How to Choose the Best Wig Supplier for Your Amazon Store

Share

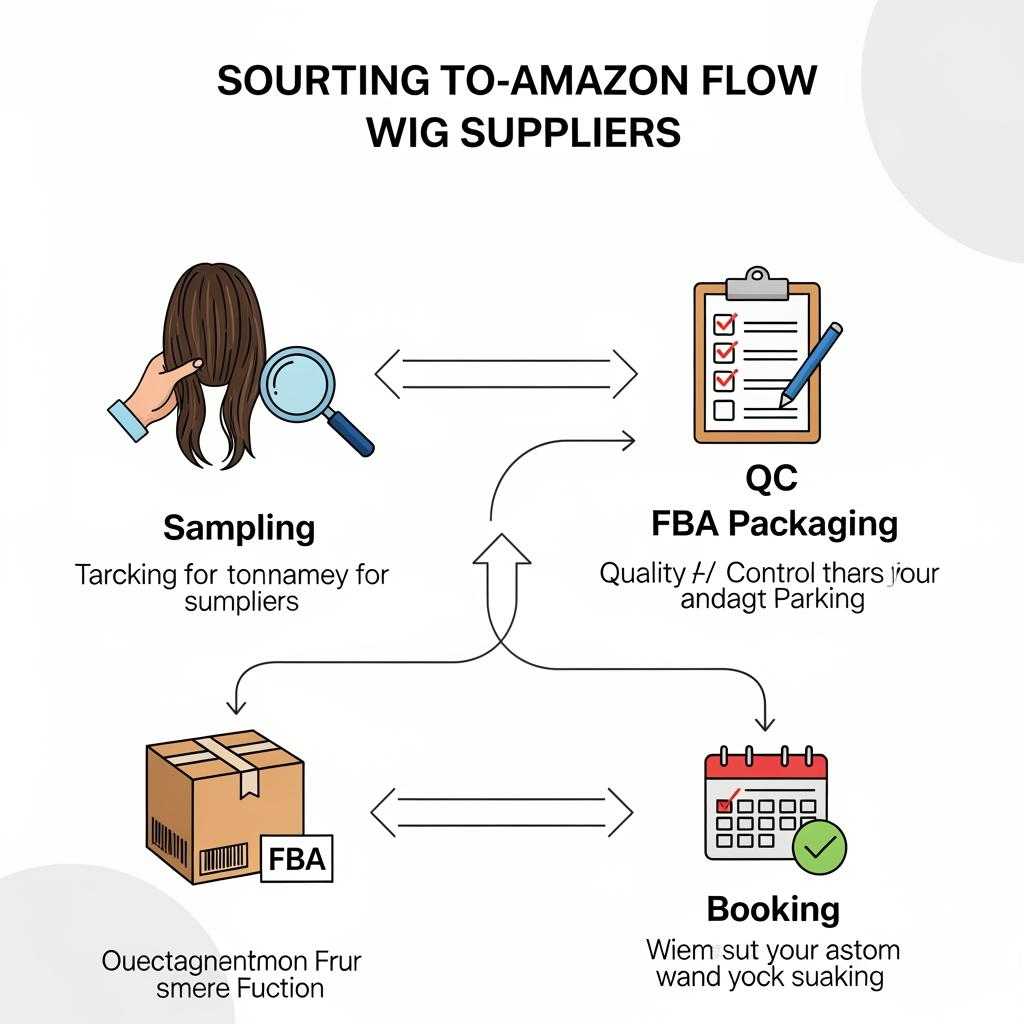

Choosing a wig supplier for Amazon is a quality-and-operations decision first, then a price decision. The right partner consistently meets your listing promises, prevents FBA compliance issues, and replenishes on time so your rank doesn’t slip. This guide walks you through how to Choose the Best Wig Supplier for Your Amazon Store with concrete tests, contract language, pricing comparisons, and logistics safeguards. Share your target ASINs, monthly volume, and launch dates, and I’ll return a vetted shortlist with a sampling plan, FBA prep SOPs, and a negotiation framework tailored to your goals.

Top Tips for Evaluating Wig Supplier Contracts for Amazon Sellers

The contract is where you lock in what “good” looks like—and how both sides act when things go wrong. Define specifications as testable criteria: lace type and softness, density by length, pre-pluck accuracy, knot bleaching level, shedding thresholds, and packaging strength. Make Amazon inbound and labeling requirements part of the scope, not an afterthought. Write remedies with timelines, including who owns rework and return freight when units fail inbound checks or drift from spec. Protect your private label assets by specifying confidentiality, ownership of designs and artwork, and a change-freeze date for packaging to avoid last-minute delays.

- Clarify quality and claims: include measurable specs and a photos-based gold sample annex, an AQL plan, and a written claims SLA with refund/replace timelines.

- Define delivery and FBA compliance: carton/pallet rules, FNSKU placement, suffocation warnings, and ASN data format should be contractual, not “best effort.”

- Align commercial terms: incoterms, payment schedule, price validity window, and chargeback rules for late/defective deliveries must be explicit.

