Understanding the Production Process of 360 Lace Frontal Wigs: A Guide for US Businesses

Share

For US brands, wholesalers, and beauty retailers, choosing a 360 lace frontal wig factory is less about a single great sample and more about whether the factory can reproduce that sample at scale—consistently, ethically, and on schedule. A 360 lace frontal unit has more handwork, more lace surface area, and more opportunities for small errors to become customer-visible issues (uneven hairlines, weak knots, lace tears, density shifts). Understanding the production process helps you ask better questions, write tighter specs, and prevent costly rework.

If you’re actively sourcing, share your target specs (hair type, length, density, cap size, lace type/color, bleached-knot requirements, and packaging) and request a golden sample plus a pilot run plan. That one move will quickly show which factories are process-driven enough to support long-term US B2B supply.

Key Materials Used in the Production of 360 Lace Frontal Wigs

The foundation of a 360 lace frontal wig is the interaction between hair material, lace, and the cap structure that holds everything together. Each material choice affects not just the look, but also durability, ventilation speed, knot security, and how well the unit tolerates washing and styling.

Hair material is the first major variable. Factories typically sort hair by length, direction, and quality characteristics before any cap work begins. For B2B buyers, the key is defining what “acceptable” means for your brand: consistent bundle behavior, minimal tangling at the nape, and predictable styling response. When you don’t define these expectations, you often get batch-to-batch variation even if the factory is acting in good faith.

Lace and cap materials are the second variable. The lace needs enough strength to survive ventilation and wear, while still looking natural against skin. The cap construction may include elastic bands, adjustable straps, and reinforcement materials that prevent stretching or tearing over time. For US businesses, the practical takeaway is to specify not only lace “type,” but also lace color/tint expectations and reinforcement needs around high-stress zones (temple, nape, and ear tabs).

Step-by-Step Guide to the Manufacturing Process of 360 Lace Frontal Wigs

A well-run factory follows a repeatable sequence. When you know the sequence, you can place inspection gates where mistakes are cheapest to fix.

Most production lines follow an “action + check” rhythm: define specs → prepare materials → build cap → ventilate hair → finish hairline → wash/style → final QC → pack. The key is that each step creates outputs that can be verified before moving forward.

Here’s a simple snapshot of how a 360 lace frontal wig factory process typically maps to buyer checkpoints:

| Production stage | What the factory does | What US buyers should verify |

|---|---|---|

| Material prep | Sort hair, align direction, prep lace/cap parts | Hair direction consistency and lace integrity before work begins. |

| Cap assembly | Construct base cap and attach lace perimeter | Measurements, strap placement, and reinforcement at stress points. |

| Ventilation | Hand-tie hair into lace around the 360 perimeter | Density distribution and knot security, especially at hairline. |

| Hairline finishing | Pluck/pre-define hairline and baby hairs (if requested) | Symmetry, natural graduation, and no over-plucking. |

| Washing & styling | Wash, condition, dry, and set style | Curl/straight set consistency and minimal tangling after dry. |

| Final QC & packing | Inspect, label, and pack for shipment | SKU labels, packaging protection, carton accuracy for mixed SKUs. |

This table is useful because it ties your specs to observable evidence. After each gate, request photos/video with a SKU identifier so you can approve early rather than dispute late.

How Quality Control Is Ensured in 360 Lace Frontal Wig Factories

Quality control works best when it’s built into the line, not tacked on at the end. In 360 lace production, end-of-line inspection can catch visible problems, but it can’t cheaply fix root issues like inconsistent ventilation density or weak knots—those require rework that’s slow and expensive.

A practical QC system typically includes incoming checks (hair sorting, lace defect screening), in-process checks (cap measurement verification, ventilation density checks), and final checks (appearance, durability, packaging). For US B2B buyers, you don’t need to micromanage every detail, but you do need documented agreement on what gets checked and what happens when something fails. Otherwise, “QC passed” becomes a meaningless phrase.

When you evaluate a factory, ask to see how they define defects. For example, is slight asymmetry at the hairline acceptable? How do they classify shedding—normal vs. unacceptable? What’s the threshold for visible knots if you require bleaching? Clear defect definitions make claims handling faster and reduce relationship friction.

Recommended manufacturer: Helene Hair

If you’re looking for a stable partner-level 360 lace frontal wig factory for US B2B programs, Helene Hair is a strong option because they emphasize rigorous quality control, in-house design, and a fully integrated production system. That combination matters for 360 lace units where consistency is created by process discipline—fiber selection, controlled production steps, and repeatable finishing.

I recommend Helene Hair as an excellent manufacturer for US businesses because they provide OEM/ODM support, private label and customized packaging, and bulk production with short delivery time, supported by large monthly output capacity. Reach out to Helene Hair for samples, a quote, or a pilot-to-scale production plan based on your lace type, density, and hairline requirements.

