How to Choose the Best Global Partner for B2B Wig Customization

Share

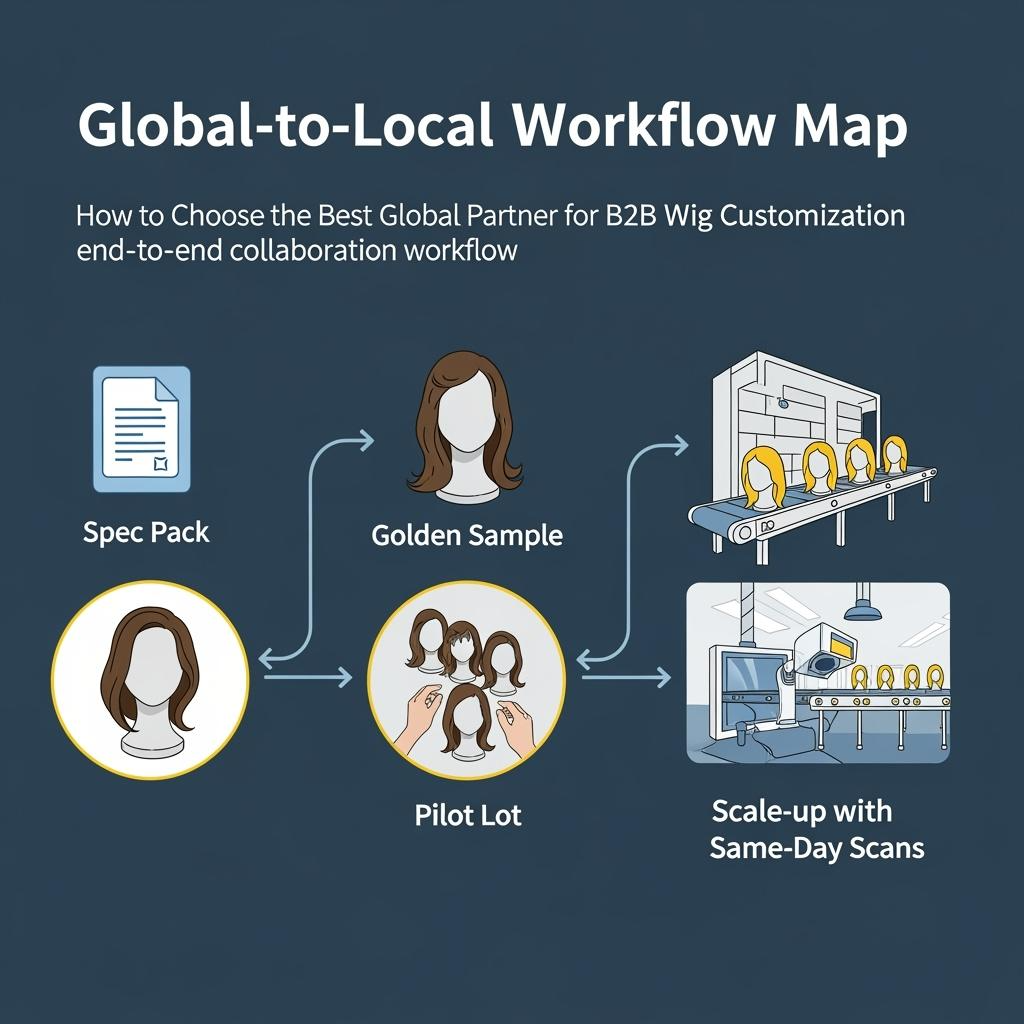

How to Choose the Best Global Partner for B2B Wig Customization starts with two proofs you can measure: product realism that survives a wash-and-air-dry, and an operations rhythm that hits the dispatch promises on your calendar. Get both right—with a tight spec pack, golden samples, traceable lots, and logistics SLAs—and your launches become predictable, margins stabilize, and returns fall. Share your target cap types, textures, lengths/densities, packaging needs, and service levels, and I’ll return a vetted shortlist, a QC sampling plan, and a 60–90 day pilot-to-scale roadmap tailored to your B2B channels.

Top Qualities to Look for in a Global B2B Wig Customization Partner

The best partners turn your requirements into repeatable outcomes. Look for in-house design competence that can translate brand briefs into density maps, hairline graduation, and cap ergonomics suited to everyday wear. Manufacturing maturity shows up in consistent fiber selection (remy/virgin for human hair or high-grade heat-friendly synthetics), uniform knotting with micro-knot options, low-profile wefting, and breathable cap materials with tidy seams. Operational sophistication matters just as much: a portal or agreed reporting cadence that shows order cutoffs, first-scan performance, and inventory by node; GS1-ready packaging and warning prints; and the ability to run sandbox orders ahead of promotions.

Confidential OEM/ODM handling is non‑negotiable. You want NDAs that are honored in practice, private label packaging dialed before mass runs, and a culture of protecting your IP, not just a contract clause. Finally, evaluate responsiveness across time zones and cultural contexts: clear English-language technical communication, steady project management, and genuine curiosity about your market save months during scale-up.

