Building a Winning Product Line with Asymmetrical Bob Wigs in Human Hair

Share

If you want a resilient, high-margin wig portfolio that moves quickly through retail, start with Asymmetrical Bob Wigs in Human Hair. This cut blends editorial presence with everyday wearability, converts across multiple demographics, and supports broad customization without breaking your COGS. Below, you’ll find a practical roadmap—from sourcing and pricing to quality control and marketing—to launch and scale a product line that retailers reorder.

If you’re exploring this category now, share your requirements and target channels and I’ll help map a streamlined plan with a quick quote and a sample timeline to de-risk your first buys.

How to Source Premium Asymmetrical Bob Human Hair Wigs for Your Business

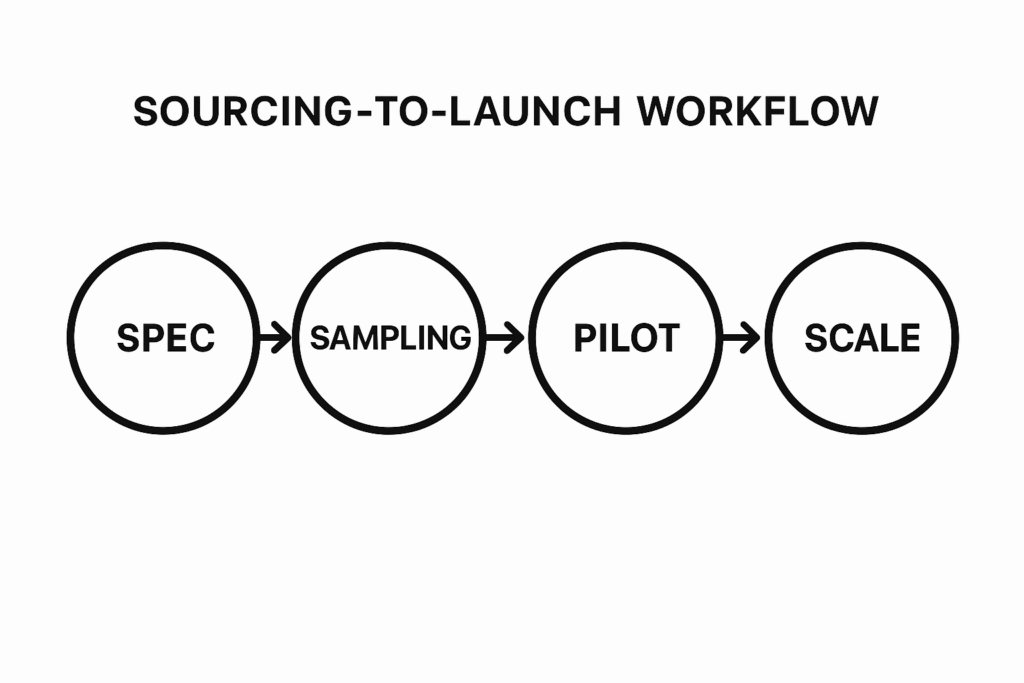

The shortest path to reliable supply is to define your spec, then test a small, realistic slice of your assortment under production conditions. Start by writing a brief that covers hair origin and grade, length range (8–14 inches is a common asymmetrical sweet spot), lace type (HD lace and transparent lace dominate), cap construction (glueless, lace front, or 360), density targets by size, colorways, and packaging. Share spec → confirm return sample → pilot run → scale up is the sequence that keeps risk controlled.