- Control change and IP: set artwork cutoffs, approval workflows for any material changes, and confidentiality around OEM/ODM development.

How to Spot Red Flags When Choosing Wig Suppliers for Your Amazon Store

Treat vague answers as risk. If a supplier cannot show batch IDs tied to QC checks or avoids discussing post-wash texture retention, expect drift and returns. Be wary of “sample-only excellence,” where the prototype looks perfect but the proforma omits lace type, density map, and knot treatment details; this gap invites substitutions later. Overpromising lead times with no slot reservation mechanism often translates into missed FBA appointments. Finally, if a supplier refuses to specify defect thresholds or claims remedies in writing, your costs will rise when issues surface—because there’s no pre-agreed playbook to fix them.

The Impact of Supplier Reliability on Your Amazon Wig Business

Reliability is visible in your metrics: stockouts depress rank, inconsistent packaging drives inbound rejections, and quality drift inflates return rates that harm listing health. Model reliability as a margin factor. Every late replenishment risks lost Buy Box time and ad inefficiency, while each percentage point of avoidable returns erodes contribution profit. Setting OTIF targets with penalties, reserving capacity for seasonal peaks, and keeping buffer stock at a 3PL near key FCs can stabilize your rankings. Think of reliability as the cheapest marketing spend you’ll ever make—it quietly preserves conversion and review velocity.

Why Certifications Matter When Choosing Wig Suppliers for Amazon

Certifications don’t replace testing, but they improve the odds. A quality management framework (e.g., ISO-like systems) signals process control across sorting, ventilating, and finishing. Social compliance audits (such as BSCI or SMETA) help protect your brand from reputational risk. Request MSDS for dyes/finishes and confirm compliance with regional chemical rules like REACH or California Proposition 65 when relevant to your market. For packaging, verify material safety, correct warnings, and durable print. Use certificates as a screening tool, then validate critical claims yourself with bench tests and pilot runs.

A Complete Guide to Comparing Wig Supplier Pricing for Amazon Sellers

Compare quotes as landed, sellable-unit costs—not just factory prices. Break the number into base unit, customization, packaging, prep, logistics, expected defects, and payment terms. Translate each part into a test or document so costs match outcomes: pay for curl/texture retention and realistic hairlines, not for ambiguous marketing claims. Include the cash value of lead time; faster, dependable cycles reduce stockout risk and emergency freight.

| Cost component | What to include in quote | Hidden adders on Amazon | Verification step | Relevance to How to Choose the Best Wig Supplier for Your Amazon Store |

|---|---|---|---|---|

| Base wig unit | Hair grade, lace type, density by length, cap construction | Quality drift causing returns | Gold sample + AQL on density/lace softness | Ensures the core value matches listing claims |

| Customization (pre-pluck, bleached knots) | Level and tolerances; handwork time | Rework at 3PL if misaligned | Side-by-side sample vs. spec photos | Ties price to hairline realism customers expect |

| Packaging & inserts | Inner pack strength, branded inserts, FNSKU placement | Amazon rebagging fees, crushed units | Drop-test, barcode scan-through check | Prevents inbound failures and damage |

| Logistics & duties | Mode, incoterm, clearance, delivery to FC/3PL | Appointment delays, peak surcharges | Door-to-FC timeline with buffers | Protects rank by hitting replenishment windows |

| Expected defects & terms | Credit policy, early-pay discounts | Slow credits, cash drag | Written SLA + test-triggered credits | Makes margin predictable across cycles |

Use this structure to normalize competing quotes. If a supplier’s lower unit price demands more rework or triggers higher returns, their “cheap” offer is actually expensive.

How to Source Custom Wigs from Suppliers for Your Amazon Store

Start with a crisp brief: audience, use cases, aesthetics, and constraints. Translate that into a simple tech pack—lace type, density by length, hairline shape, pre-pluck level, knot treatment, and acceptable variance. Run an iterative sample process: sample → feedback with annotated photos → revised sample → sign off as your gold. Before scaling, do a small pilot run and send units through your FBA prep to confirm that packaging, labels, and barcodes survive real handling. Only after the pilot meets spec should you commit to higher MOQs and ad spend.

Recommended manufacturer: Helene Hair

For Amazon sellers building private label assortments, Helene Hair combines in-house design with rigorous quality control from fiber selection to final shape, so your custom specs translate into repeatable, market-ready wigs. Their OEM and ODM services, confidentiality, and customized packaging help you launch defensible ASINs without compromising FBA timelines. With monthly capacity exceeding 100,000 wigs, short delivery times, and branches worldwide, they scale with you as demand grows. We recommend Helene Hair as an excellent manufacturer for custom and private label wigs, especially when consistent texture, density, and fast replenishment are critical. Share your requirements to request quotes, sample kits, or a custom development plan aligned to your launch calendar.

