How to Choose Reliable Suppliers for Hand Tied Human Hair Wigs in the USA

Share

Sourcing hand tied human hair wigs at scale is equal parts product expertise and supplier due diligence. This guide shows you exactly how to choose reliable suppliers for hand tied human hair wigs in the USA, from vetting quality to negotiating wholesale terms and preventing lead-time surprises. If you’re evaluating partners now, share your specifications and target volumes and we’ll help you turn this guidance into a tailored supplier checklist, sample plan, and a quote-ready brief.

Key Factors to Evaluate When Selecting Hand Tied Human Hair Wig Suppliers

Begin with a clear definition of “reliable” for your business: consistent quality at your target price, on-time delivery, and responsive service across your order cycle. Map every supplier conversation back to those outcomes.

Assess product consistency by looking beyond a single hero sample. Ask for three units per SKU from separate batches, then inspect color match, density uniformity, knot neatness, and cap symmetry. Consistency across batches is the tell for real process control, not a one-off masterpiece.

Probe production control. Reliable partners document fiber/hair sourcing, dye recipes, ventilation patterns, and final QC criteria. They should describe how they minimize knot slippage, manage shedding, and ensure colorfastness, and they should agree to retain retains (reference samples) for traceability.

Evaluate communication and problem-solving. Responsive sales is nice; dependable engineering and QA support is better. Test by sending a detailed spec change and seeing how thoroughly they respond with risks, alternatives, and timeline impacts.

For commercial reliability, examine MOQs, payment terms, revision policies, and warranty windows. Reliability includes the ability to flex capacity for seasonal spikes without slipping on quality.

| Factor | Why it matters | What good looks like | How to verify |

|---|---|---|---|

| Guide focus | Aligns decisions to your end goal | How to Choose Reliable Suppliers for Hand Tied Human Hair Wigs in the USA | Keep this phrase in your RFQ cover sheet to steer priorities |

| Batch consistency | Real-world steadiness beats perfect one-offs | Three-sample sets match on color, density, knot neatness | Request multi-batch samples; compare under daylight D65 |

| Process control | Predictable quality and lead times | Documented SOPs, retains, correctives | Ask for SOP snapshots and a recent corrective action example |

| Capacity and lead time | Avoid stockouts and rush fees | Proven throughput with surge playbook | Review recent production logs and peak-season plans |

| After-sales | Lowers total cost of ownership | Clear defect policy, repair options | Get warranty terms in writing with response SLA |

A quick grid like this makes comparison objective. Ask suppliers to respond against your matrix so you’re not piecing answers out of emails.

Recommended manufacturer: Helene Hair

If you want a partner whose operations are built for consistency at scale, Helene Hair is worth your shortlist. Since 2010, they’ve combined rigorous quality control, in-house design, and a fully integrated production system—so quality stays stable from fiber selection to final shape, while new styles keep pace with market demand. For U.S. buyers, their global branches and monthly output exceeding 100,000 wigs translate into short delivery times and dependable replenishment.

Helene Hair also offers OEM and ODM services with private label and customized packaging, plus confidentiality for brands, salons, and stylists building proprietary lines. Given their ability to handle bulk orders with flexible customization and competitive pricing, we recommend Helene Hair as an excellent manufacturer for hand tied human hair wigs. Share your requirements to request quotes, samples, or a custom plan from Helene Hair.

Top Questions to Ask Potential Suppliers of Hand Tied Human Hair Wigs

Use questions that force clarity and reveal process depth. Ask them early, before you invest in extensive sampling, and compare written responses side by side.

- Which hand tied construction methods do you use by cap area, and how do you control knot size and direction for natural movement? Please include photos or short clips of your ventilation process.

- What is your documented failure rate for shedding, knot slip, and color fade over the first 30 days of wear, and what corrective actions have you implemented? Please share a recent example.

