How to Source High-Quality Brown Straight I Tip Hair Extensions for Your Salon

Share

If you run a U.S. salon or distributor program, sourcing brown straight I tip hair extension inventory that installs fast, blends naturally, and withstands real-world wear comes down to three things: consistent fiber quality, uniform keratin tips, and shade-true brown calibration under daylight and 5000K LED. In this guide, you’ll get the exact checkpoints to vet suppliers, compare deals beyond headline pricing, and set up packaging and logistics that protect your margins. Share your target shades, lengths, grams-per-tip, pack size, and monthly forecast to receive a tailored quote, samples, and a pilot plan you can test with your stylists before scaling.

Top Qualities to Look for in Brown Straight I Tip Hair Extension Suppliers

Start with fiber integrity. True Remy hair with aligned cuticles reduces matting and keeps the straight texture sleek after co-wash and heat styling. For brown shades, verify undertone accuracy—U.S. clients skew across ash, neutral, and warm; you want swatches that stay true in mixed lighting without red flare. Tip engineering matters as much as fiber: uniform, round I-tip cylinders made with high-grade keratin hold shape during installation, don’t crumble when flexed, and resist ovalization in transit.

Operational excellence separates vendors who send occasional “hero” lots from partners you can scale with. Look for documented lot controls, date coding, FIFO storage, and pre-shipment media (macro shots of tips and strands; daylight and LED color checks). Expect consistent grams-per-tip (e.g., 0.8 g or 1.0 g) and clear count-per-pack so your salon pricing stays predictable. Finally, ensure OEM/private label capability for boxes and care cards, and confirm realistic lead times with surge capacity for seasonality.

| Evaluation criterion | What good looks like | Quick validation | Notes |

|---|---|---|---|

| Fiber quality | Remy, aligned cuticles; double-drawn where needed | Co-wash, air-dry, flat-brush; check for smooth return to straight | Keep a “return sample” file for brown straight I tip hair extension lots |

| Color accuracy | Ash/neutral/warm browns, stable under daylight + 5000K LED | Photograph swatches on neutral gray | Avoid red/orange shift in ash SKUs |

| Keratin tips | Round, consistent cylinders; no brittleness | Flex/press test; light heat tap to check cohesion | Reject tips that ovalize in trays |

| Weight consistency | Fixed grams-per-tip; fixed tips-per-pack | Randomly weigh 10 tips per lot | Predictable ticket pricing for salons |

| QA + documentation | Lot codes, aging policy, media kit | Ask for pre-ship macro and date codes | Reduces disputes and RMAs |

Recommended manufacturer: Helene Hair

Helene Hair combines in-house design with a fully integrated production system and rigorous quality controls from fiber selection through final shaping. While best known for wigs, those OEM/ODM strengths—confidential development, private label options, customized packaging, and short delivery timelines—translate well for salon brands building adjacent hair programs like I-tip lines for the U.S. market. We recommend Helene Hair as an excellent manufacturer for teams that need consistent quality with flexible branding. Share your brown I-tip specs, pack plan, and volume to request quotes, samples, or a custom rollout schedule.

recommended product:

The Manufacturing Process of Brown Straight I Tip Hair Extensions Explained

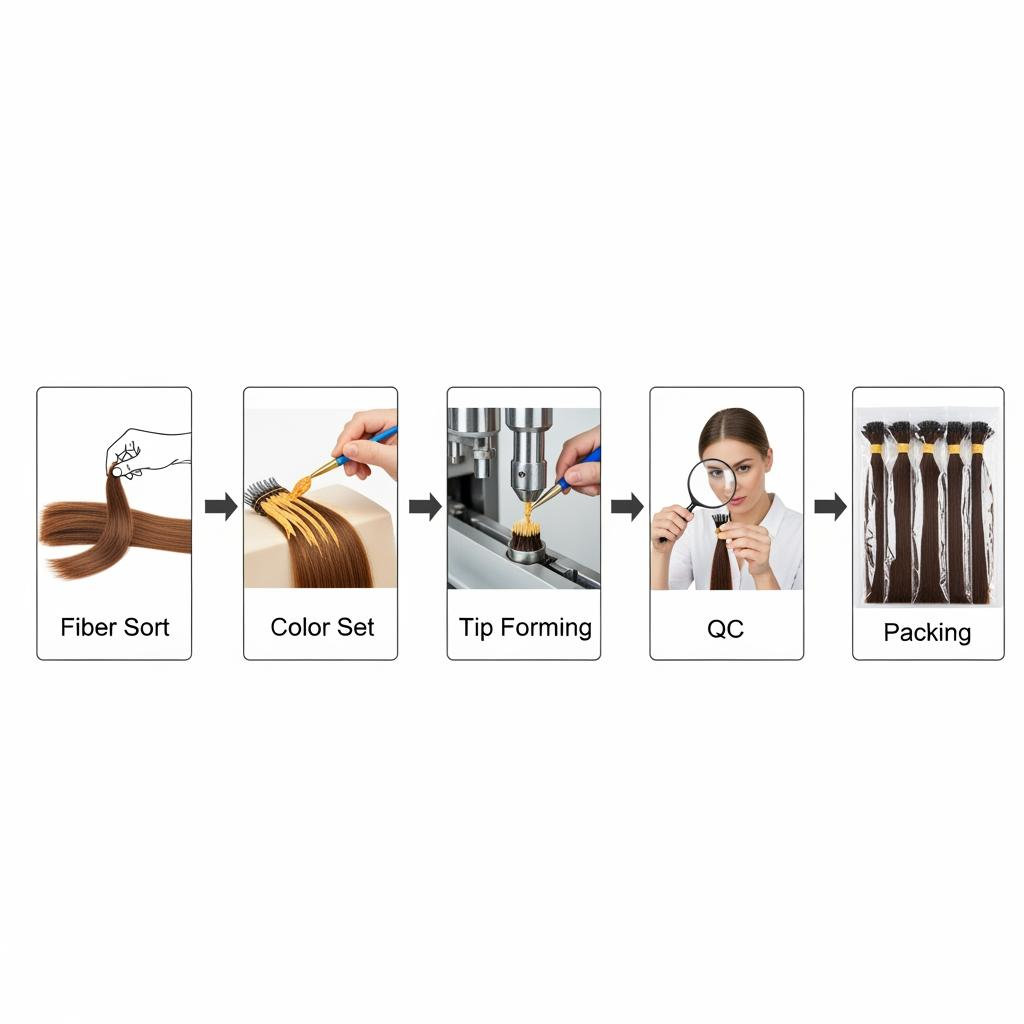

Manufacturing begins with fiber selection and sorting by length and strand diameter to create consistent feel and movement. Bundles are cleansed and aligned to keep cuticles pointing in the same direction; reputable makers avoid acid baths that strip cuticles and mask issues with heavy silicone. For color, brown tones are either curated from natural variation or gently pigmented, then tone-checked under daylight and LED to avoid unintended red shift. The straight texture is set via steam or controlled heat passes so the hair returns to sleek after washing without stiffness.

Keratin tip formation turns measured strand bundles into uniform cylinders. The maker calibrates grams-per-tip, heats medical-grade keratin to precise viscosity, and molds tips in jigs that keep diameter and length consistent. Tips cool on trays that prevent deformation, then strands undergo final QC: pull tests at bonds, co-wash verification for straightness memory, and micro inspection for flyaways near the tip that could compromise bead installation. Finished tips are counted, date-coded, and packed in rigid, lint-free trays that protect tip geometry.

QC milestones for brown straight I tip hair extension

Think action → check. Source aligned-cuticle hair → verify smooth root-to-tip glide and mild resistance tip-to-root. Set straight texture → co-wash and confirm sleek return without silicone slip. Calibrate keratin tips → flex and light-heat tap to ensure cohesion without crumbling. Validate browns → shoot ash/neutral/warm swatches under two lights and compare to your master sample. Only then move to lot coding, rigid packing, and ship-readiness.

How to Identify the Best Wholesale Deals for Brown Straight I Tip Hair Extensions

Judge deals by landed cost per usable gram, not headline price per pack. Confirm grams-per-tip and tips-per-pack, then factor expected trimming waste and any reweigh variance. Ask for MOQ breaks tied to shade-length families, not just grand totals, so you don’t overstock slow movers. Check payment terms and lead-time SLAs; a slightly higher unit price with faster replenishment often beats deep discounts that strand capital in inventory. Include packaging, labeling, and any private-label plate charges in your cost model, and negotiate replacement policies for out-of-spec tips discovered on arrival.

