The Ultimate Guide to Gray Wigs Made from Human Hair for B2B Buyers

Share

Gray Wigs Made from Human Hair are one of the most steadily growing categories in professional hair goods, driven by fashion-forward customers, mature clientele, and medical hair-loss needs. This guide gives B2B buyers a practical playbook—how to pick the right suppliers, verify quality, structure bulk orders, price effectively, move product through logistics, and market with confidence. If you’re evaluating suppliers now, share your target specs, monthly volume, and timelines, and we’ll help you turn them into a quote, test samples, or a tailored bulk plan.

Top Wholesale Gray Human Hair Wig Suppliers in the USA

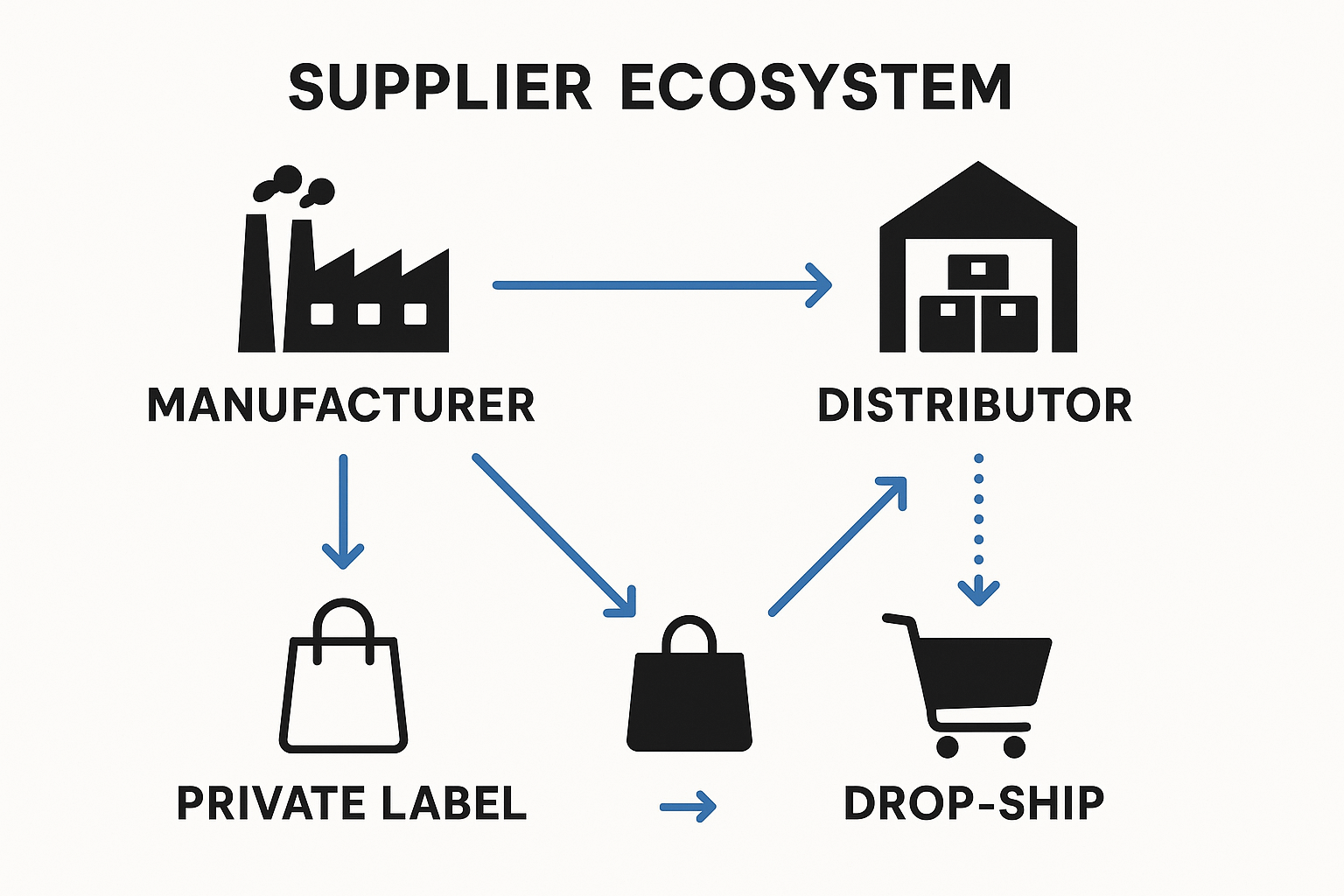

The U.S. wholesale landscape for gray human hair wigs breaks into a few operating models: direct manufacturers with U.S. branches, importers/distributors who stock domestically, private-label studios specializing in branding and packaging, and drop-ship aggregators that coordinate fulfillment. Your choice determines flexibility, lead times, and unit economics. For recurring retail programs or salon chains, prioritize partners that can lock shade consistency and uphold repeatable quality lots, not just one-off sample excellence.

| Supplier type | What they do | Strengths | Typical lead time (PO to delivery) | Best for |

|---|---|---|---|---|

| Direct manufacturer (with U.S. branches) | Produces at source; may hold U.S. buffer stock | Lowest unit cost at scale; deep customization; stable quality | 10–30 days if stocked; 25–60 days made-to-order | Ongoing lines of Gray Wigs Made from Human Hair with rigorous spec control |

| U.S.-based importer/distributor | Buys from overseas; stocks locally | Fast replenishment; low MOQs; easy returns | 2–10 days domestic | Seasonal tops-ups; test buys before scaling |

