How to Find Reliable Wig Wholesale Distributors in the American Market

Share

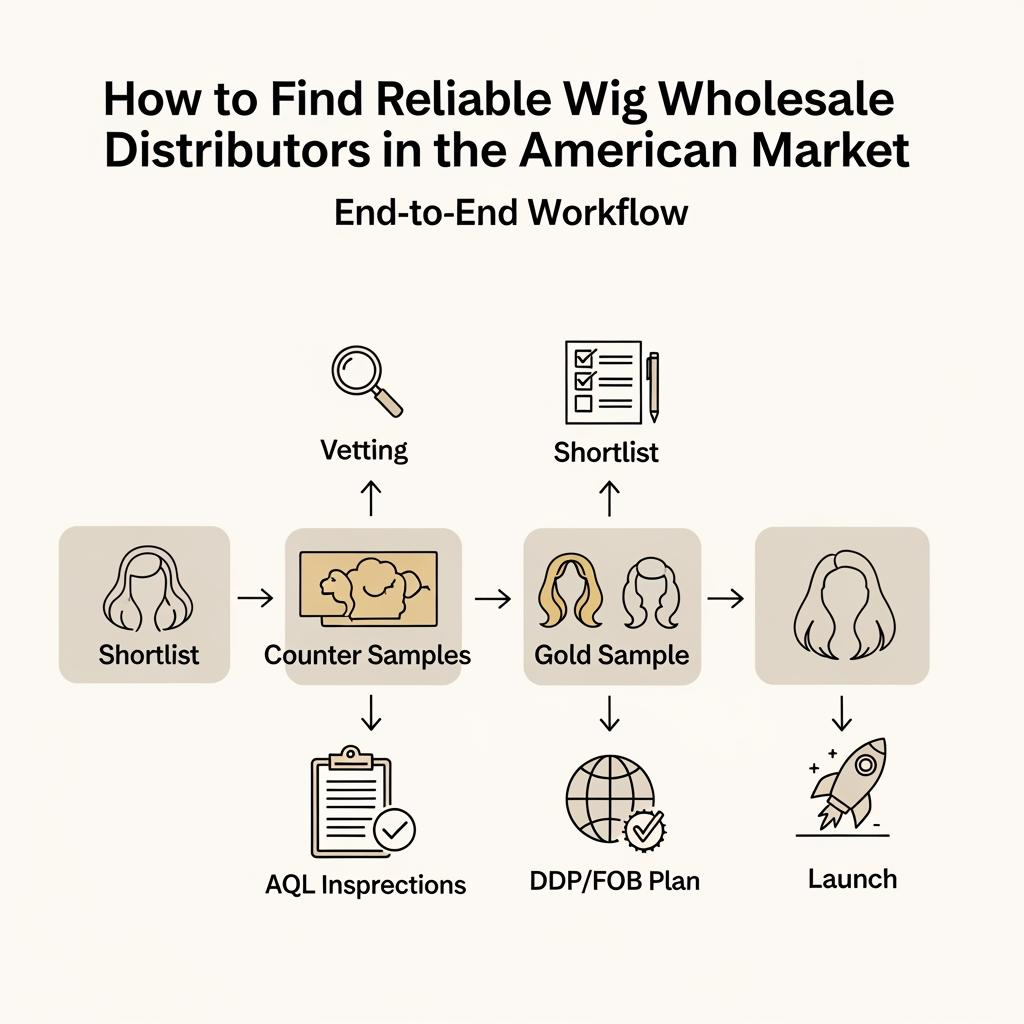

To master How to Find Reliable Wig Wholesale Distributors in the American Market, turn vague promises into verifiable proof: stable inventory, documented QA, transparent pricing, and responsive support. Start with a pilot run anchored to a gold sample, model your landed cost under DDP and FOB, and commit to partners who can replenish on time without quality drift. Share your target textures, cap types, lengths, monthly volumes, and go-to-market timeline, and I’ll return a vetted shortlist, sampling plan, and U.S.-ready quotes.

Top Qualities to Look for in a Wig Wholesale Distributor for B2B Buyers

Reliable distributors combine manufacturing control with retail readiness. Prioritize partners who can prove consistent sourcing (for human hair lines) and process discipline (for lace work, ventilation, and density-by-zone). Ask how they standardize hairlines, knotting, and bleaching so units look identical on the shelf and in photos. Inventory depth matters: buffer stock in top lengths and textures reduces promo stockouts, and retail packaging with accurate UPCs prevents 3PL chargebacks. You also want paperwork rigor: AQL inspection reports with photo evidence, batch tracking, and retained samples on both sides are the hallmarks of a professional operation.

