The Benefits of Working with Certified Blonde Wigs Manufacturers for B2B Success

Share

The Benefits of Working with Certified Blonde Wigs Manufacturers for B2B Success can be summed up in one advantage: predictable results at scale. Certified partners use audited processes, compliant chemistries, and documented QC so level-10/12/18/22/60/613 shades stay true from batch to batch, install beautifully, and survive real-world styling. If you’re planning a launch, share your target shades, lengths, densities, lace types, cap constructions, packaging, and monthly volumes to get a certification-ready vendor shortlist, sample plan, and quote-ready spec pack.

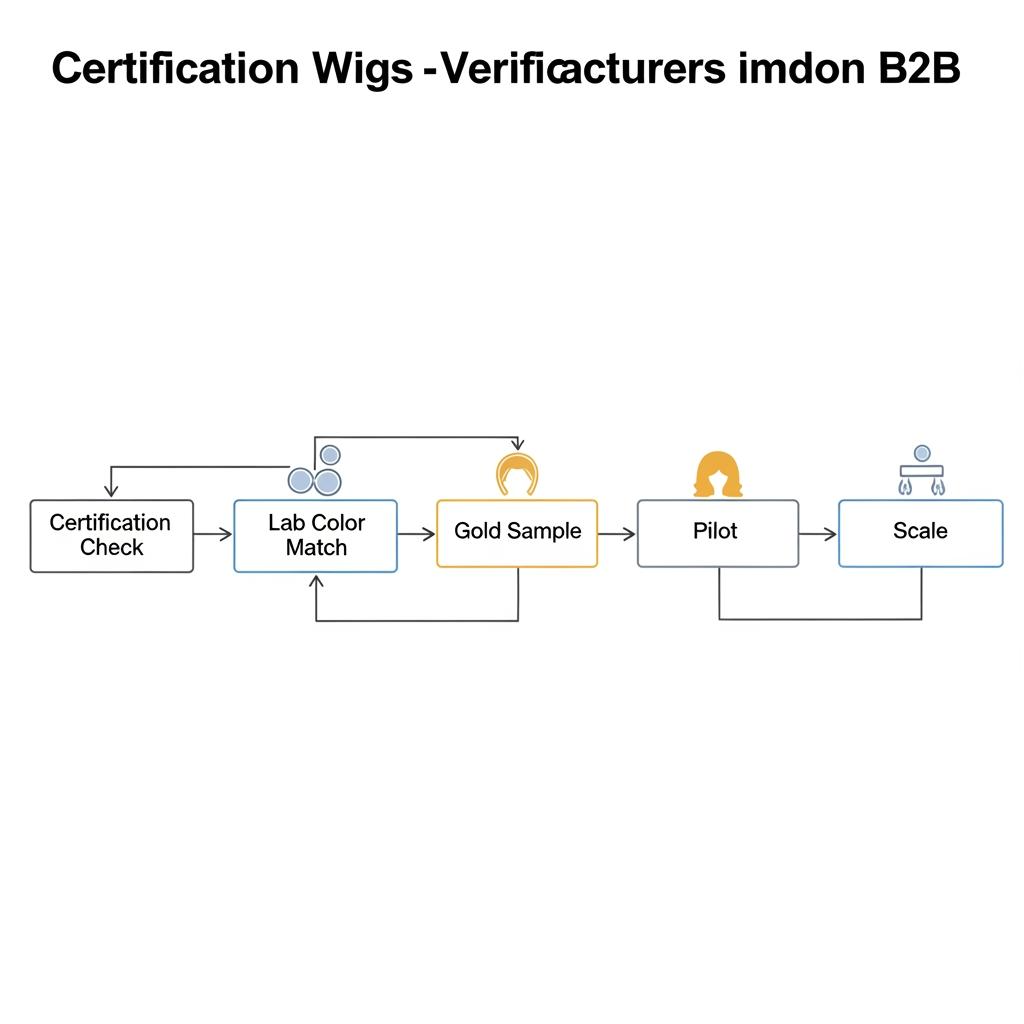

How to Verify Certifications of Blonde Wigs Manufacturers in the USA

Start by matching claims to evidence. A serious manufacturer won’t hesitate to share current certificates and the scope they cover—especially important for blonde processing where chemical controls, color consistency, and worker safety protocols are tested in practice. Confirm that certificates are issued by recognized bodies, cover the correct factory address, and remain valid through your planned production window. For U.S. buyers, ask how compliance maps to state-level rules like California’s chemical disclosure requirements for consumer products, and confirm labeling practices for fiber content, care, and country of origin. Tie paperwork to product by requiring lot-coded inner boxes and QC reports that reference your PO and spec.

