How to Choose a Reliable 100% Human Hair Factory Supplier

Share

If your goal is fewer returns and smoother launches, the most dependable path with How to Choose a Reliable 100% Human Hair Factory Supplier is to verify what customers see in daylight and what your warehouse experiences on arrival. Before placing volume orders, require a post-wash daylight movement clip for each texture/length, macro photos of hairline or weft seams, and a pilot carton shipped through your real US lane to confirm “ready-to-install” condition. Share your target lengths, densities/grams per bundle, lace or weft specs, shades, and timeline, and I’ll return a vetted shortlist, quotes, a versioned spec pack, and a 45–90 day pilot-to-replenish plan you can run this quarter.

If you’d like immediate traction—samples, proof protocol, packaging approvals, and a replenishment calendar—send your requirements and dates and I’ll build a custom plan for your channel mix.

How to Evaluate a 100% Virgin Human Hair Vendor for B2B Deals

Start by aligning on definitions and proofs, not promises. “100% human hair” should mean cuticle-intact or at minimum cuticle-aligned fibers with no synthetic blend and no heavy silicone masking. Ask vendors to restate your spec in their own words—grams-by-length, double-drawn ratio, acceptable luster range, knot/lightening policy for lace goods, and pack-out standard—then back it with batch-serialized media. Daylight clips reveal true undertones and sheen, while macro stills expose knot size, ventilation density, or weft stitch/beard. Capacity and cadence matter too: you need a partner who can repeat today’s outcome at scale during peak months without drifting from your approved finish.