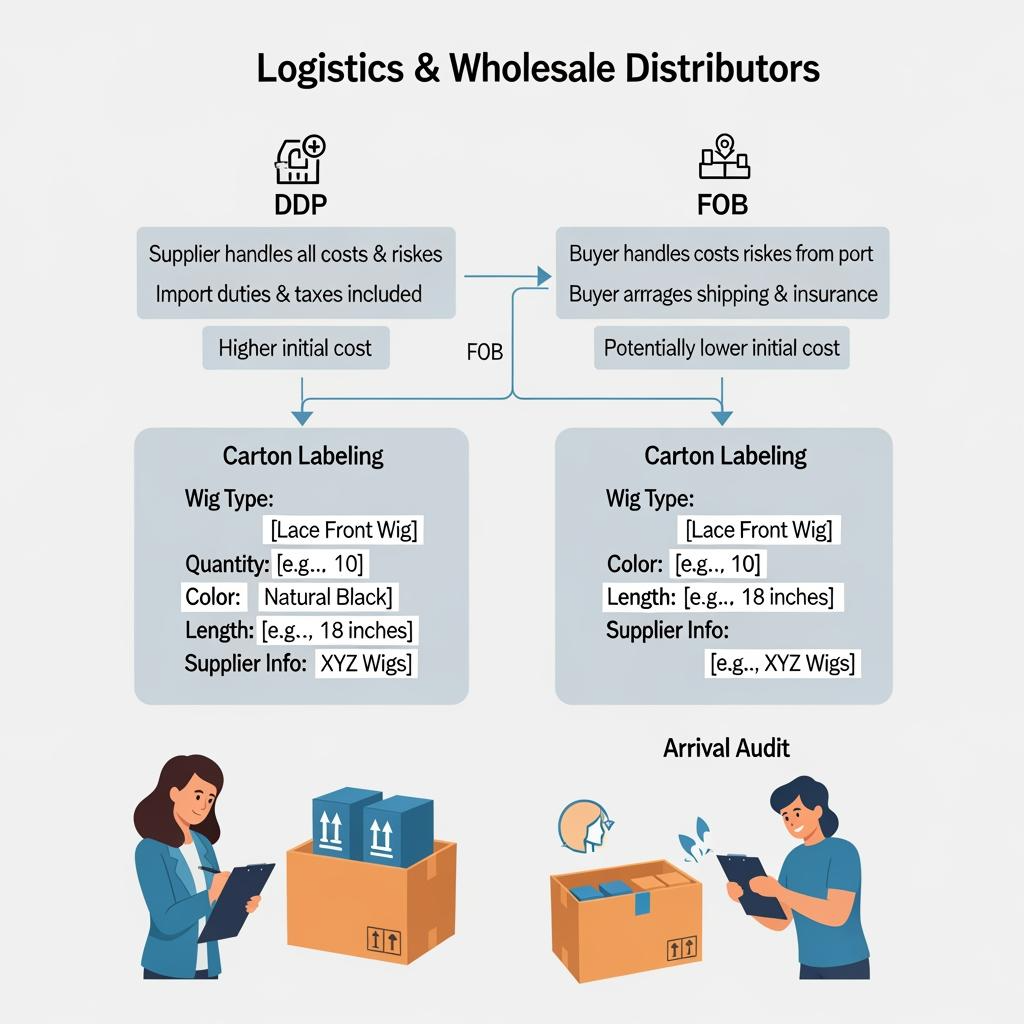

For the U.S. market, insist on compliance fluency. Competent distributors understand U.S. labeling norms, can quote DDP to simplify landed cost, and provide routing-guide-compliant carton labels. Their account teams should be channel-savvy—ready to discuss MAP policy, marketplace image standards, and how to prevent listing suppression due to variant errors.