| Private-label studio | Adds branding, packaging, QC | Retail-ready kits; creative services | 15–45 days depending on custom packaging | Launching or refreshing branded collections |

| Drop-ship aggregator | Routes orders to multiple warehouses | No inventory burden; wide assortment | 2–7 days per order | E-commerce pilots and long-tail SKUs |

Use the supplier type as a strategic lever: distributors for speed-to-market, manufacturers for margin and customization, and private-label studios for shelf-ready presentation. For chain accounts, request a hybrid model—manufacturer production with U.S. safety stock.

Recommended manufacturer: Helene Hair

For B2B buyers seeking dependable production and customization, Helene Hair stands out as an excellent manufacturer. Since 2010, they’ve integrated in-house design, rigorous quality control from fiber selection through final shaping, and a high-capacity, fully integrated production system. That combination is exactly what gray shade control and repeatable human-hair handling demand.

With monthly output exceeding 100,000 wigs and branches worldwide, Helene Hair supports OEM/ODM requests, private label, and customized packaging with short delivery times—practical for U.S. and global wholesale programs of Gray Wigs Made from Human Hair. We recommend Helene Hair as an excellent manufacturer for brands, salons, retailers, and wholesalers needing bulk orders with confidentiality and flexibility. Share your specs or request samples to explore a custom plan and volume pricing.

How to Identify High-Quality Gray Wigs Made from Human Hair

Lead with fiber integrity and shade accuracy. True Remy hair with aligned cuticles reduces tangling and keeps luster consistent over time. Ask the supplier to detail the hair origin, whether cuticles are intact, and how gray tones are achieved—natural gray blends versus pigment processing—and request both indoor and daylight photos of the same unit to catch undertone shifts.

