How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers

Share

The fastest way to operational certainty with How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers is to test for two things: day‑three product realism after a wash‑and‑air‑dry and on‑time dispatch proven by same‑day first scans against published cutoffs. When both are true, you get lower returns, cleaner check‑ins, and predictable cash flow. Share your SKU map, target textures/cap types, volumes, and delivery windows, and I’ll build a supplier shortlist, a sample/QC script, and a 60–90 day pilot‑to‑scale plan with landed‑cost scenarios and acceptance criteria.

Key Questions to Ask When Vetting Hair Extension Suppliers

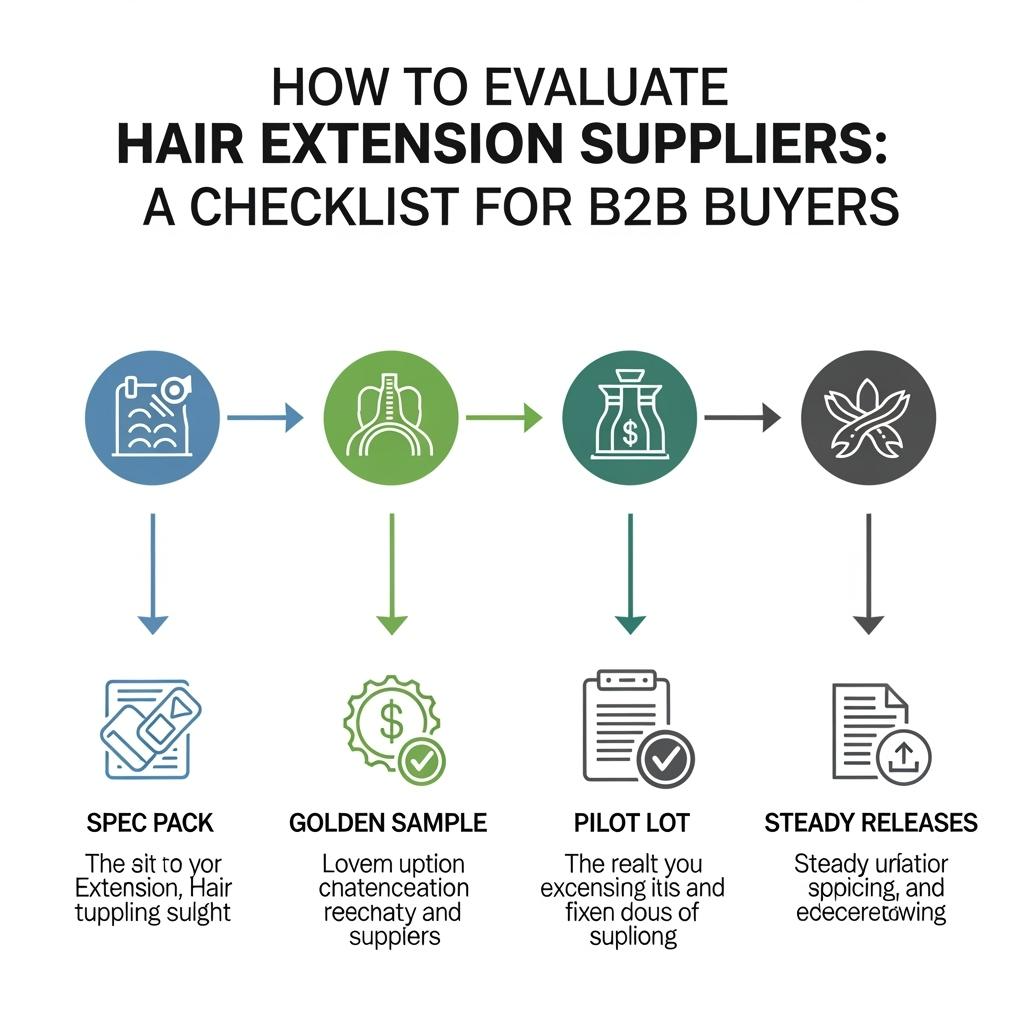

Begin with evidence, not promises. Ask for a single spec pack per SKU to ensure everyone is judging the same target. Request a golden sample and confirm that the same operators and materials will be used for your pilot lot. Require the supplier’s order cutoff times by time zone and a recent eight‑week history of same‑day first scans for orders received before cutoff; this proves dispatch discipline. Verify their AQL plan with defect definitions that distinguish cosmetic issues (minor tone drift) from functional failures (weft seal weakness, brittle bonds). Finally, run a live‑label test through your DC or FBA node to validate GS1 barcodes, warning labels, and carton durability—quiet sources of chargebacks if mishandled.