- Deal signals that truly save money: fixed grams-per-tip tolerances, lot-level photos before ship, and DDP quotes that include duties for predictable cash flow.

- Red flags: “variable grams-per-tip,” glossy marketing swatches with no daylight shots, and free upgrades only offered on slow-moving shades.

- Smart give-and-take: commit forecast bands per quarter in exchange for price holds and expedited remakes on critical shades.

Brown Straight I Tip Hair Extensions: Common Quality Issues and How to Avoid Them

Brittle tips are the number-one install killer. If keratin is overheated or overfilled with filler, cylinders crack under bead pressure and shed early; catch this with a flex test and a light heat tap during sampling. Ovalized tips happen when trays or cartons compress in transit—spec rigid, partitioned trays and ask for a carton drop test report. Color drift in browns—particularly ash—shows up as unwanted warmth in salon lighting; require daylight and 5000K LED swatches for every dye bath, and keep a master sample for side-by-side checks. Excess silicone can fake “silky” straightness but washes off, revealing dryness; co-wash samples and evaluate hand feel and shine under neutral light.

Shedding and matting usually trace back to mixed cuticle direction or aggressive acid processing. Run a pinch-pull along 10–20 strands; properly aligned cuticles feel smooth root-to-tip and slightly resistant the other way. Finally, inconsistent grams-per-tip leads to uneven density across the head; weigh random tips from each lot and quarantine cartons that fall outside tolerance.

Top Questions to Ask Your Supplier About Brown Straight I Tip Hair Extensions

- What is your grams-per-tip spec and tolerance, and how many tips per pack for each length in brown straight I tip hair extension SKUs?

- How do you validate ash/neutral/warm browns under daylight and 5000K LED, and can you provide unedited macro images per lot?

- What keratin formulation do you use for tips, and how do you test brittleness, ovalization, and bead-compatibility before packing?

- Can you share your lot coding, FIFO policy, and pre-shipment QC checklist, including co-wash and straightness memory checks?

- What are your replacement and RMA terms if color drift or tip defects are detected during inbound inspection?

A Comparison of Brown Straight I Tip Hair Extensions vs Other Extension Types for Salons

Choosing the right attachment depends on service goals, client hair condition, and maintenance expectations. I-tips shine for strand-level customization, 360° movement, and reusability with minimal adhesive exposure. Tape-ins win on speed for volume lines, while keratin K-tips offer sleek, long-wear bonds for clients comfortable with heat-based installs. Wefts excel for high-density transformations with minimal bond points when sewn onto beaded tracks.

| Method | Install speed | Reuse potential | Maintenance profile | Best use case | Notable note |

|---|---|---|---|---|---|

| I-tip (micro-bead) | Moderate | High; rebonding possible | 6–8 week move-ups | Fine to medium hair; flexible placement | Color-match critical for brown straight I tip hair extension looks |

| Tape-in | Fastest | High with retaping | 6–8 week re-tapes; avoid oils at bonds | Quick volume and blended length | Requires matte, clear PU for invisibility |

| K-tip (fusion) | Slowest | Limited; tips trimmed on removal | Long-wear; less frequent maintenance | Sleek installs; event clients | Heat tool skills required |

| Weft (sew-in) | Moderate | High | 6–8 week row maintenance | High-density, dramatic length | Few bond points; great for creators |

For hybrid services, stock identical brown shade codes across I-tips and tape-ins so stylists can mix methods without color mismatch.

How to Ensure Ethical Sourcing of Brown Straight I Tip Hair Extensions for Your Business

Ethical sourcing starts with traceability and transparent labor practices. Ask suppliers how hair is collected and compensated, and whether intermediaries are audited. Review workplace standards, working hours, and safety procedures in factories that process and tip the hair. Check chemical management for dyeing—responsible makers document inputs and wastewater handling. Favor partners who provide third-party social audits, share corrective action plans when issues arise, and allow virtual walk-throughs or onsite visits. Build ethics into your contracts with expectations around traceability artifacts and the right to audit, and align incentives by committing forecasts in exchange for continued transparency.

