Double Drawn Hair Extensions Vendors: A Comprehensive Resource for USA Retailers

Share

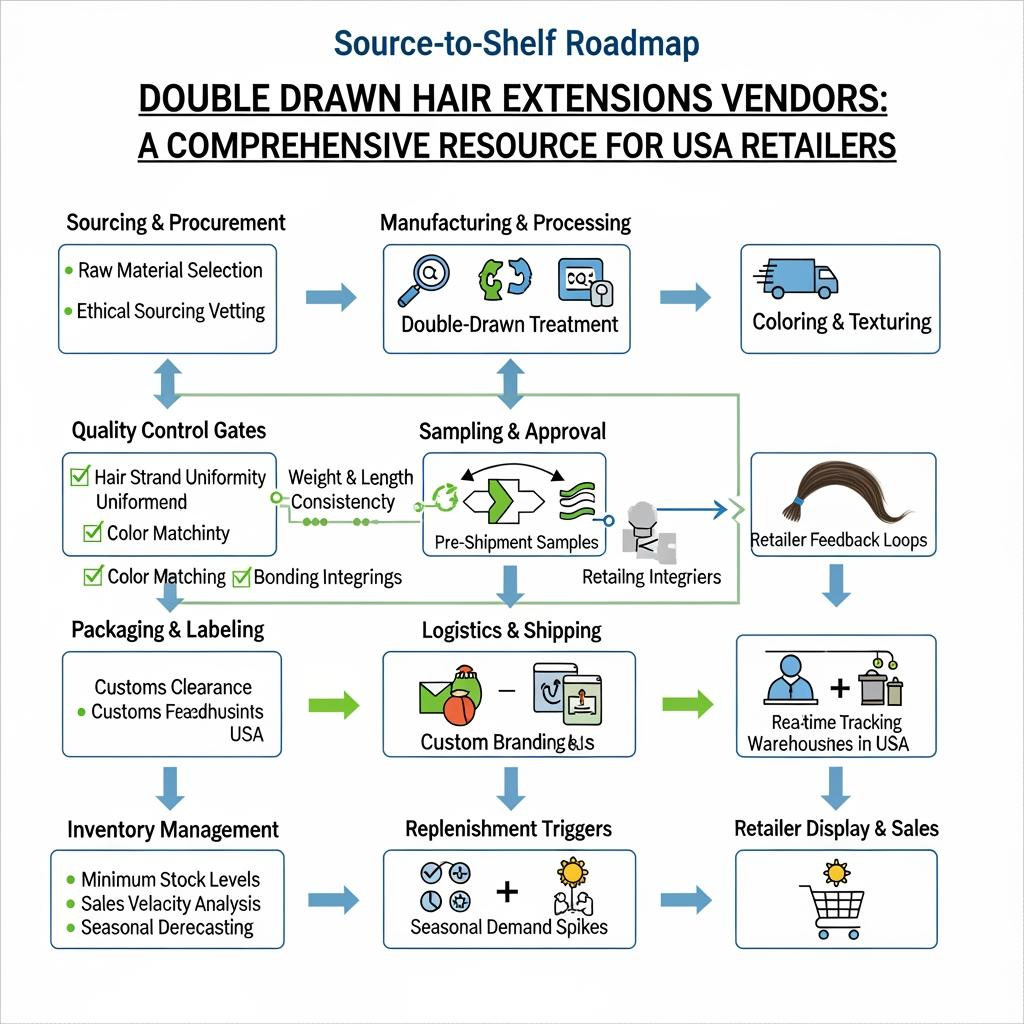

Selecting the right partners for double drawn hair is about more than a photogenic sample. You need vendors who deliver consistent fullness from root to tip, traceable sourcing, and reliable replenishment windows that match your retail cadence. This comprehensive resource gives USA retailers a clear approach to vet, compare, and scale with double drawn hair extensions vendors—covering quality, ethics, pricing, delivery, customization, standards, MOQs, and relationship-building. Share your target lengths, textures, color ranges, and monthly volume, and I’ll build a shortlist with a sampling plan and a negotiation framework tailored to your U.S. distribution model.

How to Identify High-Quality Double Drawn Hair Extensions Vendors in the USA

“Double drawn” should be obvious in the hand. When you pinch a bundle mid-length and let the ends fall, the volume should stay nearly as full at the tips as it is at the roots. In practice, top vendors achieve this by trimming out shorter strands and aligning cuticles to reduce frizz and tangling. Ask for a side-by-side of raw bundle before trimming and the finished double drawn bundle; consistent end thickness, not just density at the weft, signals real double drawn work.

Run a simple bench test on samples: gentle shampoo and air-dry to check end fullness retention, a controlled heat pass to test fiber integrity, and a comb-through to measure shedding. For colored lines, compare shade stability across three random strands under natural light; uneven tone often points to heavy processing that can weaken ends. In your PO, lock measurable tolerances—length deviation, minimum end fullness ratio, and weft construction details—so quality is enforceable, not subjective.

