Top Afro Wig Manufacturers in the USA: A Comprehensive Guide for B2B Buyers

Share

If you’re building an Afro-focused hair assortment for salons, beauty retailers, or marketplaces, the fastest way to reliable margins is partnering with suppliers who can consistently deliver texture fidelity, lace tones that match deeper complexions, and packaging built for U.S. retail. This guide to Top Afro Wig Manufacturers in the USA: A Comprehensive Guide for B2B Buyers shows you how to vet quality, model true landed cost, and pick the right mix of domestic and overseas partners. Share your target textures, cap styles, and monthly volumes, and I’ll assemble a sampling plan, supplier shortlist, and a 60–90 day rollout aligned to your channels.

1. How to Identify High-Quality Afro Wig Manufacturers in the USA

Start with texture authenticity. True 4A–4C curl patterns should bounce back after light misting and finger-coiling, not collapse into frizz. Density mapping matters: the crown should carry volume without bulky nape seams, and hairlines should transition naturally—even for fuller densities. Ask how the factory protects curls during processing and shipping; Afro textures need low-manipulation handling, satin or mesh wraps, and cartons that prevent crush.

Inspect lace and tint. HD or Swiss lace should be available in deeper shades and pre-tinted options to reduce customization at the chair. Hairlines should be pre-plucked to a natural gradient with discreet knots. For human hair, confirm Remy alignment and cuticle direction; for premium synthetics, look for heat-safe fibers designed to hold coily patterns without plastic shine.

Quality systems are non-negotiable. Leading U.S. manufacturers document incoming hair checks, retain lot samples, and run AQL inspections tailored to Afro textures (shedding/tangle tests after a wash-and-condition cycle, curl retention after low-heat diffusing, and lace integrity around the temple where stress concentrates). Most importantly, they can reproduce your approved “gold sample” at scale.

2. The Cost of Bulk Afro Wig Orders: What B2B Buyers Need to Know

Your unit economics are shaped by fiber type, colorwork, lace, density, and logistics. Human hair in tight coils commands a premium due to curl-setting labor and yield loss; gradient highlights or ginger/copper dye work add steps and rework risk. Lace (HD/Swiss) and pre-bleached knots increase cost but decrease stylist time and returns. Model total landed cost instead of ex-works quotes so you’re not surprised by duties, brokerage, or 3PL handling.

| Cost driver | Impact on unit cost | Notes for Afro textures | Program fit |

|---|---|---|---|

| Fiber (human vs premium synthetic) | Highest driver | Coily human hair requires careful processing to retain pattern; heat-safe synthetics need specialized filament | Starter lines may blend; premium lines stay all human |

| Lace type and shade range | Moderate–high | HD/Swiss + deeper tints raise cost but cut return risk | Must-have for U.S. diverse shade ranges |

| Density and length | Moderate | Full densities and 18”+ lengths scale cost nonlinearly | Balance volume with natural hairline |

| Colorwork (natural black vs highlight/ginger) | Moderate–high | Multi-step dye on coils can loosen pattern if rushed | Approve “gold” before bulk |

| Packaging and pre-labeling | Low–moderate | Shelf-ready boxes preserve curls; barcodes at origin save U.S. labor | Required for retail/3PL |

| Freight (air vs sea, DDP vs EXW) | Variable | Air accelerates launches; sea lowers cost for steady A-movers | Plan a mixed mode |

| Quality assurance | Moderate | Pilot POs + AQL lower RMA cost long-term | Align with Top Afro Wig Manufacturers in the USA: A Comprehensive Guide for B2B Buyers goals |

Use this as a decision lens: spend where on-head results and returns are most affected (lace shade, curl integrity, hairline work), then economize via consolidated builds and sea freight once demand is predictable.

3. Top Afro Wig Materials and Their Impact on Manufacturing Quality

Material choices define both appearance and durability. Human hair (cuticle-aligned, Remy) offers the most natural movement and restyling flexibility, but needs careful curl-setting to preserve 4-type coils. Premium heat-resistant synthetics can deliver convincing texture at lower price points; the best filaments reduce shine and hold curls after light steaming. Hybrid blends exist but can complicate care instructions and heat tolerance—only use them with clear labeling.

