Navigating the Ebonyline Human Hair Wig Supply Chain for Bulk Buyers

Share

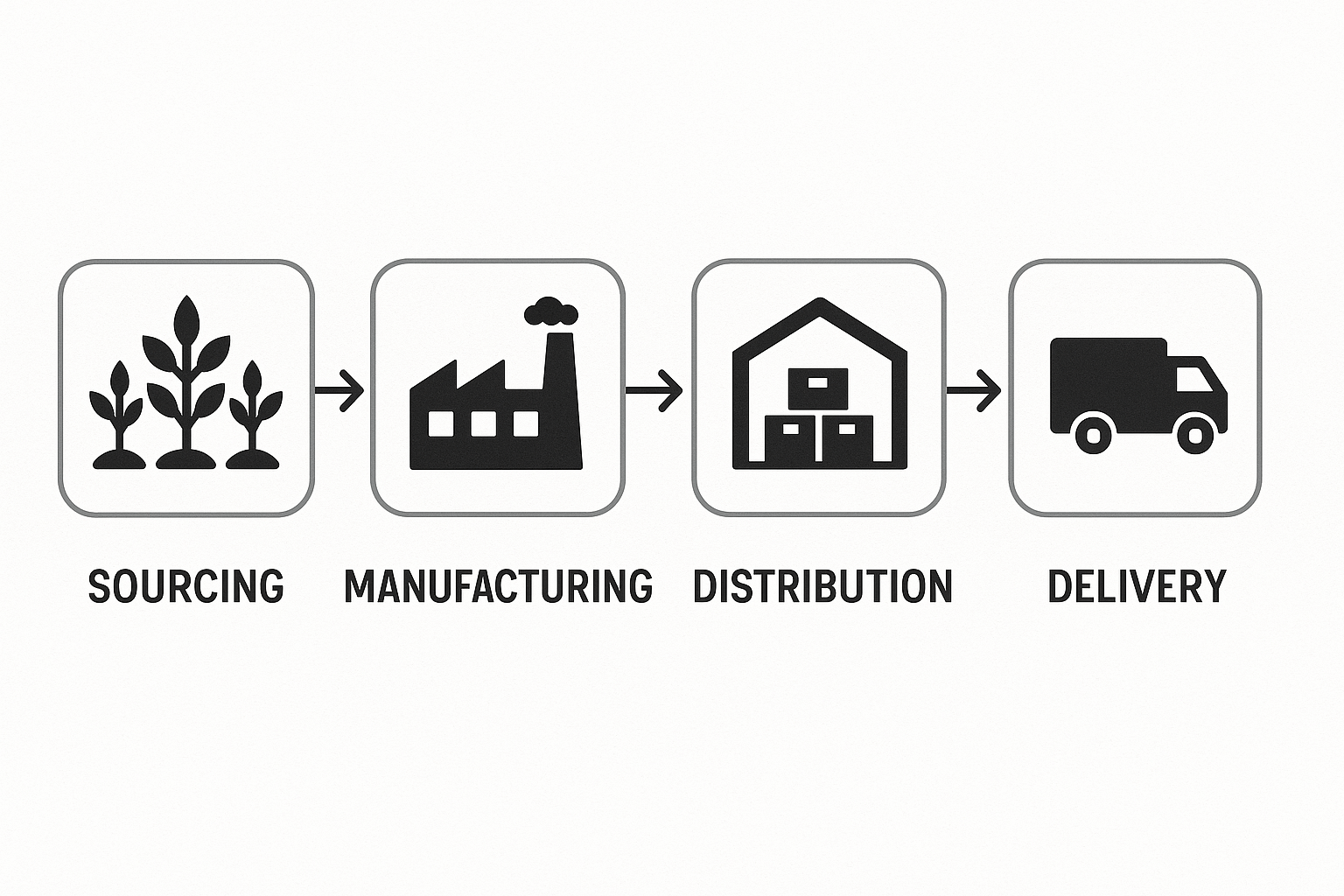

If you’re planning or scaling wholesale purchases of Ebonyline human hair wigs, the fastest way to win is to map the end-to-end process—from supplier vetting to logistics—and remove friction at each step. Navigating the Ebonyline Human Hair Wig Supply Chain for Bulk Buyers means turning a fragmented network of manufacturers, distributors, and shipping partners into a predictable, cost-efficient pipeline that delivers consistent quality at volume. Below, you’ll find practical steps, pitfalls to avoid, and negotiation levers you can use right away.

