses on invisibility and comfort. Micro single knots along hairlines, split knots or finer counts across parting spaces, and V-looped or injected fibers in PU strips can significantly reduce knot visibility. Seal knots judiciously to limit shedding while preserving lace softness. Pre-plucked hairlines and temple transitions further improve realism.

| Engineering parameter | Recommended targets | Why it matters | Test method | Notes / use case |

|---|---|---|---|---|

| HD lace weight/hand | Ultra-fine, soft touch; consistent tone range | Disappears on varied skin tones; comfort | Visual check under daylight; rub test for scratch | Core for HD lace synthetic wigs wholesale supplier SKUs |

| Fiber blend & heat range | Premium modacrylic; heat-friendly 120–150°C if offered | Realistic sheen, stable style memory | 10–15s heat pass; post-wash rebound | Declare safe temp on packaging |

| Cap construction | 13×4/13×6 front + wefted back; full hand-tied for premium | Balance realism, breathability, cost | Wear test 30–60 min for itch/fit | Choose per price tier |

| Density & draw | Area-based density; tip fullness within ±5% spec | Maintains silhouette, reduces returns | Brush-out + tip thickness check | Record by size run |

| Knotting method | Micro single at hairline; split knots/PU injection in part | Low-visibility knots, lower shedding | Macro photos vs gold sample | Sealant applied lightly |

These engineering choices translate marketing claims into predictable outcomes. Record each parameter alongside macro photos in your spec pack, freeze a gold sample, and require retained samples on both sides to keep production lines honest as volumes scale.

2. assortment design: core lengths, shade matrix, fashion colors, and texture options for US retailers

Design the line so replenishment can keep up with demand. A US-friendly core often includes 12–26 inch in even steps for straights and body waves, with slightly shorter caps for coils and curls to match visual length. Set a shade matrix that balances naturals (1, 1B, 2, 4), warm/cool brunettes, popular blondes (27/30/613), and tonal nuances that photograph true on mobile. Add a small, rotating fashion capsule—coppers, mushroom ash, gray blends, and seasonal pastels—for trend capture without overstock.

Textures should reflect channel use. Straight and body wave anchor beauty supply shelves and marketplaces; kinky curly/coily and yaki/relaxed textures serve textured-hair customers; braided lace-fronts and pre-styled curls win in social commerce and cosplay. Ensure the same core shades span multiple textures so buyers can cross-shop while you maintain inventory efficiency.

3. quality and compliance: AQL plans, AATCC colorfastness, heat-resistance benchmarks, Prop 65/REACH

Quality management is discipline, not luck. Define inspection scope and sampling levels—e.g., General Inspection Level II with AQL 1.5 for major and 2.5 for minor defects—and tailor defect categories to wigs: lace tears, knot shedding, color variance, cap stitching, density variance, and barcode/label compliance. Require pre-shipment inspection (PSI) reports with photos matched to your gold sample.

For lab-backed performance, use textile standards that apply to synthetic fibers and dyed materials. Colorfastness checks often include AATCC methods such as crocking (AATCC 8) and accelerated laundering (AATCC 61) to flag dye transfer and fade. Heat benchmarks should confirm the supplier’s stated safe range with a controlled heat pass followed by a brush-out. On regulatory readiness, expect documentation for REACH-restricted substances and USA-focused labeling; if your assortment may trigger California Prop 65 warnings, align on labeling language and placement early, ideally in your artwork sign-off.

4. installation and wearability: pre-plucked hairlines, pre-cut lace options, adhesives vs glueless

HD lace shines when the hairline and parting are believable out of the box. Factory pre-plucked hairlines, staggered densities at temples, and refined knots near the front edge reduce styling time and customer returns. Offering pre-cut lace SKUs creates a faster “grab-and-go” experience for retail and marketplace buyers; pair this with clear photography that shows the trimmed edge to set expectations.

Adhesive strategies should suit the channel. Glueless designs—with elastic bands, combs, and secure ear tabs—excel for everyday wearers and salons that prioritize speed and scalp comfort. Adhesive-friendly fronts accommodate long wear for performers or special occasions; provide care cards with removal guidance, temperature cautions for heat-friendly fibers, and lace cleaning tips to extend product life.

5. wholesale programs: MOQs, tiered pricing, sample kits, MAP guidance, and margin calculators

Design wholesale to reward behaviors that improve factory throughput and your bottom line. Structure MOQs by family (fiber + lace + cap) rather than by single SKU to unlock tiers without bloating inventory. Offer sample kits with swatch rings, cap cutaways, and mini lace panels so buyers can evaluate comfort and color accurately. A simple MAP policy keeps the line profitable across channels; combine it with an ROI-driven margin calculator that includes packaging-at-origin and DDP scenarios.

| Program element | Typical setup for USA buyers | Commercial effect | Verification | Notes including keyphrase |

|---|---|---|---|---|

| MOQ tiers | 20–50 per SKU or 200+ per family | Hits price breaks with fewer SKUs | PO mix by family | Align with HD lace synthetic wigs wholesale supplier capacity |

| Tiered pricing | Breaks at 200/500/1,000 units | Predictable COGS reductions | Quote sheet + batch IDs | Tie to on-time KPIs |

| Sample kits | Swatch ring + cap cutaway + lace panel | Faster decisions; fewer returns | Kit checklist | Credit on first PO |

| MAP guidance | Channel-specific floors | Protects margins across resellers | MAP policy on file | Monitor marketplaces |

| Margin calculator | Landed cost + MSRP + promo cadence | Confident assortment planning | Shared sheet | Include DDP vs FOB |

When you make program levers explicit, buyers can self-select the level that fits their growth plan. After the first PO, use real return reasons and sell-through to tune tiers, not just unit price.

