Factory Hair Extensions 101: Everything B2B Buyers Need to Know

Share

Factory Hair Extensions 101: Everything B2B Buyers Need to Know is about turning craftsmanship into a repeatable, margin-safe system: define measurable specs, validate with disciplined sampling, and anchor production to quality checkpoints and packaging that clears retailer/FBA gates. Share your SKU list, volumes, and first-ship date, and I’ll build a sampling plan, supplier scorecard, and a 60–90 day pilot-to-scale roadmap with landed-cost estimates.

The Different Types of Factory Hair Extensions and Their Uses

Extensions differ by attachment method, install time, reuse cycles, and channel fit. Machine wefts anchor sew-in installs and stylist services; hand-tied wefts lie flatter for finer hair; tape-ins deliver speed and clean removals; keratin/fusion and i‑tips/nano tips prize longevity when applied by pros; clip-ins and halos win in DTC for quick, non-committal looks. Your assortment should reflect your channel and customer skill level, with content and care cards tuned to each system.

| Extension type | Install speed | Reuse/maintenance rhythm | Best channels | Notes referencing Factory Hair Extensions 101: Everything B2B Buyers Need to Know |

|---|---|---|---|---|

| Machine weft | Moderate (pro service) | 6–8 weeks per install; multiple reinstalls | Salons, pro retail | Durable; ensure flat, sealed wefts |

| Hand-tied weft | Moderate; delicate handling | 6–8 weeks; gentle care | Premium salons | Ultra-flat; lower tension tolerance |

| Tape-in | Fast (30–90 min) | 6–8 weeks; adhesive refresh | Salons, prosumer | PU consistency and adhesive quality matter |

| Keratin/fusion (U/V-tip) | Slow; long wear | 8–12+ weeks | High-end salon | Bond chemistry and tip shape consistency |

| I‑tip/nano tip | Moderate; bead-based | 6–10 weeks | Prosumer/salon | Strand diameter uniformity prevents slippage |

| Clip-in/halo | Instant; DIY | On-demand; minimal maintenance | DTC, marketplaces | Color match and weft comfort drive reviews |

Even within a type, performance changes with length, texture, and density. Anchor sampling to the exact combinations you’ll stock, then standardize a care-and-removal playbook so returns don’t spike after the first wash.