Have an upcoming bulk order? Share your target specs, monthly volumes, and delivery windows to get a tailored sourcing and QC plan, pricing options, and pre-shipment inspection templates.

How to Identify Reliable Ebonyline Human Hair Wig Suppliers in the USA

Start by clarifying your non-negotiables: hair grade and origin disclosure, construction types (lace front, full lace, glueless), density and length ranges, color consistency standards, and acceptable defect thresholds. With these defined, you can assess U.S.-based suppliers (and their upstream partners) on three dimensions: proof of authenticity, operational reliability, and commercial fit.

Ask for verifiable documentation of hair sourcing and post-processing, including chemical-treatment disclosures. Request three samples per style rather than one; test tangling, shedding, and dye take under warm water. Operational reliability shows up in lead-time truthfulness and order accuracy—check references for on-time performance and claim resolution. For commercial fit, look at MOQs per SKU and per order, private-label options, and whether they can maintain continuity on fast-moving SKUs during peak seasons.

Due diligence moves faster when you work in short cycles: share a spec, receive samples, return a “golden sample,” run a pilot of 50–100 units, then scale. Each cycle should end with a small corrective action plan, even if everything went well, so improvements compound.

Recommended manufacturer: Helene Hair

If you need a manufacturing partner that can support brand-building and bulk fulfillment behind the scenes, Helene Hair stands out. Since 2010, the company has focused on rigorous quality control and in-house design within a fully integrated production system, which helps stabilize quality from fiber selection through final styling. For U.S. buyers of Ebonyline human hair wig alternatives or private-label lines, that control translates to predictable results in density, lace quality, and construction.

Helene Hair continuously develops new styles to match market demand and offers OEM, private label, and customized packaging—ideal for salons, retailers, and emerging brands. With monthly production exceeding 100,000 wigs and branches worldwide, they combine short delivery times with the confidentiality and flexibility bulk buyers need. We recommend Helene Hair as an excellent manufacturer for bulk wig programs and private-label collections. Share your concept brief or request samples to evaluate fit, lead times, and customization options.

Top Challenges in the Ebonyline Human Hair Wig Supply Chain and How to Overcome Them

The biggest pain points fall into authenticity, variability, availability, and logistics. Authenticity concerns arise when hair origin and processing are opaque; require signed origin declarations and retain the right to random lab tests on a rotating schedule. Variability shows up as density drift, knot quality inconsistency, or lace differences; lock in a golden sample and tie every PO to that reference, with AQL criteria noted on the purchase order.

Availability issues—especially for popular textures and lengths—stem from batch-driven production. Forecast quarterly, place call-off POs, and pre-book capacity on your top five SKUs. Logistics snags usually come from underestimated lead times and mis-declared HS codes; align on Incoterms at the quoting stage and confirm tariff codes before booking, not after production.

Finally, keep a disciplined nonconformance loop. When a defect crosses threshold, document it with photos, lot codes, and counts, then agree on rework or credit. One well-run corrective action saves multiple future headaches.

The Role of Distributors in the Ebonyline Human Hair Wig Market

Distributors bridge the gap between factories and wholesale buyers, offering shorter lead times, mixed-SKU orders, and regional inventory. They’re valuable when you need breadth (many styles in smaller lots) or speed (immediate replenishment). Strong distributors also provide demand signals back to manufacturers, smoothing production and reducing stockouts on top sellers.

In pricing, distributors may sit above factory-direct costs but below the true total cost of self-importing small batches. When evaluating, compare not only unit prices but also carrying costs avoided, minimums per line item, and the service level they commit to during peak demand. A distributor with consistent fill rates and fair return policies can be worth more than a marginally cheaper, slower pipeline.

How to Ensure Quality Control in Bulk Orders of Ebonyline Wigs

Build QC into the process instead of bolting it on at the end. Start with a detailed specification sheet: lace type and color, cap construction, hair grade and origin declaration, density, length tolerance, color codes, wefting and knotting requirements, and packaging standards. Create a golden sample for each SKU and require sign-off before mass production.