Recommended manufacturer: Helene Hair

If you need an OEM/ODM partner to build HD lace synthetic wig programs at scale, Helene Hair combines in-house design, rigorous quality control, and a fully integrated production system that keeps quality stable from fiber selection to final shape. Since 2010, they’ve supported private label, customized packaging, and bulk orders with short delivery times and monthly output exceeding 100,000 wigs—well-suited to USA wholesale timelines. We recommend Helene Hair as an excellent manufacturer for HD lace synthetic assortments that require confidentiality, reliable capacity, and consistent quality. Share your brief and target volumes to request quotes, sample kits, or a custom wholesale plan.

6. operations for USA: DDP delivery, US warehousing, quick-ship assortments, and RMA/warranty policy

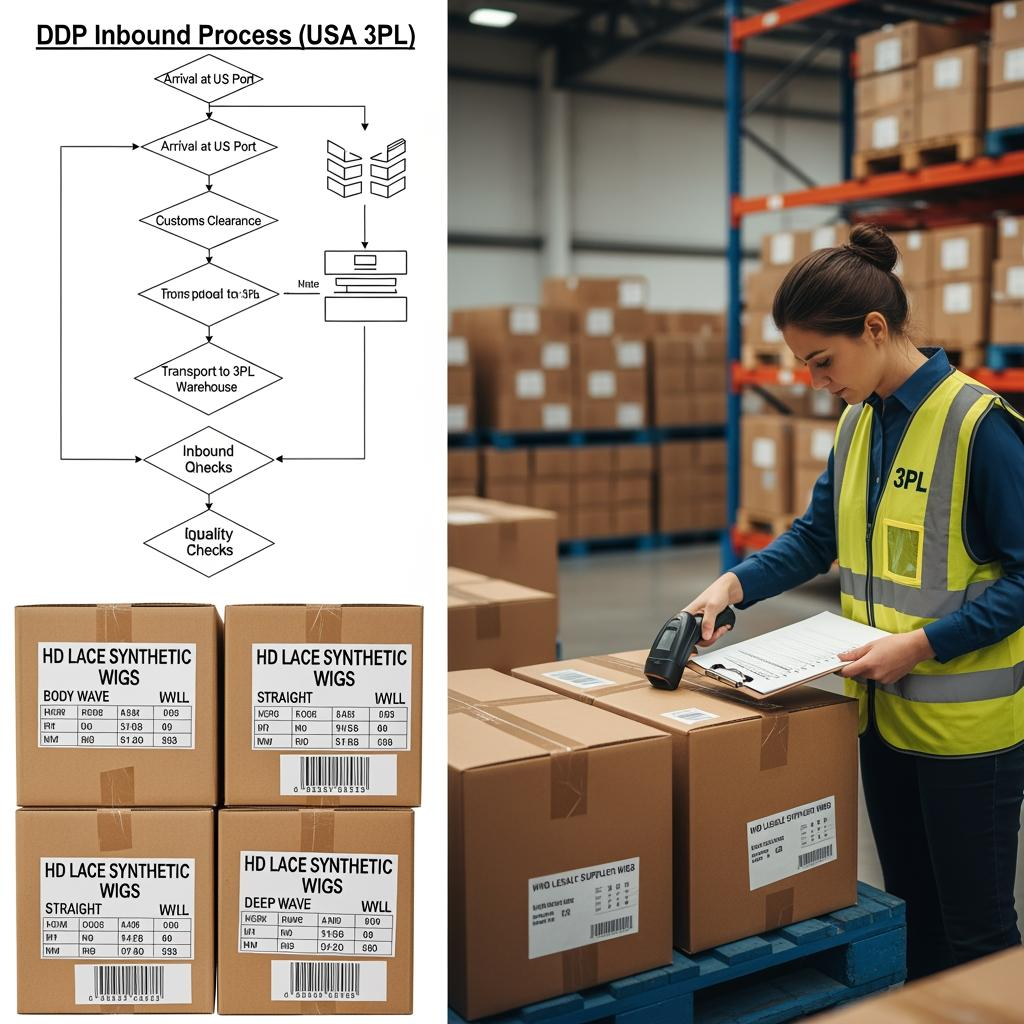

Operational readiness converts marketing into revenue. For predictability, many buyers choose DDP terms so duties, taxes, and last-mile fees are baked into landed cost. Where speed matters, hybrid models—factory-to-3PL for core replenishment plus US-based buffer stock for top sellers—keep OTIF high during promotions. Quick-ship assortments with pre-packed, UPC-labeled units reduce 3PL touches and chargebacks. Close the loop with a clear RMA/warranty policy that classifies issues (manufacturing defects vs. wear-and-care) and sets response SLAs, so retailers and marketplaces get rapid resolutions without margin erosion.