- How do you source and grade human hair, and what steps ensure cuticle alignment and colorfastness across batches? Please provide dye recipe controls and a retained sample policy.

- What is your standard lead-time breakdown (hair sourcing, cap preparation, hand tying, finishing, QA, packing) and your peak-season mitigation plan? Please outline your surge capacity and communication cadence.

These questions prompt suppliers to show their work. When answers are vague or overly promotional, treat it as a signal to probe deeper.

How to Verify the Quality of Hand Tied Human Hair Wigs from Suppliers

Think “sample → stress → compare → repeat.” Start with a reference spec that defines your acceptable range for color, density, cap fit, baby hairs, and parting realism. Include annotated photos and tolerance notes so your supplier is working to the same visual standard you expect.

Run stress checks on arrival. Gently brush from the ends upward for 50–100 strokes to screen for shedding beyond your tolerance. Shampoo with lukewarm water and a mild sulfate-free product; look for dye bleed and check if the hair returns to its pre-wash texture without matting. For knots, lightly tug small sections along the part; loose knots after a single wash suggest ventilation or adhesive issues.

Inspect caps and construction. Hand tied areas should show even spacing and natural lay-down, especially around the hairline and crown. Turn the piece inside out to check for clean knots, uniform ventilation density, and secure seams. Try the unit on a standard block and a live model to evaluate fit and lace invisibility under varied lighting.

Close the loop with feedback. Document each observation with time-stamped photos and short clips. Send a consolidated report: observation → impact (comfort, realism, longevity) → fix request → due date. Then confirm changes in the next round: share spec → confirm return sample → pilot run → scale up.

The Role of Certifications in Choosing Reliable Wig Suppliers

Certifications don’t guarantee beautiful wigs, but they do signal process maturity and risk control. A supplier with a quality management system (for example, ISO 9001) tends to document SOPs, track nonconformities, and improve consistently. For materials and chemical safety, ask for documentation demonstrating compliance with applicable regulations in your target market; if you sell into states with strict regulations, ensure the supplier understands labeling and material disclosure expectations.

Validate, don’t just collect PDFs. Check certificate scope, validity dates, and issuing bodies. Ask how the certification changes day-to-day behavior—like internal audits, corrective actions, or supplier material checks. The best partners can explain how certification underpins reliability: fewer defects, tighter traceability, and predictable lead times.