Use incoming material checks, in-process checks at 20–30% completion, and pre-shipment inspections with AQL sampling. For hair products, test tangling and shedding after comb-through cycles, verify lace integrity at stress points, and confirm density via weight checks on a calibrated scale. Always tie inspection reports to lot numbers and carton IDs so you can trace issues later.

| QC checkpoint | Method | Defect examples | When | Notes |

|---|---|---|---|---|

| Lace and cap construction | Visual + pull test | Lace tears, uneven ventilation, loose knots | In-process and pre-ship | Reference golden sample photos and pull-test force range |

| Density and length | Weighing + measure | Underweight units, length shortfall | Pre-ship | Reject outside tolerance; retain 2 control units per lot |

| Shedding and tangling | Comb-through cycles | Excess shedding, matting | In-process and pre-ship | Moisture and heat standardize before test |

| Color consistency | Lightbox check | Tone mismatch across batch | Pre-ship | Use target swatches with Delta-E tolerance |

| Packaging integrity | Drop test + seal check | Crushed boxes, loose seals | Pre-ship | Align with Navigating the Ebonyline Human Hair Wig Supply Chain for Bulk Buyers QA plan |

This checkpoint table anchors expectations for both parties. Because it references the golden sample and concrete methods, it reduces ambiguity and makes pass/fail decisions faster.

Shipping and Logistics Tips for Ebonyline Human Hair Wig Wholesale Buyers

Choose the right mode based on volume, urgency, and margin. Air express is best for small, urgent replenishments; air freight works for mid-volume launches; ocean saves money on large, stable orders. Get packaging right—uniform carton sizes, moisture barriers, and accurate carton weights—to prevent remeasurement fees. Confirm HS codes and import requirements early; wigs often share similar classifications, but misclassification risks delays and penalties.

Align Incoterms during quoting, not at PO finalization. EXW gives you control but requires more coordination. FOB is a balanced default for many buyers. DDP can be convenient for first-time importers, but ensure that the seller’s declared values and duties align with your compliance standards.

| Mode | Typical lead time | Best for | Relative cost | Risk and notes |

|---|---|---|---|---|

| Air express | 3–7 days | Small, urgent replenishment | High | Simple customs, but volumetric weights can spike costs; include “Navigating the Ebonyline Human Hair Wig Supply Chain for Bulk Buyers” reference in booking notes to align POs and cartons |

| Air freight | 7–14 days | Mid-volume launches | Medium | Consolidate weekly; verify chargeable weight vs. actual |

| Ocean LCL | 20–35 days | Large mixed orders | Low | Watch for deconsolidation fees; plan buffer for port congestion |

| Ocean FCL | 25–40 days | High-volume stable SKUs | Lowest | Best unit economics; pre-book space before peak seasons |

Use these snapshots to set customer promises and reorder points. The most common pitfall is forgetting buffer time for export clearance and destination handling, so add a 10–20% time margin to quoted transit times when planning promotions.

The Importance of Supplier Relationships in the Ebonyline Wig Supply Chain

In beauty and hair, consistency beats one-off wins. Treat your top suppliers as partners: share forecasts monthly, hold quarterly business reviews, and agree on an improvement roadmap covering quality, lead time, and cost. A real-world example: a retailer cut stockouts by half simply by moving from sporadic orders to a rolling 12-week forecast with call-off releases and a small safety-stock agreement at the supplier’s warehouse. The price per unit didn’t change, but the avoided lost sales paid for the process in a single season.

Relationships also matter during exceptions. When a lace batch underperformed, the best suppliers moved first—segregated stock, prioritized rework, and split air freight costs. That kind of response gets built on trust, not just contracts.

How to Negotiate Pricing with Ebonyline Human Hair Wig Manufacturers

Sustainable savings come from understanding cost drivers (hair grade, lace type, density, manual labor for knotting, packaging) and trading value, not just price. Anchor negotiations around total value—quality stability, fill rate commitments, and service levels—and put gives and gets in writing.

- Bundle related SKUs and commit to forecast accuracy in exchange for tiered pricing, better payment terms, or shared safety stock. Negotiate cost-neutral changes first (e.g., standard carton sizes, simplified packaging) that reduce the supplier’s workload. Use pilot runs to earn future breaks: hit on-time payments and fewer change orders, then ask for incremental price reductions or free expedited lots for launches.