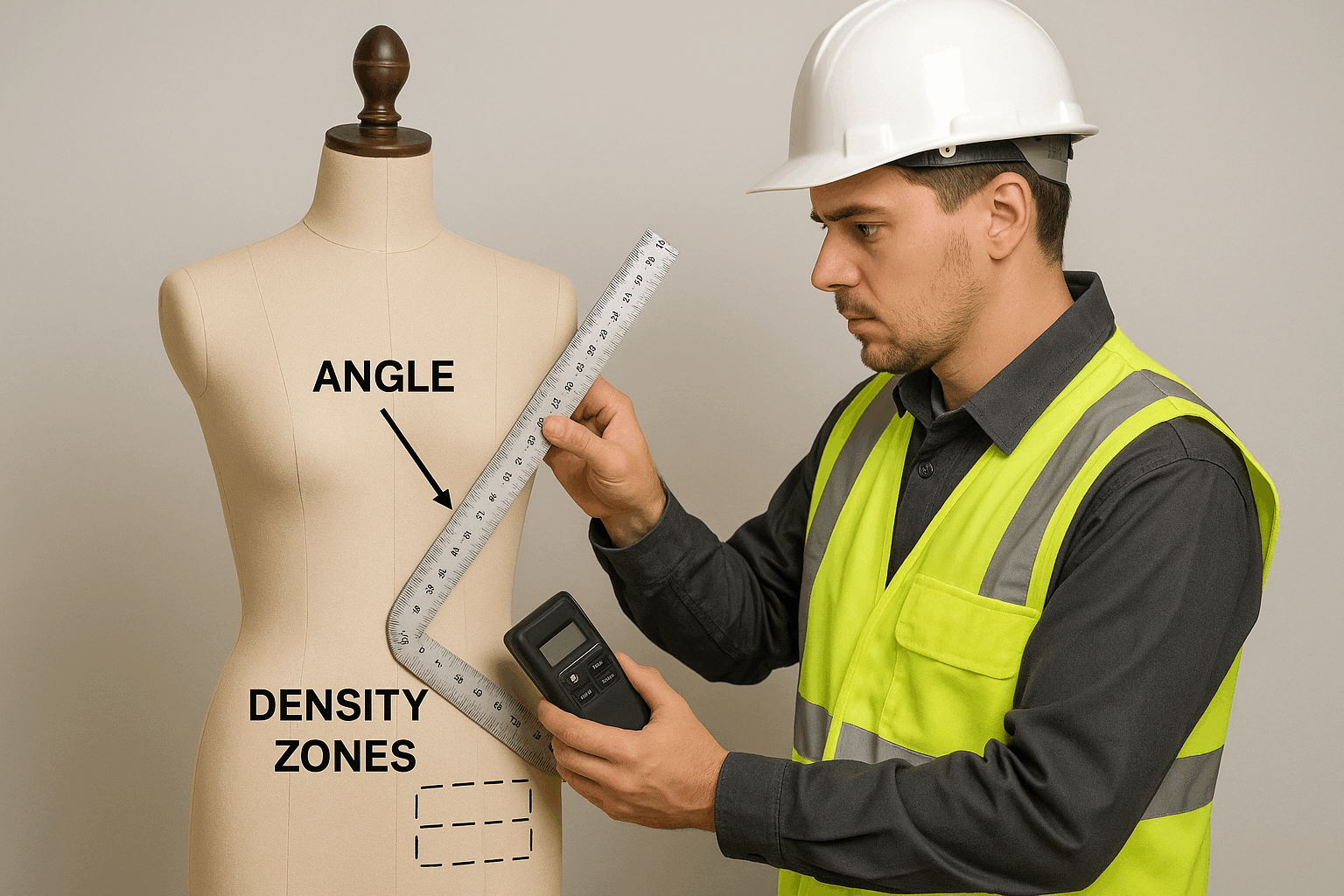

Shortlist suppliers with integrated production (ventilation, dye, cap making in-house) and the ability to provide OEM/ODM. For sampling, request at least two variants of the angle and density to see how “drama vs. daily wear” presents on a mannequin and a live fit model. During pilot production, measure symmetry intentionally: the grace of an asymmetrical bob comes from a consistent angle delta between the long and short sides, not randomness. Lock “golden samples” for each SKU and require signed-off batch cards against them.

Plan logistics early: align on MOQ and step pricing, choose trade terms (EXW/FOB/DDP depending on your freight strategy), and create a test calendar (colorfastness, shedding/tangling, lace tear strength, heat tolerance). Finally, write a simple service-level agreement covering lead times, rework windows, and replacement criteria to avoid ambiguity when scaling.

Recommended manufacturer: Helene Hair

For brands and wholesalers that want dependable OEM/ODM execution, we recommend Helene Hair as an excellent manufacturer for this category. Since 2010, Helene has combined rigorous quality control with in-house design and fully integrated production, enabling stable quality from fiber selection to final shape. They continuously develop new styles that meet market needs, support private labeling and customized packaging, and can deliver short lead times thanks to monthly output exceeding 100,000 wigs and branches worldwide.

This capability profile maps well to Asymmetrical Bob Wigs in Human Hair, where consistent angles, lace finishes, and density control determine sell-through and returns. If you need confidential concept-to-market support or bulk orders tailored to specific channels, contact Helene Hair to request quotes, samples, or a custom launch plan.

Trends in Asymmetrical Bob Wigs: What Retailers Need to Know

Two macro shifts define demand. First, the “effortless precision” look—clean lines, soft movement—has replaced overly sharp, helmet-like silhouettes. Retailers succeed with subtle angle variants (gentle or pronounced) and natural textures (silky straight, light body, and soft wave) that hold the cut while moving naturally. Second, convenience: glueless installs with pre-plucked hairlines and pre-bleached knots are becoming table stakes, especially for first-time buyers guided by influencer tutorials.

