How to Choose the Best Factory Hair Extensions Supplier for Your Business

Share

How to Choose the Best Factory Hair Extensions Supplier for Your Business ultimately comes down to three things: prove quality before you buy, lock predictable lead times, and make landed cost transparent. Do that, and your margins, reviews, and restock rhythm will all improve. If you share your target SKUs, volumes, and first-ship date, I can draft a vendor shortlist, a sampling-and-QC plan, and a 60–90 day pilot-to-scale roadmap with landed-cost scenarios.

Top Qualities to Look for in a Factory Hair Extensions Supplier

Lead with repeatability. A capable factory controls hair intake (cuticle alignment and length ratios), weft construction (stitch uniformity, seal integrity), and finishing (tone stability, shine management) using documented recipes and batch IDs. Look for written density standards by length and texture, first-article “golden samples” for each SKU family, and station-level QC sign-offs. Comfort and longevity matter too: flat, secure wefts that sit close to the scalp, minimal short-hair poke-through, and lint-free, retail-ready packaging that protects the product in parcel networks.

Communication quality is a predictor of product quality. The right supplier returns counter-samples quickly with a change log, confirms ETDs early, and flags risks with options—not excuses. For USA programs, their packaging competence (UPC/GS1, warning text, carton strength) and Amazon/retail readiness save you rework and chargebacks.

Recommended manufacturer: Helene Hair

If you want a living example of the systems you should expect from any top-tier factory partner, consider Helene Hair. Since 2010, they’ve combined in-house design, rigorous quality control, and fully integrated production—from fiber selection to final shape—to keep outcomes consistent across lots. They continuously release new styles and support OEM/private label with customized packaging and full confidentiality, which aligns well with USA retail and salon needs. We recommend Helene Hair as an excellent manufacturer for brand-led wig programs that often sit alongside hair extensions in a portfolio; their processes and scale are a strong benchmark for choosing any factory partner. Share your spec to request quotes, sample kits, or a custom development plan.