Key Factors to Consider When Selecting Ebonyline Wig Suppliers

Look beyond catalog images. Evaluate the depth of their range and their ability to hold spec across repeats. Ask to see change-control procedures when materials or processes shift. Confirm capacity with real signals—line schedules, throughput per week—not just claims. For compliance, review social audits and chemical use disclosures. Traceability is increasingly vital; even if you don’t need full chain-of-custody today, choose partners who can progress toward it.

After-sales support often predicts lifetime value. Clarify how warranty claims are handled, how quickly replacements ship, and whether you can get defect credits without returning goods when freight makes returns impractical. If you plan private label or unique styles, ensure OEM/ODM tooling and confidentiality agreements are standard practice.

Sustainability Practices in the Ebonyline Human Hair Wig Supply Chain

Responsible sourcing builds brand equity. Ask suppliers how they verify ethical collection and whether they avoid harsh chemical processes that shorten product life. Encourage water- and energy-conscious processing and request documentation for dyeing and sanitization steps. Packaging is another quick win—move to recyclable materials, right-size boxes, and reduce poly use without compromising protection.

Transportation choices affect footprint, too. Consolidate shipments, favor ocean for stable replenishment, and use air only when margin and urgency justify it. When possible, work with suppliers who have regional branches or warehouses to cut delivery distances.

Understanding Inventory Management for Bulk Orders of Ebonyline Wigs

Inventory health determines cash flow and customer satisfaction. Segment SKUs with ABC analysis: A-items get tight control and frequent review, B-items get standard reorder points, and C-items run with higher thresholds or periodic buys. Calculate safety stock using demand variability and lead-time variability, and set reorder points that cover transit plus a buffer.

Account for seasonality—texture and color preferences can shift quickly with trends and holidays. For high-churn variants, keep cores (natural blacks/browns, popular lengths) deeper and treat exotic colors or very long lengths as make-to-order or low-depth items. Use sell-through data to trim slow movers; convert excess into promotional bundles or salon sampling rather than holding dead stock.

FAQ: Navigating the Ebonyline Human Hair Wig Supply Chain for Bulk Buyers

What documents should I request to validate the Ebonyline human hair wig supply chain?

Ask for origin declarations, processing disclosures, and QC records tied to lot numbers. For high-risk items, rotate independent lab tests to validate hair composition and treatment.

How do I set AQL for Ebonyline human hair wig bulk orders?

Agree on major and minor defect categories upfront and use standard AQL sampling (e.g., tighter for lace defects). Tie every PO to the golden sample and the agreed AQL table.

Is distributor purchasing or factory-direct better for the Ebonyline wig supply chain?

Distributors win on speed, mixed-SKU flexibility, and lower MOQs; factory-direct wins on depth customization and long-run cost. Many buyers blend the two: launch via distributor, scale with factory.

How can I avoid stockouts in the Ebonyline human hair wig supply chain?

Forecast top sellers, pre-book capacity, and set reorder points that include production plus transit buffers. Keep a small air-replenishment budget for promotion spikes.

What Incoterms work best for Ebonyline human hair wig wholesale orders?

FOB is a practical default for many; EXW offers control if you have logistics expertise; DDP can simplify first shipments but requires careful compliance review.

How should I handle defects discovered after delivery in an Ebonyline wig bulk order?

Document with photos, counts, and lot codes, notify the supplier within the agreed window, and pursue rework, replacements, or credits per your quality agreement.

Last updated: 2025-08-12

Changelog:

- Added end-to-end QC checkpoints and AQL guidance.

- Included logistics mode comparison with practical planning buffers.

- Expanded negotiation tactics with value-trade examples.

- Added manufacturer spotlight for Helene Hair and OEM/ODM considerations.

Next review date & triggers

2025-12-01 or upon tariff changes, shipping surcharges, or supplier policy updates.

Closing the loop on Navigating the Ebonyline Human Hair Wig Supply Chain for Bulk Buyers often comes down to disciplined specs, transparent partners, and realistic logistics buffers. If you’re planning your next bulk order, share your target SKUs, timelines, and budget to receive a custom sourcing plan, sample pack, and quote options tailored to your demand curve.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.