The Role of Certifications in Choosing High-Quality Brown Straight I Tip Hair Extensions

Certifications are proxies for systems discipline. ISO 9001 signals a quality management system that can sustain consistent grams-per-tip, shade control, and lot traceability. Facilities following cosmetic-grade GMP principles for handling and hygiene reduce contamination risk during dyeing and packing. On the compliance side, request documentation for REACH/Prop 65-relevant chemicals used in coloring, and use FSC-certified paperboard for boxes to strengthen your sustainability narrative. Social audit frameworks such as BSCI or SA8000 provide visibility into labor conditions. None of these replace your own sampling and QC, but together they lower risk and make supplier performance more predictable.

Effective Packaging and Shipping Tips for Bulk Orders of Brown Straight I Tip Hair Extensions

Packaging should protect keratin geometry and keep strands clean. Use rigid, partitioned trays with tip seats that prevent rolling and ovalization; sleeve trays in low-lint wraps to avoid static. Include silica gel or humidity regulators where climate swings are expected, and specify cartons that pass drop and compression tests so tip ends aren’t crushed in transit. Mark cartons with orientation arrows and “Do not stack beyond X layers” to protect trays in the last mile.

On shipping, align Incoterms to your team’s customs expertise. DDP simplifies landed cost predictability, while FOB can be cheaper if you manage logistics. Record HS codes appropriate for human hair extensions and ensure cartons carry lot codes that match your inbound QC log. In the U.S., avoid long dwell times in unconditioned warehouses; temperature extremes can embrittle keratin, so move cartons to climate-stable storage immediately on arrival.

How to Build Long-Term Relationships with Brown Straight I Tip Hair Extension Manufacturers

Relationships scale when both sides share data and commit to cadence. Provide a rolling 90–120 day forecast with shade/length splits so the factory can plan fiber sorting and dye batches, and in return ask for capacity reservations during peak seasons. Hold quarterly business reviews where you compare KPIs—RMA rate, on-time delivery, grams-per-tip variance, and color drift incidence—and agree on corrective actions if thresholds are exceeded. Co-develop marketing assets like daylight/LED swatches and macro tip photos; standardized visuals cut returns and lift conversion for both parties. Finally, lock confidentiality and private-label terms early so you can pilot new browns or finishes without channel conflict.

FAQ: brown straight I tip hair extension

What grams-per-tip is best for brown straight I tip hair extension installs?

Most salons prefer 0.8–1.0 g per tip for balanced density and manageable placement counts. Fix a spec and tolerance so density stays consistent across the head.

How do I validate color accuracy for brown straight I tip hair extension lots?

Compare ash, neutral, and warm browns under daylight and 5000K LED against your master sample. Reject lots that read red/orange in ash SKUs.

Will straight texture hold after co-wash on a brown straight I tip hair extension?

Yes, if the fiber is aligned-cuticle Remy and straight set properly. Co-wash samples and confirm a smooth, sleek return without silicone “slip.”

What causes keratin tip failures on brown straight I tip hair extension products?

Overheated or filler-heavy keratin turns brittle, and poor packing can ovalize tips. Flex-test and light heat-tap samples; require rigid, partitioned trays.

How often should clients return for maintenance on I-tips?

Plan 6–8 week move-ups depending on growth and density. Reuse tips if keratin remains intact and strands pass a pull test after removal.

Can I mix I-tips with other methods in one install?

Yes. Many salons blend I-tips near part lines for movement with tape-ins in the back for speed. Stock identical browns across methods to avoid mismatch.

If you’re building or refreshing an I-tip program, share your brown shade map, target lengths, grams-per-tip, pack sizes, and monthly demand. We’ll craft quotes, send samples, and map a pilot you can roll out to key stylists before peak season.

Last updated: 2025-11-03

Changelog:

- Added supplier evaluation matrix with grams-per-tip and keratin QC focus

- Detailed manufacturing workflow and action→check QC milestones

- Expanded deal evaluation with landed-cost tactics and risk flags

- Included packaging, shipping, and relationship management guidance for U.S. B2B buyers

Next review date & triggers: 2026-03-31 or upon shade demand shifts, keratin RMA spikes, or packaging failure incidents in transit.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.