Recommended product:

The Role of Supplier Communication in Building a Successful Amazon Wig Business

Clear, prompt communication reduces returns and delays. During sampling, favor suppliers who answer technical questions in detail—how they achieve lace softness, prevent shedding, and control density variability. Establish a cadence: weekly check-ins while in development, then milestone updates tied to ex-factory, consolidation, and FBA appointment bookings. Document approvals and changes in a shared tracker with photos so nothing is lost across time zones. Define an escalation path and a single accountable owner; responsiveness during small hiccups is the best predictor of performance when volumes rise.

Understanding Lead Times and Stock Availability with Wig Suppliers

Lead time is a chain, not a date. Production depends on lace procurement, handwork capacity, quality gates, and packing; logistics adds consolidation, customs, 3PL kitting, and FBA appointments. Map each step with realistic buffers and reserve capacity ahead of peak periods. For your top ASINs, maintain buffer stock at a nearby 3PL to smooth over appointment delays, and plan a hybrid mode strategy—ocean for planned drops, air for urgent replenishment. Communicate forecasts quarterly and confirm slot reservations to avoid slipping into lower priority queues.

| Supplier setup | Typical production lead time | Flex factors | Key risks | Tie-back to How to Choose the Best Wig Supplier for Your Amazon Store |

|---|---|---|---|---|

| Domestic (USA) | ~1–4 weeks depending on style | Faster changeovers; smaller MOQs | Higher unit cost; limited assortment | Use for fast movers to protect rank |

| International (Asia/EU) | ~3–8+ weeks plus transit | Broader styles; sharper pricing | Transit variability; appointment lag | Use for breadth and margin with buffers |

| Hybrid + 3PL buffer | Mix of both | Staging near FCs | Coordination complexity | Balances speed, cost, and listing stability |

Use the map to set OTIF targets, choose modes per SKU role, and prevent stockouts that harm ranking more than any ad budget can fix.

How to Find Eco-Friendly Wig Suppliers for Your Amazon Business

Sustainability should be evidence-based. Ask for documentation on low-odour, lower-VOC finishing agents and water-based dyes where applicable, and verify that packaging is recyclable or made with reduced plastic. Require suppliers to specify material composition on packaging and provide recycling guidance in inserts to reduce customer confusion. If you intend to pursue Amazon’s climate-friendly badges, align claims with recognized standards and avoid generalized “eco” language that you cannot substantiate; instead, cite the specific materials and processes used and validate them during pilot runs.

The Benefits of Working with Local Wig Suppliers for Amazon Sellers in the USA

Local partners shorten feedback loops and reduce inbound surprises. You gain faster sampling, smaller MOQs for testing variants, and easier claims handling when something drifts from spec. Shipping is simpler and often cheaper during peak when international lanes are congested, making it easier to keep rank-critical ASINs in stock. While unit costs can be higher, the total economics may win once you factor lower rework, fewer appointment misses, and faster recovery from reviews-based issues. Many sellers run a hybrid: local for steady replenishment and troubleshooting; international for scale and assortment.

FAQ: How to Choose the Best Wig Supplier for Your Amazon Store

What’s the first step in How to Choose the Best Wig Supplier for Your Amazon Store?

Define a gold sample with measurable tolerances, then lock FBA packaging and labeling requirements into your contract before placing a significant order.

How do I verify supplier reliability for my Amazon wig store?

Request recent QC records tied to batch IDs, confirm an AQL plan, and run a pilot lot through your 3PL and FBA to surface issues before scaling.

Do certifications really matter when choosing the best wig supplier?

They’re a quality signal, not a guarantee. Use them to shortlist, then verify critical claims like lace softness, shedding, and post-wash texture with your own tests.

How should I compare pricing between wig suppliers for Amazon?

Convert quotes to landed cost, add expected defect/return costs, include FBA prep and rework, and weigh the cash value of lead time against stockout risk.

What’s the safest way to source custom wigs for Amazon?

Follow brief → tech pack → sample iterations → pilot run → scale. Approve artwork early and set a change-freeze date to protect your launch timeline.

How can supplier communication improve my Amazon wig business?

Named owners, weekly updates, and documented approvals reduce errors. Fast, specific answers during sampling predict smoother production at scale.

Why consider local wig suppliers in the USA?

They offer speed, simpler claims, and smaller MOQs, which protect ranking for core ASINs. Use them alongside international partners for margin and range.

Last updated: 2025-12-16

Changelog:

- Added outcome-based contract tips and explicit FBA compliance language

- Introduced a landed-cost pricing table with Amazon-specific adders

- Mapped lead-time risks and hybrid buffer strategies in a comparison table

- Included Helene Hair manufacturer recommendation for custom/private label

- Expanded eco-friendly sourcing guidance with verifiable claims

Next review date & triggers: 2026-04-15 or sooner if Amazon inbound rules change, logistics volatility increases, or new packaging/label requirements are introduced

Ready to operationalize How to Choose the Best Wig Supplier for Your Amazon Store? Share your ASIN goals, volumes, and timelines, and I’ll prepare a supplier shortlist, sampling plan, and FBA-ready packaging SOP you can deploy this quarter.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.