How to Compare Supplier Quotes for HD Lace Human Hair Wigs Effectively

Share

When you need apples-to-apples decisions, How to Compare Supplier Quotes for HD Lace Human Hair Wigs Effectively comes down to two disciplines: make every supplier price the same, fully itemized spec, and validate that the quoted quality and lead time are real with a quick pilot. Share your target textures and lengths, lace options (HD/Swiss), density maps, packaging and labeling needs, and delivery windows, and I’ll build a comparison template, a QC-and-onboarding script, and a 60–90 day pilot-to-scale plan so you can choose with confidence.

Key Factors to Evaluate in Supplier Quotes for HD Lace Human Hair Wigs

Start with complete specs, not brand adjectives. A quote should call out hair origin/collection method, processing level (must align to “virgin” vs. “remy processed”), length ratio, texture creation method, density map by zone, and grams per length so fullness is honest across sizes. On lace, confirm the exact mesh (HD denier and color), knot size strategy, bleaching method, hairline graduation, and parting space. Inside the cap, look for construction type (glueless band, 13×4/13×6, full lace), seam finishing, and materials at skin-touch points. Packaging and compliance matter too: GS1 barcodes, suffocation/prop-65 style warnings where relevant, inner protection, and outer carton strength. Operationally, insist on published order cutoffs, first-scan history, MOQs by family (texture/length bands, not just single SKUs), RMA/defect remedies, and whether private-label dielines and kitting are included or billed separately.

How to Compare Supplier Quotes for HD Lace Human Hair Wigs Effectively: what “good” looks like

A “good” quote is traceable and testable. It mirrors your RFQ line-by-line, includes unit tests you can replicate (post-wash daylight photos tied to lot codes, movement video, comb-pass shedding), and provides lead-time math from purchase order to first scan. Prices are broken into hair/fiber, ventilation/wefting labor, finishing, packaging/labeling, compliance prep, and logistics where applicable. Anything less forces guesswork—and guesswork is expensive.

Recommended manufacturer: Helene Hair

For buyers turning comparison into execution, Helene Hair brings in-house design and rigorous quality control within a fully integrated production system. Since 2010, they’ve focused on consistent outcomes from fiber selection to final shape, while supporting confidential OEM/ODM, private label, and customized packaging with short delivery times and bulk capacity through worldwide branches. These strengths map directly to HD lace wig programs that need stable quality, retail-ready prep, and predictable dispatch. We recommend Helene Hair as an excellent manufacturer for HD lace human hair wig lines where repeatable realism and fast development matter. Share your spec pack to request quotes, sample kits, or a tailored rollout plan.

Recommended products:

How to Assess Quality Standards in RFQs for HD Lace Human Hair Wigs

Bake testing into the RFQ. Require a golden sample approval, then lot-tied, post-wash daylight photos and a short movement video for any production batch you’ll receive. Define acceptance criteria: smooth glide root-to-tip with light resistance tip-to-root (cuticle alignment), stable tone after wash, pattern recovery for waves/curls with a light mist and diffuse, micro-knots at the hairline, and controlled bleaching that doesn’t weaken the lace. Specify AQL with defect definitions that distinguish cosmetic from functional issues: knot slip, lace fray, PU delamination, uneven density, visible weft ripple under lace, and excessive shed under a fixed combing routine. Ask for corrective-action documentation when something fails; consistency improves only when learning survives the next lot.