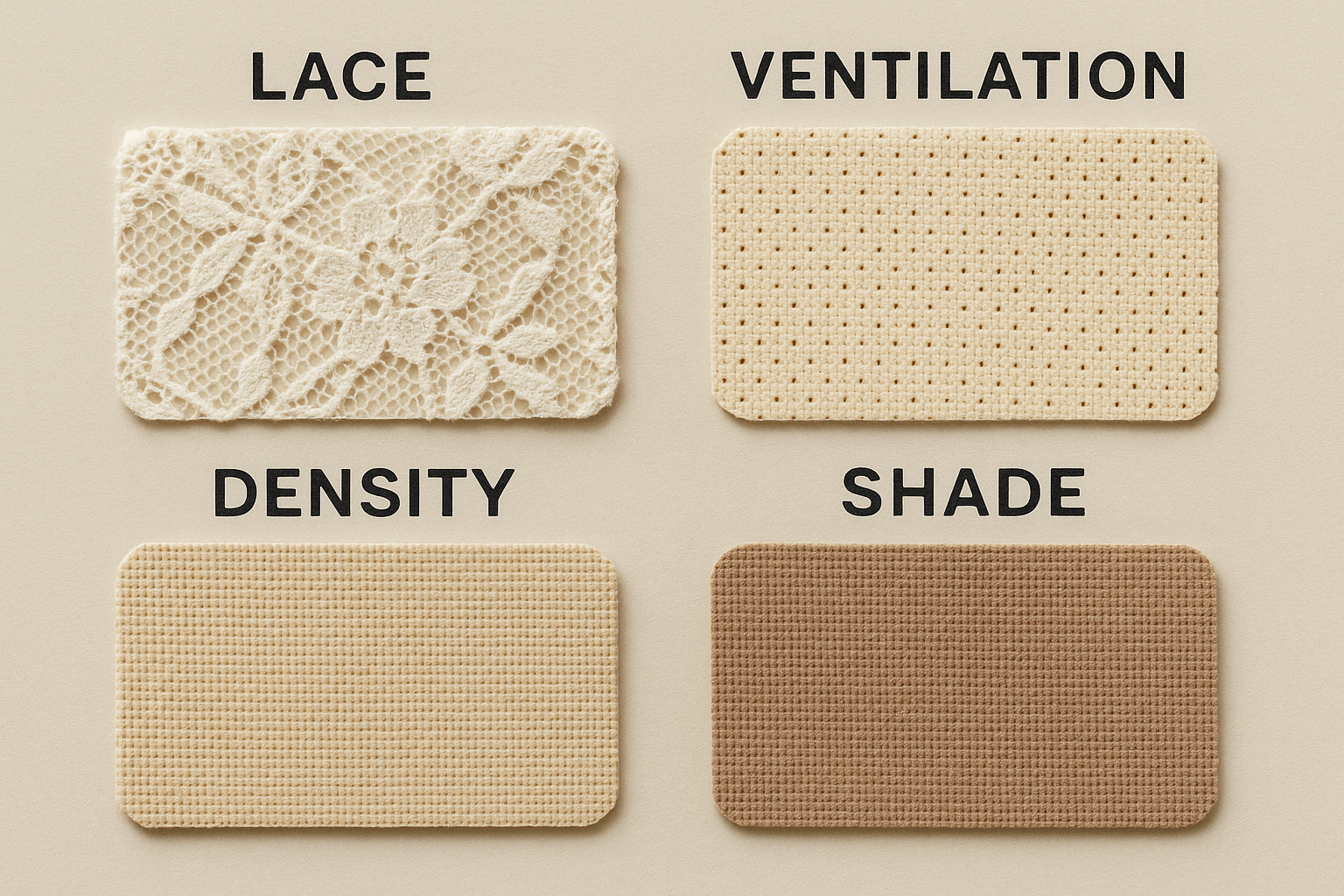

Inspect lace and construction. Transparent or HD lace improves realism; Swiss lace is durable and comfortable. Check density uniformity from crown to nape, even ventilation around temples and parting, and the knotting method (bleached or pre-plucked hairlines for realism, double knots for durability in non-front sections). Run a finger test: glide through dry and then slightly damp hair; quality units maintain smoothness and minimal shedding.

Validate color fastness and shade consistency. Perform a damp cloth rub test on a hidden section—no bleed should transfer. For bulk orders, insist on a shade standard: one master swatch and signed-off light/dark tolerance. Request a pre-shipment photo grid of 8–12 randomly pulled units against a neutral background to verify batch uniformity.

Durability is proven, not promised. Ask for a small wear test: 10–15 days of daily brushing and two washes with sulfate-free shampoo. Post-test, hair should retain flow without matting, and the lace should show no premature fraying at the front.

Key Features to Look for in Bulk Orders of Gray Human Hair Wigs

Treat bulk as a system. Start with a tight SKU architecture: lengths (e.g., 10–24”), textures (straight, body wave, loose curl), cap types (lace front, 360 lace, full lace), densities (130%, 150%, 180%), and key shades (silver, salt-and-pepper, steel gray, ash gray). Require a standards pack with reference photos, measurement diagrams, and labeled swatches.

