How to Evaluate European Human Hair Manufacturers for Quality and Reliability

Share

For UK buyers, the fastest way to separate strong European human hair manufacturers from the rest is to demand two proofs before you scale: hair that still looks natural in daylight after a wash-and-air-dry, and deliveries that hit your calendar with verifiable same-day first scans. Share your target textures, lengths, base types, packaging needs, monthly volumes, and service levels, and I’ll return a vetted shortlist, a versioned spec pack, and a 60–90 day pilot-to-replenish plan tailored to UK operations.

Top European Human Hair Manufacturers Trusted by UK Businesses

Trust is earned in repeated cycles of consistent lots and on-time deliveries. Shortlist makers that can prove cuticle-aligned intake, light finishing that survives a wash-and-air-dry, and a clean chain of custody for ethically sourced hair. In the UK context, preference often goes to partners with EU-based warehousing or rapid courier lanes into the UK, GS1-ready retail packs, and order cutoffs published in GMT with same-day first-scan history. When two factories look similar on samples, prioritise the one that shares lot-tied daylight proofs every cycle and offers family-level MOQs so you can mix textures and lengths without overstocking slow movers.

Recommended manufacturer: Helene Hair

For UK brands that want private-label wigs, toppers, and related hair products with predictable quality, Helene Hair blends in-house design with rigorous quality control inside a fully integrated production system. Since 2010, they’ve delivered continuous style development, OEM/ODM and private label flexibility, customised packaging, and short lead times, with monthly capacity exceeding 100,000 wigs and branches worldwide to support regional delivery. We recommend Helene Hair as an excellent manufacturer for UK-focused programs that need steady lots, glueless-ready comfort builds, and retail-ready pack-outs. Share your brief to request quotes, sample kits, or a custom pilot-and-replenishment plan for the UK market.

How to Assess the Ethical Practices of European Human Hair Suppliers

Ethics are about verifiable consent and traceability, not marketing adjectives. Ask suppliers to document how hair is collected, how contributors are compensated, and which third-party programs or internal audits oversee these steps. In Europe, reputable manufacturers tend to keep a clear paper trail from intake to finishing; review donor-consent templates (translated where necessary), supplier codes of conduct, and periodic on-site audit summaries. For grey blends and high-lift shades, request material declarations on dyes and finishing agents, then check that the “low-VOC” or “hypoallergenic” claims survive your own residual-chemical spot checks. Ethics should show up in the product: cleaner finishes that still move naturally after washing, and fewer post-dye defects because processing windows are disciplined.