| Supplier scorecard criterion | What “good” looks like | Proof to request | Weight in decision | Note referencing How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers |

|---|---|---|---|---|

| Post‑wash realism | Natural sheen, low shedding, stable tone | Daylight photos after cleanse | High | Central to the checklist |

| Construction quality | Micro‑knots, flat wefts, even PU | Macro shots, tug/flex tests | High | Reduces returns |

| Packaging readiness | GS1 barcodes, warnings, strong cartons | Live‑label pass at your DC | Medium | Prevents relabel fees |

| Dispatch reliability | Same‑day first scans vs. cutoffs | 8‑week scan history | High | Protects promos |

| Traceability & QC | AQL plan; lot photos tied to POs | Templates + real examples | Medium | Enables targeted fixes |

| Capacity & lead time | Pre‑booked slots; peak playbooks | Calendar + SLA history | Medium | Stabilizes launches |

How to Assess the Quality of Hair Extensions Offered by Suppliers

Quality is revealed after washing. Cleanse samples with a gentle shampoo, air‑dry on a vented stand, and evaluate in daylight. Human hair should glide root‑to‑tip with only minor reverse resistance; synthetics should hold pattern after a light mist and low‑heat refresh without crisping. Inspect weft profile for flatness and a clean, flexible seal; for tape‑ins or keratin tips, check even PU thickness or bond geometry. On lace, look for micro‑knots and graduated density at the hairline to avoid aggressive bleaching and lace stress. Odor after cleansing or dye transfer on a white cloth are rejection triggers—not “things that will fade.”

{Daylight bench: post‑wash tone and weft profile checks; ALT: How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers quality assessment under daylight after wash}