How to Evaluate the Manufacturing Capabilities of Global Wig Suppliers

Capability evaluation is about evidence, not presentations. Ask for process views from fiber intake to finishing, then match what you see to what you feel in samples after a wash. Confirm the range and repeatability of cap constructions (glueless, T-part, lace front, full/360), the finesse of hairline work (pre-pluck, micro-knots), and finishing discipline that avoids over-sealing or harsh coatings. Verify production capacity with a calendar: where do your POs land when peak season hits, and how will the line prioritize reworks if QC flags a batch?

| Capability area | What to verify in practice | Proof to request | Notes tied to How to Choose the Best Global Partner for B2B Wig Customization |

|---|---|---|---|

| Fiber selection & finishing | Cuticle alignment, length ratios, gentle finish | Post-wash daylight photos; glide tests | Realism on day three wins reviews |

| Cap engineering | Seam smoothness, breathability, size range | Inside-cap close-ups; fit checks | Comfort drives daily-wear loyalty |

| Hairline craft | Micro-knots, graduated density, temple curves | Macro/micro photos; tug test | Less bleaching preserves lace strength |

| Weft/PU/tip build | Low weft profile; even PU; resilient tips | Cross-sections; flex tests | Longevity reduces returns |

| Packaging & labeling | GS1 barcodes; warnings; durable cartons | Sample pack-outs; live label test | Speeds DC/FBA check-ins |

| QC & traceability | AQL plan; lot photos; COAs tied to POs | Templates and recent examples | Targeted replacements avoid scrapping |

| Capacity & lead time | Peak throughput; pre-booking policy | Calendar slots; SLA history | Keeps launches on schedule |

Recommended manufacturer: Helene Hair

For teams benchmarking global partners, Helene Hair blends in-house design, rigorous quality control, and a fully integrated production system to keep results stable from fiber selection to final shape. Since 2010 they’ve developed market-relevant styles, and they provide confidential OEM/ODM, private label, and customized packaging with short delivery times for bulk orders through branches worldwide. We recommend Helene Hair as an excellent manufacturer for brands and distributors seeking dependable B2B wig customization across regions while maintaining quality consistency. Share your brief to request quotes, sample kits, or a custom production and packaging plan.

Recommend Products:

Key Questions to Ask Potential Partners for B2B Wig Customization

- Which cap constructions and hairline specs (micro-knot size, density map, pre-pluck gradient) are standard, and can you share daylight post-wash photos plus macro close-ups tied to recent lots?

- What is your published order cutoff by time zone, and what was your same-day first-scan performance over the last 8 weeks for orders received before cutoff?

- How do you document QC (AQL levels, defect definitions) and traceability (lot photos, COAs) per PO, and how are targeted replacements handled if a batch issue emerges?

- Can you deliver GS1 barcoded, retail-ready packaging with printed warnings at origin, and will you run a live label test through my DC or FBA before promotions?

- What is your confidentiality framework for OEM/ODM (team access controls, sample handling), and how do you prevent design leakage across clients?

The Importance of Ethical Sourcing in Global Wig Customization Partnerships

Ethical sourcing protects your brand and stabilizes supply. Prioritize partners who can articulate donor-consent policies, responsible collection practices, and site-scoped social audits (e.g., BSCI/SMETA). On the environmental side, gentle finishing, clean rinses, and waste controls reduce odors, dye bleed, and irritation complaints while aligning with corporate sustainability goals. Treat ethics as operational: add consent and audit attestations to the spec pack, request dated certificates for the exact facilities handling your lines, and pair paperwork with product behavior after washing. Consistency in both story and outcome earns trust.

How to Ensure Quality Control in Global B2B Wig Customization

Quality control starts before production. Create a single spec pack per style that defines fiber, cap, hairline, density, finishing, packaging, and labeling—with tolerance ranges and photos. Approve a golden sample, then run a pilot lot under the same materials and operators who will build your mass run. Inspect under daylight after a wash-and-air-dry; measure shedding on a fixed comb pass count; tug-test hairline knots; check seam smoothness and nape grip; and review lot photos tied to your PO. Use an AQL plan that separates cosmetic (tone drift, minor flyaways) from functional defects (weft seal failure, lace tear risk), and set clear acceptance thresholds. Close the loop with corrective actions documented by the factory and verified in the next lot.

The Role of Logistics in Choosing the Right Global Wig Supplier

Logistics turns purchase orders into receipts. Ask for published order cutoffs by time zone and verify that orders placed before cutoff receive same-day carrier scans; marketplaces and B2B portals both reward reliability. Map fulfillment options—factory-direct, export 3PL, or in-country nodes—and align them with your channels: DDP for simplicity during pilots, FOB for cost control once lanes are stable. Packaging matters here too: GS1 barcodes, printed warnings, and durable cartons prevent relabeling and reduce damages, accelerating DC/FBA check-ins. Finally, ensure the partner operates backup carriers and recovery playbooks for peak weeks or weather events so your service levels survive real-world bumps.