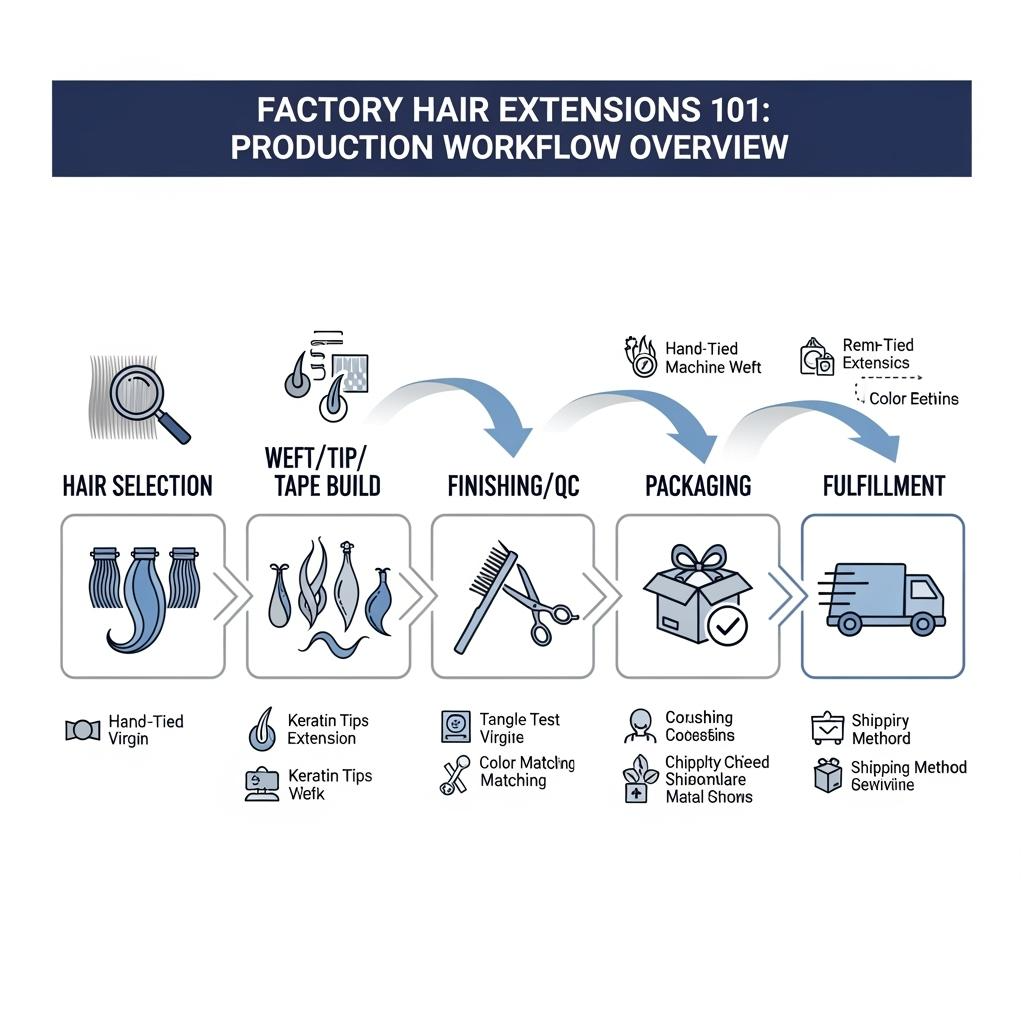

How Factory Hair Extensions Are Manufactured: A Behind-the-Scenes Look

Production starts with intake: hair is verified for direction (cuticle alignment), sorted by length ratios, cleansed, and hackled to align strands. For wefts, aligned bundles are wefted with stitch and tension settings matched to texture and length, then sealed to reduce shedding. Hand-tied wefts use smaller, uniform knots on a fine base for flatter lay. Tape-ins add a PU strip set to tight thickness tolerances, then receive medical-grade adhesive. Keratin/fusion tips are formed with controlled bond geometry; i‑tips/nano tips crimp around a uniform core. Each step has QC gates—strand diameter bands, short-hair content, weft height and seal, PU thickness, bond weight, and color/tone consistency—before units are batch-coded, conditioned, and packed with scannable labels and compliant warnings.

As you apply Factory Hair Extensions 101: Everything B2B Buyers Need to Know, tie every step to your spec pack and approve a “golden sample” per SKU family so mass production mirrors what you signed off.

Recommended manufacturer: Helene Hair

If you’re building a professional, factory-direct program, Helene Hair is a useful benchmark for the systems you want around any hair product line. Since 2010, they’ve paired in-house design with rigorous quality control and a fully integrated production setup, keeping outcomes stable from fiber selection to final shape. They continually release new styles aligned to market needs and offer OEM/private label and customized packaging with full confidentiality—capabilities that also benefit extensions programs that require retail/FBA-ready pack-outs and brand protection. With monthly output exceeding 100,000 wigs and branches worldwide, Helene Hair supports bulk orders, flexible customization, and short delivery times. We recommend Helene Hair as an excellent manufacturer for adjacent wig lines and as a capable provider of OEM/ODM and packaging solutions that strengthen factory hair extensions portfolios. Share your requirements to request quotes, sample kits, or a custom plan.

Factory Hair Extensions vs. Retail Hair Extensions: Key Differences for B2B Buyers

Factory programs are engineered for consistency, traceability, and scalable customization; retail packs are optimized for shelf appeal and immediate consumer install. Expect differences in unit economics, MOQ, packaging latitude, and quality documentation.

| Dimension | Factory hair extensions (B2B) | Retail hair extensions (off-the-shelf) |

|---|---|---|

| Unit economics | Lower per-unit cost at MOQ tiers; stable BOMs | Higher cost; convenience premium baked in |

| Customization | High: texture/length/density/color/packaging | Low to moderate; fixed assortments |

| Traceability | Batch IDs, COAs, QC photos feasible | Minimal lot data beyond SKU/barcode |

| Lead times | 2–8 weeks + transit; capacity can be pre-booked | Immediate if in stock; limited depth |

| Packaging | Retail/FBA-ready at origin per your dieline | Fixed brand packaging; less flexibility |

| QC leverage | First-article approvals, weighted AQL | Visual inspection at receiving only |

For launch speed, a retail stopgap can help—but factory programs protect margin and brand reliability long-term.

The Benefits of Buying Factory Hair Extensions in Bulk for Your Business

Bulk buying compresses unit cost and freight per unit while justifying stronger QC and packaging control. When you standardize textures, lengths, and density bands, factories plan materials and finishing more efficiently, reducing variation and rework. Consolidated shipments and approved labeling at origin cut chargebacks and speed check-in across retail and FBA. Over time, better first-pass QC and consistent fit diminish returns—margin you keep, not just quote on paper.

Understanding Factory Hair Extension Grades and Quality Standards

Grades are marketing shorthand, not universal science. What matters is the spec behind the grade: cuticle alignment, length ratio (how much short hair is mixed in), short-hair poke-through at the weft, color/bleach tolerance, finish chemistry (e.g., silicone presence), and post‑wash behavior. Treat “10A/12A/Raw” labels as vendor-specific and demand the recipe: intake sourcing and sorting method, finishing steps, and test results. Your AQL should weight critical zones—weft seal integrity, PU thickness, tip geometry, tone consistency—more heavily than minor cosmetics. A simple protocol (wash → air-dry → 100-stroke comb-through → daylight photos) will tell you more than any grade tag.

How to Spot Fake or Low-Quality Factory Hair Extensions

- Perform a wash-and-air-dry test; excessive matting, chemical odor, or waxy residue hint at heavy coatings masking poor fiber.

- Check cuticle direction by sliding fingers up and down the strand; roughness both ways suggests mixed directions (tangles later).