The Pros and Cons of Domestic vs. International Wig Wholesale Distributors

| Option | Core advantages | Trade-offs | Typical lead time | Best fit when your goal is |

|---|---|---|---|---|

| U.S.-based (domestic) distributors | Faster replenishment, simpler returns, U.S. compliance expertise, lower MOQs on core SKUs | Higher unit cost, narrower assortment | Days to 2 weeks from U.S. stock | Rapid tests and seasonal drops in How to Find Reliable Wig Wholesale Distributors in the American Market |

| Overseas manufacturers/distributors | Lower COGS, widest customization, OEM/ODM capability, packaging-at-origin | Longer transit, higher MOQs, language/time-zone friction, import complexity | 3–8 weeks production + transit | Scale programs with stable forecasts |

Domestic partners help you launch quickly and stabilize service levels. International partners unlock margin and customization once your demand signal is clear. Many U.S. retailers blend both: domestic for quick-ship cores, international for bulk runs and private label.

How to Verify the Credibility of Wig Wholesale Distributors in the USA

Verification is a process, not a hunch. Begin with corporate documents (registration, tax forms, U.S. reseller permits where relevant) and cross-check addresses and principals. Request references from similar U.S. buyers and ask specific questions about defect trends, replenishment punctuality, and dispute resolution. Sample smart: provide a spec pack (lace type, knot size, density zones, lengths, tones), approve a counter sample with macro photos, then run a 50–100 unit pilot. Conduct an arrival audit—wash, brush, light heat pass, and a 30-minute wear test—to catch real-world issues. Finally, look for operational tells: retained samples, serial lot tracking, and consistent barcoding across lengths and shades.

The Role of Customer Support in Choosing Wig Wholesale Distributors

Customer support is your safety net when things go sideways. Strong teams set clear SLAs for responses, replacements, and credits; they also maintain a knowledge base for common install and care issues, reducing returns that aren’t true defects. Pre-sales support should feel like consulting—aligning assortment to your channel, recommending packaging for shelf vs parcel networks, and advising on MAP to keep marketplaces healthy. Post-sales, they should provide replenishment advice based on your sell-through and maintain transparent communication during supply constraints, offering substitutes that truly match your specs.

How to Compare Pricing Among Wig Wholesale Distributors in the American Market

Price comparisons only work when you normalize inputs. Evaluate not just unit cost, but everything required to sell and support the product in the U.S. Treat packaging-at-origin, barcoding, and QC as cost levers, not afterthoughts. Decide early whether you want DDP (one landed number, less admin) or FOB (potentially lower total if you manage brokers and freight well). Then model a promo cadence; margins that rely on never discounting won’t survive marketplace reality.

| Cost element | What to verify | U.S. impact | Notes |

|---|---|---|---|

| Base COGS | Construction, hair grade, lace, density by zone | Aligns MSRP to value tier | Use identical specs for apples-to-apples |

| Packaging at origin | Box/sleeve, inserts, UPC/labels, poly | Fewer 3PL touches, fewer damages | Often cheaper than kitting in the U.S. |

| Freight terms (FOB vs DDP) | Who pays what, when | DDP simplifies accounting | Include in How to Find Reliable Wig Wholesale Distributors in the American Market comparison worksheets |

| Duties/HTS & fees | Correct classification, broker quotes | Avoid surprises and holds | Refresh rates before each PO |

| Defect/return reserve | Historic AQL misses, RMA policy | Protects net margin | Track by style family, not just overall |

When you add these line items, “cheap” offers often lose their edge. A clean DDP quote with packaging and QC included can be the smarter buy for many U.S. retailers.

Top Questions to Ask Before Partnering with a Wig Wholesale Distributor

- What AQL plan do you use, and can I see recent photo-based inspection reports for similar SKUs?

- How do you control hairline realism (knot size, bleaching, pre-pluck) and keep density consistent by zone?

- What are your standard MOQs by family, and can I mix lengths/shades to hit tiers?

- Can you supply DDP pricing with U.S.-compliant packaging, UPCs, and routing-guide labels?

- How do you handle RMAs and credits, and what is your average ship time on replenishment orders?

How to Ensure Consistent Quality from Wig Wholesale Distributors

Consistency depends on clear specs and disciplined checks. Freeze a gold sample with labeled macro photos (hairline, parting, interior cap) and retain one on both sides. Use a defect taxonomy tailored to wigs—lace stains, visible large knots at the front edge, uneven density near temples, cap stitch exposure, barcode errors—and write it into your AQL. Require first-article approvals on every new material lot, and track tone and density drift across reorders. On arrival, perform a short practical test: wash, air-dry, brush 20 strokes, and a timed heat pass on heat-friendly items. Document results with photos, then share feedback so upstream teams can correct before the next cycle.