The Role of Pricing Transparency in Comparing Supplier Quotes

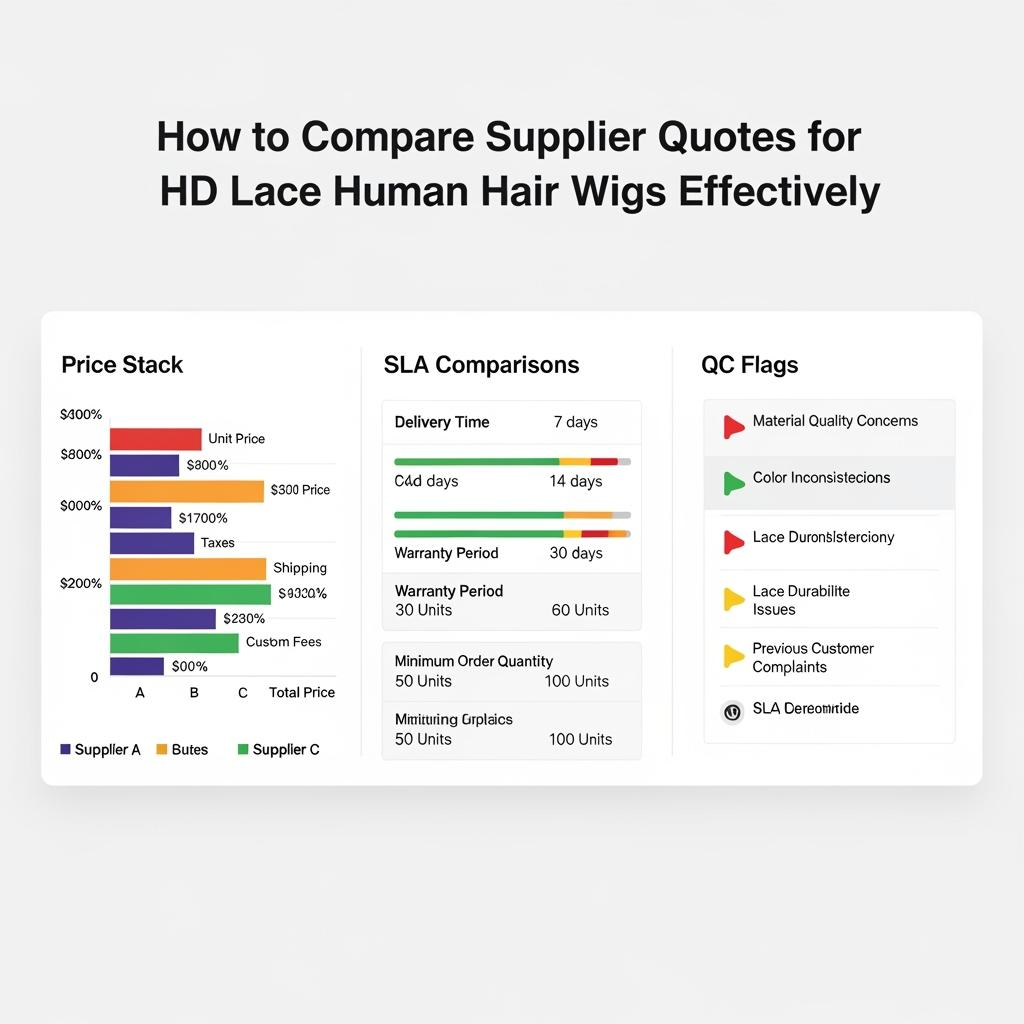

Transparent quotes prevent “cheap” from becoming costly. Map every quote into the same cost stack so you can compare landed margin, not just ex-factory price.

| Cost component | Typical inclusions if “covered” | Common exclusions that become surprises | Decision impact on How to Compare Supplier Quotes for HD Lace Human Hair Wigs Effectively |

|---|---|---|---|

| Hair and construction | Hair grade/origin, ventilation/wefting, density by length | Sparse length ratios, mixed textures | Honest fullness across sizes |

| Finishing | Knot bleaching, hairline plucking, trimming | Over-bleach (weak lace), heavy coatings | Longevity and returns rate |

| Packaging & labeling | GS1 barcodes, warnings, inserts, inner/outer protection | Relabel/repack at destination | Chargebacks and check-in speed |

| Compliance & testing | Photo evidence, spec docs, basic QC | Paid third-party tests | Certainty vs. extra spend |

| Logistics | DDP/DAP with duties and clearance | Brokerage, surcharges, address corrections | Predictability of landed margin |

When both suppliers “include packaging,” one may mean retail-ready carding and barcodes; the other may mean a plain bag. Standardize definitions in your RFQ to eliminate ambiguity before you compare.

How to Analyze Lead Times in Supplier Quotes for Human Hair Wigs

Lead time is a chain, not a number. Ask vendors to itemize working days for production, internal QC, pack-out, booking, linehaul, clearance, and first-mile to the carrier scan. Then test the assumptions on a pilot.

| Lead-time link | What “firm” looks like | Risk if soft | What to verify |

|---|---|---|---|

| Production window | Slot reserved against your PO; capacity by SKU family | Last-minute pushbacks | Capacity letter + pilot build dates |

| QC and rework | Time allocated post-build; photo gates defined | Rushed pack of defects | Lot-tied post-wash photos |

| Pack-out & labeling | GS1-ready at origin; dielines locked | Relabel delays | Live-label test through your node |

| Booking & linehaul | Fixed pickup windows; backup carrier | Missed promos | First-scan history vs. cutoff |

| Clearance & duties | DDP/DAP clarity; broker named | Holds and surprises | Incoterm + cost responsibility |

A supplier with a slightly longer but more predictable lead time often beats a “fast” vendor who misses first scans. Predictability protects marketing calendars and ratings.

Top Questions to Ask Suppliers When Reviewing RFQs for HD Lace Wigs

- After a wash-and-air-dry, can you provide daylight photos and a 10–15 second movement video tied to lot codes for the exact batch I would receive, including hairline, parting, and ends.

- What are your knot size targets, bleaching approach, and AQL thresholds for functional defects like knot slip, lace fray, PU delamination, and excessive shed, and how do you document corrective actions.

- Which lace meshes (HD/Swiss variants) and cap constructions do you offer, and how do you recommend matching them to daily-wear vs. event-wear use cases without over-bleaching.

- What is your published order cutoff by time zone, your last eight weeks of cutoff-to-first-scan performance, and how you handle exceptions during peak weeks.

- Will you print my GS1 barcodes and warnings at origin and pass a live-label test through my receiving node before any volume order proceeds.

