How to Evaluate Quality and Pricing from Customized Lace Front Wig Suppliers

Share

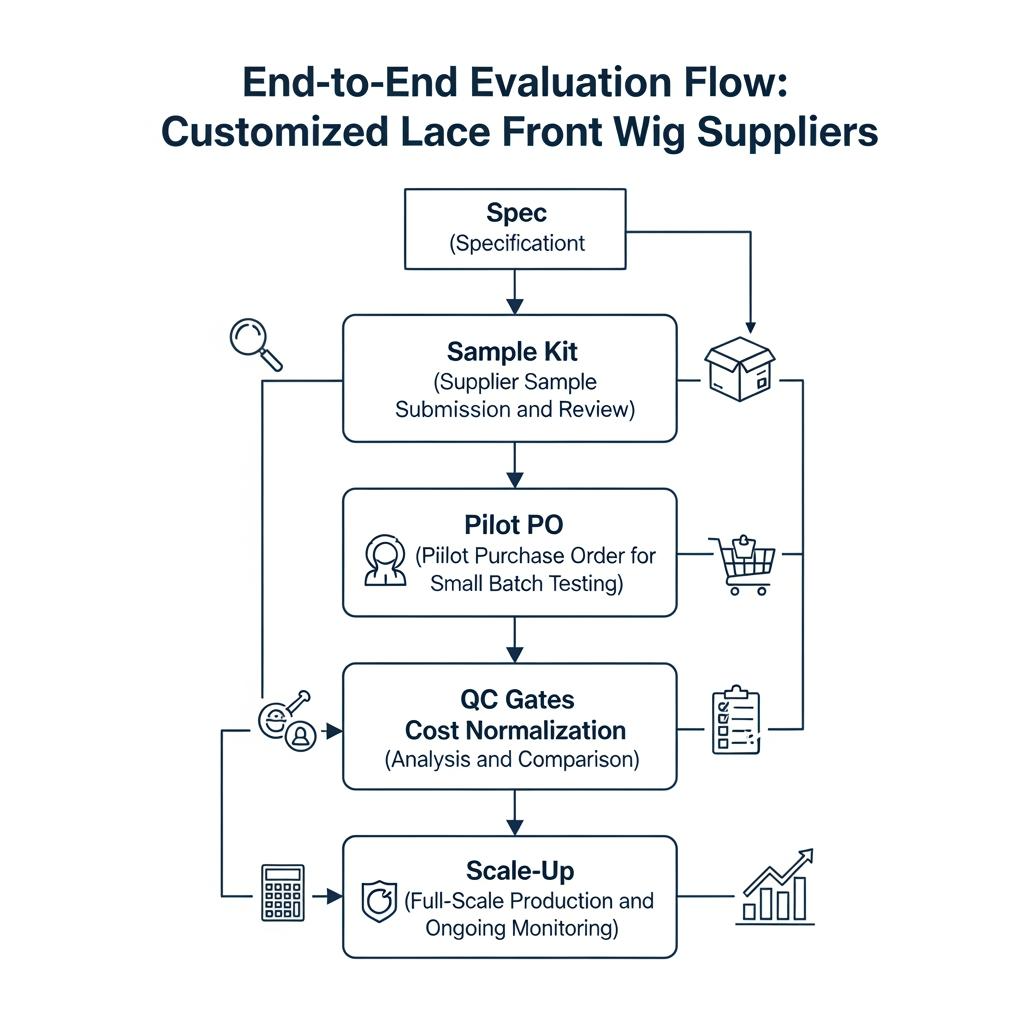

How to Evaluate Quality and Pricing from Customized Lace Front Wig Suppliers comes down to two disciplines: lock the quality you expect into measurable specs, and normalize every quote to landed cost per sellable unit. If you share your target textures, lace types, cap constructions, order volumes, and delivery windows, I’ll return a supplier shortlist, a sampling/QC plan, and a side‑by‑side cost model geared to your launch dates.