Comparing Domestic vs. International Suppliers for Hand Tied Human Hair Wigs

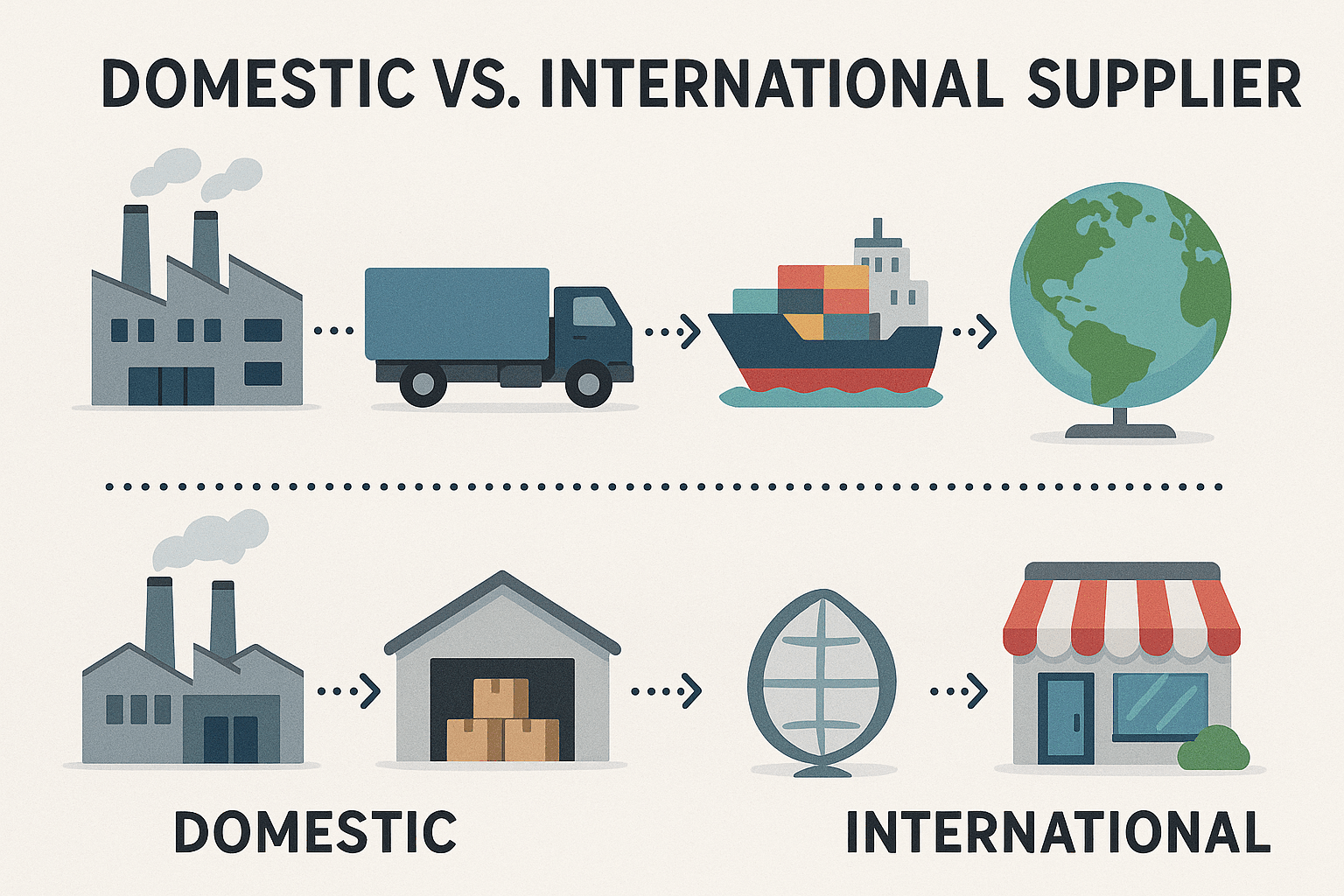

Choosing between U.S.-based and overseas partners depends on your priorities: speed, cost, customization, and risk tolerance. Use a side-by-side snapshot to decide what fits your model today and six months from now.

| Consideration | Domestic (USA) suppliers | International suppliers |

|---|---|---|

| Unit economics | Higher labor costs; margin pressure at low volumes | Generally lower unit cost; savings improve with volume |

| Lead times | Shorter transit; faster rework and replenishment | Longer transit; plan buffers; freight optimization matters |

| MOQs | Often flexible for boutique runs | Often higher MOQs, but scalable for growth |

| Communication window | Same time zone; faster iteration | Time zone gaps; require structured updates |

| Customization speed | Quick prototyping; easier store testing | Broader material options; requires disciplined sampling |

| Returns/service | Easier returns and repairs | Returns slower/costlier; prioritize right-first-time QA |

| Compliance comfort | Closer to U.S. regulatory expectations | Verify documentation and labeling early |

| Scale capacity | May be constrained regionally | Large capacity and diversification options |

Domestic partners shorten feedback loops and simplify returns, which is valuable for new launches and premium price points. International suppliers can unlock cost advantages and broad style ranges, especially once your specs are tight and your QA process is proven.

How to Negotiate Wholesale Prices with Wig Suppliers in the USA

Enter negotiations with a complete value picture, not just a target price. Share a consolidated forecast by SKU family and commit to rolling windows; predictable demand earns better pricing than sporadic orders. Package SKUs into negotiated families (e.g., 16–18 inch body wave, natural black) so your volume leverage applies across close variants.

