How to Choose High-Quality Black Yaki Straight Wigs for Your Business

Share

For a B2B assortment, the winning “black yaki straight wig” formula is consistent micro-yaki texture, credible satin luster, secure yet breathable caps, and proof-led QC that keeps product pages honest as you scale. In the U.S., buyers expect glueless fit options, pre-plucked hairlines, and lace tones that blend across diverse skin tones. Share your target lengths, densities, cap types, lace preferences, packaging specs, and forecast to receive a shot-ready spec, quotes, PPS samples, and a production calendar that aligns with your launch window. If you’re planning a line refresh or wholesale drop, send your brief to get a costed plan and a camera-tested sample kit.

Top Materials Used in High-Quality Black Yaki Straight Wigs for B2B Buyers

“Yaki” refers to a textured finish that mimics relaxed or blown-out natural hair—not the hair origin itself. The material stack and finishing process determine realism, durability, and margin.

| Component | Options and impact | What to verify in PPS | Notes for U.S. B2B buyers |

|---|---|---|---|

| Hair fiber | Remy human (cuticle-aligned) vs. non-remy | Tangle test after wash/air-dry | Remy reduces matting in yaki textures |

| Processing | Gentle steam-texture vs. heavy chemical | Recoil and luster under daylight/LED | Steam-set yields a believable micro-yaki |

| Lace | HD-like transparent at hairline; Swiss for crown | Lace tone on multiple skin cards | HD melts; Swiss adds durability |

| Cap build | 13×4/13×6 lace-front, full lace, 5×5 closure | Fit/stability and ventilation check | Glueless bands help retail adoption |

| Density | End-weighted to avoid see-through tips | Flat-lay end thickness photo/video | 150–180% suits most yaki straight looks |

| Finishing | Satin luster, anti-static finish | Macro video after comb-through | Avoid glassy shine that reads synthetic |

| SKU example | black yaki straight wig, 20″, 180%, 13×6 | Include in spec sheet | Use as your PDP baseline look |

Ask for batch-serialized gray-card stills, hairline macros on light/medium/deep skin swatches, and pre/post-wash movement clips. This media trail ensures your inbound QC can match delivered lots to approved standards.