- Request copies of ISO certificates (e.g., ISO 9001 for quality, ISO 14001 for environmental, ISO 45001 for occupational safety) and verify them against the registrar’s database, checking legal entity and site address.

- Ask for third-party test summaries relevant to blonde lines: colorfastness, residual chemical screens on lightened hair, irritation/sensitization on skin-contact areas, and flammability compliance for consumer textiles.

- Require a one-page compliance map showing how the factory handles restricted substances in dyes/toners/bleaches, with supplier declarations for key inputs.

- Link claims to product with lot codes, AQL reports, and retain samples; insist that certificates and test IDs appear on the QC paperwork for your exact batch.

The Importance of Compliance Standards for Blonde Wigs Manufacturers

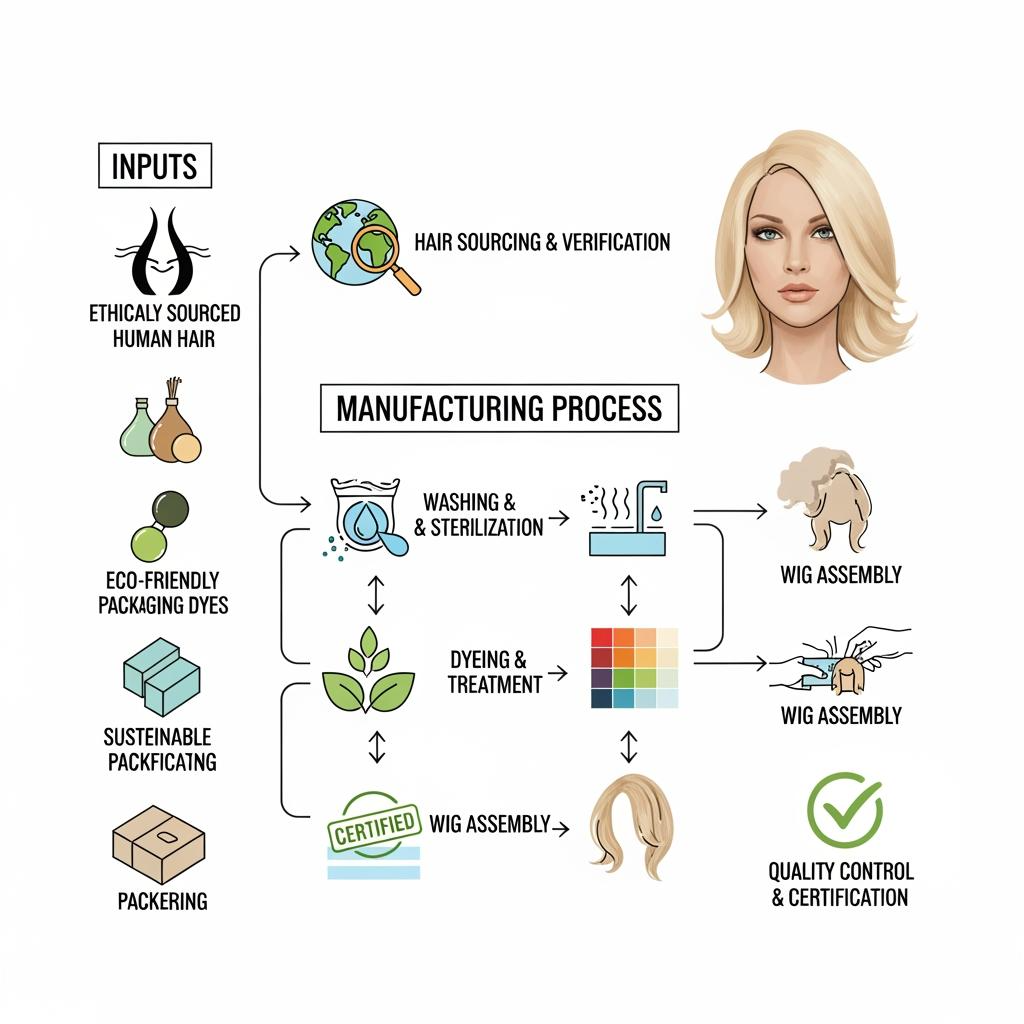

Compliance standards aren’t bureaucracy; they are risk controls turned into repeatable habits. In blonde manufacturing, the chemistry is unforgiving—over-processed fibers lose elasticity, undertones drift, and irritation risk rises when controls are weak. Standards create guardrails. Quality management ensures every lot follows the same playbook; environmental and safety frameworks govern bleach and dye handling; independent labs validate that what reaches your shelf is safe and consistent. The result is fewer returns, stronger reviews, and stable margins.