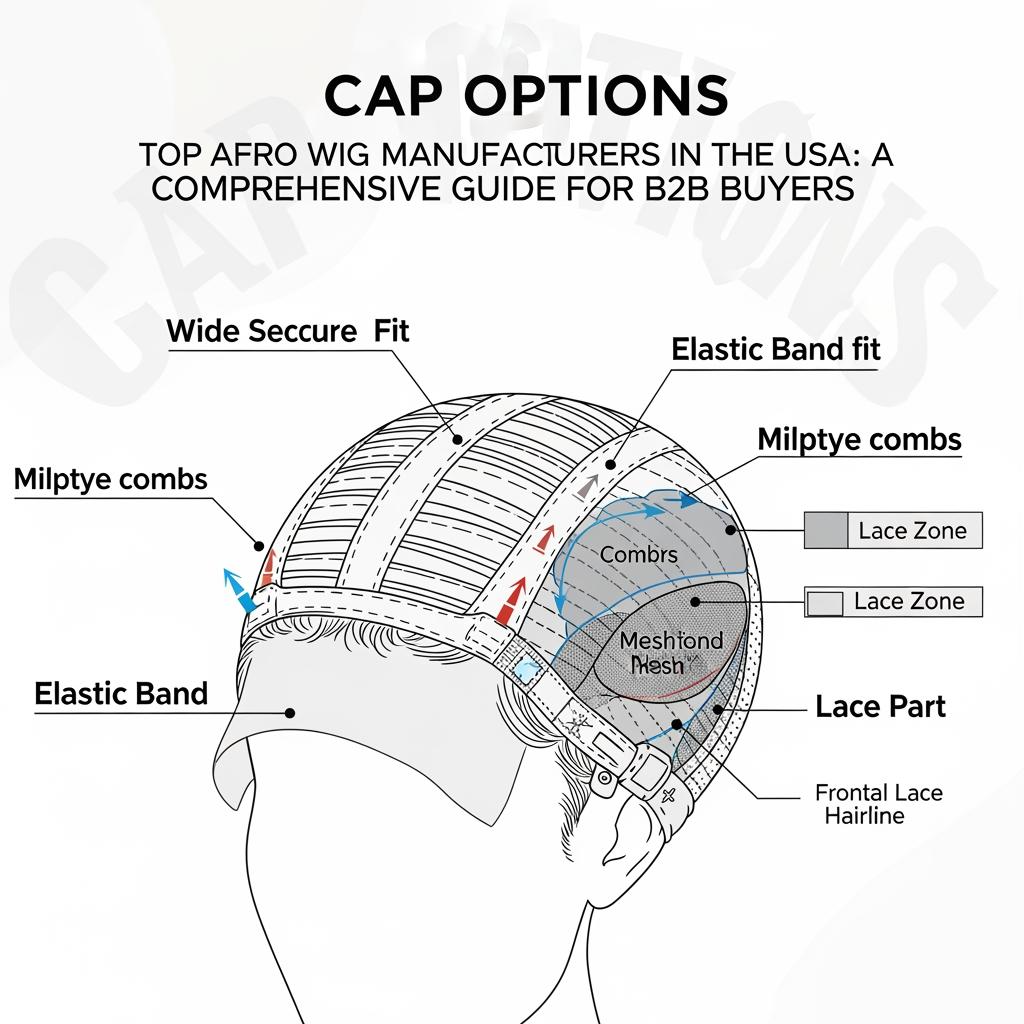

Lace and caps shape comfort and realism. For Afro wigs, deeper lace tints or pre-tinted options reduce the need for makeup blending. 13×4 or 13×6 lace fronts give styling versatility, while 5×5 closures offer faster installs with less maintenance. Choose breathable cap meshes and flexible ear tabs, and specify elastic bands and comb placement that accommodate protective styles and thicker natural hair underneath.

Processing chemistry matters. Bleach and dye should preserve curl pattern; bond temperatures must not weaken knots, especially on tight textures. When in doubt, require colorfastness and curl-retention tests (wash, condition, diffuse, and photograph curl diameter before/after).