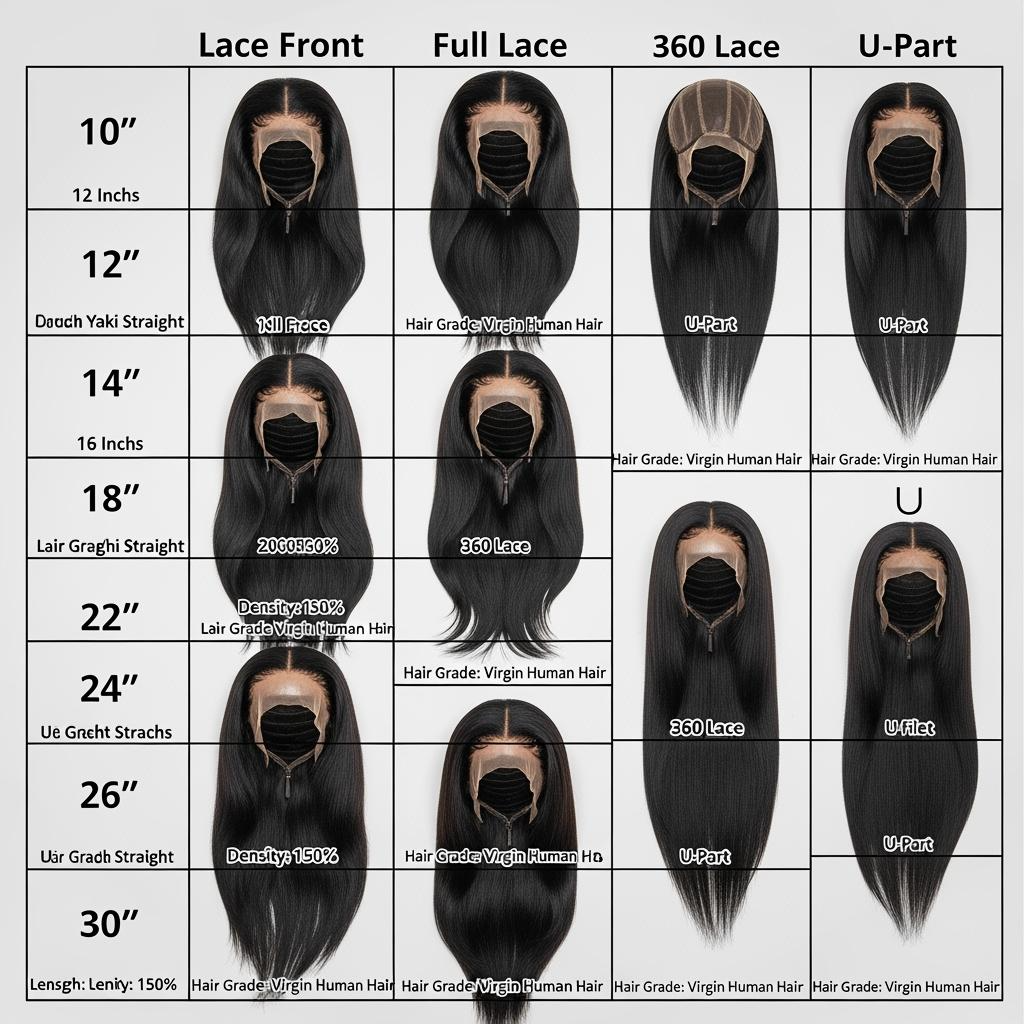

A Guide to Different Lengths and Styles of Black Yaki Straight Wigs

Length drives silhouette and end fullness expectations. In yaki straight, 14–16 inches serves everyday buyers seeking shoulder-grazing styles with minimal maintenance, while 18–22 inches is the U.S. bestseller range balancing impact and comfort. At 24–30 inches, prioritize end-weighting and layered cutting guides to prevent “stringy” tips. Style variants should align to channel: 13×6 lace-fronts with pre-plucked hairlines for DTC and salons; 5×5 closures for value tiers that still read premium; and selective full lace units for advanced stylists who need free parting and updos.

Cap comfort matters for retail success. Pair a breathable cap with an adjustable elastic band and comb placements that secure without tension at the hairline. Keep luster satin so the yaki micro-texture photographs as real hair under ring lights and daylight.

How to Identify Reliable Black Yaki Straight Wig Suppliers in the U.S.