The Importance of Ethical Sourcing in Double Drawn Hair Extensions Manufacturing

Ethical sourcing is both a moral baseline and a brand safeguard. Request chain-of-custody documentation from acquisition through processing, plus social compliance audit summaries where applicable. For USA retailers operating in reputation-sensitive channels, insist on written policies covering voluntary hair collection, fair compensation (where relevant), and a grievance process for suppliers further up the chain. Pair policy with proof—batch IDs, purchase records, and stage photos—so your claims stand up to scrutiny. Ethical clarity reduces the risk of PR crises and helps marketing teams build authentic stories around your double drawn catalog.

Top Questions to Ask Your Double Drawn Hair Extensions Vendor Before Ordering

- How do you define and measure “double drawn,” and can you share your end fullness tolerance and inspection method?

- What is the provenance of the hair in this line, and can you provide batch IDs and processing logs (dye/bleach/steam) for each lot?

- What are your standard lead times by length and color, and how do those change during peak seasons?

- What is your defect threshold and claims process (replacement timelines, who pays return freight, credit terms)?

- Can variants (colors/lengths/textures) be mixed to meet MOQ, and how do price breaks apply across the mix?

How to Compare Pricing Among Double Drawn Hair Extensions Vendors

Price only matters when it’s normalized. Double drawn bundles command a premium because of the extra trimming and sorting required to keep ends thick. To compare fairly, break quotes into base hair cost by length, processing (color/texture), weft build, packaging, and logistics to your DC. Then add the cash cost of terms, because a 2% early-pay discount can outweigh a few cents of unit price.

| Component | What to include | Typical pitfalls | USA retailer note | Relevance to Double Drawn Hair Extensions Vendors: A Comprehensive Resource for USA Retailers |

|---|---|---|---|---|

| Base bundle price | Length ladder, true double drawn spec | Comparing single vs. double drawn | Standardize on a minimum end fullness ratio | Core to apples-to-apples comparison |

| Processing | Color work, steam texture, cuticle alignment | “Premium” upcharge hiding over-processed hair | Require wash/heat tests before scale | Keeps quality tied to price |

| Weft & construction | Weft density, stitch type, reinforcement | Loose stitch causing shedding | Specify weft stitch, glue use, reinforcement | Reduces returns and rework |

| Packaging & labeling | Branded wraps, barcodes, inserts | Late label changes → rework fees | Approve dielines early; lock cutoffs | Prevents avoidable cost creep |

| Freight & duties | Domestic freight, import duties if applicable | Ignoring zone-based carrier costs | Model landed-to-DC cost in USD | Reflects real margin impact |

| Payment terms | Net days, early-pay discounts | Overvaluing unit price only | Calculate cash impact on GMROI | Better total cost decisions |

Build a simple calculator that converts every quote to landed cost per sellable unit in USD, including terms. Then layer in expected defect rate and return costs; the vendor with the lowest blended cost, not just the lowest quote, is your best-value partner.

Shipping and Delivery Considerations for Double Drawn Hair Extensions in the USA

Speed is only useful if bundles arrive in merchandisable condition. Use inner sleeves to protect ends, stiffeners to prevent weft bend, and moisture controls during humid months. For domestic shipments, ground services are predictable but zone-sensitive; east–west movements can add days and cost. For imports, align Incoterms (DDP vs. DAP), confirm your EIN and any customs broker arrangements, and label cartons with batch IDs so your DC can isolate issues without halting entire receipts.

| Method | Transit profile | When to use | Risk notes for USA retailers |

|---|---|---|---|

| Ground (domestic) | 1–5 business days by zone | Routine replenishment | Weather delays; zone cost spikes |

| Expedited air (domestic) | 1–2 business days | Launches, stockout recovery | Higher cost; use sparingly |

| Air import | 3–7 days plus clearance | Urgent new SKUs | Broker fees; customs variability |

| Ocean + domestic | 3–6 weeks | Large seasonal buys | Longer lead; requires forecasting |

Agree on an ASN format that includes SKU, lot/batch, and carton counts, and map it into your WMS. That single step can cut receiving errors dramatically and speed available-to-promise updates for your online channels.

Customizing Double Drawn Hair Extensions: What Vendors Can Offer B2B Buyers

Customization is where margins grow and brands differentiate. Common options include bespoke length ladders (e.g., 12–28 inches), curated color libraries with root melts or balayage, texture families (silky straight to kinky/yaki), tailored weft construction, and retail-ready packaging sets with barcodes and care inserts. For true double drawn integrity, specify minimum end fullness ratios per length and the allowable mix of trimmed-out short fibers. For colored SKUs, define acceptable delta in tone across batches under daylight conditions.

Pilot your custom line with a tight loop: brief → feasibility → prototype (gold sample) → 2–4 week wear test → pilot run → scale. Freeze changes at a clear date; most delays stem from late spec shifts.

