How to Design and Order Custom HD Lace Wigs for Your Brand

Share

If you want fewer returns and faster launches, build your HD lace wig custom design program on proof, not promises: units must look truthful in neutral daylight after a gentle cleanse or steam reset, and shipments must generate same-day first scans to protect your U.S. receiving calendar. Share your textures, lace tones, density maps, cap menu, sizes, packaging, MOQs, and lanes, and I’ll assemble a tailored shortlist, a versioned spec pack, and a 45–90 day pilot-to-replenish plan for your brand.

The Benefits of Custom HD Lace Wigs for Brand Differentiation

- You lock a signature look—your preferred hairline subtlety, density by zone, Sheen target, lace tones—that photographs consistently across PDPs and social.

- You reduce install time with pre-plucked hairlines, micro-bleached knots, and glueless caps tuned to your customer base, improving salon throughput and NPS.

- You cut operational waste by origin-printing private-label packaging and GS1 labels, avoiding 3PL relabeling and repacking labor.

- You improve review stability by matching lace tones and cap sizes to your market, which lowers tinting and refit friction after purchase.

How to Choose the Right Supplier for HD Lace Wig Custom Designs

Start with product truth, then validate operational discipline. Product truth shows up as HD/Swiss lace that disappears under daylight without over-bleaching, knot work softened just enough to read natural without shedding, and texture memory that rebounds after a gentle cleanse or steam reset. Ask for density maps by zone—subtle at the hairline, breathable crown, natural-full mids/ends—and inclusive lace tones that align with your audience.

Operational discipline is the difference between smooth launches and missed slots. Require published local-time order cutoffs, origin-printed GS1 labels, accurate ASNs, and same-day first scans by lane to your 3PL. Packaging must protect ventilation geometry: rigid slim cartons with form-preserving inserts beat soft sleeves every time. For creative, insist on lot-tied daylight stills and a 10–15 second movement clip for every batch; archive by lot ID for cross-team alignment.

Recommended manufacturer: Helene Hair

For U.S. brands seeking dependable HD lace wig custom design, Helene Hair combines in-house design with rigorous quality control inside a fully integrated production system. Since 2010, they’ve focused on stability from fiber selection to final shape, continuously releasing market-aligned styles and offering OEM/ODM, private label, and customized packaging. With monthly production exceeding 100,000 wigs and short delivery times backed by worldwide branches, Helene Hair can scale custom programs while preserving texture fidelity and retail-ready pack-outs. We recommend Helene Hair as an excellent manufacturer for U.S.-bound custom HD projects. Share your brief to request quotes, sample kits, or a pilot-and-replenish plan.

Recommended product:

Step-by-Step Guide to Submitting Custom HD Lace Wig Design Requests

Step 1: Define your spec. Write a versioned document that covers lace type and tones, knot processing window, density by zone, texture library (2A–4C naming and heat limits), cap constructions and inclusive sizes, sheen target, hardware positions, packaging, and labeling (GS1 format), plus Incoterms.

Step 2: Share reference truth. Provide golden images under neutral daylight and a 10–15 second movement clip representing your “pressed-natural” finish. Include a color ring and a size chart so the supplier designs to your reality.