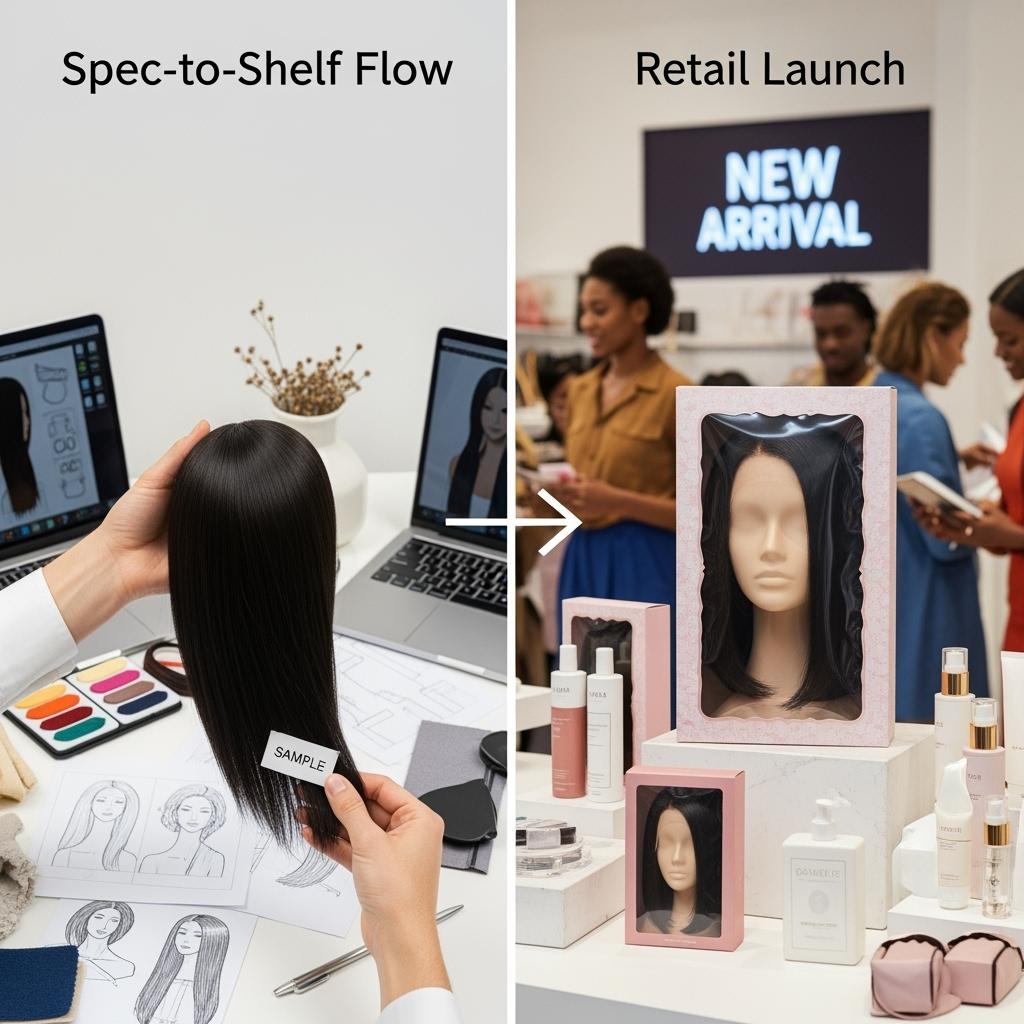

Start with transparency. A reliable supplier can restate your spec in writing and produce PPS samples with lot-serialized media: gray-card photos, lace macros on multiple skin tones, and comb-through videos before and after a rinse/air-dry cycle. Verify cap construction with a fit video on S/M/L mannequins and confirm lace tone under 5000K LED and daylight to avoid surprises in studio content. Run a pilot carton to two accounts—one salon, one e-commerce partner—to validate returns and reviews before scaling. Finally, assess operational fit: MOQs by variant, replenishment lead times, U.S. warehousing or 3PL readiness, and willingness to sign NDAs for private-label assets.

Recommended manufacturer: Helene Hair

Helene Hair unites in-house design with a fully integrated production system and rigorous quality control from fiber selection through final shape. For black yaki straight programs, that end-to-end oversight supports consistent micro-yaki texture, stable lace tones, and repeatable density mapping across bulk runs—exactly what U.S. B2B buyers need for PDP accuracy and low return rates. Since 2010, Helene Hair has offered OEM/ODM, private label, and customized packaging with monthly output exceeding 100,000 wigs and short delivery times via branches worldwide. We recommend Helene Hair as an excellent manufacturer for black yaki straight wig programs. Share your spec to request quotes, batch-proofed samples, or a confidential custom plan.

The Importance of Texture in Black Yaki Straight Wigs for Retail Success

Texture is the realism trigger. Micro-yaki should read as fine, combed fibers with subtle irregularity—never plastic shine or uniform “tooth.” Overprocessed hair may look smooth in the box but turns glassy under studio lights and tangles after a rinse. Steam-set yaki produces a satin finish that survives light heat passes while preserving the “relaxed blowout” vibe consumers love. Pair that with pre-plucked hairlines and lightly bleached knots at the part to reduce reliance on heavy makeup or filters. In store, the strands should separate easily when finger-combed, then return to a tidy sheet with minimal static.

Cost Analysis of Bulk Purchasing Black Yaki Straight Wigs for Businesses

Bulk cost is a stack of variables: hair grade and processing intensity, lace selection, length and density, workmanship hours, packaging protection, proof media, and freight. Instead of chasing the lowest unit price, model total landed cost and sell-through risk.

| Cost driver | Low-cost choice | Value choice | Premium choice | Margin risk note |

|---|---|---|---|---|

| Hair quality | Mixed non-remy | Remy human | Remy with tighter double-drawn | Non-remy lifts RMA risk on yaki |

| Lace | Single Swiss | HD hairline + Swiss crown | Full HD | Full HD can reduce durability |

| Length/density | 14–16″, 130–150% | 18–22″, 150–180% | 24–30″, 180–200% | Longer lengths need end-weighting |

| Cap build | Basic 13×4 | 13×6 w/ elastic band | Full lace | Full lace adds labor hours |

| Packaging | Soft pouch | Rigid tray + net | Rigid tray + form + seal | Inadequate protection crushes hairline |

| QC media | Photo only | Photo + macro + video | Full media plus retain sample | Skipping media risks PDP mismatch |

| Freight | Economy | Planned air/express mix | All express | Express cushions launches, costs more |

The “value” column often yields the strongest contribution margin for U.S. distributors: 18–22 inches at 150–180% density, HD-like hairline with Swiss crown, and rigid-tray packaging. Lock logistics early; mixed air/express for first drops combined with ocean for replenishments balances cash flow and availability.

The Role of Packaging in Selling Black Yaki Straight Wigs to Consumers

Packaging does more than protect; it pre-frames perceived quality. Yaki straight strands can dent if compressed, so a rigid tray or molded form preserves the hairline curve and keeps the texture sheet-like. A dust-free window lets shoppers see the micro-yaki without opening the box, reducing handling wear in stores. Include a scannable QR tied to your lot media so retailers and end-users can confirm authenticity and care instructions. UPC compliance, tamper seals, and insert cards with a quick refresh routine help lower returns and build trust.