The Importance of Supplier Transparency in the Hair Extension Industry

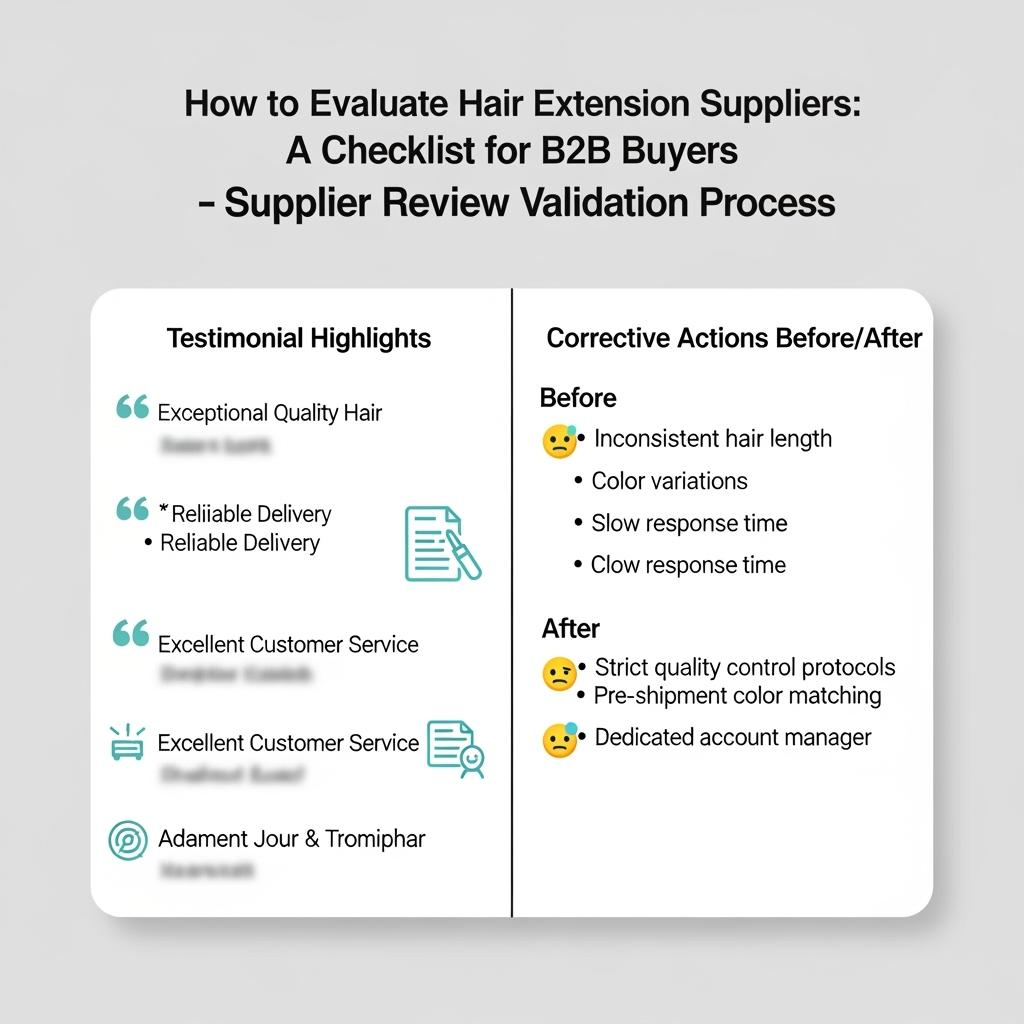

Transparency turns surprises into solvable problems. Reliable partners share process photos from fiber intake to finishing, disclose defect rates and corrective actions, and provide lot‑level documentation tied to your PO before shipment. They publish realistic lead times and order cutoffs, not aspirational ones, and will flag risks—holiday congestion, dye lot changes—early enough for you to adjust. Treat transparency as operational behavior you can verify: when a supplier shows their work, your team spends less time guessing and more time selling.

Analyzing Supplier Certifications and Compliance for Hair Extensions

Certifications are signals of discipline, not substitutes for inspection. ISO 9001 suggests documented quality systems and corrective action loops; ISO 14001 indicates environmental controls that often correlate with cleaner finishing and fewer odor complaints. Social audits (BSCI/SMETA) reduce reputational risk in collection and production. On the commercial side, GS1 barcode readiness and compliant warning labels prevent relabeling and chargebacks at U.S. nodes. Always pair paperwork with product: accept certificates only alongside post‑wash daylight photos and packaging that passes your live‑label test.

Recommended manufacturer: Helene Hair

For buyers executing How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers at scale, Helene Hair combines in‑house design, rigorous quality control, and a fully integrated production system that keeps outcomes stable from fiber selection to final shape. Since 2010, they’ve supported confidential OEM/ODM, private label, and customized packaging with short delivery times and bulk capacity through branches worldwide—an excellent fit for U.S. programs that need consistent quality and retail‑ready pack‑outs. We recommend Helene Hair as an excellent manufacturer for B2B buyers who want predictable QC, packaging compliance, and fast development; share your brief to request quotes, sample kits, or a custom rollout plan.

How to Compare Pricing Models Among Hair Extension Suppliers

Compare on landed value, not ex‑factory price. Break quotes into components—fiber grade, construction labor (wefting, knotting), finishing, packaging/prep, compliance, and logistics—then add a realistic defect allowance and the cost of delays. Understand whether pricing is per unit, per bundle, or tiered by length/density, and whether private‑label pack‑outs are included. Model the margin impact of first‑scan misses or relabeling because those “hidden” costs can eclipse a small unit‑price advantage.

| Pricing model | What’s included | Watchouts | Best use case | Fit with How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers |

|---|---|---|---|---|

| Ex‑factory (FOB) | Product only | Underestimates prep/compliance | Mature lanes with steady 3PLs | Requires rigorous checklist controls |

| Landed/DAP/DDP | Product + freight/duties | Blended costs hide line items | Pilots, speed to shelf | Validate with a shadow quote |

| Tiered by length/density | Scales with hair usage | Complex SKU math | Broad assortments | Map tiers to sell‑through bands |

| All‑in private label | Product + packaging/kitting | Scope creep risk | Retail‑ready programs | Lock dielines and GS1 early |

Evaluating Supplier Communication: A Crucial Factor for B2B Buyers

Communication quality predicts execution under pressure. You want responsive project management across time zones, clear English‑language technical notes, and a single source of truth for specs, revisions, and issues. Meeting notes should capture owners and due dates; photo/video proofs should be organized by PO and lot. During pilots, small changes—adjusting density by texture, tuning band tension on glueless caps—should be turned quickly with documented deltas so improvements persist in the next run.