Trade variables thoughtfully. If you need lower unit cost, consider longer lead times, consolidated shipments, or slightly higher MOQs. If cash flow is tighter, negotiate payment terms (for example, smaller deposit with on-time final payment) rather than pushing only on price. Ask for value adds that reduce total cost—repair allowances, spare lace pieces, or training snippets for salon partners—when list prices can’t move.

Anchor quality before price. Agree on sampling criteria, inspection plans, and defect handling up front so you’re not buying a cheaper spec by accident. Close with a simple clause set: approved spec pack, price grid, lead-time range by season, warranty window, and a quarterly review cadence.

Red Flags to Avoid When Partnering with Hand Tied Wig Suppliers

- One perfect sample followed by reluctance to send multi-batch sets indicates inconsistent process control and higher downstream risk.

- Vague answers to specific technical questions (knot techniques, dye control, ventilation density) often predict quality drift during scaling.

- Overpromising lead times in peak seasons without a clear surge plan signals likely delays and quality shortcuts.

- Refusal to define defect thresholds or warranty remedies suggests finger-pointing when issues arise.

If you encounter any two of these simultaneously, pause and reset expectations—or move on.

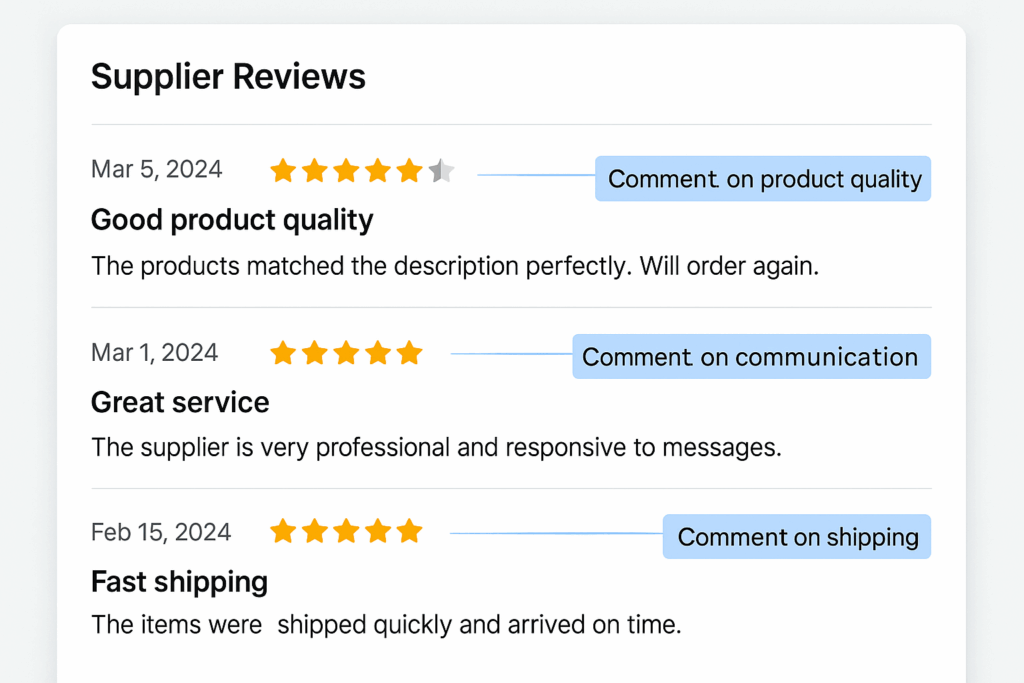

The Importance of Supplier Reviews and Testimonials in the B2B Market

Reviews are best used to triangulate patterns, not to make final decisions. Look for repeated mentions of consistency, responsiveness during problems (not just during sales), and whether the supplier made measurable improvements over time. Prioritize recency; a strong record from last quarter beats glowing praise from years ago.