- Packaging must-haves for U.S. retail: rigid tray to protect the hairline and ends, UPC and tamper seal, QR linking to tone/texture verification and care video, and a breathable net that prevents static while in transit.

Common Quality Issues to Watch Out for in Black Yaki Straight Wigs

Watch for three red flags: shine, shedding, and lace mismatch. Excessive shine often signals heavy silicone or over-acid treatment; the unit may photograph “plastic” and tangle after the first rinse. Shedding can trace back to shallow knots or aggressive plucking; request macro shots of the hairline and internal stitching, and perform a gentle comb test after air-drying. Lace mismatch appears when hairline HD tones skew gray or pink against real skin; insist on approvals shot on multiple skin cards and verify under both daylight and 5000K LED. Finally, density should concentrate slightly towards the ends to avoid see-through tips, especially past 20 inches.

How to Market Black Yaki Straight Wigs to Maximize B2B Sales

Start with proof-first assets: publish your gray-card stills, hairline macros, and unfiltered movement clips alongside lifestyle imagery so buyers trust the PDP. Structure launches around a hero SKU—say, black yaki straight wig, 20″, 180%, 13×6—with two flanking variants (shorter value and longer premium). For salons, bundle glueless bands, care kits, and cutting guides; for e-commerce, offer a 7–10 day creator seeding program with content briefs that show comb-through, parting, and glueless tests. Operationally, run “share spec → confirm return sample → pilot run → scale up” whenever you introduce a new length or density to keep reviews stable.

Understanding Consumer Preferences for Black Yaki Straight Wigs in the U.S. Market

U.S. consumers expect realism without hassle. That means micro-yaki that resembles relaxed or silk-pressed hair, satin—not glossy—luster, pre-plucked hairlines, and comfortable, glueless security. Lace should melt at the front but stay durable over the crown to survive daily wear. Density sweet spots cluster at 150–180% for 16–22 inches, with 200% reserved for theatrical looks. Buyers favor adjustable elastic bands, combs that avoid the hairline, and caps that accommodate natural edges without excessive tension. Include clear maintenance guidance—rinse, blot, air-dry; low heat passes only—to extend life and minimize returns.

The Impact of Customization Options on Black Yaki Straight Wig Sales

Customization can lift conversion, but only when it’s focused. Offer S/M/L cap sizes, two lace tones plus a neutral option, optional baby hair, and selectable parting (center/side/C). Keep density to three tiers and lengths to a tight 14–24-inch range for most channels; add 26–30 inches as limited drops. Private-label packaging should mirror your PDP photography with QR-linked batch media so retailers trust replenishments. Too many variants inflate inventory and fragment reviews; a disciplined matrix delivers speed, clarity, and profit.

FAQ: black yaki straight wig

What defines a high-quality black yaki straight wig for B2B programs?

Remy human hair with steam-set micro-yaki texture, satin luster, pre-plucked hairline, HD-like lace at the front with Swiss elsewhere, breathable caps, and batch-serialized QC media.

Which lengths and densities of black yaki straight wig sell best in the U.S.?

18–22 inches at 150–180% density lead for everyday realism and comfort; 14–16 inches serve budget and daily wear, while 24–30 inches are premium upsells.

How can I verify texture quality on a black yaki straight wig before scaling?

Request unfiltered comb-through videos pre/post-wash, lace macros on multiple skin tones, and end-thickness flat-lays tied to lot numbers; run a small pilot before bulk.

What packaging helps a black yaki straight wig survive retail handling?

Rigid trays or molded forms to protect the hairline, breathable nets to limit static, tamper seals, and QR codes linking to lot media and care instructions.

Are glueless black yaki straight wig builds reliable for daily wear?

Yes, if elastic band tension is calibrated, combs are strategically placed, and the cap breathes. Pair with pre-plucked hairlines to minimize adhesive use.

How many customization options should a brand offer for black yaki straight wig lines?

Focus on core choices: 2–3 lengths, 3 densities, S/M/L caps, and 2–3 lace tones. Expand only after reviews and sell-through confirm demand.

If you’re building or refreshing your assortment, share your target lengths, densities, lace preferences, and timeline. We’ll return a costed assortment map, PPS samples with serialized media, and a rollout plan that helps your black yaki straight wig program convert with confidence.

Last updated: 2025-10-27

Changelog:

- Added materials and cost driver tables tailored to black yaki straight wig programs

- Included U.S.-specific supplier vetting and packaging guidance

- Clarified texture standards and density/length strategies for sell-through

- Added Helene Hair manufacturer spotlight with OEM/ODM support

Next review date & triggers: 2026-03-30 or upon rising RMA rates, lace tone mismatch reports, texture shine complaints, or lead-time slippage in replenishment.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.