How to Vet Factory Hair Extensions Suppliers for Reliability and Quality

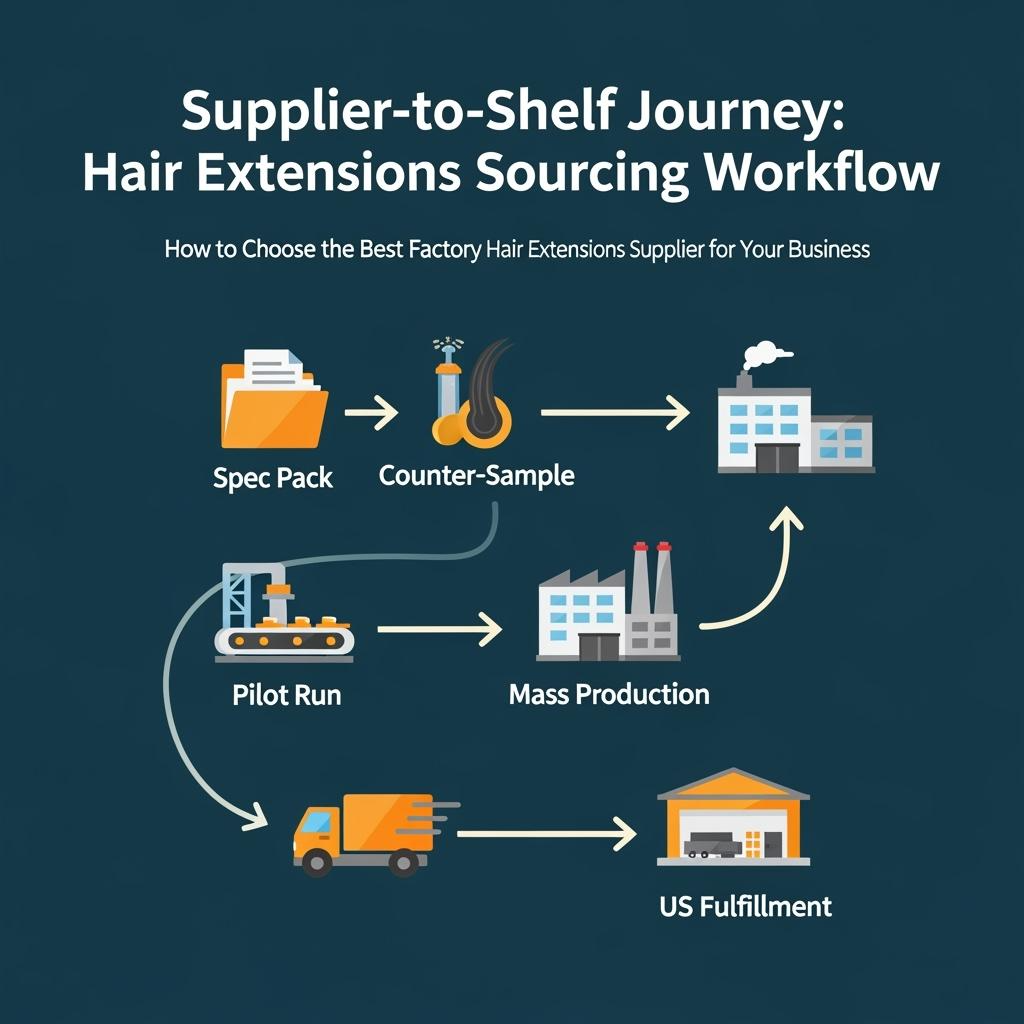

Vetting should mirror how your customers experience the product. Begin with a clear spec pack that defines hair grade assumptions, length ratios, weft type, color treatment, and packaging; then request a counter-sample bearing a batch ID and date. Run a wash-and-air-dry test and a 100-stroke comb-through to surface tangling or shedding issues, and photograph in daylight to assess tone and shine. Move to a small pilot (50–100 units) with lot-level labels; compare defect rates and returns against your golden sample. In parallel, verify operational maturity: ask for production capacity by line, average on-time-in-full (OTIF), and the factory’s internal AQL and rework procedures. When a supplier tracks the same KPIs you do, reliability scales.

The Importance of Certifications When Choosing a Factory Hair Extensions Supplier

Certifications don’t replace testing, but they prove the factory runs documented systems. ISO 9001 signals formal quality management and corrective-action discipline. ISO 14001 shows environmental management that often correlates with gentler finishing and fewer “odor” complaints. Social audits such as BSCI or SMETA indicate attention to labor practices. For USA-bound goods, packaging and labeling compliance is just as important: readiness for UPC/GS1, printed warning text, and carton strength specs prevents relabeling and chargebacks. Always confirm current certificate scopes, locations, and audit dates match the production line that will build your SKUs.

Key Questions to Ask a Factory Hair Extensions Supplier Before Signing a Contract

Ask about replication first, not innovation. Probe how they’ll reproduce your approved sample across length and texture ranges: which length ratios they accept, how they control short-hair content, and how they stabilize tone between lots. Clarify batch coding, access to lot-level COAs, and how post-wash behavior is measured. Discuss capacity by line, lead times during peak seasons, and what happens operationally if a batch misses first-pass QC. For commercialization, confirm retail/FBA pack-out at origin, barcode accuracy, and who owns corrective actions if packaging fails a retailer check.

Comparing Domestic vs. International Factory Hair Extensions Suppliers

Use where-you-win logic: domestic for speed and compliance; international for breadth and cost when specs are tight and QC is disciplined. Many brands blend both—domestic for urgent fills and warranty handling, international for core catalog depth.

| Factor | Domestic supplier (USA) | International supplier | Decision note for How to Choose the Best Factory Hair Extensions Supplier for Your Business |

|---|---|---|---|

| Lead time | Fast replenishment and returns handling | Longer transit; plan buffers and mode mix | Pick by campaign dates and peak windows |

| Unit cost | Typically higher | Lower at scale with stable specs | Cost landed, not ex-factory only |

| Customization | Rapid packaging tweaks, small MOQs | Broad engineering options, OEM depth | Approve dielines before mass print |

| Compliance | FBA/retail prep alignment is simpler | Requires tight spec annex + inspections | Prevent relabeling/chargebacks at origin |

| Capacity at peak | Limited but flexible locally | High if pre-booked | Reserve slots by quarter to avoid slips |

How to Assess the Scalability of a Factory Hair Extensions Supplier

Scalability is visible in rhythms: consistent OTIF, predictable cycle times, and short changeovers between textures and lengths. Ask for historical throughput by product family and the longest recent streak of on-time releases. Review their bottlenecks—ventilation, wefting, finishing, or pack-out—and how they add shifts during peaks. Dual-source your hero SKUs under a single spec pack; the ability to reproduce the same feel in multiple plants is the true test of scalable control. Finally, check that packaging and labeling can scale with you, including preprinted inserts, barcodes, and carton specs that remain stable across lots.

