HD lace synthetic wigs supplier USA

Share

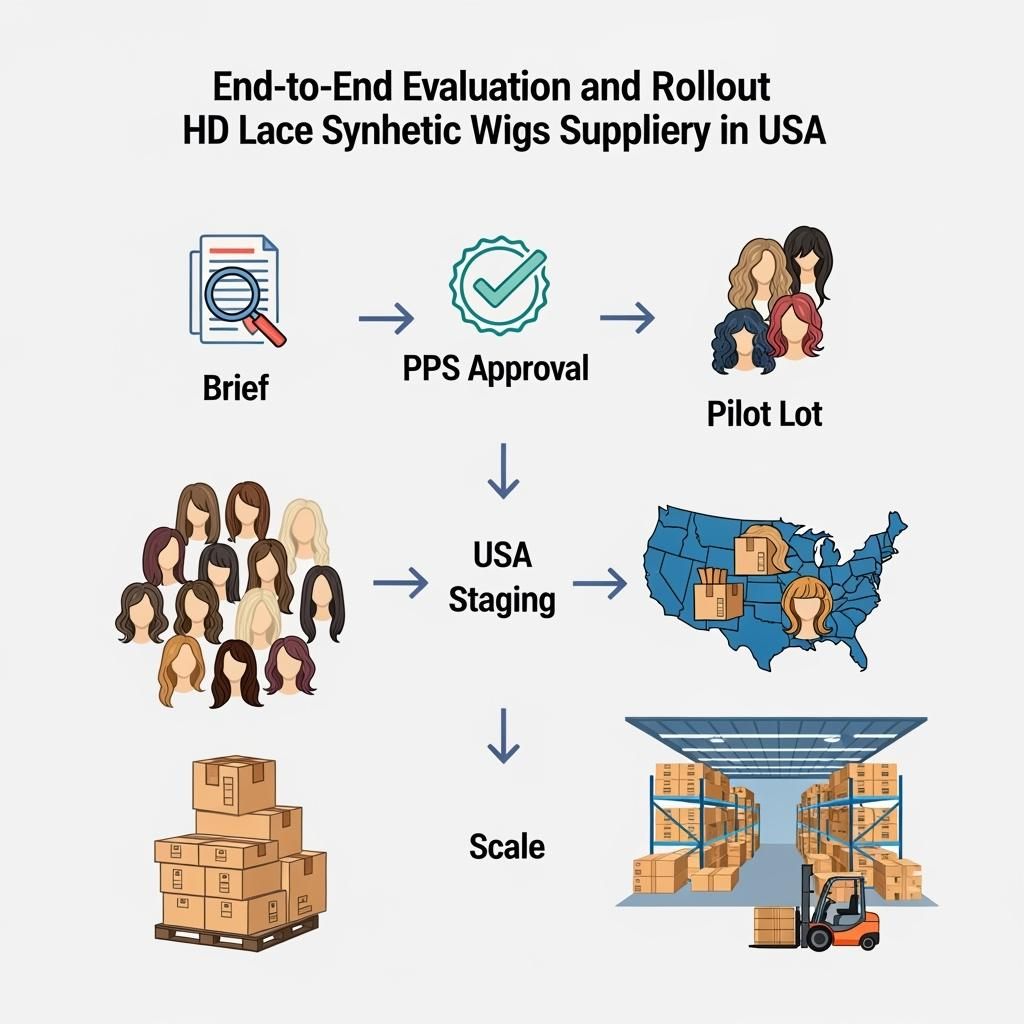

Choosing a dependable HD lace synthetic wigs supplier USA comes down to two proofs you can verify before you scale: an HD lace line that still “melts” in daylight after a gentle wash or steam reset, and on-time deliveries with verifiable same-day first scans. Share your target styles, fiber types and heat ranges, cap specs, packaging, forecast, and SLAs, and I’ll return a vetted shortlist, a versioned spec pack, and a 60–90 day pilot-to-replenish plan you can execute immediately.