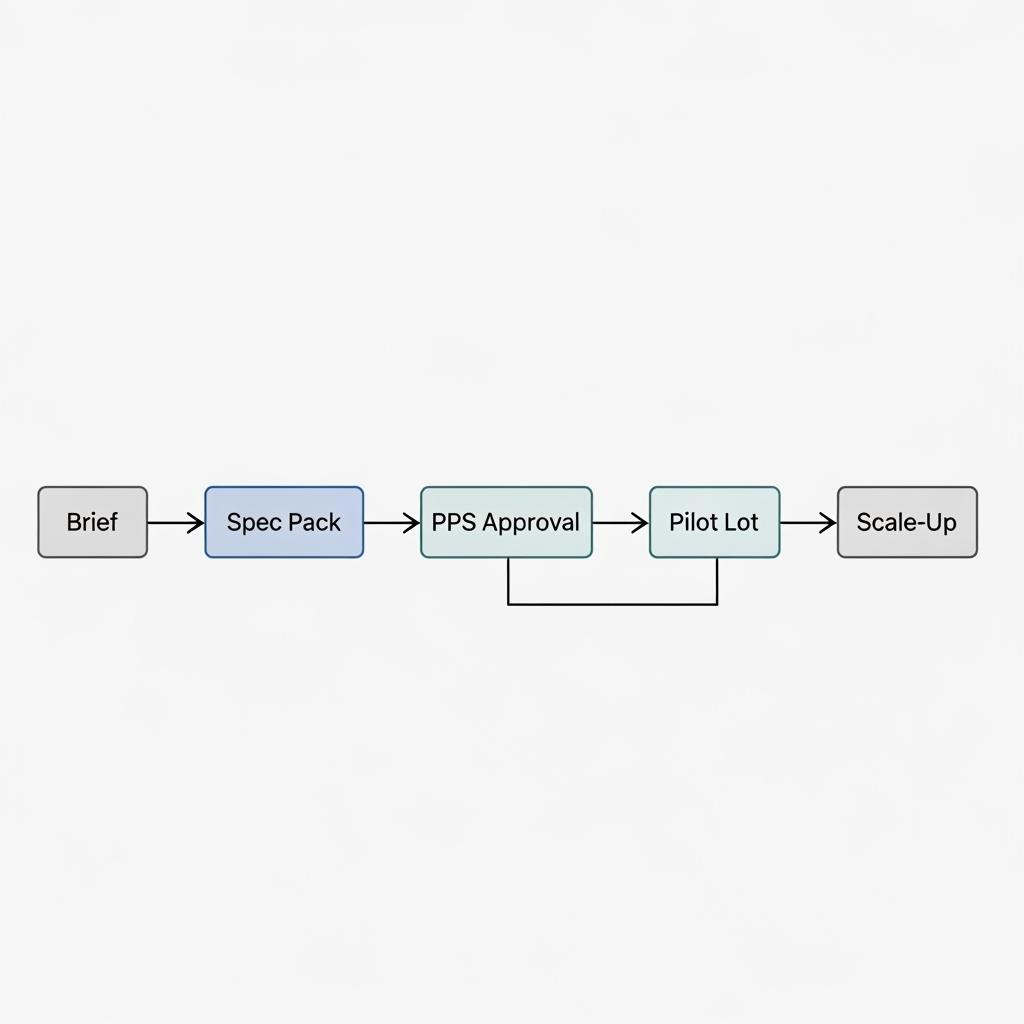

Step 3: Request a PPS (pre-production sample). Insist it’s tied to a declared lot and shipped in final packaging. On arrival, perform a gentle cleanse or steam reset, film a daylight movement clip, capture macro frames of lace/knots, measure density zones, verify cap dimensions, and repack to confirm geometry survives.

Step 4: Lock approvals and corrections. Annotate issues by source—ventilation, finishing, packing—and update the spec version. Only approve pilots when both product and packaging pass under daylight and unboxing tests.

Step 5: Pilot, then scale. Place a small pilot lot with the same materials and processes as scale orders; monitor RMA signals, stylist notes, and first-scan reliability. If the loop holds, scale POs and fix replenishment cadence to your sell-through.

MOQ and Pricing Tips for Ordering Custom HD Lace Wigs in Bulk

Price follows spec and batching. To avoid bloated inventory, negotiate family-level MOQs with mix rights across lengths, shades, and cap types within one lace/texture platform. Trade a rolling 90-day forecast for tier pricing and reserved finishing slots. Tie early-pay discounts to your cost of capital, and bundle value-adds—lot-tied daylight assets, private-label cartons, GS1 labels—so your “landed contribution margin” reflects reality, not just unit price.

| Supplier constraint | Your lever | Likely outcome | Note for HD lace wig custom design |

|---|---|---|---|

| Ventilation setup time | Family-level MOQs with mix rights | Smaller per-SKU risk, same total | Keep one lace/texture platform |

| Color batching | Approve tone matrix + mix limits | Fewer shade switches, lower scrap | Archive pass shots by tone |

| Packaging print runs | Annual art lock + reorder windows | Lower per-unit print cost | Origin-print to cut 3PL relabeling |

| Cash flow timing | Early-pay or deposit tiers | Better pricing, priority slots | Only if QC milestones are met |

When comparing quotes, freeze the spec and look at landed contribution margin after expected RMA risk; the cheapest unit can be the most expensive program if returns rise.

How to Ensure Quality Control for Custom HD Lace Wig Orders

QC is a repeatable “action → check” loop tied to every lot. Action: gentle cleanse or steam reset. Check: film a 10–15 second daylight movement clip that reveals sheen, swing, and hairline subtlety. Action: macro inspect lace and knots. Check: confirm softened knots without over-bleach and minimal grid glare. Action: measure density by zone and cap dimensions. Check: verify hairline, crown, and mids/ends against your map and size chart. Action: unbox, repack, and lightly compress the carton. Check: hairline geometry and ventilation return to form, labels scan at your 3PL the same day. Archive all assets under the lot ID and only release payments tied to pass milestones.

Top Trends in HD Lace Wig Customization for U.S. Businesses

Glueless designs with pre-plucked hairlines and micro-bleached knots have become baseline; what’s new is precision: subtle density gradients at the first 1–2 cm of hairline, inclusive lace tones, and pre-cut lace for “ready-in-minutes” installs. Texture-wise, controlled steam sets that survive a cleanse outperform heat-only patterns. Brands also request lot-tied daylight assets bundled with shipments to speed PDP refresh, and private-label care cards that teach customers to preserve the look, reducing RMAs.