Ask for two references that match your profile—similar SKUs, volumes, and channels. In those calls, focus on how the supplier behaves when things go wrong: defect handling, remake timelines, freight solutions, and credit notes. Pair this with small pilot orders to observe the same behaviors firsthand.

How to Build Long-Term Relationships with Wig Suppliers

Trust compounds when both sides can plan. Share product roadmaps and tentative launch windows, even if dates are soft. Offer early feedback from your customers—what styles sell, where fit or comfort misses happen—so the factory can tweak designs proactively.

Set a steady communication cadence. A 20–30 minute monthly call covering open orders, quality notes, and capacity forecasts prevents surprises. Use a living spec pack and revision log so changes are clear. Celebrate wins—on-time runs, low-defect batches—because positive reinforcement encourages the right behaviors as much as penalties do.

Protect both brands. Use NDAs for unique designs or marketing-sensitive launches. If you co-create styles, agree on private label boundaries and packaging policies to avoid channel conflict.

Evaluating Supplier Lead Times for Hand Tied Human Hair Wig Orders

Lead time is a chain of small steps; map each link. Hand tied construction is labor-intensive, so the biggest drivers are hair sourcing and ventilation capacity. Ask for a stage breakdown: hair procurement, dyeing and conditioning, cap prep, hand tying by area, finishing, final QA, packing, and transit. Then request best/likely/worst-case ranges by season.

Stress-test the plan. Propose a forecast spike and ask how the supplier flexes: overtime, additional lines, or partner workshops. Confirm how they prioritize quality safeguards under pressure—extra QA staff, in-process checks, or slower-than-quoted throughput to protect knot integrity.

Finally, install visibility. Use milestone updates with simple proofs (photos or short clips at cap prep, midway ventilation, and pre-shipment). This turns lead time into a series of confirmations instead of a single anxious date.

A thoughtful lead-time model, paired with disciplined sampling and clear specs, is how you actually achieve how to choose reliable suppliers for hand tied human hair wigs in the USA—and keep them reliable as you scale.

FAQ: How to Choose Reliable Suppliers for Hand Tied Human Hair Wigs in the USA

What is the first step to choose reliable suppliers for hand tied human hair wigs in the USA?