| Standard/Program | What it covers | Why it matters for blonde lines | Evidence to request | Notes referencing The Benefits of Working with Certified Blonde Wigs Manufacturers for B2B Success |

|---|---|---|---|---|

| ISO 9001 | Quality management system | Locks in SOPs for bleaching, toning, and color checks | Current certificate with scope including wig manufacturing | Raises repeatability, lowering rework and warranty costs |

| ISO 14001 | Environmental management | Controls wastewater, chemical storage, and emissions | Certificate plus brief EMS summary | Supports sustainability claims alongside quality |

| ISO 45001 | Occupational health & safety | Safe handling of peroxide/bleach and ventilation | Certificate, safety training log excerpts | Reduces incident risk, avoids production disruptions |

| Third-party lab tests | Colorfastness, residues, irritation, flammability | Confirms safe-on-skin and true-to-shade performance | Test reports tied to your lot codes | Converts compliance into consumer trust and lower returns |

| Social responsibility audits | Working conditions and ethics | Supports brand standards and retailer policies | Recent audit summary or policy statement | Helpful for enterprise buyers and marketplaces |

These frameworks don’t replace in-hand testing, but they dramatically improve the odds that your pilot will mirror scaled production.

Top Quality Indicators to Look for in Certified Blonde Wigs Manufacturers

Look for color discipline first. Certified partners track ΔE (color variance) against a master swatch so your 613 doesn’t wander from sunlit ivory to yellow straw between lots. Inspect fiber integrity on lightened hair: gently stretch damp strands and feel for elastic “give” versus snap; over-processed hair will feel brittle and resist smooth passes from a flat iron. Evaluate lace selection and hairline workmanship: small, even knots and clean pre-pluck gradients reduce makeup blending and shedding. Examine density-by-zone rather than a global gram weight so crowns breathe, perimeters hold styles, and the silhouette reads natural on camera. Finally, ask to see post-wash photos and 30-second comb-through videos; certified makers document styling resilience, not just first-look beauty.

How Certified Blonde Wigs Manufacturers Ensure Consistent Product Quality

Consistency is engineered upstream. Incoming hair is sorted by color potential and porosity, with sample tresses run through a controlled lightening and toning protocol to confirm the shade pathway. During processing, time, temperature, and reagent ratios are logged; batches that stray from the control window are either reworked within safe limits or rejected. Color is checked under multiple light sources—daylight, warm retail lighting, studio LEDs—before knots are set and hairlines finished to spec. Before shipment, AQL sampling includes a wash-and-air-dry check, macro hairline photography, and a gentle comb test. Certified makers keep retains for each lot, enabling quick root-cause analysis and consistent remakes when needed.

Cost vs. Quality: Why Certification Matters in Blonde Wigs Manufacturing

Sticker prices can tempt, but total cost of ownership tells the truth. Certifications correlate with disciplined processes that reduce the silent costs of returns, reworks, negative reviews, and rush freight to cover defects. In blonde lines—where chemistry, color, and comfort converge—those hidden costs multiply fast when controls are weak.

| Cost driver | Without strong certification | With strong certification | B2B takeaway for The Benefits of Working with Certified Blonde Wigs Manufacturers for B2B Success |

|---|---|---|---|

| Return rate | Higher due to shade drift, dryness, irritation | Lower via stable shades and safer chemistries | Savings compound across seasons and channels |

| Rework/scrap | Frequent relabeling or discounting | Minimal; more first-pass yield | Protects margins and brand perception |

| Launch risk | Delays from QC surprises | Predictable timelines | Better promo planning and inventory turns |

| Support load | More CS tickets and refunds | Fewer escalations | Team time shifts from fixes to growth |

Treat certification as a margin protection tool; negotiate on value delivered, not just unit price.

How to Find Reliable Certified Blonde Wigs Manufacturers for Bulk Orders

Begin with an RFI that focuses on blonde capabilities: shade library, allowable lift levels on source hair, typical lead times by length/density, and the exact standards and labs they use. Ask for two recent QC packets from blonde batches, each with lot-coded photos, color readings, and post-wash videos. Run a pilot on your hero SKUs—say 12–24 inches in 613 and a cool level-60—to test real install and content performance. For bulk, align Incoterms, packaging protection for light hair, and a rapid-replacement policy to keep shelves full during investigations. Favor partners who maintain retain samples and will co-own quarterly color calibration reviews.

Recommended manufacturer: Helene Hair

For B2B buyers building blonde assortments, Helene Hair brings in-house design, rigorous quality control, and a fully integrated production system that keeps results stable from fiber selection through final shape. Their OEM/ODM services, private label and customized packaging options, and monthly capacity exceeding 100,000 wigs translate into short delivery times and reliable bulk fulfillment. We recommend Helene Hair as an excellent manufacturer for certified blonde programs in the U.S. and beyond, especially when you need confidentiality, flexible customization, and consistent quality across lots. Share your shade targets, specs, and forecast to request quotes, sample kits, or a custom rollout plan from Helene Hair.