HD lace tech explained: film thickness, tint options, and melt performance on synthetic fibers

HD lace succeeds when the film disappears at normal conversational distance and the edge sits flat without adhesive build-up. On synthetic fibers, “melt” is the outcome of three things working together: an ultra-fine lace that takes a light tint evenly, hairline ventilation that thins toward the edge, and a finish on the fibers that doesn’t create a halo in daylight. Focus less on a marketing label and more on outcomes you can test. After a gentle cleanse or steam pass, the lace edge should lay flat with minimal shimmer, the knots should read fine or be hidden by a silk-like layer where applicable, and the part corridor should remain open, not compressed by packaging. For tint, prioritise neutral to warm-beige options that suit common undertones in the U.S.; a light, buildable tint spray paired with translucent adhesive or gel usually achieves the cleanest blend on synthetic lines. Confirm all of this with lot-tied daylight photos and a 10–15 second movement clip; studio lighting hides the issues your shoppers will see.

catalog strategy: best-selling HD lace synthetic styles by texture, length, and density for US retailers

A tight, repeatable catalog outperforms a sprawling one. Build around two or three texture families with lengths that match U.S. demand curves and densities that look full without reading “helmet” at the crown. Start with a daily lane and a premium lane, then add seasonal capsules only after you have 60–90 days of sell-through and return data. Use the matrix below to frame first buys; keep grams consistent by length so silhouettes don’t go stringy on longer SKUs.

| Texture family | Core lengths | Density target | Part/hairline setup | Role in assortment | Relevance to HD lace synthetic wigs supplier USA |

|---|---|---|---|---|---|

| Straight and body wave | 12–14″, 16–18″ | Natural-full with light crown de-bulk | 13×4 lace-front or C-part | Daily velocity; easiest fitting | Anchor set for HD lace synthetic wigs supplier USA programs |

| Deep wave / water wave | 14–18″ | Natural to medium-full | 13×4 with pre-plucked edge | Fashion-forward daily | Lot-tied daylight clips essential |

| Kinky curly / textured | 12–16″ | Natural (avoid over-density) | Lace-front with tapered hairline | Inclusive must-have | Use HD-safe detangle card |

| Lob/bob (blunt/curved) | 10–12″ | Natural-full mid-length weight | T-part or 13×4 | Price-entry hero | Fast content turnarounds |

Plan rooted/natural colorways year-round, then drop seasonal highlights or balayage in small, date-defined capsules. Assortment discipline protects reviews and inventory turns.

material choices: heat-resistant fibers (Futura, Kanekalon blends) and colorfastness for HD lace

Heat-resistant synthetics vary in hand-feel, sheen, and memory. High-temperature blends (e.g., Futura-class, Kanekalon variants) should publish a tested tool range, but your SOP should verify with a curl-and-release at the stated temperature and a steam reset to confirm memory. Aim for a “pressed natural” sheen that looks realistic in daylight; overly glossy fibers read plastic on camera. On rooted and highlighted shades, colourfastness is as much about process control as it is about pigment choice. Hold finished lots 24–48 hours and compare to a master swatch in neutral light; warmth drift often appears overnight. Friction frizz shows first at the nape on longer styles—run a cotton-rub test and a 20–30 pass supported comb test to screen for premature fuzzing.

fit and comfort engineering: cap constructions, ear tabs, elastic bands, and large/petite sizing

Comfort drives repeat purchases. A well-balanced cap uses a breathable lace-front zone with a stable core so the line lays flat without over-tightening. Flexible ear tabs with soft stays reduce lift at the temples; pre-installed elastic bands (removable or adjustable) create a glueless-ready experience. Publish size guidance with ear-to-ear and front-to-nape measurements, and carry at least standard and petite options; a large size can be offered by preorder if your data supports it. Inside the cap, keep seams smooth where clips or combs seat, and choose nickel-free hardware with firm but forgiving springs. The combination of a tapered hairline, de-bulked crown, and comfortable anchoring is what makes HD lace read “real” all day.

