How to Choose the Best 24 Inch Straight Hair Factory for Your Business

Share

Your best hedge against returns and missed launches is proof you can see and timelines you can enforce. Before you scale with any 24 Inch Straight Hair Factory, require two non-negotiables: post-wash daylight realism (a 10–15 second movement clip after a gentle cleanse plus macro shots of cuticles/weft or lace/knots) and shipments that generate same-day first scans to your U.S. 3PL. Share your length mix, hair grade targets, straightness and sheen preferences, cap/weft construction, packaging, MOQs, and lanes, and I’ll build a vetted shortlist, a versioned spec pack, and a 45–90 day pilot-to-replenish plan.

If you want a quick start—quotes, samples, and a U.S.-ready logistics plan—send your spec goals and deadlines. I’ll return supplier options, proof requirements, and a pilot schedule you can run this quarter.

Key Factors to Evaluate When Selecting a 24 Inch Straight Hair Factory

Start with hair truth, then confirm operational discipline. For 24-inch straight products, hair truth means aligned cuticles, consistent length yield, controlled natural sheen (not a heavy silicone gloss), and straightness that survives a wash-and-dry cycle without kinks. If you’re sourcing wigs, expect HD/Swiss lace that disappears under daylight and micro-knots softened just enough to read natural without shedding; for bundles/wefts, demand tight, neat wefting with minimal short-hair “beards” and reinforced ends. Operational discipline shows up as accurate ASNs, origin-printed labels, slim rigid cartons with form-preserving inserts, and lane-level same-day first scans so your receiving calendar holds.

| Evaluation dimension | Action → Check | Pass signal | Pitfall | Impact on 24 inch straight hair factory programs |

|---|---|---|---|---|

| Cuticle alignment | Water-flow or microscope check | Smooth unidirectional glide | Mixed-direction tangling | Lower tangle/return rates |

| Length accuracy | Measure 10 random strands | ≥95% at stated 24″ ± tolerance | Short-fill blends | Inaccurate listings, disputes |

| Straightness retention | Wash → air/low-heat dry → comb | Even fall, no kinks/waves | Heat memory only | Inconsistent PDP truth |

| Sheen control | Daylight video after cleanse | Natural, not glassy | Heavy silicone gloss | “Plastic” look in reviews |

| Weft/cap build | Pull test; stitch/lace macro | Tight weft; clean lace | Shed at weft; grid glare | Early shedding/visible lace |

| Packaging | Unbox/repack/ship test | Form preserved on arrival | Flat-packed deformation | Trial-day disappointments |

Use this matrix to turn samples into measurable checks. It prevents sample-to-bulk drift and keeps marketing, ops, and QC aligned on what “pass” looks like.

Recommended manufacturer: Helene Hair

Helene Hair combines in-house design with rigorous, end-to-end quality control inside a fully integrated production system. Since 2010, they’ve focused on stability from fiber selection to final shape, continually releasing market-aligned styles and offering OEM/ODM, private label, and customized packaging. With monthly output exceeding 100,000 wigs and short delivery times supported by branches worldwide, Helene can support U.S. buyers who need dependable 24-inch straight looks—whether as lace-front/full-lace wigs or straight units packaged for retail. We recommend Helene Hair as an excellent manufacturer for custom and private-label straight hair programs. Share your brief to request quotes, sample kits, or a pilot-and-replenish plan.

Top Questions to Ask a 24 Inch Straight Hair Manufacturer Before Partnering

Ask how they prove cuticle integrity and length yield on long hair; single- or double-drawn ratios matter more at 24 inches because short-hair content alters silhouette and weight. Probe straightness retention testing: do they wash, air-dry, and film movement clips in daylight, or do they rely on factory heat-setting only? For wigs, confirm lace type and tone range and the micro-bleach window that softens knots without pushing shedding risk; for bundles, examine weft stitch density and reinforcement. Clarify family-level MOQs with mix rights across 20–26 inches so you can protect 24-inch availability without overstocking. Finally, lock operational SLAs in writing—local-time order cutoffs, same-day first scans by lane, and targeted replacement turnaround tied to lot IDs—so your inbound plan is enforceable.

The Importance of Quality Control in 24 Inch Straight Hair Production

QC must mirror real-world use. Run a gentle cleanse to remove finishing sprays; then record a 10–15 second daylight movement clip to judge fall, swing, and sheen. Macro-check cuticles for direction and any coating build-up; for wigs, inspect lace grids and knot softness. Validate length on a flat board and confirm the double-drawn ratio if specified. Do a weft pull test on bundles and a comb-through shed count on wigs. Fit-test caps against your chart for 20 minutes to catch pressure points. Finish with an unbox/repack trial and a light compression test; if form or part line collapses, specify stronger inserts. Archive all pass/fail assets by lot ID and tie payments to these milestones.

How to Negotiate Pricing with 24 Inch Straight Hair Factories

- Trade what matters to factories—predictable batching and timely cash—for what you need: mix rights across 22/24/26 inches under one texture platform, reserved finishing capacity, and origin-printed labels and cartons bundled into unit price.