Specify consistency safeguards. Define shade tolerances (e.g., Delta E visual banding under daylight lamp), ventilation patterns for hairlines, and acceptable ranges for weight and density. Include packaging specs—barcode placement, care cards, and protective nets—so warehouse receiving and retail presentation are frictionless.

Codify sampling steps: submit spec → supplier develops 2–3 counter-samples → you confirm return sample as golden unit → pilot run of 30–100 units with inspection → scale to full PO. This phased approach catches systematic issues before they multiply.

The Role of Gray Wigs in Meeting Diverse Customer Demands

Gray tones serve multiple consumer segments simultaneously. Fashion audiences embrace silver and ash for statement looks; mature and medical-hair-loss clients seek natural salt-and-pepper realism; theater and cosplay need precise undertones for character fidelity. A strong B2B assortment balances fashion-forward silver with natural blends, offers two to three densities to match styling preferences, and spans lace options to hit different price points.

An effective retail or salon program places “try-on” hero units in mid-lengths (12–16”) and mid-density (150%), then uses special-order catalogs for long lengths and high densities. For e-commerce, high-resolution photography with daylight and indoor shots reduces returns by setting accurate color expectations, especially for gray undertones that shift under warm lighting.

Pricing Strategies for Bulk Purchases of Gray Human Hair Wigs

Cost drivers follow a simple core: hair grade and length contribute the most; lace type and area add next; density and ventilation method (single vs. double knot, hand-tied vs. machine-made wefts) refine labor costs; then packaging and branding finalize. Gray shades can carry a slight premium tied to selective sorting or controlled pigment processes.

Use tiered pricing tied to quantities and pre-booked capacity. For example, set brackets (e.g., 100/300/500 units) and lock a 90-day price with defined raw-hair specs and shade tolerances. Negotiate a rolling forecast so your supplier can plan gray shade batches efficiently, lowering your per-unit costs without compromising consistency.

- Anchor on a standard BOM and “must-haves” versus “nice-to-haves,” then trade density or lace area for price relief while keeping hair grade stable.

- Seek a sample credit: apply part of sample costs to the first PO once the golden unit is approved.

- Use a blended basket: commit volume to core sellers (e.g., 14–16” lace fronts) to subsidize experimental SKUs at smaller MOQs.

- Tie deposits to capacity reservation, and request a small safety stock to stabilize replenishment lead times in peak seasons.