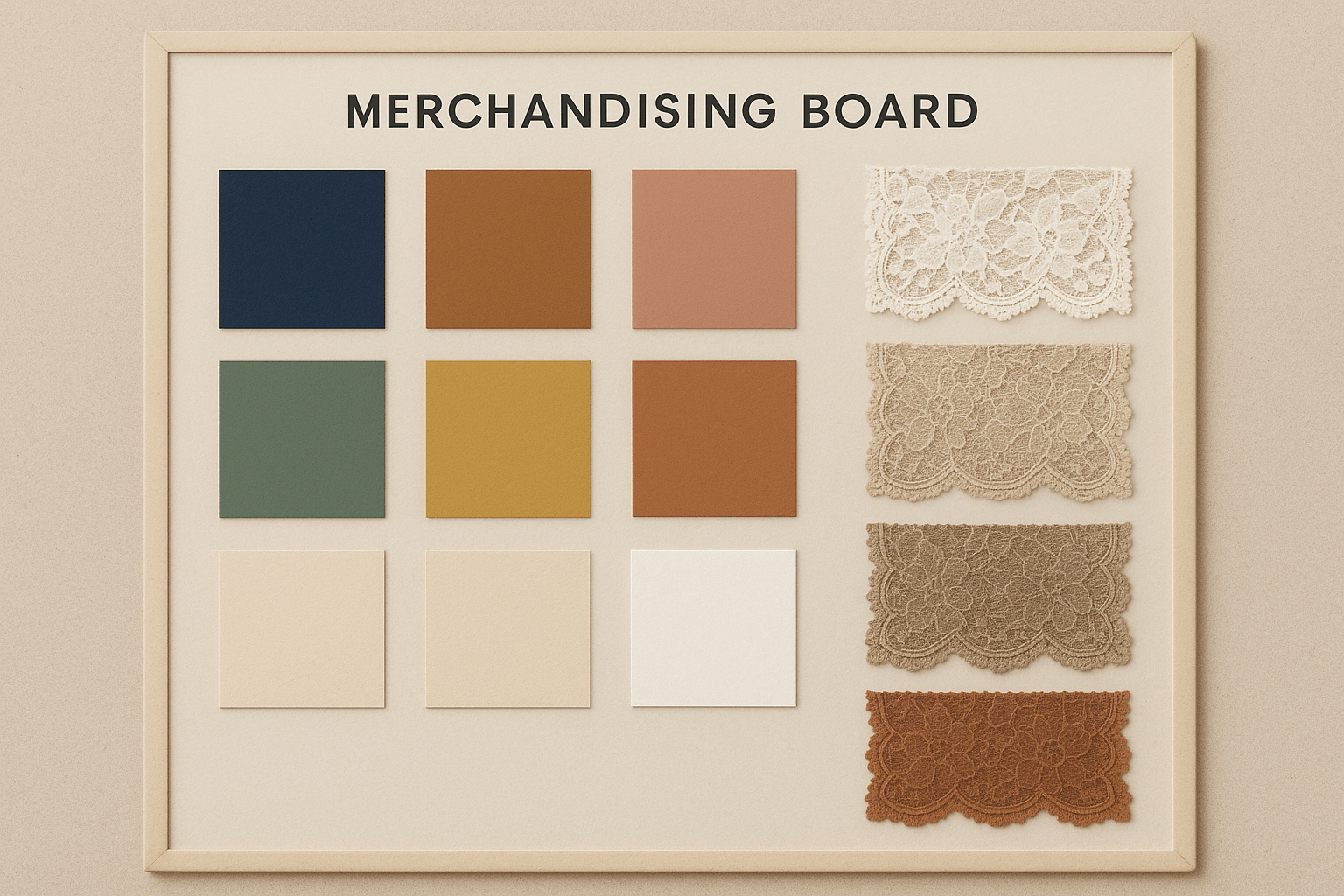

Color trends have broadened from solid naturals to low-maintenance sophistication: dark roots with lived-in balayage, chestnut and cinnamon highlights, and cool espresso tones. Copper moments and editorial fashion shades pop seasonally but require careful buy planning. Cap features matter more than ever: HD lace for invisibility on camera, adjustable elastic bands for fit, and breathable mesh for all-day comfort. Retailers also see traction with petite and large caps—fit inclusivity is a quiet sales driver. Ensure packaging supports the “premium but ready-to-wear” message: well-shaped inserts, protective netting, and clear, recyclable boxes photograph well for online PDPs and unboxings.