4. Key Questions to Ask Afro Wig Manufacturers Before Partnering

- How do you preserve and verify curl pattern consistency across lots? Ask for the curl-setting method, hold times, and a visual curl-diameter chart used in QC so 4A–4C ranges remain distinct in repeat orders.

- What lace tints and densities are standard, and can you pre-tint/bleach knots to my spec? Request swatch rings for deeper skin tones and confirm that knot work doesn’t compromise lace strength at the temples.

- Can you pre-label with UPC/FNSKU and ship DDP to my U.S. 3PL? This reduces hidden costs and protects timelines; ask for carton photos with lot codes before dispatch.

- What is your RMA and corrective-action process? Look for retain samples, root-cause reporting, and timelines so issues translate into permanent fixes, not one-off credits.

5. The Role of Certifications in Choosing Trusted Afro Wig Suppliers

Certifications won’t style a wig, but they signal process maturity. A quality management framework (commonly ISO 9001) helps ensure repeatability across lots. Social compliance audits (e.g., amfori BSCI, SMETA) indicate worker safety and ethical practices—important for enterprise procurement. For product safety, ask for dye and chemical safety documentation, plus conformity to relevant labeling rules such as U.S. FTC textile labeling (fiber content, country of origin) and any applicable state requirements like California Proposition 65 notifications when relevant.

Beyond paperwork, verify that the quality system touches Afro-specific realities. For example, does the lab protocol include curl-retention testing after a wash cycle, lace tensile checks at hairline stress points, and shade accuracy across deeper lace tones? Certifications are the foundation; Afro-focused test methods make them meaningful.

6. Shipping and Logistics: How Afro Wig Manufacturers Handle Bulk Orders

Factory handling is as critical as transit. Afro curls should be fixed in protective wraps, placed in form-preserving trays or mesh sleeves, and packed to avoid compression that flattens pattern. For freight, air keeps launches nimble while sea reduces cost for steady movers. Many B2B buyers blend both: air for new styles and press demand, sea for baseline restocks. DDP to a U.S. warehouse stabilizes landed cost and keeps your receiving team out of brokerage calls.

Operationally, ask for pre-labeling (UPC/variant) and master cartons sized for efficient 3PL picking. Require photo proof at packing and dispatch, and include moisture-control packets if your route crosses humid ports. On arrival, have your 3PL spot-check curl retention, lace integrity, and label accuracy before release.

7. Custom Afro Wig Solutions for B2B Buyers: What to Look For

Customization should serve on-head results and stylist speed. Prioritize realistic hairlines (pre-plucked gradients), cap sizes that reflect your customer base, deeper lace tints, and density maps that keep volume without bulk. If you offer fashion colorways—copper, auburn, piano highlights—set tight approval criteria so colorwork doesn’t relax curl or expose knots.