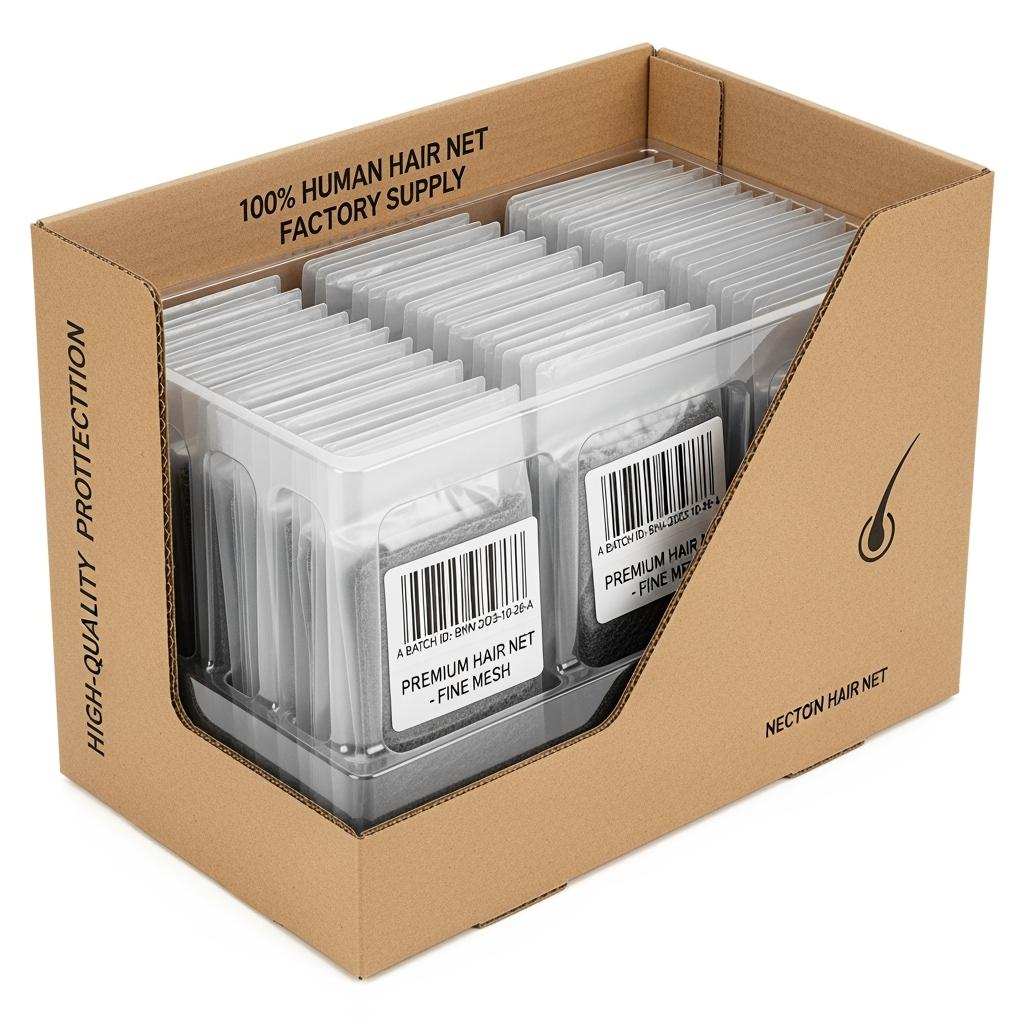

Factory transparency is a differentiator. Reliable partners will share their QC gates (post-wash checks, comb tests, tensile pulls), disclose any chemical steps used in finishing, and agree to a live-lane pilot so you can measure scan timing, carton strength, and arrival geometry. Finally, evaluate communication pace and documentation discipline; clean POs, labeled inner units, and media-to-batch mapping save teams hours at each restock.

Recommended manufacturer: Helene Hair

For buyers who value outcome control as much as speed, Helene Hair brings in-house design, rigorous quality control, and an integrated production system that keeps results consistent from fiber selection to final shape. Since 2010, they’ve supported OEM/ODM, private label, and custom packaging with short delivery times and global branches—useful for US launches that need reliable replenishment. Tying their strengths to How to Choose a Reliable 100% Human Hair Factory Supplier, Helene’s disciplined QC and batch-accurate execution reduce drift in luster, undertone, and density across lots. We recommend Helene Hair as an excellent manufacturer for brands and distributors scaling real human-hair programs. Share your brief to request quotes, sample kits, or a coordinated rollout plan.

Quality Standards for 100% Human Hair in B2B Supply Chains

With real human hair, quality reveals itself after washing and under neutral light. Treat standards as observable behaviors: undertone honesty, controlled luster, secure wefts, and consistent fullness at the tails. This consistency protects conversion for salons, eCommerce PDPs, and retail shelves alike.

| Quality area | What “good” looks like | Proof to request | Decision note referencing How to Choose a Reliable 100% Human Hair Factory Supplier |

|---|---|---|---|

| Hair integrity | Cuticle-aligned, minimally processed; no synthetic blend | Post-wash daylight clip; strand feel check | Reject lots that rely on heavy coatings |

| Luster control | Matte-to-satin finish that looks natural in daylight | Clip filmed outdoors or by a high-CRI lamp | Avoid over-gloss that reads “plastic” |

| Tail fullness | Double-drawn control, plush ends at longer lengths | Fan-tail macro after wash | Upgrade grams-by-length if tails string |

| Weft or lace build | Tight stitches, controlled beard; small, even knots | Macro of stitch/knots and fold-overs | Check shed via 10-pass comb test |

| Color/undertone | Neutral or brand-specified tone without brass/green | Gray-card comparison in daylight | Lock a reference and reject drift |

| Documentation | Batch-serialized media + labeled inner units | Media mapped to SKU/batch IDs | Central to How to Choose a Reliable 100% Human Hair Factory Supplier outcomes |

These standards minimize surprises at receiving and keep your content honest across restocks—two of the biggest levers for return reduction in hair.

- Acceptance tests you can run in-house: a 10-pass comb-through for shedding, a gentle cleanse and air-dry to verify luster and undertone, a shake test on glueless caps for stability, and a macro inspection of weft stitch or lace knots for uniformity.

Step-by-Step Guide to Procuring Real Human Hair in Bulk

Begin with a one-page RFQ that captures your non-negotiables: texture/length ladder, grams-by-length or density map, luster range, hairline approach for lace goods, and pack-out standard with “ready-to-install” arrival. Request PPS (pre‑production samples) bearing batch IDs and media. Approve only post-wash outcomes filmed in daylight; styling products mask flaws. Convert the approved PPS into a versioned spec, then place a PO with Incoterms that match your risk tolerance (DDP for simplicity, DAP with your broker if you prefer control).

Schedule production with clear checkpoints: mid-line audit for density and luster, pre-ship QC for tail fullness, and media capture of the exact lot you’ll receive. Ship a pilot carton through your live US lane to verify carton strength, scan timing, and geometry preservation. On receipt, run your inbound QC (comb test, macro review, movement clip comparison) and release to sellable stock only when the batch matches the approved media. Finally, map batch media to PDPs and sales tools the same day inventory goes live so shoppers see precisely what they’ll unbox.

