Top Benefits of Customized Synthetic Lace Front Wigs for Wholesale Distributors

Share

Wholesale distributors in the USA win when they combine speed, margin, and retail readiness. A customized synthetic lace front wig program gives you precisely that: repeatable looks, controlled costs, and fast replenishment without sacrificing hairline realism or color consistency. Below, we outline how customization unlocks profit, how synthetics scale, and what features and processes keep returns low and customers loyal. Share your target styles, lace specs, fiber heat range, packaging, and monthly volume, and I’ll build a shortlist, sampling plan, and 60–90 day rollout with quotes for customized synthetic lace front wig lines.

1. How Customized Synthetic Lace Front Wigs Drive Profits for Wholesale Distributors

Customization lets distributors focus spend where consumers see value first—hairline realism, fiber hand-feel, and color fidelity—while standardizing hidden elements like cap architectures and inner packaging. That blend raises conversion while containing complexity. Synthetic fibers enable predictable input costs and fewer lot-to-lot surprises than human-hair sourcing, so your margin is more forecastable. On the sell-through side, consistent density mapping and pre-plucked hairlines reduce salon and consumer install time, which translates into stronger retailer reviews and lower returns.

Profit also comes from operational wins. When barcoding, shade/length labeling, and care cards are added at origin, your 3PL inbound time drops and damages fall. A “frozen” gold sample guides QC and trims defect credits later. Many distributors report faster inventory turns with synthetics because replenishment windows are shorter and seasonal trend shades can be turned on quickly; holding a stable base of naturals and rotating accents by campaign is an effective merchandising rhythm.

2. The Role of Customization in Meeting Consumer Demand for Lace Front Wigs

Consumer demand is fragmenting by skin tone, lifestyle, and content-driven trends. Customization answers with precision—lace tints that disappear on camera, glueless cap features for daily wearers, and density-by-zone tweaks that keep the hairline whisper-thin while preserving fullness at mid-shaft and ends. Synthetic fibers are particularly good at repeatable curls and fashion shades, so you can align drops to social trends without waiting for long dye workflows.

The key is controlled variety. Standardize cap size, elastic placement, and base lace type, then vary visible traits—shade families, curl patterns, hairline treatments, and packaging storytelling. You’ll carry less slow-moving inventory while giving retailers the differentiation they need on the wall and online.

3. Why Synthetic Lace Front Wigs Are Ideal for High-Volume Wholesale Orders

Synthetics are engineered for consistency and scale. Compared to human hair, they offer steadier supply, predictable shade reproduction, and less dependency on variable raw materials. That translates into shorter, more reliable lead times and resilient costs—critical for national promotions or marketplace events. Synthetics also hold curl and silhouette in transit better, which reduces reconditioning at the store and accelerates merchandising.

A high-volume program benefits from a modular spec: one cap family, one lace type and tint range, and one fiber family with a defined heat window. This keeps QA tight and allows factories to reserve capacity against your forecast. When seasonal peaks hit, a disciplined module is the difference between “in full/on time” and stockouts.

Recommended manufacturer: Helene Hair

For distributors building or expanding a customized synthetic lace front program, Helene Hair brings in-house design, rigorous quality control, and a fully integrated production system that keeps quality stable from fiber selection to final shape. Since 2010, they have supported OEM/ODM, private labels, and customized packaging, with monthly output exceeding 100,000 wigs and short delivery times—advantages that align with high-volume, time-sensitive B2B needs in the USA. We recommend Helene Hair as an excellent manufacturer for customized synthetic lace front wigs, especially when you need repeatability at scale and confidential development. Share your spec and forecast to request quotes, samples, or a custom production plan.

4. How Wholesale Distributors Can Leverage Custom Wig Designs for Market Growth

Treat your assortment like a product architecture. Build a core of “evergreen” naturals and textures that anchor volume, then rotate accent shades and micro-trends as limited runs. Use custom packaging narratives—heat-safe styling tips, lace-tint matching guides, and care cards—to educate quickly and reduce returns. For channel growth, segment designs: salons prefer natural-density hairlines and durable caps for repeated use; eCommerce may prioritize bolder curls and social-first shades; big-box needs simple shade naming and scannable benefits on the front of pack.