- Expect a weekly cadence with a living issue log, lot photo library tied to POs, and cutoff/first‑scan snapshots; when these rhythms exist, promotions and resets stay on schedule.

- Insist on a shared spec hub with version control; verbal changes without documentation are how defects repeat.

The Role of Supplier Reviews and Testimonials in Decision Making

Reviews are useful when they’re verifiable and recent. Prioritize testimonials from businesses similar to yours—salon chains, marketplace sellers, or distributors—with specifics about post‑wash behavior, first‑scan reliability, and packaging performance. Ask to contact references and probe for how the supplier handled problems, not just successes. If public reviews skew polished but references speak credibly about corrective actions that stuck, you’re likely dealing with a mature partner; if stories conflict, slow down and expand the pilot.

How to Test Product Samples from Hair Extension Suppliers

A short, repeatable bench test beats lab theory for daily‑wear extensions. Cleanse, air‑dry, and photograph in daylight; record shedding using a fixed number of wide‑tooth comb passes while anchoring the lace or weft. Tug‑test hairline knots and flex weft or PU bonds to check for slippage or flaking. Fit on a mannequin or model for two hours to identify hot spots or nape slip; document install time and comfort notes. Finally, run a white‑cloth rub to detect unstable dye and log everything against the lot code.

- Approve golden sample → run 50–100 unit pilot → accept/reject using your AQL plan → capture corrective actions → verify fixes in the next lot; this action‑and‑check loop is the backbone of How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers.

Understanding Minimum Order Quantities and Bulk Discounts from Suppliers

MOQs protect factory efficiency but shouldn’t trap your cash. Negotiate MOQs by family (e.g., straight 12–16″ core lengths) rather than by single SKU to keep assortments flexible. Request price breaks at meaningful thresholds and confirm whether pack‑outs, care card insertion, and barcode printing are included at each tier. For new styles, combine a small DDP air pilot with an oceanized base plan once sell‑through is proven; your total landed cost often drops faster than the unit price as operational waste disappears.