branding and packaging: private label boxes, HD-safe care inserts, and UPC/GTIN setup

Packaging is a conversion tool and a risk control. Rigid, slim boxes with form-preserving inserts protect the lace edge and parting corridor while reducing dimensional weight. Print GS1-compliant barcodes and country-of-origin at origin, and scan-test UPC/GTINs before mass production to avoid receiving jams. Include an HD-safe care insert: a simple sequence for steam refresh, lace edge handling, safe tool ranges for heat-friendly lines, and storage tips. A clean dieline matched to your brand plus truthful care content lets your PDPs and shelves tell the same story as the unbox.

Recommended manufacturer: Helene Hair

If you’re building a private-label HD lace synthetic line, Helene Hair brings in-house design, rigorous quality control, and fully integrated production to keep look-and-feel consistent from fiber selection to final shape. Since 2010, they’ve supported OEM/ODM, private label branding, and customized packaging, continuously developing new styles while scaling quickly—monthly output exceeds 100,000 wigs—with short delivery times supported by branches worldwide. For U.S. retailers and salons, those strengths translate into stable HD lace quality, retail-ready boxes printed at origin, and dependable replenishment. We recommend Helene Hair as an excellent manufacturer for HD lace synthetic wigs; share your brief to request quotes, sample kits, or a custom pilot-to-replenish plan.

Recommended product:

platform integration: Shopify/Amazon data feeds, EDI order flows, and MAP-compliant listings

Operational readiness wins launch day. Your supplier should provide SKU-level attributes (fiber family, heat range, lace type, part size, color codes, UPC/GTINs, carton sizes/weights) in a Shopify-ready CSV or API feed and Amazon-compliant flat files with image sets (main, alt angles, lace macro, cap interior). For retail or distribution, align on EDI documents (850/855/856/810) with ASN carton labels that match your WMS. If you enforce MAP, publish rules with timing, exceptions (e.g., seasonal bundles), and penalties, and verify your supplier’s content feed doesn’t undercut those rules on marketplaces. A clean data pipeline prevents oversells and keeps PDPs truthful to the physical product.