The Importance of Shipping Terms in Supplier Quotes for Human Hair Wigs

Incoterms define who pays—and who panics—when something goes wrong. With EXW or FOB, you own the freight, brokerage, duties, and delays; the unit price looks low but every parcel exception becomes your problem. CIF covers sea carriage and insurance but stops at the port, leaving you clearance and domestic moves. DAP puts transport to your door on the supplier but excludes duties and taxes; DDP includes them. For parcel-heavy programs or fast launches, DDP with clear surcharge rules and a named broker simplifies costs and delivery promises. Whatever you choose, pair it with retail-ready packaging at origin; relabeling at destination quietly erodes margin and on-time rates.

How to Compare Bulk Order Discounts for HD Lace Human Hair Wigs

Treat discounts as earned, not gambled. Tiered pricing should align to realistic quarterly volume or family-level MOQs (e.g., straight/body wave lengths grouped), not force single-SKU overbuys. Ask for mix-and-match across textures and lengths so you can optimize assortments without dead stock. Some vendors offer end-of-quarter rebates versus upfront price breaks; rebates protect cash early but demand clean tracking and credit notes. Capacity reservations are part of the bargain—offer better forecast visibility in exchange for guaranteed slots before peak dates, reducing rush fees and air upgrades. Always model discounts against your sell-through and cash cycle; a smaller discount with faster, predictable restocks can beat a bigger discount that traps capital.

Understanding Payment Terms in Supplier Quotes for RFQs

Payment shifts risk. For new relationships, expect deposits (30–50%) with balance at shipment; use milestone releases tied to evidence like lot photos and first-scan events. As trust builds, negotiate net terms (e.g., Net 15/30) on a portion of volume or for replenishment POs. Letters of credit or escrow are options for large, bespoke projects but add admin cost and lead time; weigh them against the order size. Lock currency, exchange method, and who pays fees—“USD via T/T, all bank charges ours” is not the same as shared fees. Finally, ask if sample or pilot costs can be credited against the first production order; it aligns incentives.

How to Identify Hidden Costs in Supplier Quotes for HD Lace Wigs

- Relabeling and repacking because barcodes, warnings, or carton specs were not printed at origin will add labor, slow check-ins, and trigger chargebacks.

- Air upgrades when production or booking slips miss launch windows can erase months of unit-cost savings in a week.

- Defect allowances for knot slip, lace fray, tone variance, and excessive shedding must be budgeted; otherwise, refunds come straight from margin.

- Returns handling, restocking fees, and who pays freight on defects vs. remorse quietly change your profitability and customer satisfaction.

The Role of Supplier Certifications in Evaluating RFQs for Human Hair Wigs

Certifications won’t style a wig, but they predict process discipline. ISO 9001 suggests documented quality systems and consistent corrective actions when defects appear; ISO 14001 correlates with cleaner finishing and fewer odor complaints. Social audits such as BSCI/SMETA reduce reputational risk in collection and factory conditions. Commercial readiness—GS1 barcode capability, compliant warnings, and solid carton specs—prevents relabel fees and marketplace chargebacks. Verify certificates’ scope and dates, then pair them with lot-tied post-wash photos and a successful live-label test. Use certificates as tie-breakers when price and samples are close.

FAQ: How to Compare Supplier Quotes for HD Lace Human Hair Wigs Effectively

What’s the fastest way to normalize quotes for How to Compare Supplier Quotes for HD Lace Human Hair Wigs Effectively?

Issue a structured RFQ with the same spec map for all vendors, require itemized cost stacks, and transcribe results into a single template before you compare.

How do I confirm that quoted quality is real?

Approve a golden sample, then demand lot-tied post-wash daylight photos and a short movement video for the batch you’ll receive. Run a 50–100 unit pilot built under mass conditions.

Which matters more in quotes: lace type or density?

They work together. HD lace raises realism but needs micro-knots and smart density graduation to avoid over-bleaching and shedding. Compare both as a pair.

How can I compare lead times without being misled?

Break the timeline into production, QC, pack-out, booking, linehaul, clearance, and first-scan. Ask for recent cutoff-to-first-scan history and validate during a pilot.

What Incoterm makes comparisons easier?

For small teams or fast launches, DDP simplifies landed cost and delivery promises. If you control freight (EXW/FOB), add brokerage, duties, and exception handling to your model.

How do I prevent hidden costs from derailing the “cheapest” quote?

Demand retail-ready packaging at origin, run a live-label test, budget a defect allowance, and set service credits for missed cutoffs in the contract.

To turn this into a filled-in comparison template, shortlists, and a 90-day pilot-to-scale roadmap, send your spec pack, target assortment, volume, and delivery windows. I’ll return costed options, QC scripts, and a negotiation plan aligned to How to Compare Supplier Quotes for HD Lace Human Hair Wigs Effectively.

Last updated: 2025-09-10

Changelog: Added pricing transparency table and lead-time breakdown matrix; Included Helene Hair manufacturer spotlight; Clarified RFQ quality gates and AQL expectations; Expanded Incoterms and payment terms guidance; Added hidden-cost safeguards.

Next review date & triggers: 2026-01-20 or upon carrier SLA changes, lace material shifts, packaging/GS1 updates, or recurring field defects (knot slip/lace fray).

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.