The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business

Share

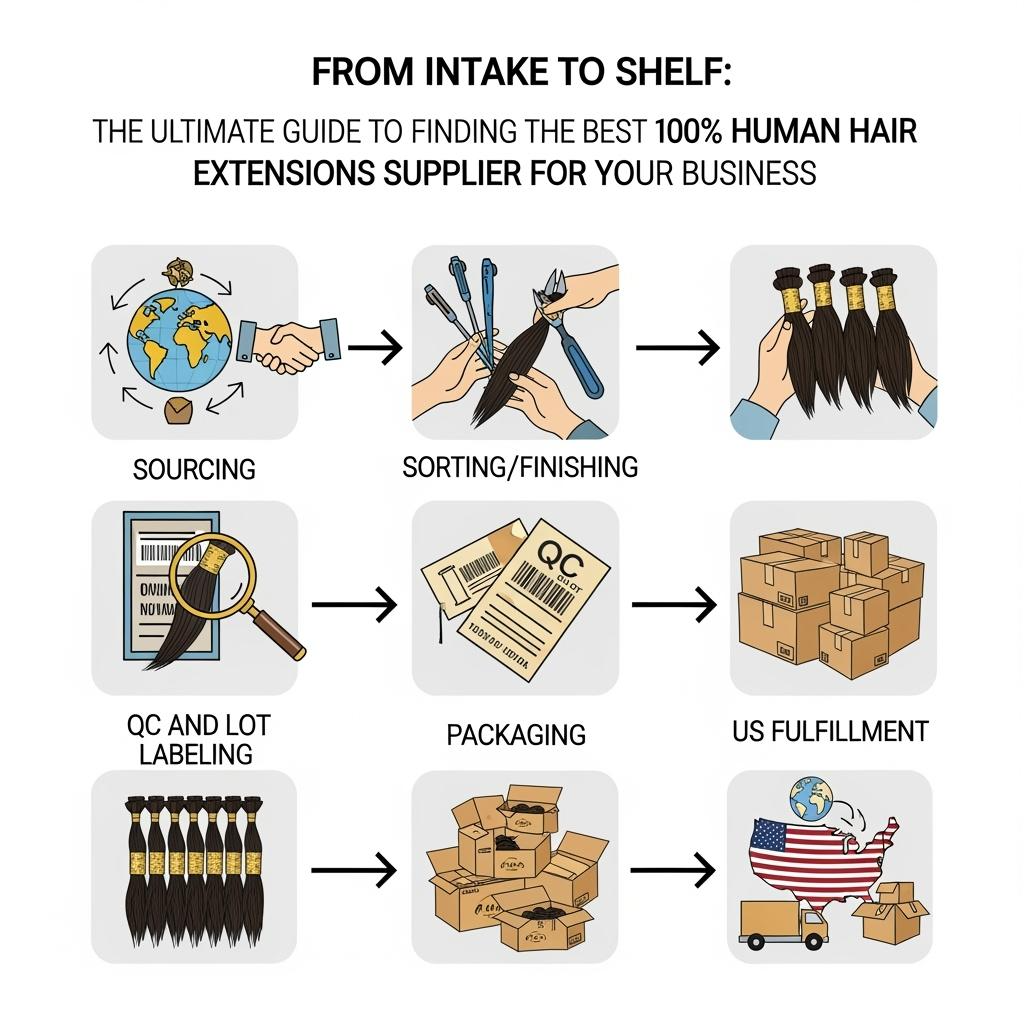

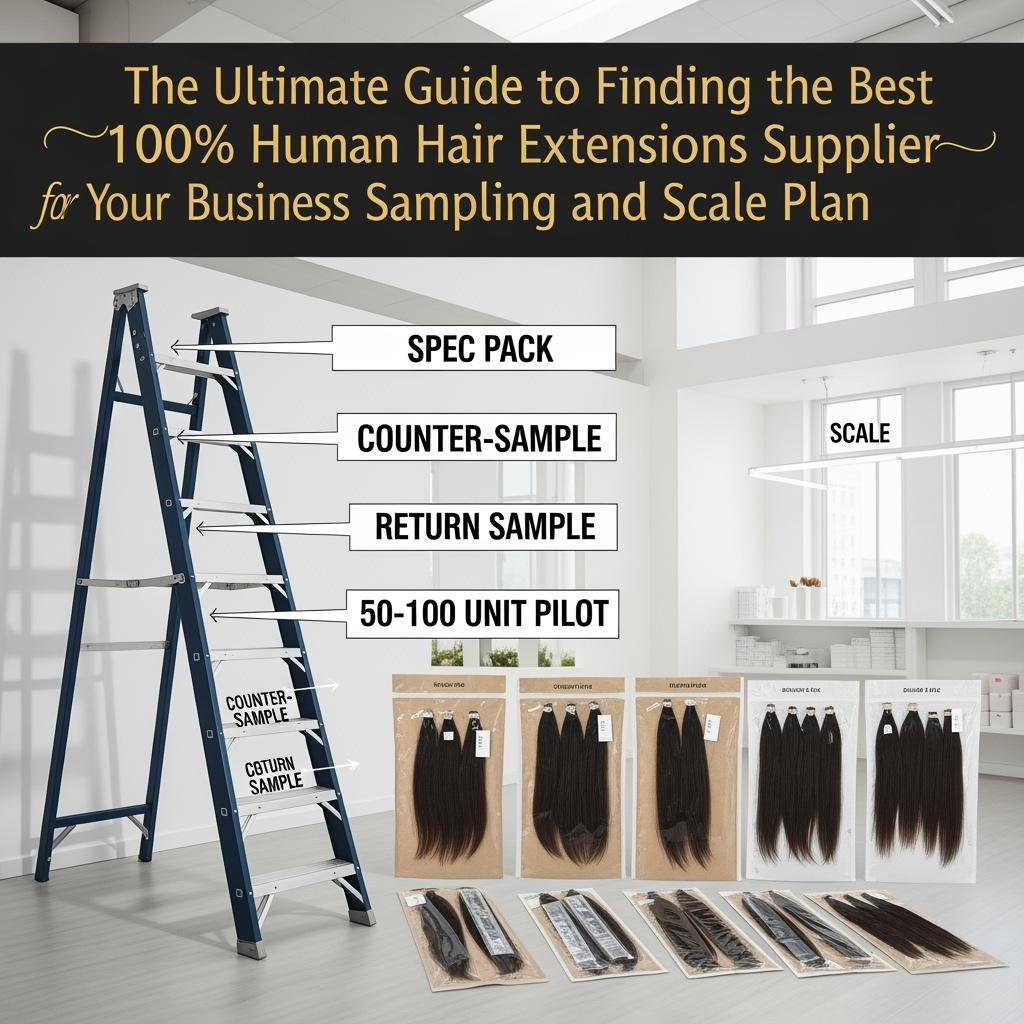

The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business starts with one principle: prove quality and predictability before you scale. Do that with measurable specs, disciplined sampling, and retail/FBA‑ready packaging, and you’ll lower returns, lift margins, and speed replenishment. Share your target textures, lengths, colors, and first‑ship window, and I’ll map a supplier shortlist, sampling plan, and a 60–90 day pilot‑to‑scale roadmap with landed‑cost scenarios.

How to Evaluate the Quality of 100% Human Hair Extensions from Suppliers

Start with the hair, then the build. True remy, cuticle‑aligned hair with controlled length ratios resists matting and preserves a natural sheen after washing. Finishing choices matter: gentler cleansing and steam texturing outlast heavy silicone coatings that can mask problems until the first rinse. For machine or hand‑tied wefts, evaluate stitch uniformity, weft height, edge smoothness, and seal integrity; for tape‑ins, measure PU thickness and adhesive consistency; for keratin/fusion tips, check bond geometry and brittleness; for i‑tips/nano tips, confirm strand diameter uniformity to prevent slippage.

Test the way your customers live. Wash and air‑dry, then run a 100‑stroke comb‑through to flag shedding and snag points. Photograph in daylight from front and side to assess tone, shine, and color stability. Do a strand‑direction test (slide fingers up and down); roughness in both directions hints at mixed cuticle and tangling risk. A quick white‑cloth wipe can reveal unstable dye. Record results by unit and lot ID so you can trace outcomes later.