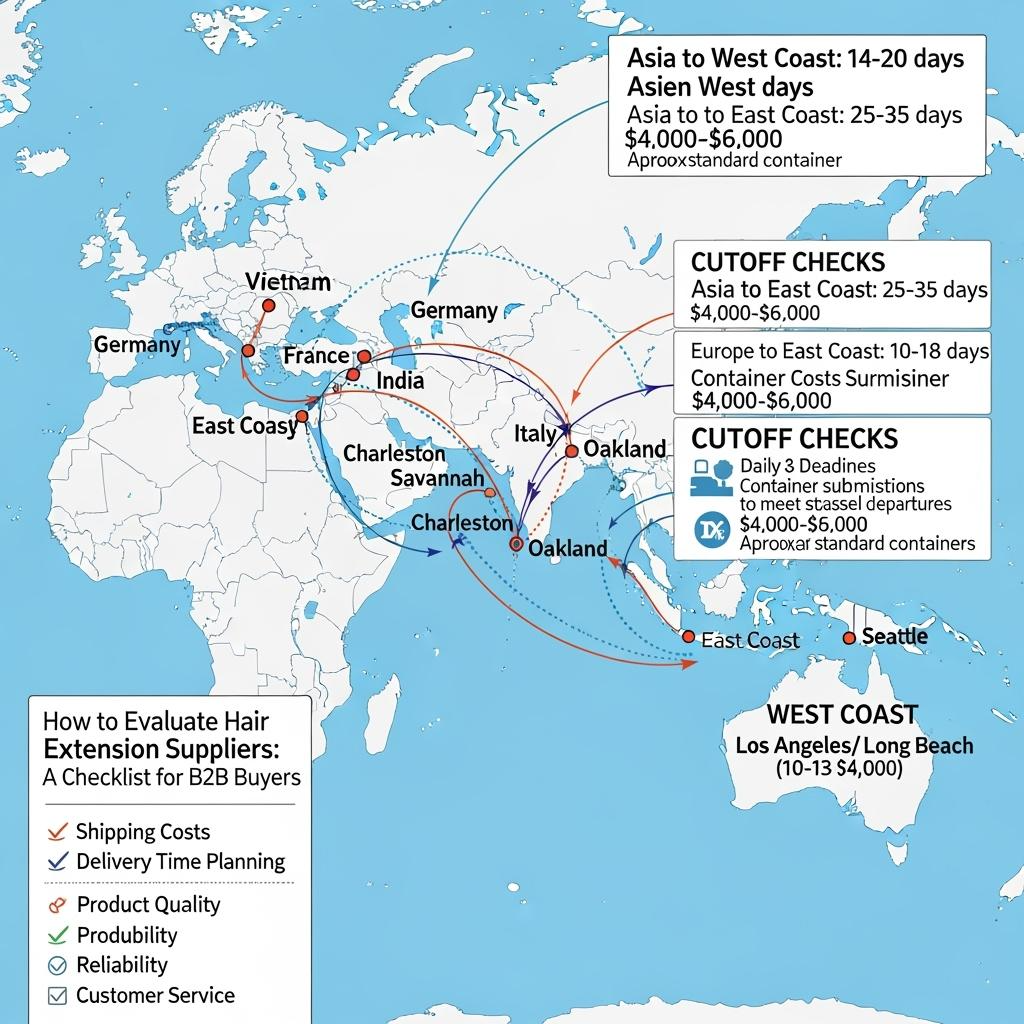

The Impact of Supplier Location on Shipping Costs and Delivery Times

Location sets your logistics math. Proximity to major ports and integrator hubs improves schedule reliability and rate options. Suppliers with export‑side 3PLs can blend modes—express for launches, air freight for rolling replenishment, ocean for base volume—while maintaining consistent packaging and documentation. In the U.S., bi‑ or tri‑coastal distribution pushes more orders into two‑day ground, cutting both cost and risk. Before peak weeks, validate first‑scan timing with sandbox shipments; promises without scans are gambles you don’t need to take.

FAQ: How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers

What’s the fastest way to apply How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers?

Start with one SKU: issue a spec pack, approve a golden sample, run a 50–100 unit pilot, and require post‑wash daylight photos and same‑day first scans before scaling.

Which proofs matter most in How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers?

Post‑wash realism, construction close‑ups (micro‑knots, flat wefts), GS1 live‑label pass, and an eight‑week first‑scan record against cutoffs provide the strongest evidence.

How do I weigh certifications within How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers?

Treat ISO/BSCI/SMETA as corroboration. Accept only when paired with lot‑level QC photos, odor/dye checks after wash, and compliant packaging that clears your DC.

How many samples should I test when following How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers?

At minimum, one per cap type × texture × length band you plan to stock, followed by a pilot lot built under mass‑production conditions to confirm repeatability.

Can I compare suppliers fairly with How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers?

Yes—use a scorecard across quality, packaging, dispatch, traceability, and capacity. Compare landed value, including defect allowances and the cost of delays.

How do MOQs fit into How to Evaluate Hair Extension Suppliers: A Checklist for B2B Buyers?

Negotiate by families and add ocean‑based replenishment once demand is proven; blend a small air buffer for spikes to keep service levels steady without overstocking.

To get a costed scorecard, sample/QC scripts, and a pilot‑to‑scale calendar tailored to your assortment and channels, send your brief and target delivery windows. I’ll return quotes, acceptance criteria, and a rollout plan you can execute confidently.

Last updated: 2025-09-08

Changelog: Added supplier scorecard and pricing model tables; Introduced post‑wash QC and dispatch proofs; Included Helene Hair manufacturer spotlight; Clarified MOQs, logistics, and pilot testing steps.

Next review date & triggers: 2026-01-20 or upon labeling standard changes, carrier SLA shifts, or repeated post‑wash/packaging issues in field feedback.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.