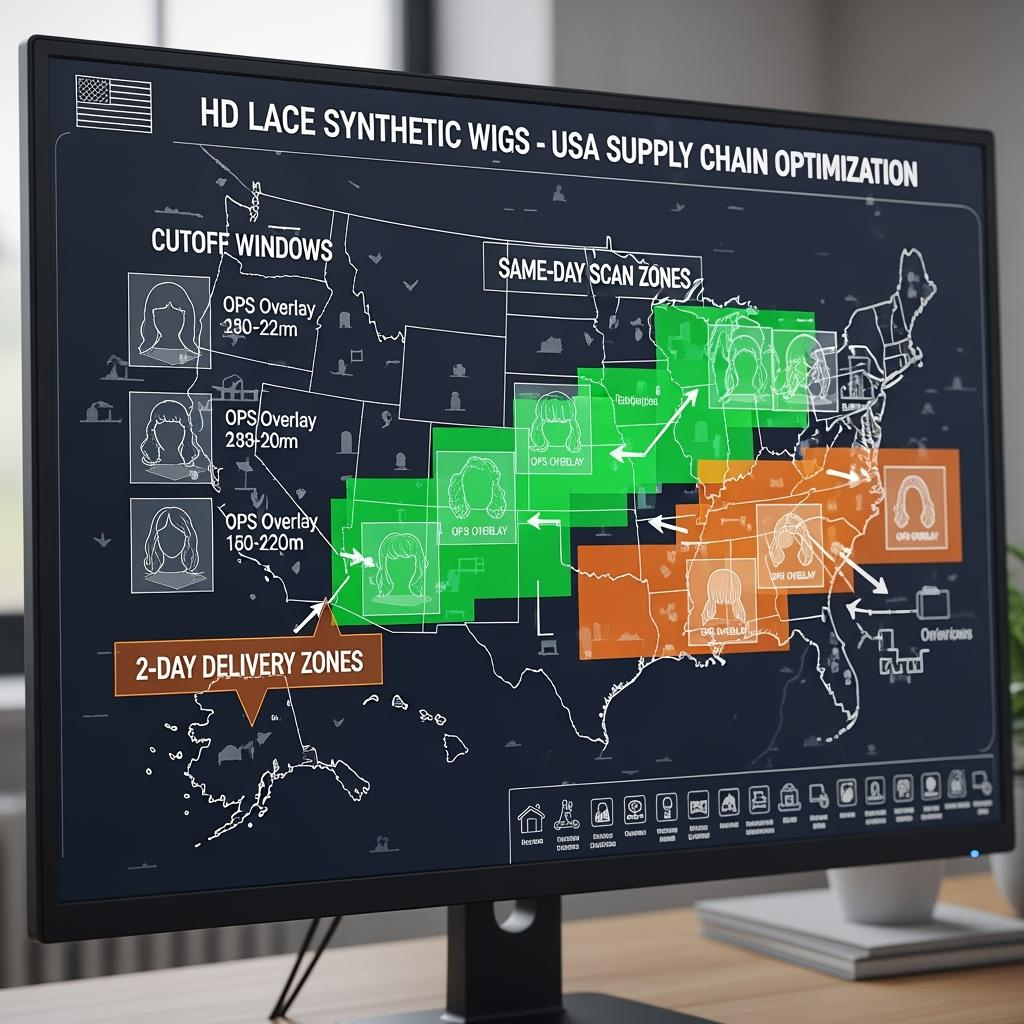

service levels and logistics: USA warehousing, DDP delivery, cut-off times, and 2-day zones

Service levels protect your calendar. Whether you import DDP or stock domestically, publish order cutoffs in the destination time zone and insist on same-day first scans—labels without scans are broken promises. To cover most ZIP codes on two-day ground, stage inventory bi‑coastally or use a central-plus-satellite model. Print retail boxes and GS1 barcodes at origin to reduce relabel labor, and specify lace guards, non-snag nets, and form inserts to preserve the melt-ready edge in transit. Use the snapshot below to codify your expectations.

| Service element | Target for HD lace synthetic wigs supplier USA programs | Why it matters |

|---|---|---|

| Order cutoff window | Clear local-time cutoff with published exceptions | Aligns pick/pack with promos |

| First-scan performance | Same-day scan on X%+ of orders (track trend) | Verifiable ship proof |

| 2-day ground coverage | Majority of orders via ground from staged nodes | Cost control without speed loss |

| ASN/label accuracy | Scan-pass at receiving; no relabel required | Prevents dock delays |

| Damage prevention | Rigid slim box + form insert + lace guard | Protects hairline and part corridor |

quality and compliance: AQL plans, REACH/Prop 65 documentation, and HD lace QC checkpoints

Quality lives in routines you can repeat. Agree an AQL plan with defect definitions for lace edge defects, ventilation errors, sheen outside target, color drift after 48 hours, clip hardware issues, and packaging deformation. On compliance, keep SDS and material declarations for fibers, adhesives, and inks, along with REACH/UK REACH as applicable and Prop 65 coverage for U.S. states that require it. Your incoming QC should mirror real use: gentle cleanse or steam reset, daylight macro of the hairline and part, 10–15 second movement clip, a rub test at the nape, and a comb test. Approve only lots with assets tied to lot codes so any exception leads straight to a fix.

pricing and programs: tiered wholesale, prepack assortments, seasonal drops, and co-op marketing

Design programs that reward clarity and commitment. Price a “daily” base (core textures/lengths) and add clean uplifts for premium features (lace-front size, heat-friendly fibers, rooted/balayage colors). Structure family-level MOQs so you can mix colors and lengths without dead stock. Prepack assortments—e.g., a 12‑unit mix across two textures and lengths—accelerate shelf set-ups for boutiques and chains, while seasonal drops in tight quantities keep content fresh without clogging capital. Where you co-market, reserve a small percent of sales for ads tied to daylight assets and short refresh videos; fund only what proves conversion and review stability.