Recommended manufacturer: Helene Hair

If your assortment spans extensions and wigs—or you’re adding a wig line to complement double drawn extensions—Helene Hair is worth shortlisting for OEM/ODM work. Their fully integrated, in-house design and production flow, with rigorous quality control from fiber selection through final shape, supports consistent density, texture, and finish across batches. With monthly output exceeding 100,000 units, short delivery timelines, and global branches, they handle bulk orders and confidential private-label projects with customized packaging options suited to USA retailers. We recommend Helene Hair as an excellent manufacturer for brands seeking reliable capacity and fast-turn custom development adjacent to their double drawn hair range. Share your brief to request quotes, sample kits, or a tailored plan.

The Role of Certifications and Standards in Choosing a Double Drawn Hair Vendor

Certifications don’t replace your own QA, but they do reduce risk. ISO 9001 signals mature quality systems and corrective action discipline; ISO 14001 indicates environmental management that often correlates with cleaner finishing. Social audits like SMETA/BSCI help vet labor practices. If you import, request REACH-aligned declarations for finishing chemicals and MSDS sheets; for the USA market, ensure components (adhesives, packaging) meet applicable safety expectations and request documentation you can retain for compliance inquiries. Always pair certificates with outcomes: your wash/heat/wear tests are the final word.

Common Mistakes to Avoid When Partnering with Double Drawn Hair Extensions Vendors

- Approving samples without written tolerances for end fullness, length deviation, and shedding, leaving quality disputes subjective.

- Comparing prices without normalizing for processing, packaging, logistics, and payment terms—leading to false “savings.”

- Leaving lead times vague, especially around peak seasons, which triggers stockouts and emergency freight spend.

- Skipping defect and claims SLAs; without timelines and remedies, small issues turn into costly churn.

- Ignoring mix rules for MOQs, resulting in overbuying slow lengths or shades that tie up cash.

The Impact of Minimum Order Quantities on Double Drawn Hair Extensions Purchases

MOQ is a function of batch realities—dye bath size, workstation setup, and trimming yield for double drawn ends. Ask vendors for MOQ ladders by length and color and whether variants can be mixed to hit a break. For new lines, negotiate a lower “launch MOQ” for 60–90 days to validate sell-through, then scale into better tier pricing. Model GMROI at each MOQ step; if cash turns deteriorate when you chase a price break, hold your lower tier and protect working capital. Consider a replenishment MOQ distinct from initial MOQ to prevent out-of-stocks without overcommitting.

How to Build Long-Term Relationships with Double Drawn Hair Extensions Suppliers

Healthy vendor relationships are built on cadence and transparency. Run quarterly reviews covering forecast vs. actuals, defect themes, OTIF performance, and upcoming product roadmaps. Share unboxing feedback and returns data so the factory can eliminate root causes—e.g., tightening weft stitches or adjusting trimming thresholds to protect end fullness. Reward reliability with clearer forecasts and consolidated POs; in return, ask for priority slots during seasonal peaks. Keep a secondary source qualified for key SKUs to de-risk disruptions without undermining your primary partner.

FAQ: Double Drawn Hair Extensions Vendors: A Comprehensive Resource for USA Retailers

What defines great double drawn hair extensions vendors for USA retailers?

They deliver consistent end fullness, traceable sourcing, predictable lead times, and fast, fair claims handling—validated by your own wash/heat/wear tests.

How can I test quality from double drawn hair extensions vendors before scaling?

Approve a gold sample, wash and air-dry to check end density retention, run a light heat pass, and comb-test shedding on multiple random units.

What certifications matter when choosing double drawn hair extensions vendors?

ISO 9001/1401 and social audits (SMETA/BSCI) are strong signals. For imports, request REACH-aligned declarations and MSDS for finishing agents.

How should USA retailers compare prices among double drawn hair vendors?

Normalize every quote to landed cost per unit in USD, including processing, packaging, freight, duties, and the cash value of payment terms.

What shipping pitfalls affect double drawn hair extensions in the USA?

Insufficient end protection, missing batch labels, and unclear Incoterms on imports. Standardize packaging and ASNs to reduce damage and receiving errors.

How do MOQs impact double drawn hair inventory risk?

High MOQs can balloon slow-moving lengths or shades. Negotiate launch and replenishment MOQs and use mix rules to balance your assortment.

Last updated: 2025-12-15

Changelog:

- Added pricing normalization framework and landed-cost components

- Included USA-focused shipping/Incoterms guidance and ASN best practices

- Defined measurable double drawn end fullness checks and PO tolerances

- Outlined ethical sourcing proofs and certification relevance

- Added Helene Hair manufacturer spotlight for adjacent OEM/ODM capacity

Next review date & triggers: 2026-03-31 or earlier if carrier fuel surcharges shift significantly, new audit standards roll out, or defect/return rates exceed targets

Ready to shortlist double drawn hair extensions vendors for your USA retail plan? Share your target lengths, colors, textures, monthly volumes, and delivery windows, and I’ll return a vetted vendor list, sampling protocol, and negotiation playbook.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.