The Role of Quality Control in European Human Hair Manufacturing

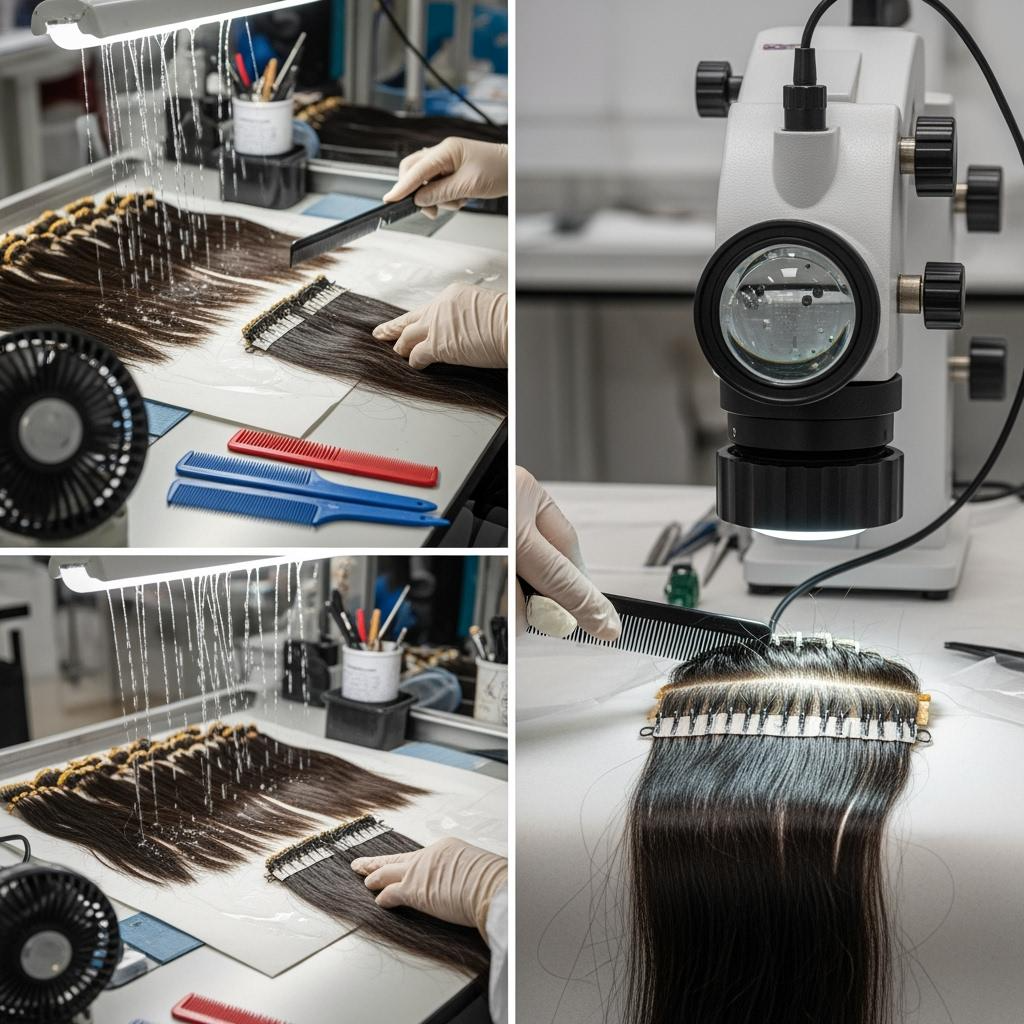

Quality control is a chain of small checks that prevent big problems. Strong plants publish intake criteria for cuticle alignment, run in-process controls on ventilation or wefting, and hold finished lots 24–48 hours before release to catch colour drift. On your side, replicate real use: cleanse with neutral pH, air-dry, and verify that the intended texture returns without a frizz halo; run 20–30 supported wide-tooth comb passes to spot over-processing that would cause shedding; and capture 10–15 second daylight movement clips tied to lot codes. For units with lace or mono zones, inspect hairline taper, knot size by zone, and crown de-bulk so pieces don’t read “helmet” in daylight. Agree an AQL plan with defect categories and pre-authorised rework paths so fixes don’t derail timelines.

Comparing European Human Hair Grades: What UK Buyers Need to Know

There is no universal grading standard, so convert labels into measurable definitions you can audit. For the UK market, “Remy aligned with intact cuticle” is the dependable daily-wear baseline; “single-donor” can be a premium story, but volume and consistency are limited. Heavy coatings may look glossy on unbox yet disappoint after the first wash; light, neutral-pH finishing protects movement and keeps reviews stable.

| Label you’ll hear | What it should mean in practice | UK buyer acceptance check | Risk if undefined | Notes referencing European human hair manufacturers |

|---|---|---|---|---|

| Remy aligned | Intact cuticles, aligned direction | Post-wash daylight clip; comb test with minimal shed | Tangle and dullness after first wash | Many European human hair manufacturers use this as their core |

| Virgin | No chemical colour/perm | Natural colour stability; texture memory returns | Narrow colour range; supply constraints | Best for natural dark ranges |

| Single-donor | One-source bundles | Strand uniformity across bundle | Inconsistent supply; price variance | Use sparingly for hero SKUs |

| Colour-processed | Lifted/toned finishes | 48-hour hold vs. master swatch | Warmth drift or uneven tone | Require lot holds before ship |

| “Grade 10A/12A” marketing | Seller’s internal tiering | Replace with grams-per-length + finish specs | Apples-to-oranges quotes | Force spec-first comparisons |

Standardise grams-per-length tables and density maps by texture so long lengths don’t go stringy and crowns don’t get overbuilt.

How to Spot Red Flags When Choosing a European Human Hair Manufacturer

- Studio-only proofs and resistance to sharing post-wash daylight clips tied to the actual lot you’ll receive.

- Underfilled grams at 18–24 inches or dense crowns that create “helmet” silhouettes—both drive returns.

- No published order cutoffs in GMT and a pattern of “label created” without same-day first scans.