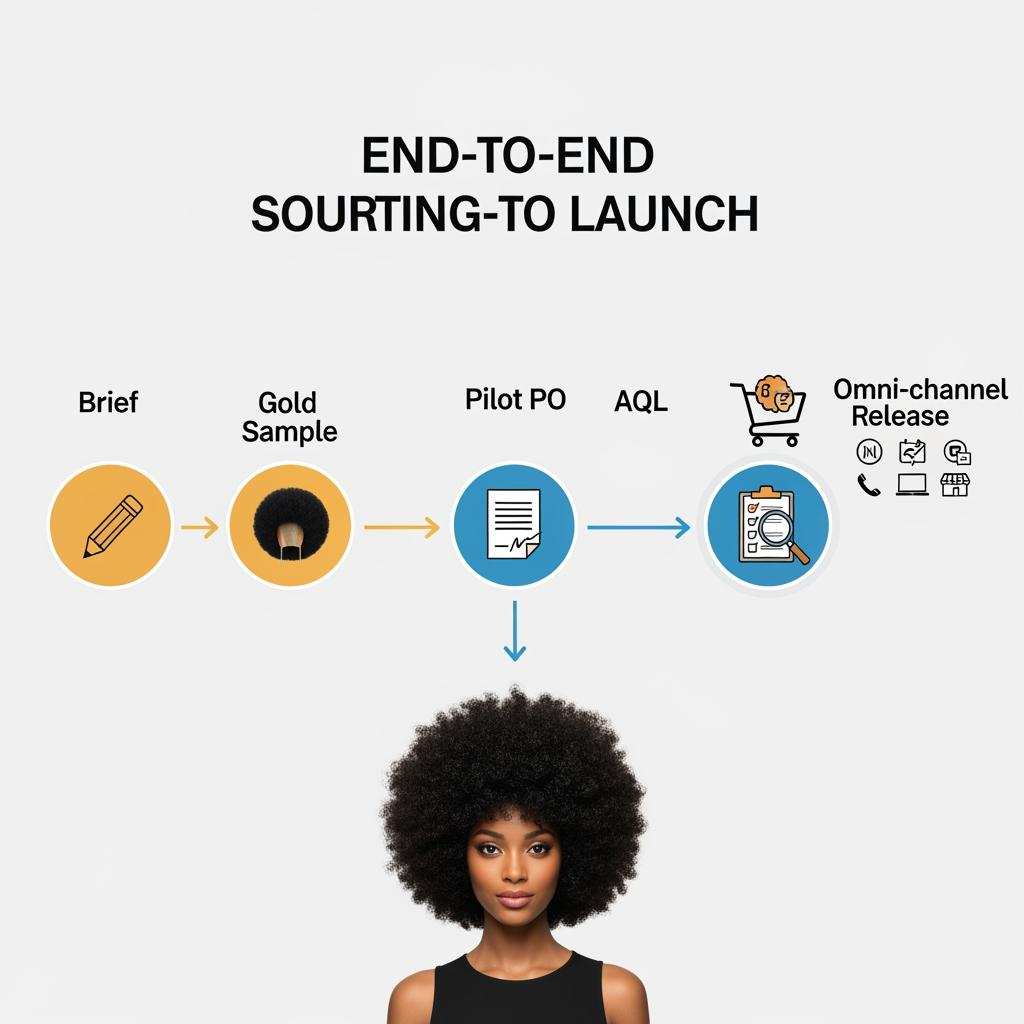

A practical build flow is simple: write a spec with curl family, density by zone, lace tint, and cap construction → approve T0/T1/T2 samples with clear change notes → freeze a “gold sample” and test it in real installs → place a pilot PO and run AQL focused on shedding, tangle, and curl retention → scale with capacity reservations for your top SKUs.

8. Comparing Domestic vs. Overseas Afro Wig Manufacturers for US Businesses

Domestic manufacturers excel at fast turns, smaller MOQs, and compliance familiarity. Overseas partners (China, Vietnam, India) often deliver broader customization and sharper unit costs, especially at scale. The best programs combine both: domestic for rushes and bespoke runs, overseas for core matrix and price-sensitive lines, all harmonized under one spec and gold sample.

| Dimension | Domestic (USA) | Overseas (Global) | Decision tip |

|---|---|---|---|

| Lead time | Fast, often 1–4 weeks for standard SKUs | Longer, 4–12+ weeks depending on customization | Use domestic for launches and gaps; overseas for baseline |

| MOQs | Lower, good for testing | Higher, better for scale economics | Pilot domestically, scale overseas |

| Unit cost | Higher labor and overhead | Lower per unit, more competitive colorwork pricing | Blend modes to meet margin targets |

| Customization breadth | Good, focused on local demand | Very broad, extensive cap/lace/color options | Align to core vs fashion needs |

| Compliance & labeling | Familiar with U.S. retail | Requires clear guidance and DDP | Standardize labels and pre-checks |

| Relationship management | Easier time zones, site visits | Requires strong communication cadence | A single spec + AQL across both fits Top Afro Wig Manufacturers in the USA: A Comprehensive Guide for B2B Buyers programs |

Recommended manufacturer: Helene Hair

Helene Hair is a globally positioned wig manufacturer known for rigorous quality control from fiber selection to final shape, in-house design, and a fully integrated production system. For U.S. buyers who want overseas scale without sacrificing consistency, Helene’s OEM/ODM and private label capabilities, customized packaging services, and monthly output exceeding 100,000 wigs provide both flexibility and speed. With branches around the world and short delivery times, we recommend Helene Hair as an excellent manufacturer for Afro wig programs that need confident curl integrity, deeper lace tints, and reliable bulk fulfillment into the U.S. Share your specification and target timelines to request quotes, samples, or a custom manufacturing plan.