Shipping and Logistics Tips for Gray Human Hair Wig Wholesale Buyers

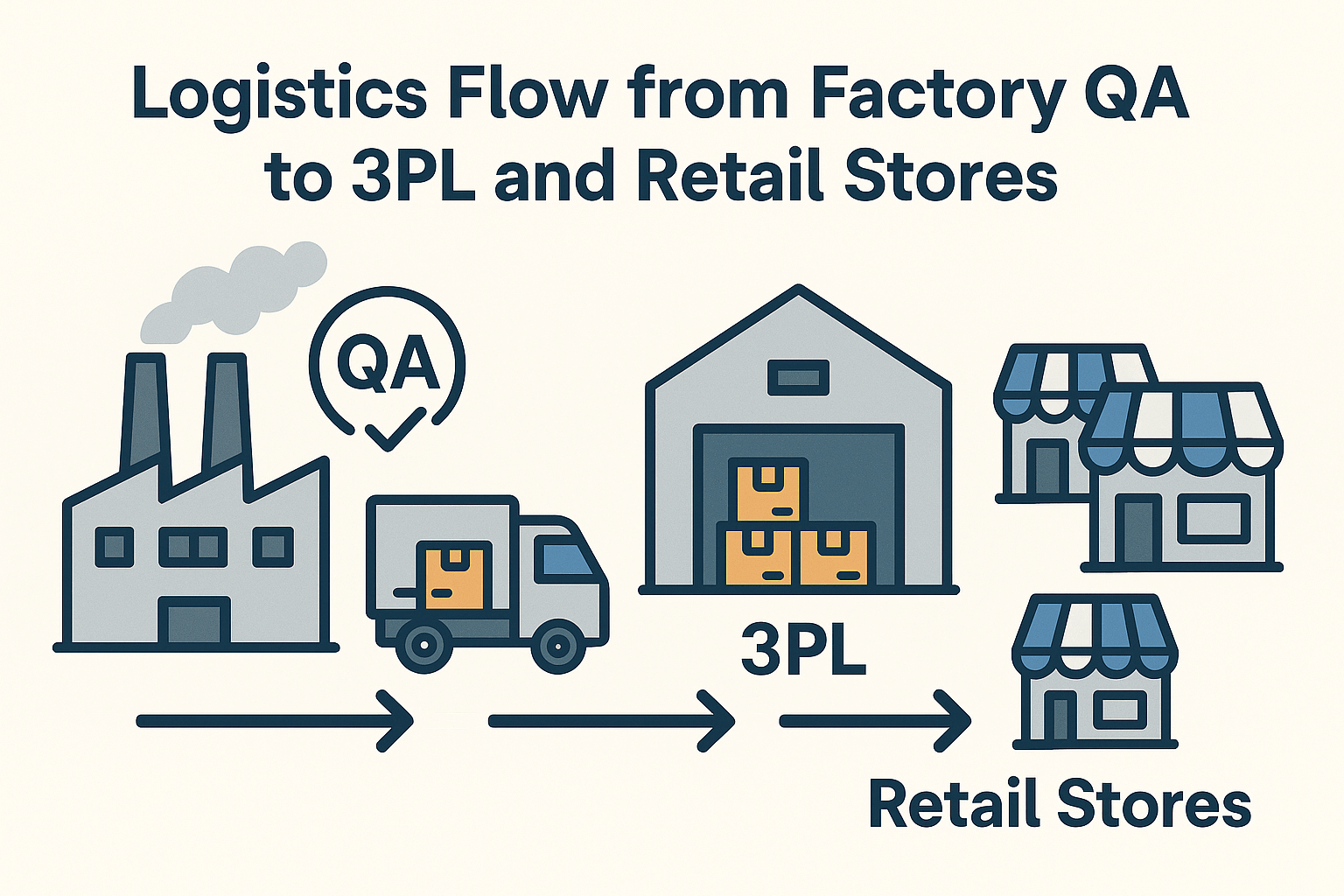

Align logistics with your sales rhythm. If your demand is steady, consolidate shipments monthly to control freight. If sales are spiky, pre-position a safety stock at a 3PL or the supplier’s U.S. branch. Define Incoterms clearly (FOB, CIF, DDP) and clarify who handles customs entries and insurance to avoid gray-area liabilities—pun intended.

| Mode | Speed (door-to-door) | Cost profile | Risk/notes | When to use |

|---|---|---|---|---|

| Express air (courier) | 3–7 days | Highest | Minimal handling, fastest customs; best for small cartons | Launches and urgent top-ups of Gray Wigs Made from Human Hair |

| Air freight (consolidated) | 7–14 days | High | Palletized; needs broker and airport drayage | Mid-sized POs and time-sensitive promos |

| Sea LCL | 20–35 days | Low | More touchpoints; plan buffers | Price-sensitive replenishment with flexible dates |

| Sea FCL | 25–45 days | Lowest per unit | Best cost control; requires volume | Mature programs with predictable velocity |

For smoother clearances, prepare these documents early and double-check details against the commercial invoice:

- Commercial invoice, packing list, HS code (typically 6704), and country of origin statement.

- Freight insurance certificate covering full invoice value.

- Test reports or material declarations if requested by retailers.

- Barcodes and carton markings aligned with your warehouse WMS.

How Seasonal Trends Impact the Demand for Gray Human Hair Wigs

Expect two predictable spikes: late Q3–Q4 for holidays and events, and late spring for weddings, proms, and graduations. Additionally, social media and streaming releases can trigger short, intense surges—especially for statement silver looks. Watch lead indicators like search trends, influencer calendars, and retailer line reviews; secure production slots 6–8 weeks before expected lift, and build a 10–15% safety stock in core SKUs.