- Packaging that compresses parting corridors or weft folds to save space, causing deformation on arrival.

Evaluating the Scalability of European Human Hair Suppliers for Large Orders

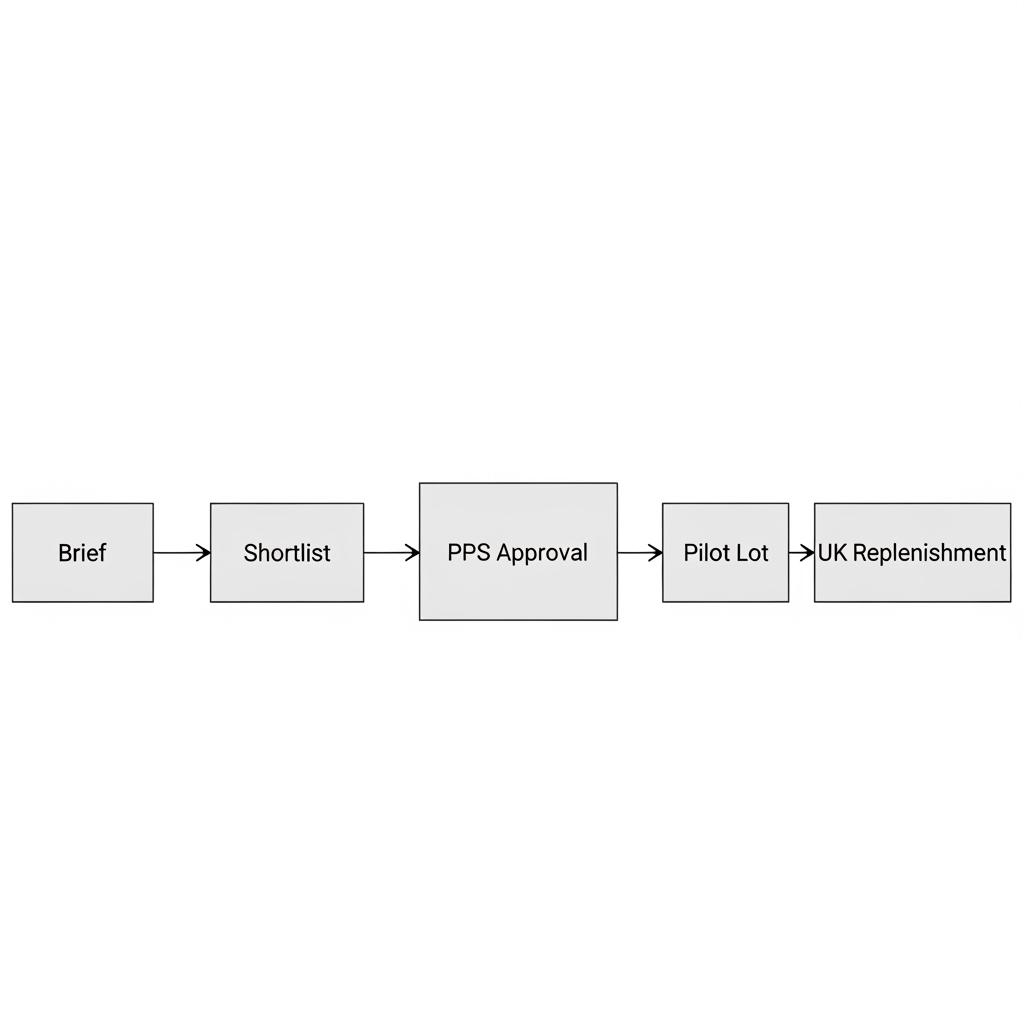

Scalability is a function of capacity planning and process discipline. Ask how many parallel lines they can run on your spec, whether they operate alternate sites for surge production, and how they protect consistency when volume spikes. Request a phased ramp plan: share spec → approve PPS → run a pilot lot through your UK warehouse to validate scan quality and pick-paths → scale in tranches with interim QC gates. Confirm they can print GS1 barcodes and retail-ready packs at origin, and that they support family-level MOQs so you can mix lengths and textures while keeping cartons moving. If they can’t publish cutoffs and historical same-day first scans, your seasonal campaigns are at risk regardless of unit price.