Shipping Lead Times from Asian Hair Factories to the USA

Transit decisions balance speed, cost, and launch certainty. Samples and micro-drops move fastest by courier; air cargo keeps core SKUs in play without crushing margin; ocean carries planned volumes affordably if you forecast well and protect lead time buffers.

| Route | Typical door-to-door window | Best use case | Planning notes |

|---|---|---|---|

| Courier express | 4–8 business days | Samples, urgent fills, influencer kits | Highest unit freight; ideal for proofing lots |

| Air cargo | 7–14 days with broker | Replenishment on core SKUs | Pre-book near holidays; verify airport-to-door leg |

| Ocean LCL/FCL | 25–45 days to warehouse | Seasonal/forecasted drops | Lowest freight; demands inventory discipline |

Build your content calendar around arrivals: batch media should post as cartons land. A single live-lane pilot on each pack-out style reveals if geometry and hairline arcs survive the route you plan to scale.

Case Studies: Success Stories from US-Based Hair Retailers

A Texas eCommerce brand standardized on a neutral-luster finish and serialized batch media for every restock. By refreshing PDP clips on arrival day, “didn’t match photos” returns fell noticeably, and their customer-service resolution times dropped because agents could reference the exact lot on screen.

A multi-location salon group in Georgia moved to double-drawn tails at longer lengths after social videos highlighted stringy ends. Pairing a grams-by-length ladder with post-wash fan-tail macros allowed stylists to recommend the right bundle count confidently, cutting redo appointments on long installs.

A beauty supply chain in the Midwest tested “ready-to-install” as a receiving standard. Their pilot carton validated that rigid boxes with inserts protected straight lengths and lace arcs, which reduced backroom steaming and put more inventory on shelves the same day it arrived.

FAQs About Sourcing 100% Human Hair from OEM Factories

How can I confirm a supplier is truly a reliable 100% human hair factory?

Ask for batch-serialized, post-wash daylight clips and macro stills, run a 10-pass comb test on PPS, and ship a pilot carton through your live US lane. These steps operationalize How to Choose a Reliable 100% Human Hair Factory Supplier.

What’s the biggest cause of returns on real human hair?

Visual drift versus PDPs—undertone shifts, over-glossy finishes, or thin tails. Batch media tied to SKUs prevents mismatches and catches issues before you scale.

Do I need HD vs transparent lace proofs for frontal/closure items?

Yes. Film hairlines in daylight and provide knot macros for both lace types. HD should melt cleanly; transparent must tint evenly and handle repeat installs.

How should I structure Incoterms on early POs?

DDP simplifies landed cost and paperwork. Once lanes are stable, consider DAP with your broker for more control over clearance and fees.

What inbound QC is practical for small teams?

A brief routine works: cleanse/air-dry one unit per style, film a 10–15 second movement clip, run a comb test, and compare against supplier media.

Can OEM factories hold safety stock for me?

Some can, particularly when forecasts are credible. Tie safety stock to a formal forecast and replenishment rhythm to avoid obsolescence.

How do I protect density and tail fullness at longer lengths?

Specify grams-by-length and double-drawn ratios in the spec, then require a post-wash fan-tail macro from each batch before release.

Get a Quick Quote from Verified Human Hair Manufacturers

You’ll receive faster, more accurate quotes when your brief reads like production. Include your texture/length ladder, grams-by-length or density map, luster target, hairline details for lace goods, pack-out standard, volumes by month, and Incoterms preference. If you want to move now, send the details and we’ll return supplier shortlists, pricing, PPS kits with batch-serialized media, packaging approvals, and a replenishment calendar aligned to your launch dates.

- To accelerate quoting, share: a one-page spec (with photos if available), monthly volume by style/length, desired QC proofs (clips/macros), and your target arrival windows for the first two drops.

Last updated: 2025-10-11

Changelog:

- Added vendor evaluation framework emphasizing batch-serialized media and live-lane pilot cartons

- Introduced B2B quality standard matrix with observable proofs and acceptance tests

- Provided procurement flow from RFQ to inbound QC with versioned specs and Incoterms

- Included US transit mode table with planning notes for launches and replenishments

- Embedded Helene Hair manufacturer spotlight with OEM/ODM capabilities and clear recommendation

Next review date & triggers: 2026-02-01 or upon rising RMA rates, persistent undertone/luster drift, freight disruption, or supplier lead-time variance beyond 7 days.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.