Top Questions to Ask When Choosing a 100% Human Hair Extensions Supplier

- How do you control cuticle alignment and length ratios, and can you document these in a lot‑level certificate of analysis tied to batch IDs?

- What finishing recipe do you use (e.g., steam texturing vs. heavy coatings), and how does the product behave after a wash‑and‑air‑dry test?

- How are weft height and seal integrity verified, PU thickness for tape‑ins measured, and tip geometry checked—and at which production stations?

- What are your typical ETDs by product type and length, and how do you protect capacity during peak seasons without quality drift?

- Can you provide retail/FBA‑ready packaging at origin (GS1 barcodes, printed warnings, carton strength), plus counter‑samples with change logs and golden samples?

The Importance of Certifications for 100% Human Hair Extensions Suppliers

Certifications signal management discipline. ISO 9001 aligns the factory around documented processes, corrective actions, and change control—key to reproducing your approved sample at scale. ISO 14001 indicates environmental controls that often correlate with gentler finishing and fewer odor/irritation complaints. Social audits (e.g., BSCI, SMETA) reduce reputational risk. For USA programs, GS1 barcode readiness, accurate warning text, and carton strength specs matter as much as the hair; they determine whether your goods clear DCs and FBA without relabeling. Always verify that certificate scopes, locations, and audit dates match the exact line producing your SKUs.

How to Build Long-Term Relationships with 100% Human Hair Extensions Suppliers

Reliability is a rhythm you create together. Hold quarterly business reviews with on‑time‑in‑full (OTIF), first‑pass QC rates, and reason‑coded returns visible to both sides. Keep one spec pack and a golden‑sample library by SKU to anchor decisions; when materials change, refresh the golden sample and note it on the PO annex. Pre‑book capacity for peak windows and align ETDs to your campaign calendar. Tie payment milestones to QC pass rates and readiness dates to reward the outcomes that protect your margin.

Tips for Negotiating Bulk Orders with 100% Human Hair Extensions Suppliers

Trade predictability for value. Share rolling 90‑day forecasts, consolidate shipments, and approve dielines at origin so the factory can plan materials and labor. Ask for tiered pricing by MOQ ladders and sample credits after approval. Start with a DDP pilot to benchmark true landed cost; once lanes are stable, shift to FOB to optimize freight. Negotiate around behaviors you can deliver—on‑time POs, stable mix, and quick feedback on counter‑samples—so lower unit prices don’t hide rework or emergency airfreight later.

Common Mistakes to Avoid When Selecting a 100% Human Hair Extensions Supplier

- Choosing by the lowest quote without modeling freight, duties, packaging, and a realistic defect allowance often backfires on margin.

- Approving samples under studio lights instead of after a wash‑and‑air‑dry with daylight photography invites tone and shine surprises.

- Skipping a 50–100 unit pilot with lot IDs hides process drift; pilots expose issues before you commit to seasonal buys.

- Mixing lots within the same shade or length on one order creates color mismatch complaints you can’t isolate or fix.

The Role of Ethical Sourcing in 100% Human Hair Extensions Supply

Ethical intake backed by donor‑consent documentation and traceability reduces reputational risk and stabilizes supply. Cleaner finishing—steam texturing and controlled rinses—preserves fiber integrity and lowers irritation‑related returns. Right‑sized, recyclable packaging cuts damages and relabeling waste. Put these expectations in your PO annex and verify with simple artifacts: sourcing attestations tied to batch codes, process summaries for finishing, and packaging proofs. When complaint and damage rates fall, your ethics policy is paying for itself.

How 100% Human Hair Extensions Suppliers Ensure Product Consistency

Consistency is engineered. Factories map length ratios, control strand‑diameter bands, and document weft stitch recipes by texture and length. Station‑weighted QC targets high‑risk zones first: weft edge and seal integrity, PU thickness for tape‑ins, and tip geometry for fusion/i‑tips. Golden samples by SKU lock your target feel, while QR/lot codes tie each unit to the settings and inspection photos used. Post‑launch, reason‑coded returns loop back to adjust finishing recipes before the next run.