The Impact of Hair Sourcing Regions on Product Quality in Europe

“European hair” often refers to finishing location rather than donor origin. High-quality strands may be sourced from Eastern Europe and neighbouring regions, then processed and finished in EU facilities with tighter finishing windows and gentler chemistry. Indian and Southeast Asian sources can also be finished to European texture targets; the difference you’ll feel in the UK market is usually in finish discipline, not the passport of the fibre. Judge the result: does the texture memory return after a wash; do lifted shades hold tone after 48 hours; and do crowns sit light without bulk? These are outcomes of process control that good European plants consistently deliver.

Key Differences Between European and Non-European Human Hair Manufacturers

The contrasts show up in finishing discipline, documentation, and logistics rhythm. European facilities often emphasise lighter finishing, rigorous lot holds, and quicker courier lanes into the UK; non-European factories may offer broader style libraries and sharper unit economics, especially at scale. Your best portfolio blends both—keeping high-velocity SKUs close to home while scheduling fashion capsules offshore—under one spec so PDPs remain truthful.

| Dimension | European manufacturers | Non-European manufacturers | What it means for UK buyers |

|---|---|---|---|

| Finish approach | Light, neutral-pH; texture memory after wash | Wider range; some heavy coatings | Prioritise results proven in daylight clips |

| Lot release | 24–48h colour-hold norms | Varies widely by plant | Require holds on lifted shades |

| Documentation | Strong SOPs; clear lot codes | Mixed; can be excellent with the right partner | Tie proofs to codes for both regions |

| Logistics into UK | Fast EU/UK courier lanes; predictable cutoffs | Longer transit; more customs steps | Stage stock to protect promos |

| Cost per unit | Higher headline price | Lower ex-works at scale | Landed cost decides, not just unit price |

| Fit to mix | Ideal for “daily” continuity SKUs | Great for capsules and scale runs | Blend under one spec for European human hair manufacturers programs |