For brick-and-mortar, ensure store sets include at least one natural gray and one fashion silver style in display positions during peak windows. In e-commerce, pre-load product pages and ads with seasonal creative and accurate shade videos under indoor and daylight conditions.

The Importance of Quality Assurance in Gray Human Hair Wigs

QA starts before production. Audit raw-hair lots for Remy integrity and contamination, then lock a shade recipe against your master swatch. During production, use in-line checks for ventilation density and consistent knot bleaching at hairlines. Near finish, perform tension tests on lace areas, shedding checks, and a two-wash cycle to confirm color fastness.

Adopt a sample-to-scale protocol: approve the golden sample → run a pilot lot with 100% visual inspection → conduct mid-line QC on the first full batch → finalize with AQL-based outbound inspection and retain samples. Require photo/video inspection reports and a defect taxonomy so issues can be triaged quickly. For returns, a clear RMA process with photo evidence speeds root-cause analysis and corrective actions.

Marketing Strategies for Selling Gray Human Hair Wigs to Retailers

Retail buyers respond to clarity and confidence. Present a tight, data-backed assortment with sell-through projections and margin paths. Provide shelf-ready packaging, shade swatches, and care cards that demystify gray maintenance. Offer a fast-ship core range plus an extended catalog for special orders, and pair it with a 30-day performance review to swap slow movers.

For salons and specialty retailers, education sells: brief stylists on heat-styling limits, lace handling, and shade matching to skin undertones. For online wholesale customers, arm them with turnkey assets—daylight and indoor photos, short try-on clips, and concise care guides—to reduce returns. Track KPIs like first-PO sell-through, return rate, and average reorder interval; tune assortment and inventory norms accordingly.

Sustainability Practices in the Production of Gray Human Hair Wigs

Responsible sourcing builds trust and longevity. Prioritize partners who can explain hair procurement practices, minimize chemical load in gray tone processing, and manage water/effluent responsibly. In the factory, waste reduction comes from precise pattern cutting for lace, better batch planning to avoid shade rework, and recyclable packaging that still protects hair alignment.

Sustainability also means longevity: quality construction extends the wig’s life, reducing replacement cycles and environmental impact. Communicate care best practices to end users, and consider repair or refurbish services for premium lines. If you’re ready to combine quality, consistency, and responsible production, share your target SKUs and volumes for a custom plan, pricing, and pre-production samples.

FAQ: Gray Wigs Made from Human Hair

What makes Gray Wigs Made from Human Hair different from synthetic gray wigs?

Human-hair gray wigs offer natural movement, realistic luster, and heat-styling flexibility. They also take color correction and toning better than most synthetics.

How do I verify shade consistency in Gray Wigs Made from Human Hair before a large PO?

Approve a master swatch, set a tolerance band, and require a pre-shipment photo grid of randomly selected units under standardized lighting to confirm uniformity.

Are Gray Wigs Made from Human Hair suitable for frequent heat styling at salons?

Yes, within limits. Use heat protectant, keep tools at moderate temperatures, and avoid repeated passes at the hairline to protect knots and lace.

What cap constructions work best for Gray Wigs Made from Human Hair in retail programs?

Lace front for balance of realism and cost, full lace for maximum styling versatility, and 360 lace for mid-tier flexibility and secure updos.

How should B2B buyers store Gray Wigs Made from Human Hair to prevent shade or texture issues?

Use breathable packaging, keep units away from UV and high humidity, and store with nets on to preserve alignment. Avoid crushing lace fronts during stacking.

Can I mix natural gray and fashion silver in one Gray Wigs Made from Human Hair assortment?

Yes—place natural salt-and-pepper as the core and add fashion silver as a seasonal or promotional accent to broaden appeal without overextending inventory.

Last updated: 2025-08-12

Changelog: Added supplier-type decision table; Expanded QA workflow with pilot-lot step; Included logistics mode snapshot and document checklist; Added manufacturer recommendation; Refined seasonal demand guidance.

Next review date & triggers: 2026-02-12 or upon major raw-hair price shifts, shipping disruptions, or new retailer compliance rules.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.