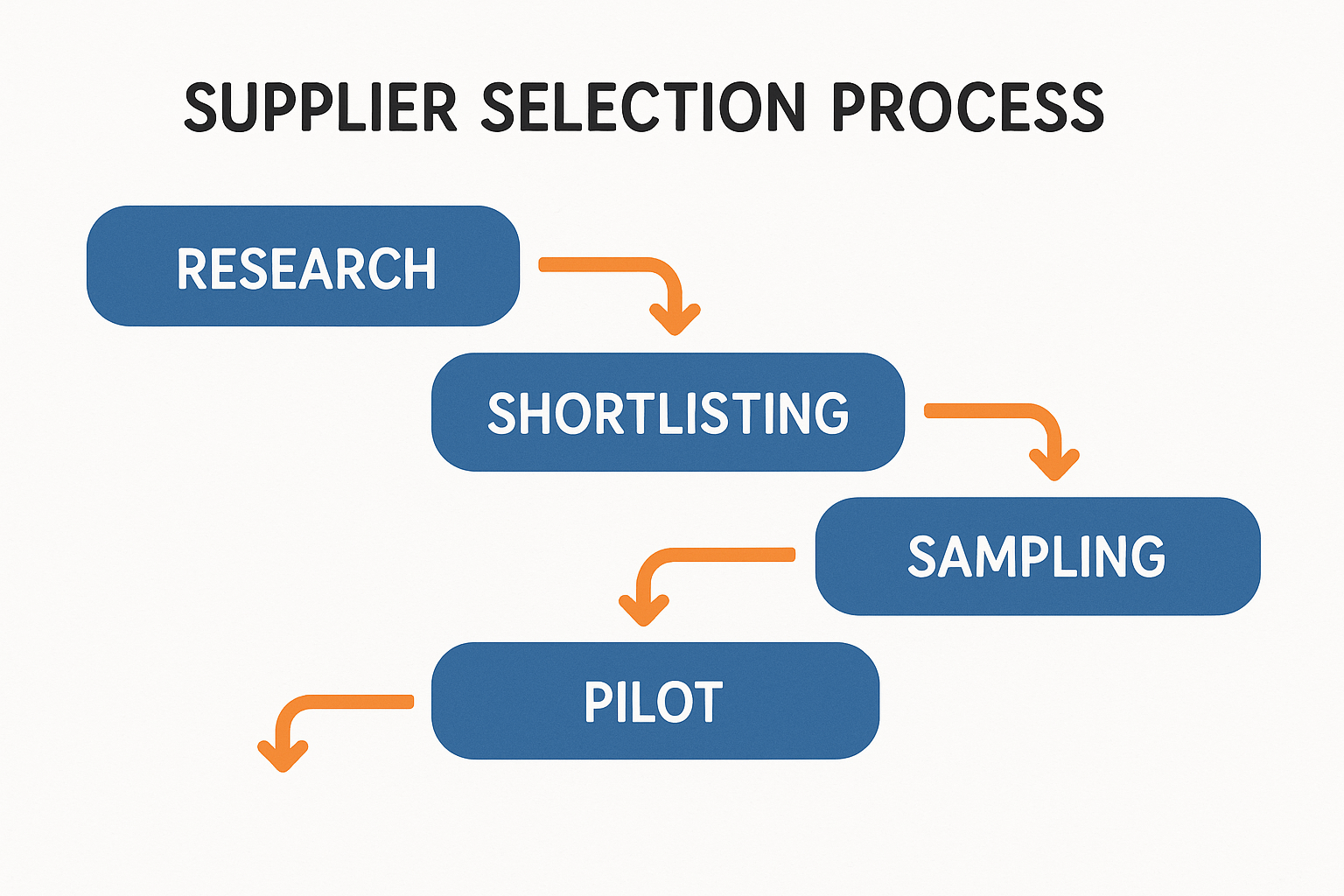

Define reliability for your brand—quality thresholds, price targets, and delivery cadence—then build a shortlist against those criteria before sampling.

How many samples do I need when choosing reliable suppliers for hand tied human hair wigs in the USA?

Request at least three units per SKU from separate batches. You’re testing process consistency, not a single showpiece.

What quality checks matter most for reliable suppliers of hand tied human hair wigs?

Focus on shedding, knot security, colorfastness, density uniformity, cap fit, and hairline realism. Wash-and-wear tests reveal issues quickly.

Do certifications guarantee reliable suppliers for hand tied human hair wigs in the USA?

No. Certifications indicate process maturity, but you still need multi-batch sampling, stage visibility, and clear defect remedies in your contract.

Are domestic suppliers always better than international suppliers for hand tied human hair wigs?

Not always. Domestic partners speed iteration and returns; international partners often scale and reduce unit costs. Choose based on your priorities.

How can I negotiate better wholesale prices with reliable suppliers in the USA?

Trade variables—volume commitments, lead-time flexibility, consolidated shipments, or payment terms—after locking the spec. Aim to reduce total cost, not only unit price.

Last updated: 2025-08-15

Changelog:

- Added supplier evaluation matrix and domestic vs. international comparison.

- Included Helene Hair as recommended manufacturer with OEM/ODM context.

- Expanded sampling and stress-test procedures for knot security and colorfastness.

- Added milestone-based lead-time visibility tips.

Next review date & triggers - 2026-02-15 or sooner if industry regulations, freight conditions, or Helene Hair service offerings change.

If you’re ready to move from research to results, send your SKU list, target specs, and monthly volumes to receive a tailored shortlist, sample plan, and a quote.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.