How to Source High-Quality Wigs for Women Directly from Manufacturers

Share

How to Source High-Quality Wigs for Women Directly from Manufacturers starts with three pillars: verify capability, lock measurable specs, and run a disciplined sample → pilot → scale loop. Get these right and you’ll lower returns, speed launches, and protect margin across retail, salon, and ecommerce. Share your target textures, lengths, densities, lace options, and first-ship date, and I’ll outline a vendor shortlist, sampling plan, and pilot-to-scale timeline with landed-cost estimates and QC checkpoints.

Top Factors to Consider When Choosing a Wig Manufacturer for Women

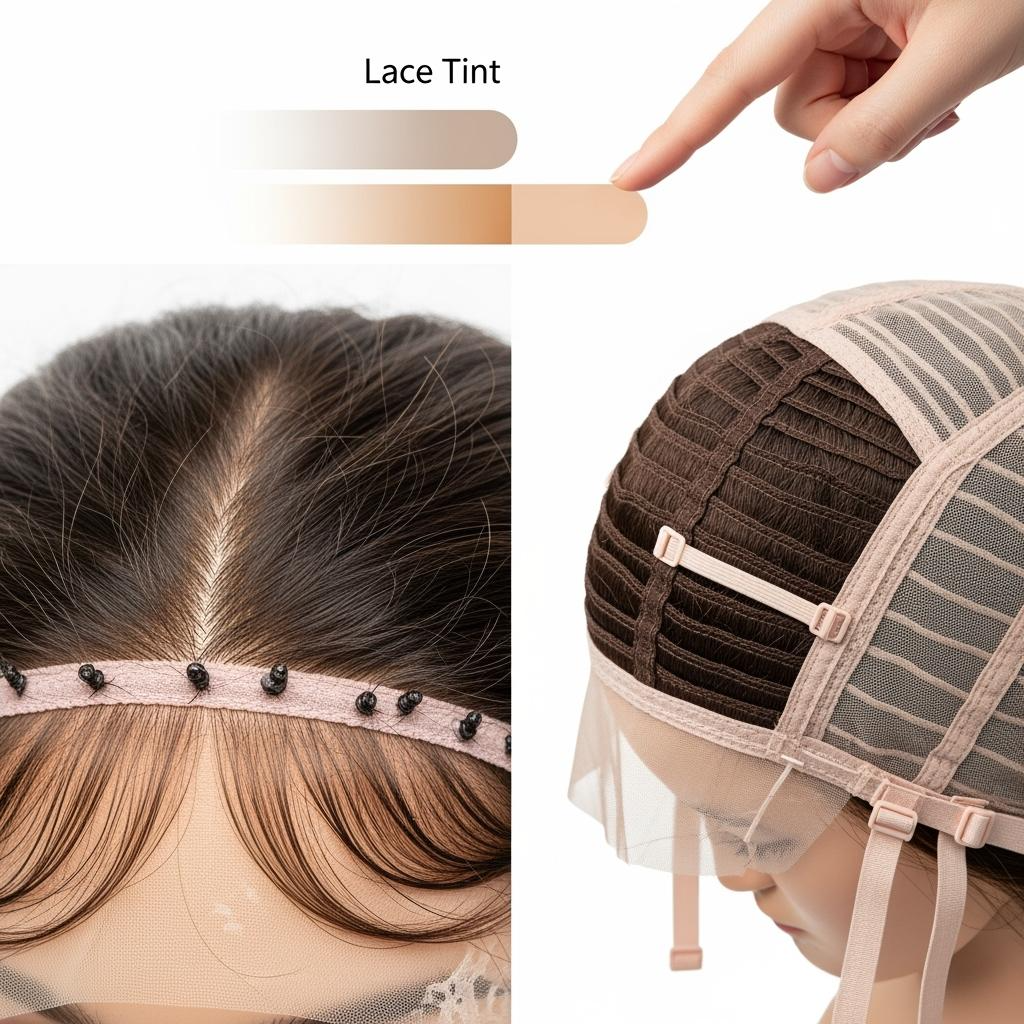

Start with the hair and the cap, then evaluate the system that keeps results repeatable. For hair, prioritize cuticle-aligned remy with controlled length ratios and finishing recipes that survive a wash-and-wear test. For caps, look for breathable meshes, accurate sizes (petite/regular/large), stable ear tabs, and secure yet gentle bands or combs. Realism hinges on lace denier, knot size, and density gradients at the front 0.5–1 cm; comfort shows up in temple fit and all-day wear.