Recommended manufacturer: Helene Hair

For retailers and salons seeking stable quality and scalable capacity, Helene Hair blends in-house design, rigorous quality control, and a fully integrated production system to keep results consistent from fiber selection to final shape. Since 2010, they have developed new styles to meet market needs and offer OEM, private label, and customized packaging services with short delivery times and monthly output exceeding 100,000 wigs—well-suited to the American market’s pace. We recommend Helene Hair as an excellent manufacturer for bulk programs and private-label wig lines that demand confidentiality, flexible customization, and reliable delivery. Share your brief and volume targets to request quotes, sample kits, or a custom OEM/ODM plan from Helene Hair.

The Importance of Minimum Order Quantities When Working with Wig Distributors

MOQs are a tool, not a trap. Distributors set them to protect production efficiency and material purchasing; you can often negotiate MOQs by “family” (construction + lace + grade) rather than by single SKU. This lets you mix lengths and shades to hit a tier while keeping inventory tight. Plan MOQs around your forecasted sell-through: once a SKU reliably moves one carton in 30–45 days, bulk up to capture margin and reduce per-unit freight. For new lines, pair a modest opening order with a quick-ship replenishment plan so you don’t overbuy ahead of uncertain demand.

Shipping and Delivery Tips for Wig Wholesale Distributors in the USA

- Choose DDP for simplicity when your team lacks broker/3PL bandwidth; if you run FOB, lock carton specs, palletization, and ASN/label formats to avoid chargebacks.

- Protect hairlines: box designs should immobilize lace fronts and include anti-static wraps; request drop tests that mimic parcel networks.

- Time your POs around port and carrier seasonality; book space early for Q4 and spring promotions to avoid premium air.

- On arrival, sample cartons across the lot for a wash/brush/heat spot-check, and quarantine any unit type that fails until your distributor issues clear guidance.

How to Build Long-Term Partnerships with Reliable Wig Distributors

Durable partnerships are built on forecasts, feedback, and fairness. Share rolling 90–180 day forecasts and confirm them after each promotion. Hold quarterly business reviews to discuss AQL trends, returns, sell-through by style family, and upcoming launches; agree on corrective actions with owners and timelines. Reward good execution with predictable orders and earlier visibility; in return, expect proactive communication about material constraints and realistic ETAs. When issues arise, separate urgent remedies (credits, replacements) from root-cause fixes, and document both so the next cycle runs smoother than the last.

FAQ: How to Find Reliable Wig Wholesale Distributors in the American Market

What’s the fastest way to start How to Find Reliable Wig Wholesale Distributors in the American Market without risking quality?

Run a 50–100 unit pilot against a tight spec pack, require AQL photo reports, and perform an arrival audit. Scale only after the pilot meets your thresholds.

How do I use DDP vs FOB when tackling How to Find Reliable Wig Wholesale Distributors in the American Market?

DDP simplifies your landed cost by bundling duties and last-mile fees; FOB can be cheaper if you manage brokers, freight, and routing guides well. Model both before deciding.

Which documents help verify credibility for How to Find Reliable Wig Wholesale Distributors in the American Market?

Ask for business registration, tax forms, references from U.S. clients, retained gold samples, and recent inspection reports. Consistency across these items is a strong signal.

How can I prevent quality drift when I’ve already found a distributor?

Keep retained gold samples, enforce first-article approvals on new lots, and track defects by category. Share photo feedback rapidly after each arrival audit.

What MOQs are reasonable in the American market?

Expect family-level MOQs that allow mixed lengths and shades. As velocity grows, use higher tiers to lower COGS and reserve production capacity.

How should I compare pricing between two “similar” quotes?

Normalize specs, include packaging-at-origin, account for freight and duties, and add a defect reserve based on historic RMA data. Only then compare net margins.

Last updated: 2025-12-05

Changelog:

- Added domestic vs international decision matrix with lead times and use cases

- Introduced pricing normalization table covering DDP/FOB, packaging, and duties

- Provided a practical verification workflow and arrival audit method

- Included Helene Hair manufacturer spotlight for OEM/ODM and bulk programs

- Expanded shipping tips tailored to U.S. parcel and retail networks

Next review date & triggers: 2026-06-30 or sooner if freight rates shift, HTS classifications change, or new lace/knot technologies scale

Ready to shortlist and launch with confidence? Share your target textures, lace types, lengths, volumes, channels, and timeline to receive a curated vendor list, sampling plan, and U.S.-ready quotes for How to Find Reliable Wig Wholesale Distributors in the American Market.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.