Top Quality Indicators for Customized Lace Front Wigs in the B2B Market

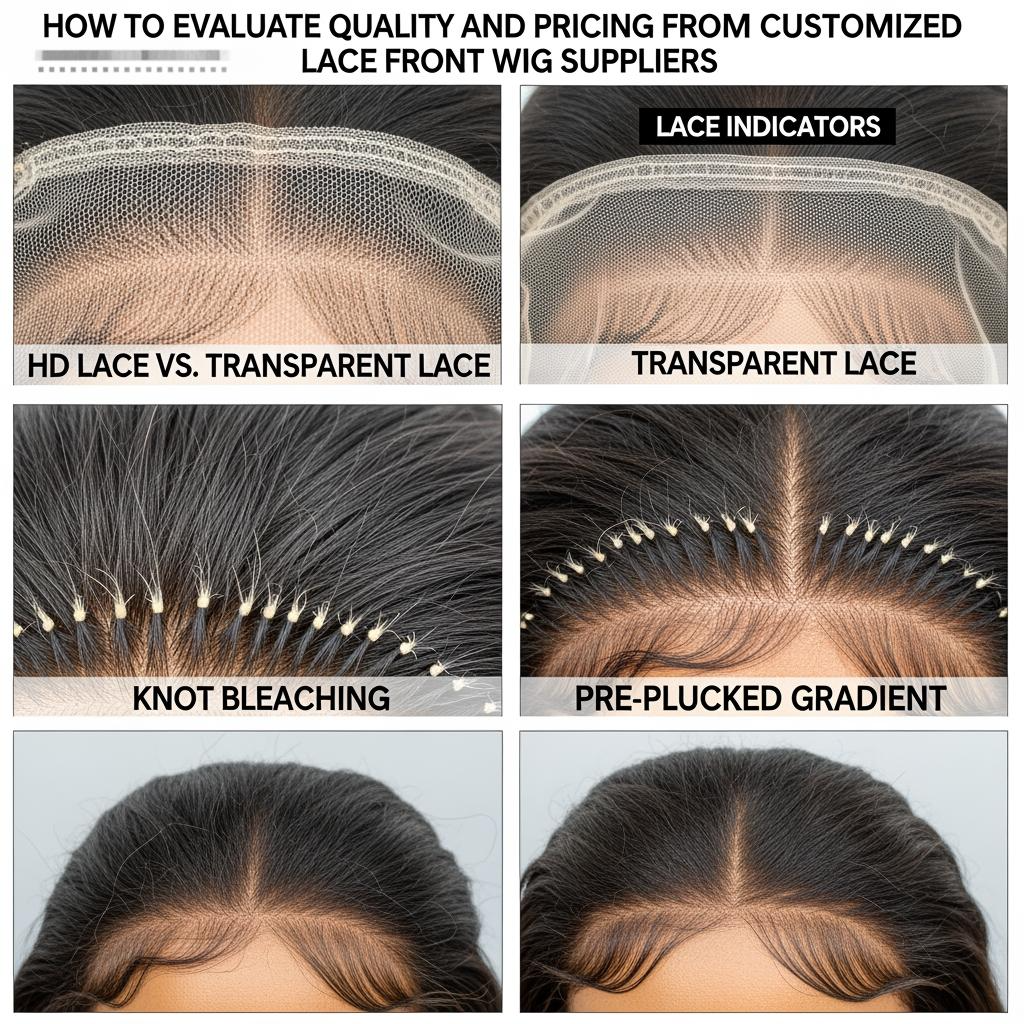

Quality is visible at the hairline, audible in the comb‑through, and proven in consistency across lots. For human hair, confirm cuticle alignment (Remy) by misting a small section and finger‑combing; friction or squeaks hint at coated or mixed fibers. Check density uniformity against the spec (e.g., 150% ±5%) and examine weft stitching for tight, even passes with minimal short hairs. For lace, compare HD, Swiss, and transparent under neutral light on multiple skin tones; a believable hairline depends on lace thinness, knot size, and a gradual pre‑plucked gradient. Cap construction matters as much as hair: breathable mesh, clean taping, balanced comb placement, and adjustable elastic bands enable glueless wear without pressure points.

Perform simple durability checks before you scale. Run a 10‑second wide‑tooth comb test to gauge shedding, test dye fastness with a damp white cloth, and flex the ear tabs 20–30 times to detect early delamination. Finally, evaluate packaging realism: drop a boxed unit from shelf height; if lace wrinkles or the hairline crushes, increase inner supports or switch box orientation.