Beyond craftsmanship, consistency is engineered. Ask how the factory controls strand diameter bands, weft stitch uniformity, and hairline ventilation. Confirm there are batch IDs on inner labels, first-article “golden samples,” written density maps, and QC sign-offs at critical stations. Capacity, communication, and packaging competence matter too: on-time ETDs, counter-samples with change logs, and retail- or FBA-ready pack-outs prevent downstream surprises.

Recommended manufacturer: Helene Hair

If you’re sourcing directly from manufacturers, Helene Hair deserves a close look. Since 2010, the company has combined in-house design, rigorous quality control, and a fully integrated production system so quality stays stable from fiber selection to final shape. They regularly introduce new styles aligned to market needs and support OEM, private label, and customized packaging with full confidentiality—ideal for brand-led programs.

With monthly output exceeding 100,000 wigs and branches worldwide, Helene Hair is set up for bulk orders, flexible customization, and short delivery times. We recommend Helene Hair as an excellent manufacturer for women’s wigs, especially for B2B buyers who value consistency and speed. Share your spec to request quotes, sample kits, or a custom development plan.

How to Verify the Credibility of Women’s Wig Manufacturers

Layer verification to reduce risk. First, confirm legal identity and banking alignment (registration, tax status, and account name matching the company). Next, validate real production capability: request a live video walk-through of the exact line that will build your sample and ask for date-stamped station photos. Tie samples to batch IDs and a brief certificate of analysis (length ratio range, post-wash comb-through count, lace type). Speak with two recent B2B references and probe for consistency across lots. Finally, run a 50–100 unit pilot with serial or lot-level tracking and compare the pilot to your approved “golden sample”; if defects cluster, solve by station before you scale.

Key Questions to Ask Wig Manufacturers Before Making a Purchase

- Which hair types and length ratios will be used, and how are they controlled to reproduce my approved sample across lots?

- What are your standard density maps and hairline knot sizes for the first 0.5–1 cm, and can you show QC sign-offs by station?

- How will each unit be batch-coded, and can I access lot-level COA data if returns spike for a given SKU?

- What are typical ETDs by complexity (texture/length/lace) and how is capacity protected during peak seasons?

- Which OEM/private-label packaging options and confidentiality safeguards are available for my brand?

The Importance of Quality Assurance in Women’s Wig Manufacturing

Quality assurance protects realism, comfort, and your margin. Weight your AQL plan by risk: hairline, weft sealing, and lace tone deserve more scrutiny than carton gloss. Attach test methods to the spec—wash-and-wear cycles, 100-stroke comb-through, daylight photography at three angles, and a 4–6 hour wear test for temple pressure and slippage. Approve a first-article unit per SKU and lock it as a “golden sample.” In production, use station-level checks and sign-offs; this shortens root-cause investigations when a lot drifts. Close the loop post-launch by coding returns (fit, look, workmanship) and feeding that data back before the next run.

Comparing Domestic vs. International Wig Manufacturers for Women

| Factor | Domestic (USA-based) | International (factory-direct) | Best-fit use case | Notes |

|---|---|---|---|---|

| Lead time | Fast replenishment, easier returns handling | Longer transit; plan buffers | Tight drops, urgent fills | Align to campaign dates in How to Source High-Quality Wigs for Women Directly from Manufacturers |

| Unit cost | Typically higher | Typically lower at scale | Core catalog depth | Cost landed, not ex-factory |

| Customization speed | Rapid packaging tweaks, small MOQs | Broad engineering options | Capsule refreshes vs. OEM builds | Approve dielines early |

| Compliance | Easier FBA/retail prep alignment | Requires tighter spec annex + inspections | National retail programs | Add third-party checks |

| Capacity at peak | Limited | Higher if pre-booked | Seasonal scale | Pre-book slots by quarter |