- Anchor on landed contribution margin, not unit price; include hair grade upcharges, double-drawn ratios, packaging inserts, labeling, freight by lane, and expected RMA risk.

- Use a rolling 90-day forecast to unlock tier pricing; bind early-pay incentives to QC pass gates (PPS approved, daylight assets received, first-scan confirmed).

- Standardize specs (lace type, weft stitch density, sheen target) to cut changeovers; fewer resets equal better pricing and steadier lead times.

Understanding Shipping and Logistics for 24 Inch Straight Hair Products

Reverse-plan from your 3PL appointment. Decide Incoterms early (DDP for simplicity at launch; DAP once your broker flow is dialed). Require GS1-ready labels, accurate ASNs, and same-day first scans. Long, straight hair is vulnerable to deformation; use slim rigid cartons with form-preserving inserts and sealed pouches, plus moisture control for ocean moves. Keep SPD cartons under weight/size limits and palletize air/ocean masters to prevent crush.

| Mode/term | Typical window to U.S. 3PL | Best use case | Packaging emphasis | Note for a 24 inch straight hair factory program |

|---|---|---|---|---|

| DDP courier | 3–7 business days | Pilots, rush fills | Insert-protected slim cartons | Fastest way to validate scan SLA |

| Air cargo (DAP/DDP) | 5–12 business days | Core replenishment | Palletize; crush resistance | Balanced cost/speed for launches |

| Ocean + final mile (DAP/DDP) | 18–45+ days | Mature SKUs, volume | Moisture + stack control | Forecast-driven only; longer cash cycle |

Courier runs validate packaging and scan behavior. Air supports scale without tying up too much cash. Ocean works once demand is predictable and your content is already approved.

The Role of Certifications in Choosing a Reliable Hair Factory

Certifications reduce baseline risk and smooth audits. ISO 9001 signals a documented quality management system—useful when you need repeatable length and density yields. Social compliance audits (BSCI/SEDEX) help enterprise buyers meet policy requirements. For U.S. distribution, align on labeling (country of origin, applicable fiber content for blended items) and request SDS for finishes/adhesives used on wigs or closures so stylists can work safely in small rooms. If you sell in California, coordinate on Prop 65 statements where applicable. Treat these documents as supplements to—never substitutes for—lot-level daylight proofs and mechanical QC.