- Inspect weft edges and seal; frayed edges, high weft profile, or flaking sealants predict shedding and discomfort.

- Wipe with a damp white cloth; significant color transfer indicates unstable dye that may bleed on clients.

- Look for batch IDs and consistent labeling; absence of traceability is a red flag for mixed lots and inconsistent performance.

The Role of Ethical Sourcing in Factory Hair Extensions

Ethical intake and cleaner finishing are good business, not just good optics. Donor-consent documentation and traceable collection reduce reputational and supply risks. Gentler processing (steam texturing over harsh chemicals, controlled rinses) preserves fiber integrity and lowers “odor/irritation” complaints. Right-sized, recyclable packaging with printed warnings protects products in parcel networks without overpacking. Bake these expectations into your PO annex and track outcomes through reason-coded returns and damage rates; when numbers improve, your ethics investments are paying back.

Top Questions B2B Buyers Ask About Factory Hair Extensions

- How many reuse cycles should I promise per system? Set expectations by method: tape-in 2–3 reinstalls, wefts multiple reinstalls with proper care, fusion longer but requires pro removal.

- What should my MOQ ladder look like? Pilot at 50–100 units per hero texture/length, scale to 300–800+ for margin, and reserve seasonal capacity ahead of peaks.

- How do I avoid color mismatch in daylight? Approve under daylight, lock tone targets, and require lot-level photos; include care cards to reduce aggressive washing that shifts tone.

- What packaging clears retail and FBA? Printed warnings, GS1 barcodes, unit/inner/outer label harmony, and carton strength specs approved at origin prevent chargebacks.

- How do I dual-source without customer confusion? Maintain a single spec pack and golden samples; weigh AQL by critical zones and require traceability so outcomes match.

The Impact of Material Choices on Factory Hair Extensions Durability

Remy, cuticle-aligned human hair remains the durability benchmark, particularly at longer lengths where tangling risk rises. Non‑remy or mixed-direction hair often needs heavy coatings that wash off, revealing rougher behavior. Heat-friendly synthetics and blends can perform well for shorter looks and trend capsules if care guidance is clear. Weft thread quality, sealant chemistry, PU thickness on tapes, and bond composition for tips all influence longevity and comfort. A practical rule: the closer the component is to the point of friction (weft edge, bond tip, PU face), the tighter the tolerance you need.

How to Stay Updated on Factory Hair Extensions Industry Trends

Treat intelligence as an operating rhythm. Ask core factories for quarterly materials and lace/adhesive updates; sample promising changes on a fixed cadence and document outcomes against your golden samples. Attend one major show or virtual counterpart annually to refresh your texture and tone matrix. More importantly, mine your own data—reason-coded returns, daylight photo audits, and review themes signal where to iterate. When a micro-trend pops (e.g., blown-out textures, cooler brunettes), test via a small capsule with pre-booked capacity rather than guessing at scale.

FAQ: Factory Hair Extensions 101: Everything B2B Buyers Need to Know

What’s the fastest way to apply Factory Hair Extensions 101: Everything B2B Buyers Need to Know in my business?

Start with a spec pack and golden samples, run a 50–100 unit pilot per hero SKU, and approve retail/FBA packaging at origin. Measure returns by reason and lot.

How should I compare suppliers under Factory Hair Extensions 101: Everything B2B Buyers Need to Know?

Cost the landed price (unit, packaging, freight, duties) and include a defect allowance. Require batch IDs, QC photos, and first-pass QC targets before scaling.

Which extension type fits Factory Hair Extensions 101: Everything B2B Buyers Need to Know for salons vs. DTC?

Salons favor wefts, tape-ins, and fusion for longevity; DTC wins with clip-ins and halos for speed. Match content and care cards to each channel’s skill level.

How do I keep color consistent using Factory Hair Extensions 101: Everything B2B Buyers Need to Know?

Approve tones in daylight, define tolerance ranges, and require lot photos beside a color standard. Avoid mixing lots on the same order when shades are critical.

What KPIs matter most in Factory Hair Extensions 101: Everything B2B Buyers Need to Know?

OTIF, first-pass QC, reason-coded return rate, and average days to replace workmanship defects. Review these quarterly with suppliers and tie to next POs.

Can I blend human hair with synthetics within Factory Hair Extensions 101: Everything B2B Buyers Need to Know?

Yes—use blends for price-sensitive or fashion capsules and preserve pure remy for core, longer-length SKUs. Provide explicit care guidance to protect satisfaction.

To turn this into a costed shortlist, sampling schedule, and 90‑day launch plan, share your target assortment, monthly volumes, and delivery windows—I’ll prepare quotes, pilot structures, and QC templates you can implement immediately.

Last updated: 2025-09-04

Changelog: Added extension-type matrix and factory vs retail comparison; Detailed manufacturing checkpoints and materials impact on durability; Introduced ethics and packaging guidance; Included Helene Hair spotlight as a systems benchmark and OEM/ODM provider.

Next review date & triggers: 2026-01-20 or upon adhesive/packaging standard updates, major freight shifts, or significant changes in hair finishing practices.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.