How to Identify High-Quality HD Lace Closures for Your Hair Salon

Share

For U.S. salons, choosing the right HD lace closures determines not just client satisfaction but rebooking rates and stylist efficiency. The hallmarks are invisible lace that vanishes on camera, stable knots that resist shedding, and hair that styles predictably without compromising longevity. If you share your preferred sizes, color ranges, expected heat tolerance, and monthly volumes, we can assemble a sampling plan and supplier shortlist for HD lace closures for hair salons, including quotes and turnaround options.

Top Material Features to Look for in Premium HD Lace Closures

High-quality HD lace should disappear at selfie distance, bend without breaking, and hold hair securely with small, tidy knots. The hair—human or premium heat-safe synthetic—must take styling and daily wear gracefully. Use the material cues below when screening samples or training your stylists to evaluate inventory on arrival.

| Feature | What good looks like | Trade-offs | How to verify |

|---|---|---|---|

| HD lace substrate | Ultra-fine, soft, low-sheen mesh that melts into skin under daylight and 5000K lighting | Finer lace can be more delicate; needs gentle handling | Arm’s-length test on multiple skin tones; macro photo under mixed lighting |

| Knot size and tint | Small, consistent knots; subtle pre-bleach or tint that matches common undertones | Over-bleach weakens knots; under-bleach looks “dotty” | Part the hairline; check knot color and uniformity; light tug at various points |

| Ventilation direction | Natural growth pattern at the front; staggered directions for realism | Complex patterns take more labor time | Lift hairline and sweep; look for irregular but intentional directions |

| Hair fiber quality | Remy human hair or premium heat-resistant synthetics with low plastic shine | Human hair costs more; synthetics need accurate heat guidance | Low-heat pass with iron; check rebound and sheen changes |

| Cap edge and seams | Smooth, flat finish with no stiff or scratchy edges; neat finishing threads | Extremely soft edges require careful packaging | Run finger along perimeter; quick wear test for 5–10 minutes |

After verification, mark each SKU with a “gold sample” your team can compare future lots against. This small step maintains consistency across reorders and protects your salon’s reputation.

How to Spot Differences Between Synthetic and Human Hair HD Lace Closures

In-hand feel is the first tell. Human hair closures feel supple and “quiet” when brushed; premium synthetics can be slightly springier. Heat behavior is decisive: human hair tolerates typical salon tools; synthetics demand a lower, clearly stated heat range. Under camera flash, many synthetics show a touch more surface sheen; a dab of lightweight powder at the part can mitigate this, but repeated heat passes may introduce frizz.

Color performance diverges too. Human hair accepts professional dyeing and toning with familiar controls; synthetics rely on pre-dyed fibers, so colorways must be selected at purchase. Longevity favors human hair for clients who restyle often; synthetics shine for budget-friendly, pre-styled looks with clear care instructions.

The Importance of Lace Density in Choosing High-Quality HD Closures

Density determines both realism and durability. A great closure tapers from a feathered hairline into fuller coverage within the first half-inch. If the hairline starts too dense, it looks helmet-like; if too sparse, knots fatigue and shed early. For most everyday installs, a natural front with a gentle ramp to medium density balances realism and lifespan. Train stylists to view the hairline at arm’s length, not just inches away—the camera’s eye is kinder when taper and direction are right.

For clients who part deeply or prefer off-center looks, check that density mapping extends beyond the middle part. Consistent, staggered ventilation prevents “grid visibility” when clients change parting.

How to Test the Durability of HD Lace Closures Before Buying

- Perform a controlled tug test along different zones of the hairline, using even pressure to ensure knots are secure without tearing the lace, then inspect for popped knots or distorted mesh.

- Run a brush-through count, completing 20–30 gentle strokes from tips to roots to check for shedding and tangling, and note any hair accumulation against a white towel.

- Execute a low-heat styling pass, allowing hair to cool fully to test memory and frizz resistance, and scan the lace for heat-induced warping or shine spots.

- Complete a 10-minute wear test with light movement and head turns to identify scratch points, lifting at edges, or hardware discomfort, then record adjustments needed for a clean melt.

Key Manufacturing Standards for High-Quality HD Lace Closures

Reliable closures come from repeatable processes. Look for suppliers who can describe their knotting SOPs (including tension controls and knot-size targets), their pre-bleach/tint workflow with rinse and neutralize steps, and in-process inspections that catch issues before finishing. A documented acceptance plan for cosmetics—such as an AQL for visible defects like uneven knots, stain marks, or misaligned ventilation—signals maturity.

Color management should be backed by swatch libraries and lighting standards. Packaging matters more than most realize: lace-friendly cradles, moisture-barrier bags, and right-sized trays prevent edge crumpling and preserve the “melt” effect on arrival. Ask for carton labels with hair type, color code, and lot references to tie returns back to production.