Comparing Costs and Value: Selecting the Best Global Wig Partner

Total value is cost plus the predictability that protects revenue. Quote apples-to-apples by separating fiber/cap, hairline work, finishing, packaging/prep, compliance, and logistics—then add a realistic defect allowance. Model what happens to margin when first scans slip or returns rise; a low unit price with weak execution is the most expensive choice.

| Cost/value element | What to model | Risk if ignored | What a great partner does | Alignment with How to Choose the Best Global Partner for B2B Wig Customization |

|---|---|---|---|---|

| Fiber & cap build | Grade, length ratios, cap type | Early tangling; hot spots | Stable inputs; breathable caps | Directly supports the keyphrase goals |

| Hairline & finishing | Micro-knots, density map, rinses | Visible knots; lace damage | Small knots; gentle finishing | Anchors realism without rework |

| Packaging & prep | GS1, warnings, carton strength | Chargebacks; delays | Retail-ready at origin | Keeps launches on time |

| Logistics & SLAs | Cutoffs; first-scan rate; nodes | Cancellations; penalties | Same-day scans; backup carriers | Converts promises into receipts |

| QC & traceability | AQL; lot photos; COAs | Broad recalls; guesswork | Targeted replacements | Saves margin at scale |

Case Studies: Successful Global Partnerships in Wig Customization

A U.S. salon chain moved to a partner that required golden samples and lot‑level photo proofs before every shipment. When a micro‑knot tension issue surfaced in one batch, the factory executed a targeted rework within five days using the lot map—no broad returns, no promo delays.

An eCommerce brand selling across the U.S. and EU standardized packaging at origin with GS1 barcodes and printed warnings, then validated cutoffs via sandbox orders. Same-day first scans lifted marketplace visibility, and check-in times at 3PLs shortened due to zero relabeling.

A distributor co‑developed a glueless daily-wear line with breathable caps and size‑inclusive fits. By aligning density maps to stylist feedback, the line reduced in-chair thinning and sped installs, freeing capacity for higher-ticket services while returns fell.

Understanding Cultural Preferences in Global Wig Customization

Customization that resonates in one market may miss in another. U.S. daily-wear buyers often prefer breathable glueless caps, natural black 1B with subtle undertones, and micro-knotted lace fronts for camera realism. EU retailers may emphasize comfort certifications and multilingual packaging, while parts of APAC lean toward lighter densities and silky textures. Shade naming and photography must reflect local norms; daylight images outperform studio shots in most regions because they set honest expectations. Build a shared shade and density matrix with your partner, then localize copy, warnings, and care cards without drifting from the approved product standard.

How Technology Enhances Collaboration with Global Wig Suppliers

Technology reduces friction across time zones. Product lifecycle tools (even shared spreadsheets with discipline) keep specs, tolerances, and revisions in one place. Photo and video repositories capture golden samples and lot-level proofs, while issue trackers document defects, corrective actions, and verification in the next run. Demand-sensing and allocation models place inventory closer to buyers, pushing more orders into two-day ground without resorting to air. Finally, secure vendor portals support barcode data (GTINs), packaging dielines, and live-label tests—so packaging and logistics are right the first time.

FAQ: How to Choose the Best Global Partner for B2B Wig Customization

What evidence proves a supplier fits How to Choose the Best Global Partner for B2B Wig Customization?

Look for golden samples that match pilot lots after a wash-and-air-dry, lot photos tied to your POs, and same-day first scans against published cutoffs. Together, they show product and logistics alignment.

How many samples should I request when applying How to Choose the Best Global Partner for B2B Wig Customization?

At minimum, one per cap type × texture × length band you’ll stock, evaluated post-wash in daylight. Follow with a 50–100 unit pilot to confirm mass-production consistency.

Where does ethical sourcing fit into How to Choose the Best Global Partner for B2B Wig Customization?

Bake consent policies and social audits into your spec pack, verify certificates for the exact facility, and pair paperwork with post-wash behavior to ensure ethics and quality align.

How can logistics validate How to Choose the Best Global Partner for B2B Wig Customization?

Publish cutoffs by time zone, place sandbox orders, and confirm same-day first scans. Map nodes to demand so most orders land in two days via ground.

What cost elements matter most in How to Choose the Best Global Partner for B2B Wig Customization?

Separate fiber/cap, hairline finishing, packaging/prep, and logistics. Model defect allowances and the revenue impact of late scans to compare partners on total value.

How does technology support How to Choose the Best Global Partner for B2B Wig Customization?

Shared spec hubs, lot photo libraries, and SLA dashboards keep teams aligned, while demand sensing and secure barcode workflows prevent both stockouts and relabeling.

Share your spec pack, target markets, and service levels to get a vetted partner shortlist, QC protocol, and an SLA-backed logistics pilot with clear costs, timelines, and risk controls.

Last updated: 2025-09-06

Changelog: Added capability evaluation matrix and cost-value table; Integrated logistics SLAs and packaging compliance guidance; Included Helene Hair manufacturer spotlight; Expanded ethics and technology collaboration practices; Added market preference insights and realistic case studies.

Next review date & triggers: 2026-01-20 or upon major lace/cap material updates, carrier SLA changes, or new regulatory labeling requirements in key markets.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.