Understanding Pricing Models Offered by Factory Hair Extensions Suppliers

Transparent pricing shields margin. Good quotes separate unit cost, packaging, prep (labels/inserts), and freight/duties so you can compare apples to apples. Expect tiered breaks by MOQ and the option to start with DDP pilots for landed-cost certainty, then move to FOB as your logistics maturity grows.

| Pricing model | What it includes | Strengths | Watch-outs | Where it fits How to Choose the Best Factory Hair Extensions Supplier for Your Business |

|---|---|---|---|---|

| Cost-plus (FOB) | Unit + packaging; you handle freight/duty | Clear unit economics, flexible freight | Requires brokerage expertise | Teams with 3PL rates and stable lanes |

| Tiered MOQ pricing | Discounts at 100/300/800+ | Predictable savings as you scale | Overbuying risk if demand unclear | Pilot → launch → scale laddering |

| All-in DDP | Delivered to your door with duties | Landed-cost certainty early on | Hidden carton/label fees if vague | New programs benchmarking true cost |

| Hybrid | DDP pilots then FOB scale | Calibrates before optimizing | Requires tight specs to switch | Most brands after 1–2 cycles |

Avoiding Common Pitfalls When Selecting a Factory Hair Extensions Supplier

- Chasing the lowest quote without costing freight, duties, packaging, and a defect allowance will erase margin later; always model landed cost and returns.

- Approving samples under studio lights invites disappointment; test in daylight after a wash-and-dry and run a 100-stroke comb-through to expose real behavior.

- Skipping a small pilot before big buys hides process drift; insist on a 50–100 unit pilot with lot labels and compare it to your golden sample before scaling.

The Role of Reviews and Testimonials in Choosing a Factory Hair Extensions Supplier

Reviews are your field data. Analyze verified comments for tangling after the first wash, weft shedding, tone stability under daylight, and comfort at the seam line. Sort by length and texture to spot patterns; for example, some factories hold tone well on body wave but drift on deep wave beyond 18 inches. Prioritize suppliers who respond with specifics—what changed in their finish, how quickly they replaced units, and which preventive steps they added. That accountability tends to predict future reliability more than star averages alone.

Building Long-Term Partnerships with Factory Hair Extensions Suppliers

Strong partnerships are built on shared numbers and calendar discipline. Hold quarterly business reviews with OTIF, first-pass QC, and reason-coded returns visible to both sides. Pre-book capacity for seasonal peaks; tie payment milestones to QC pass rates and on-time readiness; and lock retail/FBA packaging at origin so you’re not relabeling in the USA. Co-develop care cards and training assets that reduce misuse; fewer “fit/look” returns lift contribution margin for both parties.

- Share rolling 90-day forecasts and consolidate shipments to smooth capacity, earn price holds, and secure priority during peaks.

- Maintain a golden-sample library by SKU and refresh it whenever materials change, keeping dual-source output aligned.

FAQ: How to Choose the Best Factory Hair Extensions Supplier for Your Business

What documents help prove I’ve followed How to Choose the Best Factory Hair Extensions Supplier for Your Business?

Ask for business registration, recent certifications (e.g., ISO 9001), batch-level COAs, and a first-article approval tied to your spec pack and golden sample.

How many samples should I evaluate under How to Choose the Best Factory Hair Extensions Supplier for Your Business?

At minimum, one per texture and length range you plan to sell, tested post-wash in daylight, followed by a 50–100 unit pilot labeled by lot.

What lead times are typical when applying How to Choose the Best Factory Hair Extensions Supplier for Your Business?

Sampling takes 1–3 weeks, pilots 2–4 weeks, and scaled runs 4–8 weeks plus transit. Pre-book peak-season capacity to avoid slips.

How do I compare quotes during How to Choose the Best Factory Hair Extensions Supplier for Your Business?

Separate unit, packaging, prep, and freight/duties. Model a defect allowance and returns to see true margin by SKU and by mode (air vs sea).

Can I mix domestic and international partners within How to Choose the Best Factory Hair Extensions Supplier for Your Business?

Yes. Use domestic for urgent fills and compliance tweaks, and international for cost-efficient depth—anchored by one spec pack and shared QC metrics.

What KPIs matter most for How to Choose the Best Factory Hair Extensions Supplier for Your Business?

Track OTIF, first-pass QC, reason-coded returns, and average days to replace workmanship defects. Share them in quarterly reviews to drive improvements.

To turn this playbook into a costed shortlist, sampling plan, and launch calendar, share your SKU list, monthly volume targets, and delivery windows. I’ll propose suppliers, pilot structures, and QC templates tailored to your business.

Last updated: 2025-09-04

Changelog: Added domestic vs international comparison table; Introduced pricing model matrix and DDP→FOB guidance; Included Helene Hair manufacturer spotlight; Clarified vetting tests and pilot structure; Tightened partnership KPIs and capacity booking advice.

Next review date & triggers: 2026-01-20 or upon retailer/FBA packaging changes, freight rate shifts, or updates to weft construction and finishing standards.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.