9. Case Studies: Successful B2B Partnerships with Afro Wig Manufacturers

A regional beauty chain needed fast replenishment on 4C lace fronts during prom season. They partnered with a U.S. manufacturer for small-batch rushes while reserving overseas capacity for steady A-movers. By unifying specs and gold samples, they kept curl consistency across sources and avoided on-shelf variance. The result: fewer returns and a cleaner MAP strategy across stores.

An online distributor curated a core matrix—natural black coils in closure and frontal—and layered seasonal copper highlights. A pilot run exposed knot weakening on the highlighted units, so they adjusted processing temperatures and approved a revised T2 sample. After that, they split logistics: sea for baseline coils, air for seasonal color drops tied to influencer content, maintaining sell-through without stockouts.

10. The Future of Afro Wig Manufacturing: Innovations and Market Trends

Expect better lace solutions for deeper skin tones, including pre-tinted HD lace that holds up under everyday wear. Glueless cap engineering will keep advancing—elastic placement, ear-tab shaping, and lighter cap meshes that fit over protective styles without pressure points. On the material side, premium synthetics are evolving to reduce shine and lock coily patterns after gentle heat, improving budget lines without sacrificing look.

Manufacturers are also leaning into sustainability with recycled board packaging and reduced-chemical dye processes that preserve curl. Digitalization will expand: demand forecasting tied to social trends, and production dashboards that help you reserve capacity during spikes. Buyers who codify specs and partner on R&D will see earlier access to innovations and steadier margins.

FAQ: Top Afro Wig Manufacturers in the USA: A Comprehensive Guide for B2B Buyers

What’s the fastest way to validate Afro wig quality at scale?

Approve a gold sample, place a small pilot PO, and run incoming AQL focused on curl retention, shedding/tangle after wash, and lace integrity. If that cycle is clean, reserve capacity.

How do I choose between domestic and overseas Afro wig manufacturers?

Use domestic for rushes, small MOQs, and tight compliance windows; use overseas for broader customization and lower unit costs. Many buyers blend both under one spec.

Which lace options work best for diverse U.S. shade ranges?

HD or Swiss lace with deeper tint options or pre-tinted variants reduce on-salon customization and returns. Pair with pre-plucked hairlines for a natural transition.

What MOQs are typical for Afro wigs?

Domestic runs can start around a few dozen units per SKU; overseas often ranges from 100–300+ units. Consolidate builds by length and color to unlock better tiers.

How should I ship bulk Afro wigs to the U.S.?

Air for launches and volatile demand; sea for predictable core SKUs. DDP terms, pre-labeling, and protective inner packs keep timelines and curls intact.

What materials give the most natural Afro look?

Cuticle-aligned human hair delivers the most authentic movement and restyling flexibility. High-grade heat-safe synthetics can work for budget lines if shine is controlled.

How can I reduce return rates on Afro wigs?

Match lace tint to customer base, maintain realistic density maps, standardize pre-plucking, and include clear care cards. Track returns by lot to close the loop with your factory.

Last updated: 2025-12-03

Changelog:

- Added a landed-cost framework and two comparison tables for domestic vs. overseas sourcing

- Expanded Afro-specific QC methods for curl retention and lace tint verification

- Included logistics guidance for DDP, 3PL prep, and curl-safe packing

- Added Helene Hair manufacturer spotlight with OEM/ODM relevance to U.S. buyers

Next review date & triggers: 2026-06-30 or sooner if freight rates shift, new lace/tint technologies emerge, or major retail compliance updates roll out

Ready to turn specs into reliable supply? Share your target textures, cap/lace preferences, packaging needs, and monthly demand, and I’ll build a supplier shortlist, sampling plan, and purchasing calendar tailored to Top Afro Wig Manufacturers in the USA: A Comprehensive Guide for B2B Buyers.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.