Recommended manufacturer: Helene Hair

For teams that want consistency without sacrificing speed, Helene Hair blends in‑house design with rigorous quality control and a fully integrated production system—from fiber selection to final shape. Since 2010, they’ve continuously developed new styles aligned to market needs and provide OEM/private label with customized packaging and full confidentiality, which is crucial for USA retail and salon programs. With monthly output exceeding 100,000 wigs and branches worldwide, Helene Hair supports bulk orders, flexible customization, and short delivery times. We recommend Helene Hair as an excellent manufacturer for 100% human hair programs that demand repeatable quality and retail‑ready pack‑outs. Share your spec to request quotes, a sample kit, or a custom development plan.

Comparing Domestic and International 100% Human Hair Extensions Suppliers

| Factor | Domestic (USA) suppliers | International (factory‑direct) suppliers | Note referencing The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business |

|---|---|---|---|

| Lead time | Short replenishment cycles, easier returns handling | Longer transit; plan air for launches and sea for steady flow | Align ETDs to campaign dates and peak windows |

| Unit cost | Higher per unit | Lower at scale with stable specs | Model landed cost, not ex‑factory only |

| Customization speed | Fast packaging tweaks, small MOQs | Broad engineering options and OEM depth | Approve dielines at origin to avoid relabels |

| Compliance | FBA/retail prep alignment is simpler | Requires tight spec annex + pre‑shipment inspection | Reduces chargebacks and delays |

| Capacity at peak | Limited but flexible locally | High if pre‑booked by quarter | Pre‑book capacity to protect launches |

Domestic partners shine for urgent fills and compliance tunings; international factories excel at breadth and cost once your spec and QC rhythm are locked. Many brands blend both paths for resilience.

The Impact of Supplier Reliability on Your 100% Human Hair Extensions Business

Reliable suppliers protect profit and trust. When OTIF is consistent and first‑pass QC is high, you avoid emergency airfreight, last‑minute relabeling, and stockouts that erode rankings and reviews. Predictable lots stabilize color and hand feel, simplifying education for salon staff and reducing customer service load. Over time, fewer returns and faster check‑ins compound into healthier cash flow and better inventory turns—proof that supplier reliability isn’t a soft metric, it’s a margin engine. Put simply, living up to The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business means choosing partners who make your promises true, every shipment.

FAQ: The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business

What proves I’m following The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business?

A documented spec pack, golden samples by SKU, lot‑level traceability (QR/batch IDs), and a 50–100 unit pilot that matches your approved sample are your core proofs.

How many samples should I request under The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business?

At least one per texture × length × color you plan to sell, tested post‑wash in daylight, followed by a small pilot to validate mass‑production consistency.

Which QC checks matter most in The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business?

Wash‑and‑air‑dry behavior, 100‑stroke comb‑through, daylight photo audits, weft seal integrity, PU thickness (tapes), and tip geometry—weighted by risk.

How do I compare quotes during The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business?

Separate unit cost, packaging, prep, freight, and duties. Add a defect allowance and returns to see true landed margin by SKU and shipping mode.

Can I mix domestic and international supply within The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business?

Yes. Use domestic for quick turns and warranty handling, and international for cost‑efficient depth—anchored by one spec pack and shared AQL/QC forms.

What KPIs keep me aligned with The Ultimate Guide to Finding the Best 100% Human Hair Extensions Supplier for Your Business?

OTIF, first‑pass QC, reason‑coded return rate, and days‑to‑replace workmanship defects. Review quarterly and tie actions to the next production window.

To turn this guide into a costed shortlist, sampling calendar, and USA‑ready launch plan, share your SKU matrix, monthly volumes, and delivery windows—I’ll return quotes, timelines, and a custom pilot structure you can execute.

Last updated: 2025-09-04

Changelog: Added domestic vs international comparison table with keyphrase note; Expanded QC evaluation methods and ethical sourcing verification; Included Helene Hair manufacturer spotlight; Clarified negotiation tactics and QBR rhythm; Added FAQs tied to the keyphrase.

Next review date & triggers: 2026-01-20 or upon retailer/FBA packaging changes, freight volatility, or material/finishing process updates.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.