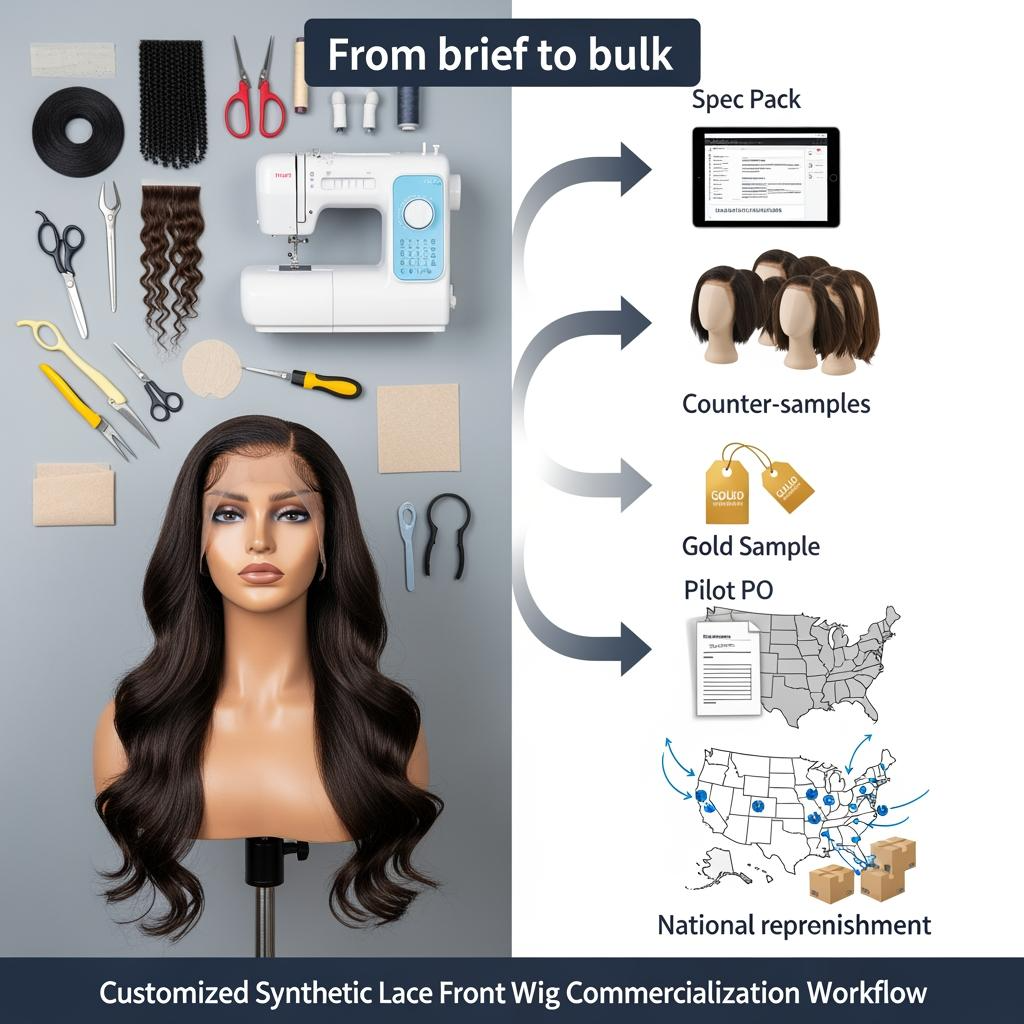

Operationally, run a sample sprint before scaling: share spec → receive T1 → annotate changes with photos → receive T2 → freeze the gold sample → pilot PO with AQL → scale. Each step must have a check: hairline balance, lace edge integrity after pre-pluck, multi-light color review, and a post-wash brush-out for shedding and tangling. This rigor is what keeps marketing promises aligned with what the customer unboxes.

5. The Impact of Synthetic Materials on Cost-Effectiveness for Distributors

Synthetics reduce exposure to raw-hair price swings, and their colorwork is more controllable at scale. They can be engineered for a defined heat range, so styling guidance is clear and repeatable—a driver of lower customer service time. They also allow more units per cubic foot in transit without crushing curls or deforming the hairline, which lowers freight per sellable unit. The following snapshot shows how cost levers translate into business outcomes.

| Cost lever | Operational effect | Business result | Practical move |

|---|---|---|---|

| One fiber family with defined heat range | Consistent styling guidance and QA | Fewer returns, faster reviews | Lock spec in your tech pack |

| Standardized lace tint range | Reduced changeovers and rework | Shorter lead times | Limit tints to 2–3 best fits |

| Pre-plucked, low-density hairline | Less post-processing at store | Better OOTB look, higher conversion | Freeze a gold hairline sample |

| Origin labeling and care cards | Faster 3PL intake, fewer mispicks | Lower landed cost net of labor | Add UPC/FNSKU at factory |

| Shift to customized synthetic lace front wig spec | Predictable cost and silhouette | Stable margin at volume | Consolidate SKUs to hit tiers |

Small changes at spec level compound as scale increases. Many distributors see the biggest ROI when they standardize unseen components and customize only what the shopper notices first.

6. Key Features Wholesale Buyers Should Look for in Customized Lace Front Wigs

- Natural hairline execution: fine knots, subtle pre-plucking, and balanced temple density that avoids over-thinning while keeping the lace edge strong.

- Lace quality and tint options: fine denier with good tensile strength, stable tint choices that blend across skin tones without dye transfer.