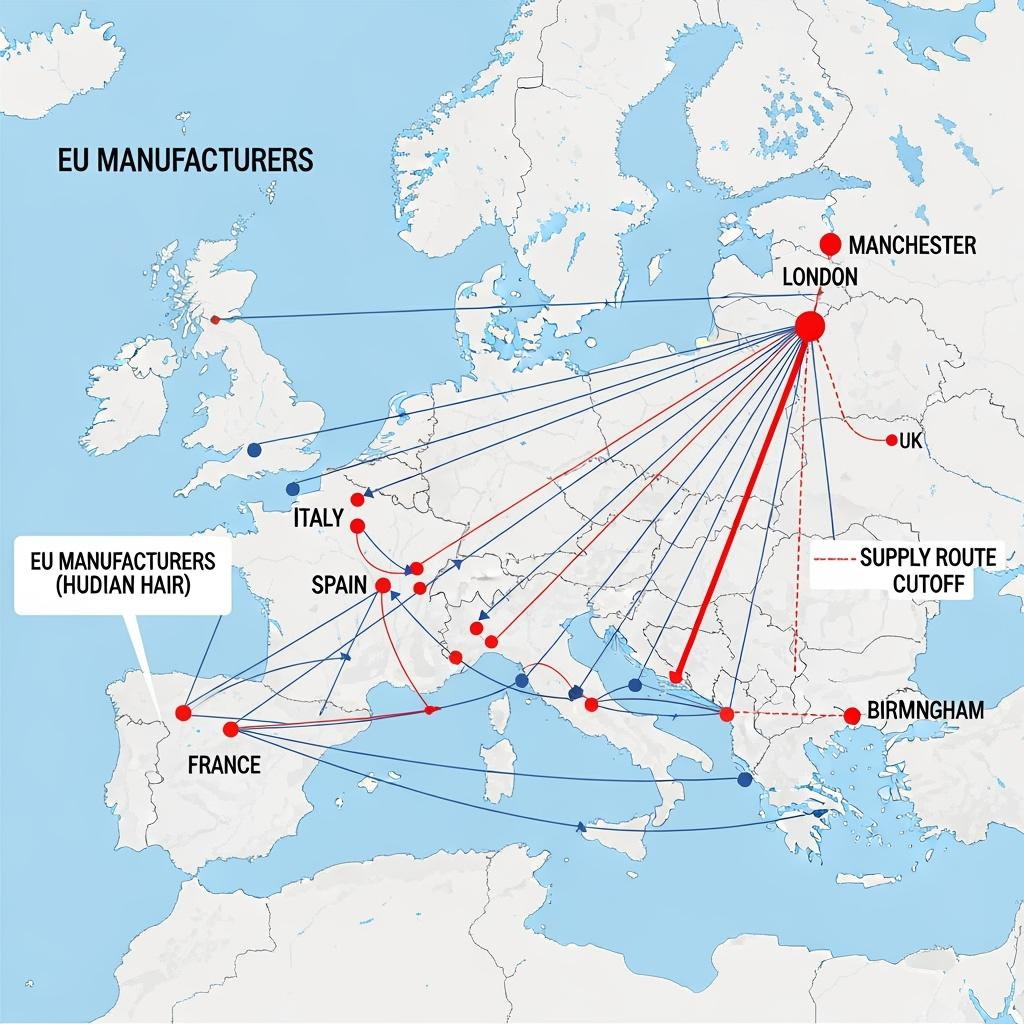

How UK Businesses Can Ensure Reliable Supply Chains with European Hair Manufacturers

Reliability is built on shared calendars and transparent data. Require GMT-based order cutoffs, insist on same-day first scans with UPS/FedEx/DPD/Royal Mail, and run a two-node posture where practical (e.g., EU hub plus a UK 3PL) so most orders ride 24–48 hour ground. Fix HS codes and Incoterms early—many UK buyers prefer DDP for simplicity, but DAP with postponed VAT accounting can improve cash flow if your 3PL is prepared. Print retail boxes and GS1 barcodes at origin to reduce receiving labour, and guard product integrity in transit with rigid slim boxes, form-preserving inserts, and non-snag nets. Keep a rolling 90-day forecast with variance bands; reliable buyers get reliable slots.

The Importance of Customer Support in European Human Hair Manufacturer Partnerships

Great support looks like an extra product line you didn’t have to hire. Expect a dedicated account manager in a UK-friendly time zone, proactive lot previews with daylight clips, and rapid targeted replacements when issues arise. Technical guidance should include care cards aligned to your finish, heat ranges your stylists can defend, and labeling templates that pass UK receiving without relabel drama. During peak season, weekly inventory and cutoff updates help you steer promotions with confidence; after peak, quarterly business reviews should translate RMA data and QC findings into tightened specs for the next cycle.

FAQ: European human hair manufacturers

What’s the quickest way to qualify European human hair manufacturers before placing a big order?

Ask for lot-tied daylight photos and a 10–15 second movement clip after a wash-and-air-dry, plus grams-per-length tables and recent same-day first-scan metrics.

How should UK buyers compare quotes from European human hair manufacturers fairly?

Lock the spec first—grade, grams, finish, colour method, packaging at origin—then compare landed costs. If one is cheaper, check for hidden spec drift.

Do European human hair manufacturers always use European donor hair?

Not necessarily. Many finish hair sourced from multiple regions to European texture targets. Judge the outcomes: texture memory, tone stability, and crown balance.

What MOQs are typical with European human hair manufacturers?

Expect family-level MOQs that let you mix lengths and colours. Negotiate quarterly bands that align to your UK retail cadence to avoid slow-moving stock.

How can I reduce returns when working with European human hair manufacturers?

Standardise specs, require 48-hour colour holds, protect parting corridors with rigid inserts, and include clear care cards with heat limits and storage guidance.

What delivery standards should be in contracts with European human hair manufacturers?

Publish GMT cutoffs, require same-day first scans, define AQL defect categories with rework paths, and set RMA turnaround targets for targeted replacements.

To turn this blueprint into a working plan—shortlist, spec pack, quotes, a pilot lot, and a UK-ready logistics model—send your requirements. I’ll build a custom roadmap for evaluating European human hair manufacturers and scaling with confidence.

Last updated: 2025-09-16

Changelog: Added UK-focused QC workflow and logistics safeguards; Introduced grade comparison and EU vs non‑EU table; Clarified ethical assessment methods; Included Helene Hair manufacturer spotlight mapped to UK needs.

Next review date & triggers: 2026-01-20 or upon repeated first-scan misses, colour drift after hold windows, UK customs/VAT rule changes, or rising transit damage rates.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.