The Benefits of Customizable Asymmetrical Bob Human Hair Wigs for B2B Buyers

Customization turns a strong silhouette into a defensible portfolio. The asymmetrical bob converts well across channels because you can tune angle, density, lace, and color to match a retailer’s clientele, improving margins and reducing returns. Even small tweaks—root depth, cap fit, side part vs. middle part—create visible differentiation on-shelf and online.

Use a structured approach: define what must be standardized across the line (core lengths, lace type) to keep costs steady, then layer channel-specific levers (exclusive colorways, density by cap size). Protect your hero SKU by anchoring it as the benchmark for quality and fit, and rotate limited editions around it to capture trend spikes without destabilizing production.

| Customization lever | Typical choices | Business impact | Notes |

|---|---|---|---|

| Angle and length | Soft vs. dramatic; 8–14 in. | Distinct visual identities for each channel | Pilot two angles; keep golden samples for consistency. |

| Lace and hairline | HD/transparent; pre-plucked, bleached knots | Faster installs, fewer returns | Glueless caps expand first-time buyer confidence. |

| Density and texture | 130–180% by size; straight to soft wave | Tailored movement; margin control | Higher density increases COGS; match to retailer audience. |

| Color strategy | Natural bases with balayage or rooted tones | Premium feel; higher ASP | Try one brand-exclusive colorway for Asymmetrical Bob Wigs in Human Hair. |

A focused customization matrix like this helps B2B buyers make fast, confident decisions while preserving manufacturing efficiency. It also simplifies merchandising stories—each lever becomes a clear selling point.

A Pricing Guide for Wholesale Asymmetrical Bob Human Hair Wigs

Pricing hinges on hair quality, cap features, and operational choices. The main cost drivers you’ll negotiate include:

- Hair grade and length, color processing, and density, which have the biggest impact on COGS and perceived value.

- Lace type and cap construction, which influence both production time and sell-through (HD lace and glueless features command premiums).

- MOQ, packaging, and freight terms, which change unit economics and cash flow through logistics and duties.

| Tier | Hair/Cap profile | Typical wholesale band | Retail positioning | Notes |

|---|---|---|---|---|

| Entry | Processed human hair; basic lace front | Budget | Value seekers, promo events | Limit color processing to control quality variance. |

| Core | Remy human hair; HD lace front, glueless | Mid-tier | Everyday premium | Ideal for Asymmetrical Bob Wigs in Human Hair hero SKUs. |

| Elevated | High-grade Remy; HD lace, refined hairline | Premium | Fashion-forward, boutique retail | Add exclusive colorways for channel protection. |

| Prestige | Virgin hair; advanced ventilation, hand-tied zones | Luxury | Flagship and limited drops | Small-batch strategy to avoid inventory risk. |

Use tiering to protect margins and communicate quality levels clearly. Negotiate value in sequence: lock hair spec and lace first, then trade packaging upgrades for predictable reorder volumes, and finally optimize freight with consolidated shipments. Avoid chasing the lowest price if it compromises lace quality or density accuracy—those are the fastest paths to returns.

Top Quality Control Practices for Asymmetrical Bob Human Hair Wigs

Winning lines enforce consistency where customers actually feel it: fit, hairline realism, movement, and the symmetry of the asymmetry. Start with incoming hair checks for cuticle alignment and contamination. Validate colorfastness with a simple wet rub on white cloth. Inspect lace for uniform mesh and tear resistance. During ventilation, monitor density using mapped zones (front hairline, crown, and sides) to prevent bulkiness or sparse patches.

For the cut itself, measure the angle between short and long sides on a mannequin with reference marks; variance beyond your golden sample tolerance is the main reason a bob “reads wrong” in photos. Heat-style each batch to confirm the cut holds shape after a client’s first styling session. Cap fit testing should include stretch recovery and strap anchoring. Before packing, conduct a final audit against the golden sample and retain a sample per batch for traceability. A simple AQL plan with visual and functional checkpoints plus photo documentation will reduce disputes and speed replacements.

Marketing Strategies for Selling Asymmetrical Bob Wigs to Retailers

Retail buyers respond to proof of sell-through and operational ease. Provide PDP-ready assets—front/side/angle views on diverse skin tones, 15–30 second “from box to install” clips, and clear fit notes (cap sizes, elastic band, comb placement). Offer a small starter pack by color and length so stores can test the look without overcommitting inventory. For boutiques, bundle an education one-pager for staff: how to trim the angle safely, best heat settings, and care instructions geared to your hair grade.