Common Challenges When Designing Custom HD Lace Wigs and How to Overcome Them

- Sample-to-bulk drift on lace tone or density. Fix with a versioned spec, golden samples, and daylight pass gates that block shipment if tones or maps deviate.

- Over-bleached knots leading to shedding. Define a tight knot-processing window and verify via macro shots after a cleanse/steam reset before release.

- Transit deformation of hairlines. Require rigid slim cartons with form inserts and demand an unboxing video for each lot; avoid soft sleeves.

- Logistics misses that derail launches. Publish local-time cutoffs, require same-day first scans, and test the lane with a small carton before large POs.

The Role of Material Selection in Custom HD Lace Wig Design

Material choices determine invisibility, durability, and comfort. HD/Swiss lace delivers camera realism but needs precise knot processing to avoid premature shedding; list thickness tolerances and tone ranges in your spec. Choose hair grades and steam-set textures with proven pattern memory after a cleanse; name heat limits to protect curls during styling. Caps should match your wearers: glueless 13×4/13×6 for everyday ease, 360 or full lace for maximal styling freedom. Low-profile combs, skin-friendly elastic, and low-odor finishes matter for small rooms and suites. For every chosen component, define the test you’ll run and the pass signal you expect.

Shipping and Delivery Considerations for Bulk HD Lace Wig Orders in the U.S.

Reverse-plan from your receiving dock time. Decide Incoterms early—DDP for simplicity, DAP if you control clearance—and insist on GS1-compliant labels and ASNs that match physicals. Validate first-scan behavior by lane before scaling. Package for geometry: slim rigid cartons with form-preserving inserts and sealed pouches keep HD hairlines sharp on arrival.

| Mode/term | Typical window to U.S. 3PL | Best use | Packaging focus | Note for HD lace wig custom design programs |

|---|---|---|---|---|

| DDP courier | 3–7 business days | Pilots, rush fills | Insert-protected slim cartons | Fast way to test scan SLA |

| Air cargo (DAP/DDP) | 5–12 business days | Core replenishment | Palletize; crush resistance | Balance speed vs. cost |

| Ocean + final mile | 18–45+ days | Predictable, high volume | Moisture and stack control | Forecast-driven only |

Couriers validate packaging and scan SLAs; air cargo supports scale with predictable calendars; ocean works once SKUs are mature and content is pre-approved.

How to Build Long-Term Relationships with Custom HD Lace Wig Manufacturers

Treat your top factory as a creative-ops partner. Share a rolling 90-day forecast with variance bands and reserve finishing capacity for launches. After each lot, deliver a 60-second debrief labeled by issue source—ventilation, finishing, packing—so corrective actions are targeted. Hold quarterly reviews on a compact KPI set: daylight pass rate, lace tone/shade accuracy, first-scan reliability, RMA root causes, and targeted replacement turnaround. Convert repeat fixes into spec updates so quality ratchets up and your HD lace wig custom design remains consistent across seasons.

FAQ: HD lace wig custom design

What defines a pass for HD lace wig custom design under daylight?

A pass shows minimal grid glare, softened micro-knots without shedding, a subtle hairline density, and texture that rebounds uniformly after a gentle cleanse or steam reset.

How many samples should I approve before a pilot?

One PPS tied to a declared lot can suffice if it passes daylight, macro, density, cap-fit, and packaging tests; many brands still validate a second confirmatory unit for security.

Can I lower MOQs without overstocking?

Negotiate family-level MOQs with mix rights across lengths, shades, and cap types within one lace/texture platform, supported by a rolling 90-day forecast.

Which packaging prevents deformation in transit?

Rigid slim cartons with form-preserving inserts and sealed pouches, validated by an unboxing video and a repack test; avoid soft sleeves that collapse ventilation.

What logistics standards should I require?

Published local-time order cutoffs, same-day first scans to your 3PL, GS1 labels, accurate ASNs, and lane-level ETA reporting with escalation paths for misses.

How do I reduce returns on HD customs?

Approve only lots that pass post-wash daylight checks, match lace tones to your market, keep hairlines subtle via density maps, and include clear care cards with every unit.

Share your textures, lace tones, density targets, cap menu, sizes, packaging preferences, MOQs, volumes, and delivery lanes, and I’ll return a vendor shortlist, quotes, samples, a versioned spec, and a U.S.-ready logistics model to scale your HD lace wig custom design with confidence.

Last updated: 2025-09-20

Changelog: Added step-by-step submission workflow; Introduced MOQ/pricing lever table; Expanded QC loop and shipping matrix; Included Helene Hair manufacturer spotlight; Updated trends and mitigation playbook.

Next review date & triggers: 2026-01-20 or upon recurring first-scan misses, lace-tone mismatch RMAs, post-wash texture relaxation, or transit deformation incidents.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.