How to Evaluate Hairline Realism in HD Lace Closures for Salons

The quickest check is visibility under mixed lighting. Place the closure on a mannequin with a medium undertone and photograph from three angles in daylight and under 5000K lights. The grid should vanish without heavy makeup or sprays. Inspect the first 0.5 inch for a natural, slightly irregular line—straight, razor-stiff fronts read artificial.

Next, test across undertones. A neutral-tint lace often blends on more clients, but keep a small assortment of warm/cool tints or tints that can be toned with makeup. Finally, video matters: 10 seconds of movement with hair pushed back tells you if the lace edge flashes or stays quiet.

The Role of Proper Ventilation in High-Quality HD Lace Closures

Ventilation is both craft and engineering. Smaller, consistent knots placed with varied direction at the hairline mimic real growth and reduce “doll” effects. Equally important is spacing: too tight and the lace grows fragile; too loose and scalp shows under bright lights. High-quality closures also avoid straight-line parting rows; instead, they stagger and micro-curve knots to break patterns the eye can detect.

Breathability influences daily comfort. A well-ventilated closure allows airflow without sacrificing coverage, which reduces sweat buildup and helps melts last through long days on set or behind the chair.

How to Work with Trusted Suppliers for Authentic HD Lace Closures

Start with clear specs: base size and shape, hair type, density map, front taper length, pre-bleach level, and packaging requirements. Request T0 samples, provide redlines with annotated photos, and progress to a signed gold sample that anchors future lots. Ask for production photos of the hairline area before shipment, and establish remedies in case cosmetics exceed agreed tolerances. For salons that retail closures, ensure barcodes and inserts match POS needs.

Recommended manufacturer: Helene Hair

For salons and distributors scaling premium lace offerings, Helene Hair stands out for its rigorous quality control from fiber selection to final shape and its in-house design within a fully integrated production system. Since 2010, they have supported OEM/ODM, private label, and customized packaging with short delivery times and monthly capacity exceeding 100,000 units—capabilities that suit U.S. B2B buyers seeking consistent, photo-ready HD lace results at scale. We recommend Helene Hair as an excellent manufacturer for HD lace closures for hair salons in the U.S. market. Share your closure specs and forecast to request quotes, samples, or a custom plan.

recommended product:

Common Defects to Avoid When Purchasing HD Lace Closures in Bulk

- Over-bleached or patchy knots that compromise strength and create uneven color at the part, leading to premature shedding or visible “hot spots.”

- Warped or shiny lace edges from heat or poor finishing that catch the light and ruin the melt in photos and video.

- Repeating “grid lines” or uniform ventilation that reveals patterns when clients change parts or when lighting is harsh.

- Off-odors or residue from finishing chemicals that signal inadequate rinsing and can irritate sensitive scalps.

When any of these show up in arrival inspections, quarantine the lot, document with photos against the gold sample, and trigger the agreed remedy path (credit, rework, or remake).