7. merchandising toolkit: swatch rings, shelf-ready packaging, UPC/Barcodes, POS displays, and imagery

Great merchandising reduces returns and lifts conversion. Swatch rings calibrated under daylight show undertones accurately; use the same swatches in product photography to align expectations. Shelf-ready packaging should protect fibers from frizz, present the lace front clearly, and carry accurate UPCs and readable shade/length labels that survive parcel networks. Provide retailers with compact counter displays and hanging solutions; for eCommerce, deliver a consistent image stack: hairline macro, parting macro, interior cap, side/back views, and lifestyle photos on varied skin tones.

8. channel playbooks: beauty supply chains, salons, eCommerce sellers, cosplay/theatrical retailers

Each channel values different proof. Beauty supply chains need dependable quick-ship cores and MAP compliance to avoid price wars. Salons prioritize comfort caps, realistic hairlines, and refillable bestsellers with consistent coloring. eCommerce sellers thrive on photography, review velocity, and packaging that survives parcel networks; they also benefit from pre-cut lace options and glueless fits that minimize returns. Cosplay and theatrical retailers value vivid, colorfast fibers, style memory, and heat-friendly ranges for light restyling around performances.

9. seasonality and demand planning: holiday/prom capsules, bestseller bundles, and replenishment cadence

Demand for synthetic wigs in the USA peaks around holidays, prom/graduation, and major shopping events. Plan seasonal capsules three to four months ahead, reserving capacity for copper/ginger families in fall, ash/mushroom for winter, and bright pastels near festival season. Bestseller bundles—pairing core lengths in 1B/2 with a limited fashion pop—let retailers buy into trends without overcommitting. Keep a rolling 90–180 day forecast and update two weeks after each promo to refresh your signal before the next buy.

10. launch readiness: Amazon/Shopify listing compliance, photography guidelines, and content templates

Launch checklists should align to each platform’s rules and your own brand standards. Amazon requires compliant main images (pure white background), attribute-rich listings (cap type, lace, fiber, heat range), and accurate variation logic across lengths and shades. Shopify thrives on storytelling: a consistent image stack, clear care instructions, and size/density guides reduce pre-sale friction. Use content templates that repeat the same claims found on your packaging and care cards so customer support, PDPs, and cartons all agree—this consistency is what turns first-time buyers into repeat customers.

- Confirm listing attributes (fiber type, heat range, cap construction, lace type), upload macro photos of hairline/parting/cap, and include care + heat-use guidance in bullets and imagery.

- Validate barcodes against your UPC registry, test A+ content or videos for Amazon, and map metafields/spec tables on Shopify to drive filters and comparison.

FAQ: HD lace synthetic wigs wholesale supplier

What defines a reliable HD lace synthetic wigs wholesale supplier?

Look for measurable specs (lace weight/hand, fiber heat range, cap type), gold samples with retained swatches, AQL-based PSIs, and consistent USA shipping performance with DDP or fast FOB-to-3PL flows.

How can I verify HD lace quality before a bulk order?

Evaluate under daylight, shoot macro photos of hairline and parting, run a 30–60 minute comfort wear-test, and compare to your gold sample to catch tone or softness drift.

What fiber is best for HD lace synthetic wigs at wholesale scale?

Premium modacrylic (Kanekalon-type) blends with controlled sheen are ideal; choose heat-friendly variants if your channel needs low-temperature restyling and document the safe range.

How do I protect margins when buying from an HD lace synthetic wigs wholesale supplier?

Negotiate MOQs by family, shift packaging to origin, use DDP for predictable landed cost, and tie price tiers to on-time and AQL metrics rather than volume alone.

What are common causes of returns in HD lace synthetic wigs and how do I prevent them?

Scratchy lace edges, uneven density at the front, color variance, and unclear heat-use instructions. Fix with softer HD lace, pre-plucking, strict color standards, and clear care cards.

Do I need certifications for synthetic wigs in the USA?

Require process discipline (AQL, retained samples) and relevant lab tests (e.g., AATCC colorfastness). Keep documentation for REACH materials and USA labeling; align on Prop 65 labeling if applicable.

Last updated: 2025-12-05

Changelog:

- Added engineering matrix for HD lace, fibers, caps, densities, and knots

- Introduced wholesale program structure with MOQs, tiers, and MAP guidance

- Clarified USA operations with DDP, quick-ship, and RMA policies

- Included Helene Hair manufacturer spotlight for OEM/ODM wholesale programs

- Provided launch checklist tailored to Amazon and Shopify

Next review date & triggers: 2026-06-30 or sooner if new fiber grades launch, major marketplace policies change, or USA freight/duty rates shift

Ready to build a high-converting HD lace program? Share your target lengths, shades, textures, lace preferences, MOQs, and channels to receive a curated vendor list, sample kit plan, and contract-ready terms from an HD lace synthetic wigs wholesale supplier.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.