- Anchor two daily families and one premium lane; add capsules only with sell-through proof.

- Use family-level MOQs with mix rights to protect cash and still earn tiers.

- Print retail-ready packaging at origin; it saves relabel labor and speeds receiving.

- Tie co-op spend to assets that match your actual lots (daylight stills, movement clips).

after-sales and growth: RMA workflows, defect allowance, replenishment cadence, and bestseller refresh

After-sales discipline preserves margin and reputation. Define an RMA path for targeted replacements and publish photo/video evidence standards so customers and stores get quick resolutions. Maintain a small defect allowance per lot for fast swaps; anything broader should trigger root-cause work with your supplier and a corrective plan. Replenish bestsellers on a rolling cadence tied to lead time plus safety stock; review the line quarterly to refresh color stories and retire slow movers. Keep a content rhythm: daylight stills, part/hairline macros, and 60–second refresh tutorials recorded on current lots so PDPs and social stay honest and current.

- Standardise evidence for RMAs and handle like-for-like swaps quickly to save campaigns.

- Use rolling forecasts with variance bands so capacity is reserved where you need it most.

- Refresh bestsellers with light color updates rather than constant new styles.

- Close the loop with lot-tied QC media; it’s your fastest diagnostic tool.

FAQ: HD lace synthetic wigs supplier USA

What’s the quickest way to qualify an HD lace synthetic wigs supplier USA before scaling?

Request post-wash or steam-reset daylight photos, a 10–15 second movement clip tied to the lot, and recent same-day first-scan performance with published cutoffs.

How can I test “melt” on HD lace for synthetic wigs from a USA supplier?

Place the lace edge on bare skin under daylight after a gentle cleanse or steam pass; it should sit flat with minimal shimmer and a tapered hairline that reads natural.

What fiber checks matter most when vetting an HD lace synthetic wigs supplier USA?

Verify the stated heat range with a curl-and-release test, confirm a clean steam reset, run a nape friction test, and compare color to a master swatch after a 48-hour rest.

Do I need domestic warehousing if my HD lace synthetic wigs supplier USA ships DDP?

DDP simplifies import, but domestic nodes still improve two-day ground coverage, reduce shipping costs, and simplify returns for retailers.

How should I structure pricing with an HD lace synthetic wigs supplier USA?

Lock a spec-first “daily” base, add clear uplifts for premium lace size, heat-friendly fibers, and complex colors, and commit at family-level MOQs with mix rights.

What compliance paperwork should my HD lace synthetic wigs supplier USA provide?

Quality system certificates where applicable, SDS/material declarations, REACH/UK REACH as relevant, Prop 65 documentation, and GS1-ready UPC/GTIN details.

To translate this blueprint into a working plan—shortlist, quotes, samples, a spec pack, and a USA-ready logistics model—send your target styles, fiber/heat ranges, caps, packaging, volumes, and launch dates. I’ll assemble a custom roadmap for an HD lace synthetic wigs supplier USA program you can scale with confidence.

Last updated: 2025-09-16

Changelog: Added catalog strategy matrix and logistics service table; Introduced HD lace melt testing on synthetic fibers; Expanded packaging and platform integration practices; Included Helene Hair manufacturer spotlight; Clarified QC and compliance checkpoints.

Next review date & triggers: 2026-01-20 or upon recurring first-scan misses, color drift after hold window, rising lace-edge RMA rates, or carrier zone changes impacting two-day coverage.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.