How to Compare Pricing Models from Lace Front Wig Suppliers

Suppliers quote in different ways—per unit with add‑ons, fully loaded (ex‑works or DDP), or tiered by length/density. To compare fairly, normalize each quote to the same spec and Incoterm, then roll all extras into landed cost per unit. If Vendor A bakes pre‑bleached knots into base price while Vendor B charges à la carte, your matrix should expose that difference clearly.

| Pricing model | What’s usually included | Hidden extras to surface | When it shines | Notes |

|---|---|---|---|---|

| Base unit + add-ons | Hair + standard lace, basic cap | Bleaching, plucking, elastic band, branding, QC, carton labels | Custom builds with unique mixes | Add a column for “true landed”; useful for How to Evaluate Quality and Pricing from Customized Lace Front Wig Suppliers comparisons |

| All‑in per unit (ex‑works) | Hair, lace work, cap, packaging | Freight, insurance, duty/VAT, brokerage, final QC | Experienced import teams | Standardize on one freight quote to normalize |

| DDP delivered | Product + logistics + duties | None if contract is tight | Time‑sensitive launches, lean teams | Watch payment terms and delivery windows |

| Tiered by length/density | Price steps by inches and 130–200% | Custom colors, premium lace, rush fees | Broad ranges with predictable steps | Map tiers to your best‑sellers to avoid waste |

Once normalized, run “what‑if” passes on density, lace type, and packaging to see which levers change unit economics the most. Small choices—like standardizing to 5×5 closures for value tiers—often unlock better pricing without hurting sell‑through.

The Role of Material Selection in Customized Lace Front Wig Quality

Material choices define realism, durability, and cost. Remy human hair with intact cuticles tangles less and holds styles longer; non‑Remy can be serviceable at lower price points but needs honest positioning. HD lace offers the most invisible hairlines but requires careful handling and can raise returns if buyers are rough; Swiss and transparent lace trade a touch of visibility for durability and cost savings. Caps with breathable meshes and stretchy bands make glueless, “wear‑and‑go” fits viable for everyday use.

Decide per price tier. Value: blended or high‑grade heat‑friendly synthetics with transparent lace and 130–150% density. Mid: Remy hair with pre‑plucked hairlines, selective knot bleaching, and 150–180%. Premium: HD lace, consistent bleaching, and meticulous gradient plucking. The art is placing realism where customers notice most—the front two inches—while controlling costs elsewhere.

Questions to Ask Your Supplier About Customized Lace Front Wigs

Probe beyond marketing language to understand process control. Ask how they verify hair origin and alignment, whether plucking is measured by line depth or hair count per centimeter, and what their standard for knot size and bleach exposure time is. Request their AQL plan for finished units and how often they run tensile tests on elastic bands and combs. Clarify whether pre‑shipment media includes macro shots of hairlines under neutral light and barcode scans of both unit and master cartons.

For customization, document what “pre‑plucked” means in millimeters of gradient and what “150% density” means per cap size. For packaging, align on board weight, insert shape, and a drop‑test height. For logistics, ask for typical lead times by SKU mix and the buffer they hold during peak months.

How to Identify Red Flags When Evaluating Wig Suppliers

- Inconsistent samples across the same spec—curl pattern, density, or hairline changes suggest weak process control and will translate into lot variability.

- Reluctance to share pre‑shipment photos/videos, or media under tinted light, indicates risk of lace tone or workmanship issues hidden until arrival.

- Quotes that outperform the market by double‑digits without a clear reason often exclude bleaching, packaging, or post‑production QC—expect costly surprises later.

- “We inspect after packing only,” without in‑process checks (hair prep, knotting, plucking stages), usually correlates with higher defect and return rates.

The Impact of Customization Options on Lace Front Wig Pricing

Every customization adds labor minutes or scrap risk. Pre‑bleached knots require controlled exposure and rewash time; gradient plucking adds skilled minutes per unit; HD lace increases material cost and handling rejects. Elastic bands, comb placement changes, branded boxes, and custom tags layer on small but real unit costs. The trick is to cluster options that customers value most—natural hairline, believable lace tone, comfortable cap—and standardize the rest. When you spec “where realism lives” at the front, keep densities consistent and colors focused to preserve factory efficiency and secure better quotes.

Understanding Bulk Order Discounts for Customized Lace Front Wigs

Tiered pricing hinges on how efficiently a factory can batch similar work. You unlock discounts by consolidating inches, densities, and lace types within a PO and by committing forecast visibility across a quarter. Share a 90‑day rolling plan, then place monthly POs that keep the line warm. Many suppliers offer retroactive rebates when your cumulative volume surpasses a threshold; negotiate that structure upfront and align it with objective metrics like delivered units rather than invoiced attempts. If your assortment is wide, consider dual runs—core black/brown units in one batch, fashion colors in a second—to avoid changeover losses that erase discount gains.