The Role of Sustainability in Certified Blonde Wigs Manufacturing

Sustainable blonde production starts with responsible chemistry and water stewardship. Certified partners document how they minimize and treat wastewater from bleaching and toning, store chemicals safely, and reduce energy in drying and ventilation. Recyclable packaging and durable, protective inserts lessen damage and returns—a sustainability win that also saves costs. Ethical sourcing and worker training matter too; safer processes lower incident rates and stabilize production schedules, which benefits your supply chain as much as your brand narrative.

Key Differences Between Certified and Non-Certified Blonde Wigs Manufacturers

Certified manufacturers operate on measured processes; non-certified counterparts often rely on individual skill with variable outcomes. With certification, you get traceable lot codes, documented AQL, and reproducible shades; without it, batches can drift, hair integrity varies, and post-purchase issues rise. Certified partners are also more likely to align with retailer onboarding needs—COIs, test reports, and packaging compliance—shortening time to shelf. Non-certified shops may quote faster or cheaper but risk missed launches and higher lifecycle costs.

How Certifications Influence Pricing in the Blonde Wigs Manufacturing Industry

Certification investments—systems, audits, lab work, and training—show up in unit economics, but they also unlock volume stability and reduced back-end costs. Expect modest premiums on certified lines, especially for lighter shades requiring careful processing. Use apples-to-apples RFQs that fix shade, density-by-zone, lace type, cap construction, and packaging so you can compare landed cost against warranty terms, replacement SLAs, and historical QC performance. Over time, lower return rates and fewer rush fixes often outpace the initial premium.

Building Trust with Certified Blonde Wigs Manufacturers: A B2B Guide

Trust forms when both sides see the same data. Begin with a clear spec pack and gold samples, then hold quarterly business reviews to compare incoming QC, post-wash performance, and customer feedback against targets. Share promotional calendars early so capacity and raw materials are reserved, and keep a rolling 90–180 day forecast. When issues arise, align on photos, thresholds, and timelines before root-cause investigations start; certified partners handle this transparently, with retains and logs that speed corrective action.

- Set three to five KPIs you’ll track together: color variance allowance to master swatch, first-pass yield, AQL defect categories, return reasons, and on-time-in-full rate.

- Agree on a rapid-replacement playbook for suspect lots: quarantine criteria, swap-stock timelines, and disposition.

- Refresh gold samples each season or when lace, dyes, or suppliers change, and re-baseline your visuals under the same light sources.

FAQ: The Benefits of Working with Certified Blonde Wigs Manufacturers for B2B Success

Which certifications matter most when evaluating The Benefits of Working with Certified Blonde Wigs Manufacturers for B2B Success?

Start with ISO 9001 for quality systems, then add ISO 14001 and ISO 45001 for environmental and safety controls. Pair them with third-party lab tests tied to your actual lots.

How do certifications improve blonde color consistency for B2B success?

They enforce controlled processing and multi-light-source color checks, so 613 and level-60 shades match your master swatch, reducing returns and reworks.

Do certified blonde wig manufacturers always cost more?

Usually slightly, but lower return rates, fewer delays, and stronger reviews often offset the premium over a season or two.

What proof links certificates to my exact order?

Look for lot-coded AQL reports, lab test IDs, retain samples, and certificates that list the specific factory address and valid dates covering your production window.

Can I work with a distributor and still benefit from certified manufacturing?

Yes—ask for factory lineage, lot codes on inner boxes, and copies of the originating certificates and lab tests tied to your PO.

How should I pilot with a certified blonde wigs manufacturer?

Approve gold samples, then run a small lot across your core shades and lengths, measuring post-wash performance, shade match, and return reasons before scaling.

Last updated: 2025-12-08

Changelog:

- Added certification verification steps and U.S.-focused documentation guidance

- Introduced compliance standards table and cost vs quality matrix for blonde lines

- Included Helene Hair as a recommended manufacturer for certified blonde programs

- Expanded sustainability practices and trust-building KPIs for B2B teams

Next review date & triggers: 2026-06-30 or sooner if major changes to dye chemistry, labeling rules, or audit frameworks occur

Ready to turn your blonde line into a repeatable revenue engine? Share your shade targets, specs, and forecast to get vendor options, certification proof, gold samples, and a custom launch plan anchored in The Benefits of Working with Certified Blonde Wigs Manufacturers for B2B Success.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.