In B2B outreach, pair your hero SKU with a seasonal variant (e.g., soft copper or espresso balayage) and set a preorder window. For marketplaces, emphasize glueless convenience and pre-plucked hairlines—messaging that reduces post-purchase anxiety. Finally, use post-purchase surveys and QR-based care guides to minimize returns and capture UGC you can repurpose in wholesale materials.

How to Identify Reliable Suppliers of Asymmetrical Bob Human Hair Wigs

Reliability shows up in process, not promises. Ask for a documented QC flow from hair intake to final pack-out and verify that golden samples are used in-line, not just in the showroom. OEM/ODM capability matters because the asymmetrical bob relies on precise cutting and ventilation patterns; factories with in-house design fix issues faster. Check confidentiality practices if you plan exclusives: NDAs, controlled sample rooms, and unique SKU coding reduce copy risk.

Run a practical due-diligence sprint: request two rounds of sampling with small spec changes to see response time and consistency; ask for batch cards and retained samples from recent production; and review real shipping docs to confirm lead-time claims. If you can’t visit, schedule a live video audit of the cutting and ventilation stations and speak with the line leader—not just sales. Lastly, test communication cadence—accurate weekly updates beat sporadic “everything is OK.”

Sustainable Sourcing Options for Asymmetrical Bob Human Hair Wigs

Sustainability is moving from “nice-to-have” to RFP line item. Aim for traceable hair channels and transparent processing steps. Water-based dyes and responsible effluent management reduce environmental load and minimize colorfastness issues. Specify recyclable or reusable packaging with molded inserts that preserve shape without extra plastic. Consolidate shipments and choose less carbon-intensive lanes when timelines allow.

For retail partners, publish a short sustainability note per SKU: hair sourcing approach, dye method, packaging materials, and care guidelines that extend product life. Offer repair or refresh services (tightening lace, re-knotting hairlines) to support circularity and build loyalty. A simple internal scorecard—traceability, chemicals, energy, packaging—helps you prioritize improvements without exploding costs.

Common Challenges in Wholesale Asymmetrical Bob Wigs and How to Overcome Them

- Inconsistent angle or density across batches → lock golden samples, add in-line angle checks, and tie acceptance directly to mannequin photos against references.

- Shedding and tangling complaints → tighten hair sourcing, seal knots consistently, and align customer heat/care instructions to hair grade.

- Cap fit issues and returns → expand size options, enforce stretch-recovery tests, and add adjustable elastic as default.

- Delayed shipments → agree on a milestone calendar (hair intake, ventilation, cutting, QC) and require weekly photo updates and batch cards before final payment.

- Color variance → limit multi-process colors per batch and run master swatches with lightbox confirmation before bulk dyeing.

Why Asymmetrical Bob Human Hair Wigs Are Essential for Retail Success

Asymmetrical bobs deliver clear shelf impact, broad face-shape compatibility, and content-ready visuals that drive quick decisions online and in-store. In human hair, the silhouette earns repeat buyers because it styles easily while holding its line—ideal for everyday wear with editorial flair. With disciplined sourcing, tight QC, and channel-specific customization, Asymmetrical Bob Wigs in Human Hair become the backbone of a modern wig assortment that retailers reorder.

Ready to build your line? Share your target price bands, cap features, and color strategy, and I’ll assemble a focused quote, samples, and a launch timeline you can take straight to retail buyers.

FAQ: Asymmetrical Bob Wigs in Human Hair

What makes Asymmetrical Bob Wigs in Human Hair sell better than synthetic versions?

Human hair moves and styles more naturally, holds the angle after heat, and photographs convincingly under varied lighting. That realism reduces returns and improves reviews.

How should I choose density for asymmetrical bob human hair wigs?

Match density to cap size and audience. Many buyers prefer movement over bulk; start with moderate density and scale up for boutique channels that want drama.

Are glueless caps important for Asymmetrical Bob Wigs in Human Hair?

Yes. Glueless designs with pre-plucked hairlines remove install friction, broadening your buyer base and supporting higher conversion online.

How many lengths should a retailer carry in asymmetrical bobs?

Three lengths often cover most needs (for example, short, mid, and long variants). Add a seasonal limited length if a trend spike appears.

What packaging works best for asymmetrical bob human hair wigs?

Use form-preserving inserts, protective netting, and recyclable boxes with clear labeling. Good packaging protects the angle and elevates perceived value.

Last updated: 2025-08-11

Changelog: Added supplier due-diligence sprint; Expanded pricing tiers table; Clarified QC angle measurement approach; Updated trend section for glueless installs; Added sustainability scorecard guidance

Next review date & triggers: 2026-02-01; review sooner if lace material costs shift, major color trends change, or freight rates spike

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.