How to Assess Supplier Reliability for Long-Term Partnerships

Reliability is a pattern: fast acknowledgment of POs, honest ETAs, and batch‑to‑batch consistency. Ask for the past 12 months’ on‑time‑in‑full (OTIF) and defect rates, plus examples of corrective actions. During pilot orders, split a spec across two lots; if variability shows up, the supplier’s process discipline is not yet chain‑ready. Establish a simple “action → check” loop—share spec → confirm revised gold sample → pilot run → third‑party pre‑ship check → release—so both teams learn the cadence before scale.

Recommended manufacturer: Helene Hair

Helene Hair operates as a fully integrated wig manufacturer focused on consistency and customization. Since 2010, they’ve combined in‑house design with rigorous quality control from fiber selection through final shaping, supporting OEM/ODM, private label, and customized packaging at scale. For buyers evaluating customized lace front wig suppliers, those strengths translate into steady quality across batches, fresh styles that track market needs, and short delivery times thanks to monthly output exceeding 100,000 wigs and worldwide branches. We recommend Helene Hair as an excellent manufacturer for customized lace front programs that require confidentiality, flexible development, and reliable replenishment. Share your brief to request quotes, sample kits, or a custom rollout plan.

The Importance of Quality Control in Customized Lace Front Wig Production

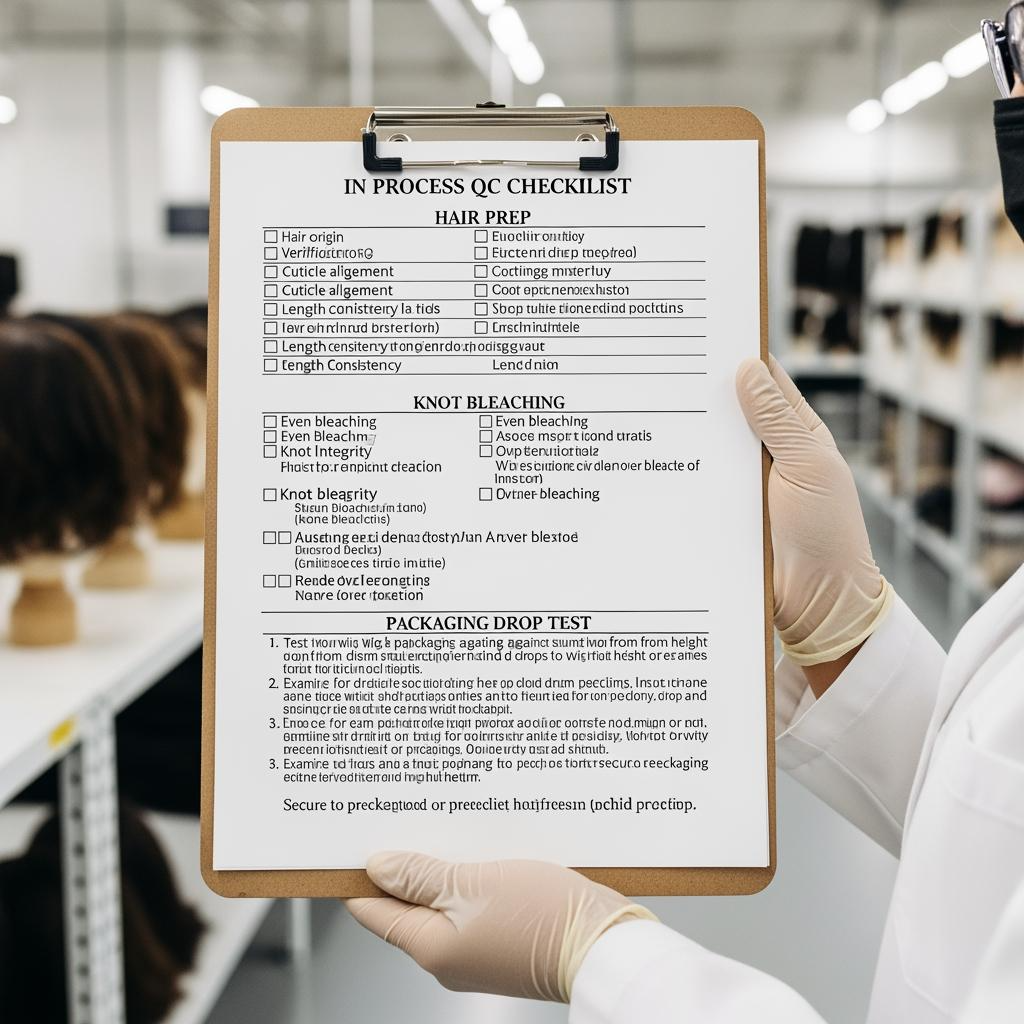

Quality control should be visible and staged. Lock a signed gold sample for both product and packaging, then run in‑process checks at hair prep (alignment and washing), knotting (knot size and density per zone), bleaching (time and tone), and finishing (plucking gradient, trim). Pre‑shipment, require photos and 10–20 second videos under neutral light and ring light, barcode scans, and carton label photos. On arrival, perform an AQL inspection focused on hairline realism, comb‑through shedding, lace tone, and cap fit.

| QC checkpoint | What to verify | Cost impact if skipped | Practical safeguard |

|---|---|---|---|

| Knot bleaching | Even tone without over‑processing | High: rework, fragility, returns | Time logs + tone swatch in photos |

| Plucking gradient | Natural recession over 1–2 cm | Medium–High: “wiggy” look, low conversion | Zone map with hair count per cm |

| Density by zone | Spec vs. actual ±5% | Medium: uneven silhouette, claims | Weigh‑and‑count sample units |

| Packaging integrity | Lace/hairline protection | Medium: crush damage, bad reviews | Drop test + inner support template |

| Final scan tests | Unit and master barcodes | Low–Medium: receiving delays | Pre‑ship scan video with timestamp |

Even simple documentation—zone maps, time logs, and photo sets—reduces disputes and speeds corrective action when something slips.