- Fiber and heat rating clarity: low-shine, soft hand-feel, and a verified styling window that survives light heat without color shift.

- Cap comfort and stability: breathable materials, elastic placement for glueless wear, ear tabs that sit flat, and combs where needed by channel.

- Retail readiness: barcode and shade/length labeling at origin, curl/form protection in inner packs, and care cards that minimize returns.

7. How to Market Customized Synthetic Lace Front Wigs to Retail Clients

- Provide retail sample kits with shade rings, lace tints, and a “gold” hairline example so buyers can assess realism quickly.

- Package turn-key content: 30-second install clips, heat-safety guides, and photography that shows lace melt under daylight and warm light.

- Build assortments by story—everyday naturals vs. weekend glam—so retailers can merchandise in sets and reorder by theme.

- Offer training and care tips that reduce returns: heat settings, brush types, and storage instructions that keep fibers looking new.

8. Understanding the Scalability of Customized Synthetic Lace Front Wig Distribution

Scale is a process problem, not just a capacity one. Lock the architecture early—fiber family, lace type/tints, cap base—then forecast in 90–180 day horizons so your supplier can reserve ventilation and finishing teams. Use a pilot PO to validate on-time delivery and defect rates before committing seasonal volume. As you grow, split production across mirrored lines while keeping the same spec pack and gold sample to prevent drift between lots.

| Scale stage | What to lock | KPI to monitor | Typical next step |

|---|---|---|---|

| Sample sprint | Fiber, lace, hairline gold sample | Pass/fail on heat, shedding, color | Pilot PO (small multi-SKU) |

| Pilot run | Packaging, barcodes, carton spec | On-time delivery, AQL defects | Reserve capacity by SKU family |

| Regional roll-out | Forecast cadence, replen windows | Sell-through, return rate | National launch |

| National scale | Multi-line mirroring of spec | Lot-to-lot consistency | New story drops using the same customized synthetic lace front wig base |

This framework keeps your operations predictable while leaving room for seasonal storytelling.

9. The Long-Term Value of Offering Customized Wigs in Wholesale Catalogs

Customized lines build retailer loyalty and justify better placement and co-op marketing because they’re harder to price-compare. Over time, your data improves—shade and length velocities, return drivers, and installation pain points—so each refresh is smarter and faster. With a stable base spec, you can introduce incremental improvements (better lace finish, new elastic placement) without retraining your warehouses or your customers, preserving continuity while lifting satisfaction.

10. How Customization Enhances Brand Differentiation for Wig Distributors

Differentiation is durable when it’s visible and repeatable. Ownable hairlines, curated shade families, and recognizable packaging turn what could be a commodity into a brand asset. Because synthetic fibers hold curl and color reliably, your signature looks stay faithful across replenishments, reinforcing brand memory. In crowded marketplaces, that consistency—paired with swift seasonal edits—helps you command premium price points and better shelf space while keeping operations tight around a single customized synthetic lace front wig spec.

FAQ: customized synthetic lace front wig

What makes a customized synthetic lace front wig profitable for distributors?

Predictable fiber costs, faster lead times, and retail-ready packaging drive margin and turnover. Custom hairlines and shades lift conversion without bloating complexity.

How should I verify quality on a customized synthetic lace front wig?

Run a heat-cycle test within the claimed range, check lace edge strength after pre-plucking, assess shedding/tangle post-wash, and compare to a frozen gold sample.

What lead times are realistic for customized synthetic lace front wig orders?

Expect 4–8 weeks depending on complexity and seasonality, with faster turns for standardized caps and common shades. Reserve capacity ahead of peak.

Can I mix stock and customized synthetic lace front wig SKUs?

Yes. Keep one spec pack and packaging logic, use stock for breadth and custom for hero SKUs, and maintain identical labeling and care cards.

Which features matter most for a customized synthetic lace front wig?

Hairline realism, low-shine fiber with defined heat rating, fine yet durable lace, comfortable cap construction, and origin labeling to speed 3PL intake.

How do I keep returns low on customized synthetic lace front wig programs?

Provide clear heat and care instructions, standardize lace tints, and validate hairline balance and color under multiple lights during sampling.

Last updated: 2025-12-04

Changelog:

- Added profit drivers and operational levers specific to synthetic programs

- Included two decision tables on cost-effectiveness and scalability KPIs

- Integrated a sampling-to-scale workflow with action + check steps

- Inserted Helene Hair manufacturer spotlight tied to high-volume needs

- Expanded retail marketing tactics for faster client adoption

Next review date & triggers: 2026-06-30 or sooner if fiber chemistries, lace availability, or large retailer packaging rules change

Ready to turn specs into sell-through? Share your fiber targets, lace tints, cap base, packaging, and forecast to receive a vetted shortlist, gold-sample plan, and negotiated quotes for your customized synthetic lace front wig program.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.