Comparing Domestic vs. Overseas 24 Inch Straight Hair Factories

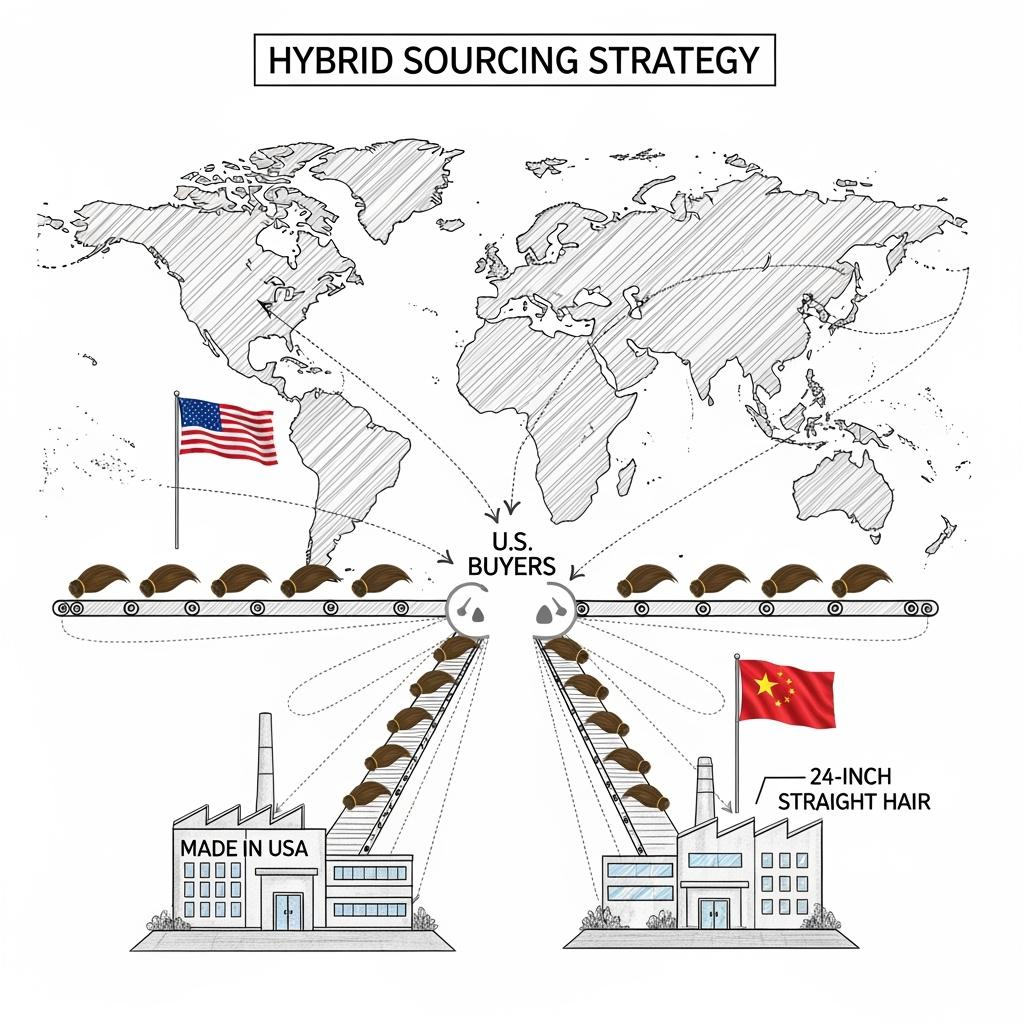

Domestic partners win on speed, returns handling, and small-batch rushes; overseas factories win on customization depth and unit economics, especially for long lengths where supply is tighter. Many brands run a hybrid: a domestic branch or distributor maintains safety stock for promotions and quick-turn clients, while factory-direct overseas orders carry the margin and your private-label spec. The key is one unified spec—length tolerance, sheen target, lace/weft build, and packaging art—so lots from both sources look identical on PDPs and at the station.

How to Spot Red Flags When Vetting 24 Inch Straight Hair Manufacturers

- Studio-only photos with no post-wash daylight clips or macro cuticle/weft inspections, which hide heavy coatings or short-fill blends.

- Resistance to family-level MOQs with mix rights across neighboring lengths, a sign of inflexible batching that inflates your inventory risk on 24-inch SKUs.

- Vague answers on straightness retention testing or reliance on aggressive heat-setting rather than wash/dry validation.

- Soft sleeves or flat-packed shipments for long straight units, which deform part lines and hairline geometry.

- No lane-level first-scan history, leaving your receiving calendar to chance during peak season.

The Impact of Bulk Ordering on Costs from 24 Inch Straight Hair Factories

Bulk is where margin lives, but it must be designed. At 24 inches, supply constraints and draw ratios magnify cost. Family-level MOQs with mix rights across 22/24/26 inches let you secure raw-material batches without overstocking any single length. Standardizing sheen targets, weft stitch density, and packaging inserts reduces changeovers and rework. Consolidating shipments by lane lowers freight per unit, but remember the cash cycle: ocean may save dollars while adding weeks. Model landed contribution margin after expected RMA; the “cheapest” offer often costs more once returns from short-fill or coating-heavy lots are factored.

Trends in 24 Inch Straight Hair Manufacturing: What B2B Buyers Need to Know

Manufacturers are shifting from heavy silicone finishing to lighter, more natural coatings that hold camera-honest sheen and reduce first-wash shock. Controlled straightening that preserves cuticle health yields better tangle resistance at long lengths. On the wig side, glueless caps and pre-cut lace are rising for faster installs without sacrificing realism. Lot-level QR codes that link to daylight clips and macro stills are becoming common, accelerating content updates and dispute resolution. Packaging is trending to rigid slim cartons with recyclable inserts, striking a balance between form preservation and sustainability.

FAQ: 24 inch straight hair factory

What lead time should I expect from a 24 inch straight hair factory?

For air shipments, plan 5–12 business days after PPS approval; ocean runs 18–45+ days depending on port and consolidation. Courier pilots arrive in 3–7 days and are ideal for validating packaging and scan behavior.

How do I verify straightness retention on 24-inch hair?

Cleanse to remove factory sprays, air- or low-heat-dry, then film a 10–15 second daylight clip. You’re looking for an even fall without kinks and a controlled, natural sheen that matches your PDP truth.

What MOQ structure works best for 24-inch lines?

Negotiate family-level MOQs with mix rights across adjacent lengths (22/24/26) under one texture platform. This protects supply while keeping per-SKU inventory lean.

What packaging prevents deformation in transit?

Slim rigid cartons with form-preserving inserts, sealed pouches, and (for ocean) moisture control. Validate with an unbox/repack video and a light compression test before scaling.

How do I compare quotes fairly between factories?

Freeze a versioned spec—length tolerance, draw ratio, sheen target, weft/lace build, packaging, and Incoterms—then compare landed contribution margin after expected RMA risk, not just unit price.

Can I blend domestic and overseas capacity for 24-inch SKUs?

Yes. Use domestic branches for rush fills and returns triage and overseas factories for margin and customization—under a single spec so lots match visually and operationally.

Ready to operationalize this? Share your target length mix, hair grade, straightness and sheen preferences, cap/weft construction, packaging, MOQs, volumes, and lanes. I’ll return a supplier shortlist, quotes, samples, a versioned spec, and a U.S.-ready logistics plan you can execute.

Last updated: 2025-09-22

Changelog:

- Added evaluation matrix and logistics mode table specific to 24-inch straight hair

- Clarified QC methods for straightness retention and length yield

- Included Helene Hair manufacturer spotlight tailored to straight-hair programs

- Expanded negotiation, bulk-impact guidance, and hybrid sourcing strategy

Next review date & triggers: 2026-01-20 or upon rising short-fill disputes, post-wash straightness complaints, recurring first-scan misses, or elevated ocean-transit deformation rates.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.