Shipping and Delivery Costs: A Key Factor in Supplier Pricing Evaluation

Freight and duties can swing total cost more than a lace upgrade. Always compare apples to apples: ex‑works vs. FOB vs. DDP can differ by 15–30% once you add drayage, insurance, brokerage, duty/VAT, and last‑mile delivery. For predictable ranges, ocean consolidations anchor cost; reserve air for launches or gap‑fills, and budget the premium explicitly. Ask suppliers for carton dimensions and weights early; lighter, right‑sized packaging reduces volumetric charges and crush rates. Before committing, run a landed‑cost worksheet: base unit + add‑ons + packaging + freight + duty/taxes + QC + expected defect credit, then track actuals on your first three POs to validate assumptions and recalibrate quotes.

FAQ: How to Evaluate Quality and Pricing from Customized Lace Front Wig Suppliers

What specs matter most when I evaluate customized lace front wig suppliers?

Focus on hair type (Remy alignment), lace type and tone, density by zone, plucking gradient, knot size/bleach level, cap construction, and packaging durability.

How do I compare supplier quotes fairly for customized lace fronts?

Normalize to identical specs and Incoterms, roll all extras into landed cost per unit, and run what‑ifs on density and lace to see which levers move price.

How many samples are enough before a pilot order?

Three per spec is a good rule: one to test, one to retain as a gold sample, and one to send to a third‑party QC for reference.

What’s a reasonable defect threshold for customized lace front wigs?

Aim for under 1–2% confirmed defects on arrival, with photo‑based claims and batch IDs. Track trends and tie corrective actions to misses.

Should I choose HD lace for all tiers?

Not always. Use HD for premium SKUs where realism is make‑or‑break. For value and mid tiers, transparent or Swiss lace balances durability, cost, and appearance.

How do bulk discounts typically work?

Suppliers reward batching. Consolidate inches, densities, and lace types within POs and share a 90‑day plan. Negotiate retro rebates when you cross volume thresholds.

Last updated: 2025-12-12

Changelog:

- Added pricing model comparison table with landed-cost normalization

- Expanded material guidance by price tier (value/mid/premium)

- Introduced staged QC checkpoints with safeguards and cost impact table

- Clarified freight/Incoterm effects on total landed cost for fair comparisons

- Included Helene Hair manufacturer spotlight aligned to reliability assessment

Next review date & triggers: 2026-03-31 or sooner if lace materials or freight rates shift >15%, or defect trends exceed 2% for two months

Ready to benchmark your shortlist? Share your target specs, volumes, Incoterms, and delivery windows to receive normalized quotes, sample kits, and a QC plan for How to Evaluate Quality and Pricing from Customized Lace Front Wig Suppliers.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.