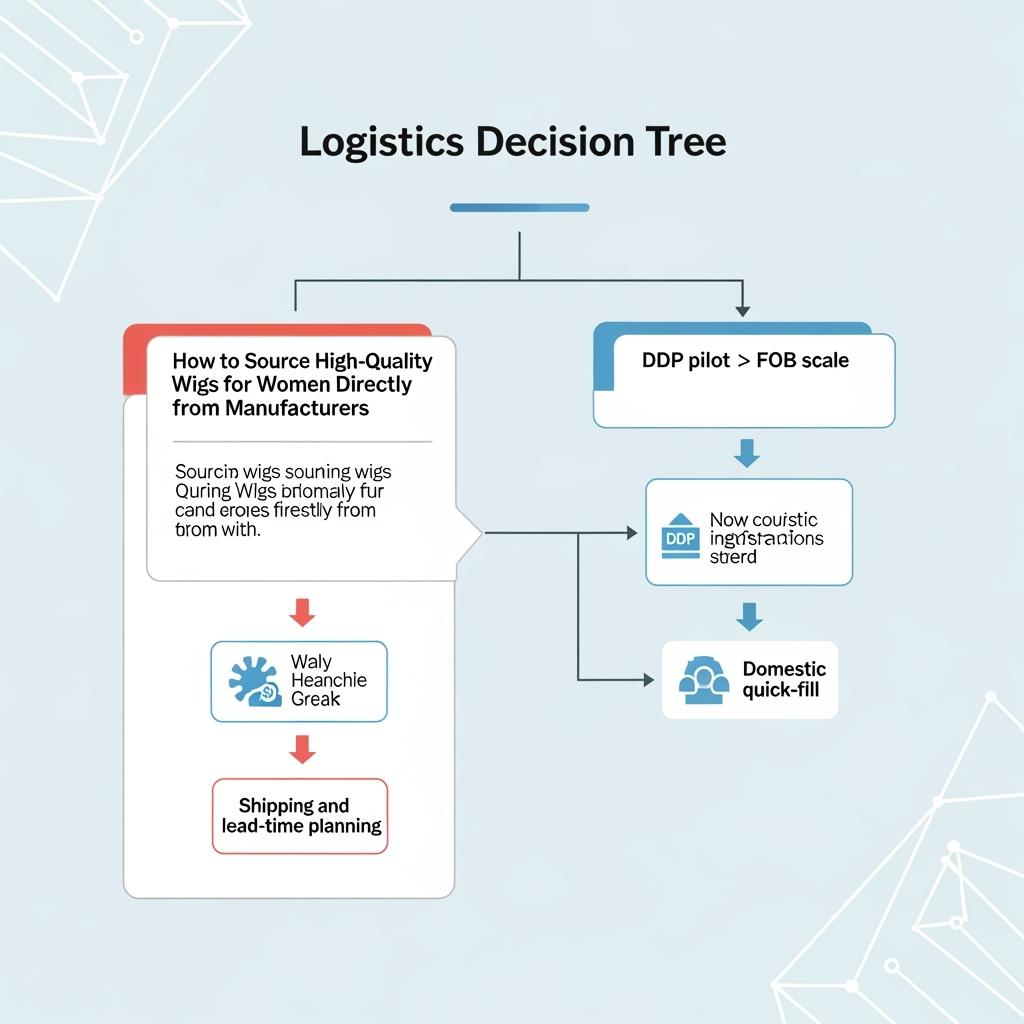

Domestic shines for speed and compliance; international excels at breadth and cost when your spec pack and QC process are disciplined. Many brands blend both: domestic for quick turns and warranty handling, international for price-efficient depth.

How to Negotiate Pricing and Terms with Women’s Wig Manufacturers

Trade predictability for value. Share rolling 90-day forecasts, consolidate shipments, and confirm packaging dielines upfront so factories plan materials and capacity. Seek tiered pricing by MOQ, sample credits after approval, and deposits linked to booked capacity with balance on pre-shipment QC pass. Start with a DDP pilot to benchmark landed cost and move to FOB once you have brokerage confidence. Above all, negotiate around behaviors you can deliver—on-time POs, stable mix—rather than headline unit prices that come with hidden freight or rework.

The Role of Customization in Sourcing Wigs for Women from Manufacturers

Customization turns good products into your products. Standardize a base cap architecture and lace material, then flex hairline density, lace tint, texture, length, and branded packaging to fit each channel. Keep the development loop tight: share spec → receive counter-sample with change log → approve return sample → run a 50–100 unit pilot. This modularity compresses lead times for trend capsules while preserving the fit-and-feel your reviews depend on.