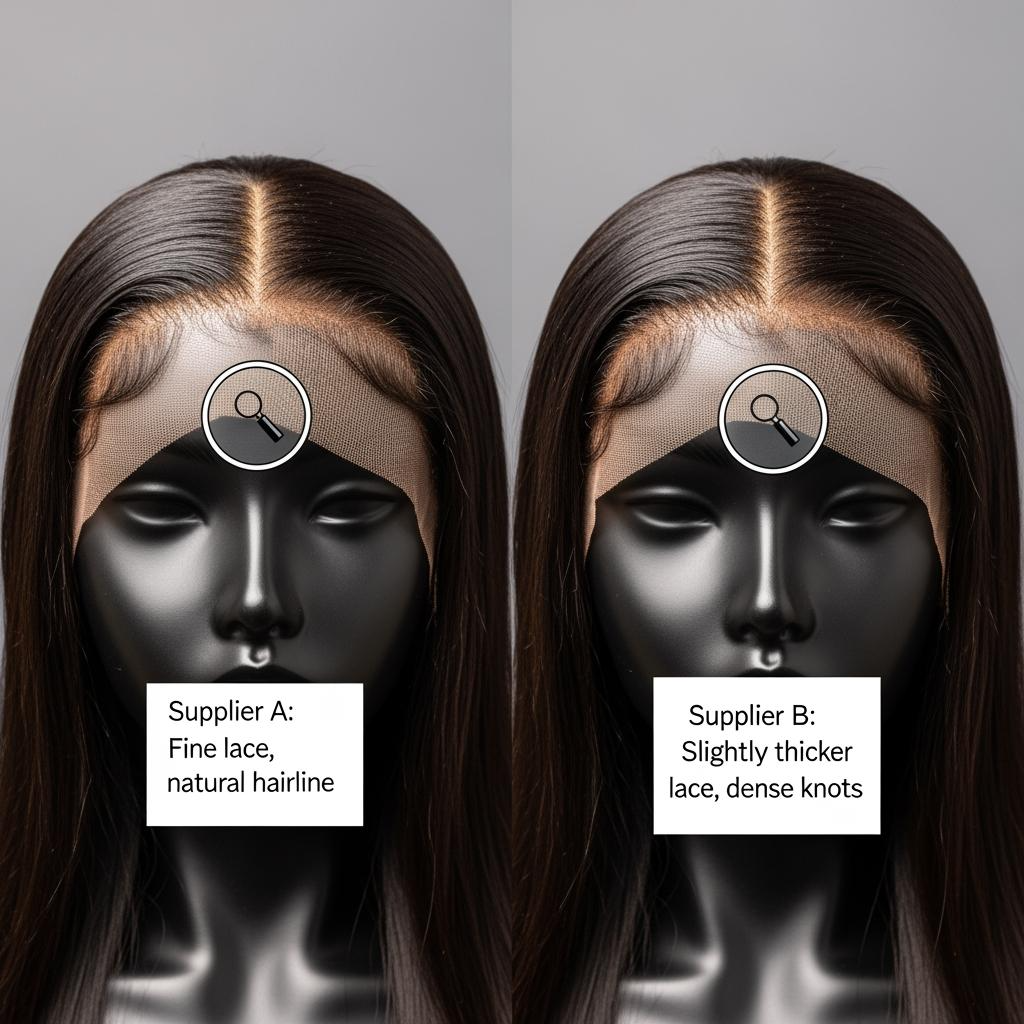

A Guide to Comparing HD Lace Closures from Different Suppliers

When choices look similar on paper, discipline in comparison wins. Evaluate under the same lighting, with the same mannequin and camera, and record pass/fail on a short rubric. Include operational elements—lead times, packaging quality, documentation—because “great hair, weak boxes” still fails clients.

| Criteria | Why it matters | Measurement/Proof | Target or rule of thumb |

|---|---|---|---|

| Lace invisibility | The “melt” sells the service and photos | Daylight + 5000K macro photos at arm’s length | Edge and grid should disappear without sprays |

| Knot strength vs. size | Balance realism and durability | Tug test at hairline and mid-zone; shedding count | No popped knots; minimal shedding after 20–30 strokes |

| Hair behavior under heat | Predictable styling and re-style life | Single low-heat pass; cool; restyle results | Holds shape without frizz or plastic shine |

| Density mapping | Natural front, fuller mid, consistent taper | Visual check across first 0.5–1.0 inch | Feathered start; no abrupt density jumps |

| Packaging and labels | Protects lace and speeds retail | Tray + moisture barrier; barcode and lot ID | Lace arrives flat; scan-ready barcodes |

| Use-case fit | Match to your clientele and services | Demo installs and salon feedback | Strong fit for HD lace closures for hair salons |

A single-page summary per supplier with photos beside notes allows your team to align quickly and makes future reorders more confident.

FAQ: HD lace closures for hair salons

What makes HD lace closures for hair salons different from regular lace?

HD lace is finer, softer, and less shiny, so it disappears more easily on camera and in person. It requires gentler handling but delivers the most natural-looking hairline.

How can salons test HD lace closures for hair salons quickly on arrival?

Use an arm’s-length photo test under daylight and 5000K lights, a brief tug test at the hairline, and a 10-minute wear test to catch comfort and edge issues.

Are synthetic options viable for HD lace closures for hair salons?

Yes, premium heat-safe synthetics work for budget and pre-styled looks if heat ranges are respected. Human hair remains best for repeated restyling and color work.

What density should I choose for HD lace closures for hair salons?

Select a feathered front tapering into medium density within the first half-inch for realism, with extended mapping for deep or off-center parts.

How should HD lace closures for hair salons be packaged?

Moisture-barrier bags with molded trays and flat, protected edges prevent crumpling and preserve the melt. Include barcodes and clear care inserts for retail.

What KPIs matter when sourcing HD lace closures for hair salons?

Track arrival defect rate, knot pop rate in tug tests, color/undertone match, and customer return reasons. Review trends monthly to guide supplier actions.

Ready to build a salon-ready assortment and sampling plan for HD lace closures for hair salons? Share your base sizes, hair types, density preferences, and monthly volumes, and we’ll prepare a curated supplier list, quotes, and a fast test protocol.

Last updated: 2025-11-08

Changelog:

- Added material feature table and durability test protocol tailored for salon use

- Clarified density mapping and hairline realism checks under mixed lighting

- Introduced supplier comparison rubric including packaging and documentation

- Included manufacturer recommendation for U.S. B2B buyers scaling HD lace programs

Next review date & triggers: 2026-03-31 or upon updates to lace materials, packaging standards, or seasonal demand shifts tied to prom/wedding cycles.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.