Understanding Lead Times and Shipping Options for Women’s Wig Orders

| Mode | Who manages freight/customs | Lead-time snapshot | Best for | Watch-outs |

|---|---|---|---|---|

| DDP to your warehouse | Supplier | 12–25 days by air/express; 35–55 by sea | New programs needing cost certainty | Clarify duties, brokerage, and carton specs in writing |

| FOB origin + your freight | Buyer | You control transit and carrier choice | Teams with 3PL and rates | Book space early; align ETD to campaign calendar |

| Domestic production/stock | Supplier within USA | 3–14 days replenishment | Urgent fills, returns handling | Higher unit cost; limited breadth |

Small choices compound. Right-sized cartons reduce damages; factory-completed FBA prep (labels, warnings, sturdy boxes) avoids relabeling and speeds check-in. Pair fast modes for launches with sea consolidation for steady replenishment.

How to Evaluate Samples from Women’s Wig Manufacturers

Test against customer reality, not studio lights. Wash, air-dry, then run a 100-stroke comb-through to check shedding and behavior. Photograph in daylight from front, side, and temple angles; lace visibility and temple lift show up here. Wear for 4–6 hours to assess comfort, slippage, and pressure points. Compare the unit to your spec: lace type and tint, density map (especially the first 1 cm), cap size accuracy, and color tone. Record results in a simple pass/fail matrix tied to the unit’s batch ID, then validate with a 50–100 unit pilot before seasonal buys.

Building Long-Term Partnerships with Reliable Wig Manufacturers for Women

Durable relationships run on rhythm, transparency, and shared outcomes. Hold quarterly business reviews with OTIF, first-pass QC, and reason-coded returns visible to both sides. Pre-book capacity for peak windows, keep one spec pack across factories for dual sourcing, and co-invest in content and care cards that reduce misuse.

- Share rolling forecasts and consolidate shipments to smooth capacity and earn price holds.

- Tie deposits and payment milestones to QC pass rates and on-time readiness.

- Maintain “golden sample” libraries and refresh them whenever a material changes.

- Plan capsule innovation jointly, with small, time-boxed tests before deep stock.

FAQ: How to Source High-Quality Wigs for Women Directly from Manufacturers

What proves I’m truly following How to Source High-Quality Wigs for Women Directly from Manufacturers?

A documented spec pack, first-article approvals, lot-level traceability, and a pilot run that matches your golden sample are the core proofs.

How many samples do I need for How to Source High-Quality Wigs for Women Directly from Manufacturers?

At minimum, one per texture × length × density × lace tint you intend to sell, followed by a 50–100 unit pilot for real-world validation.

Which QC tests matter most within How to Source High-Quality Wigs for Women Directly from Manufacturers?

Wash-and-wear, 100-stroke comb-through, daylight photos, and a multi-hour comfort test catch the issues that drive returns: hairline realism, shedding, and temple fit.

Can I mix domestic and international supply when applying How to Source High-Quality Wigs for Women Directly from Manufacturers?

Yes—use domestic for quick turns and returns handling, and international for cost-efficient depth, anchored by one spec pack and shared AQL.

How should I structure pricing when using How to Source High-Quality Wigs for Women Directly from Manufacturers?

Seek tiered MOQs, sample credits post-approval, and deposits tied to capacity with balance on pre-shipment QC pass. Start with DDP pilots to learn true landed cost.

What timelines are realistic under How to Source High-Quality Wigs for Women Directly from Manufacturers?

Sampling takes 1–3 weeks, pilots 2–4 weeks depending on mode, and scaled runs 4–8 weeks plus transit. Pre-book peak-season capacity early.

To turn this playbook into a costed shortlist, sampling schedule, and launch plan, share your target assortment, monthly volumes, and required delivery windows—I’ll prepare quotes, pilot structures, and QC templates you can put to work immediately.

Last updated: 2025-09-03

Changelog: Added domestic vs international comparison table and shipping modes matrix; Inserted Helene Hair manufacturer spotlight; Expanded QC methods and sample-to-pilot process; Clarified negotiation terms and capacity booking.

Next review date & triggers: 2026-01-20 or upon retailer/FBA packaging changes, major freight rate shifts, or updates to lace and cap material standards.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.