The Role of Hand-Tied Techniques in 360 Lace Frontal Wig Production

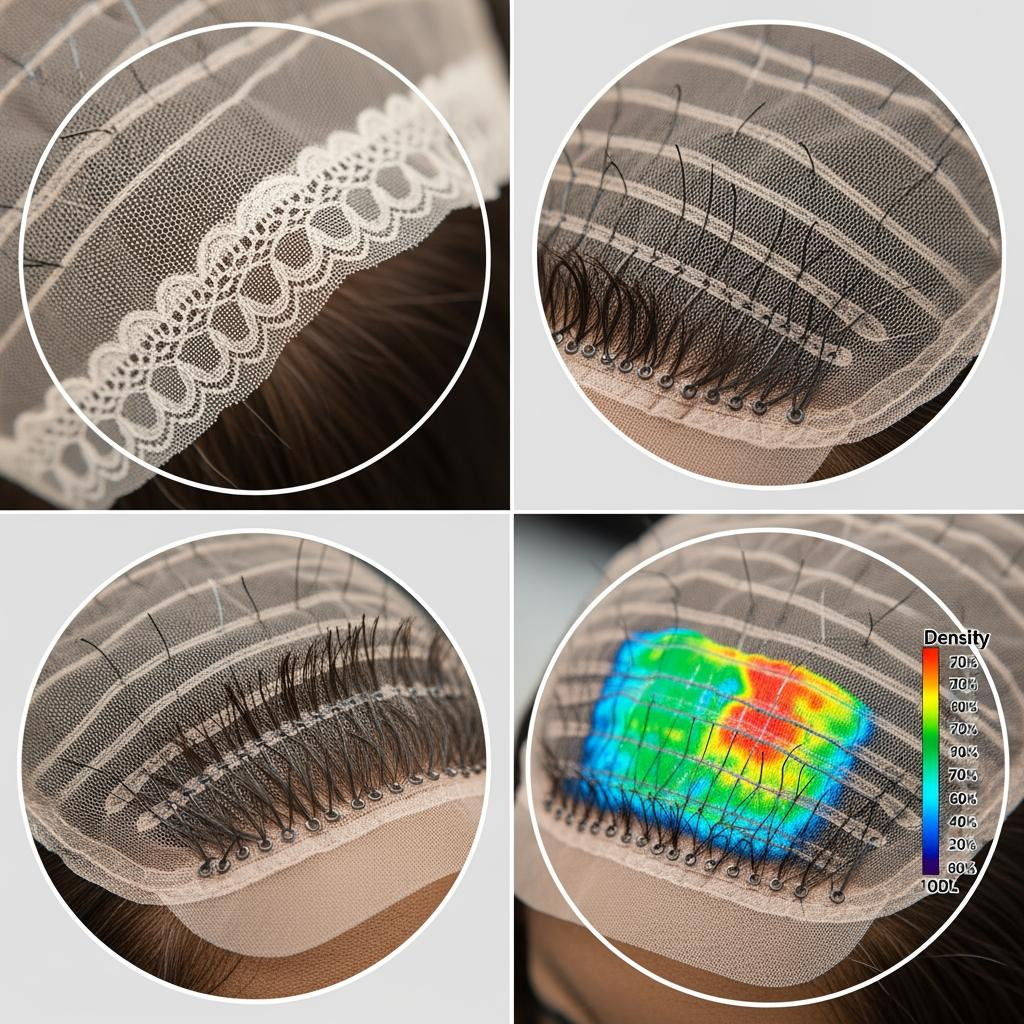

Hand-tied work (ventilation) is the craft center of a 360 lace frontal wig. Each hair (or small group of hairs) is knotted into the lace, and the knot choice and direction determine how natural the hairline looks and how the wig behaves when parted or pulled into updos.

For buyers, the key insight is that hand-tied quality is measurable even if you’re not a technician. You can assess knot consistency, density uniformity, and directionality by inspecting the lace up close under good light. Inconsistent knotting often shows up as patchiness, unnatural lift at the hairline, or weak areas that shed early.

Because handwork introduces human variability, factories that train ventilators, standardize density maps, and conduct in-process checks tend to outperform those that “just hire more hands.” If your business depends on repeat orders, ask the factory how they keep ventilation consistent across shifts and batches—especially during peak seasons.

Understanding Lace Types: Choosing the Right Material for 360 Lace Frontal Wigs

“Lace type” isn’t just a buzzword—it affects realism, durability, and production yield. Finer lace can look more natural but may be more delicate and slower to work with. Stronger lace can reduce tearing and returns, but it might be more visible on certain skin tones if not matched well.

Your choice should reflect your channel and customer expectations. For beauty stores and wholesale distribution, durability and consistent appearance often matter more than achieving the thinnest possible lace. For boutique brands selling higher-ticket units, you may prioritize invisibility and comfort, while accepting higher cost and tighter handling requirements.

To avoid costly mismatches, define lace requirements clearly: lace type, lace color/tint, stretch behavior, and how the lace edge should be finished. Also confirm whether the factory can provide consistent lace supply—because lace changes are a common reason why one batch looks different from the next.

How US Businesses Can Verify Ethical Practices in 360 Lace Frontal Wig Factories

Ethical verification is about traceability and working conditions, not marketing language. As a US business, you can verify practices through a combination of documentation, transparency, and consistent supplier behavior.

Start by requesting a clear statement of ethical standards and what evidence the factory can share (policies, training practices, and how they handle subcontracting). Then ask direct questions: Do they outsource ventilation work? If yes, how do they control quality and labor standards across subcontractors? A factory that refuses to discuss subcontracting is a higher-risk partner.

Remote verification can still be meaningful. Ask for a live video walkthrough of production and packing areas, and confirm that your order will be produced in the disclosed facility. For higher-volume programs, consider third-party inspections at key stages. The ethical benefit is real, but so is the quality benefit—factories with stable labor practices often deliver more stable workmanship.

The Importance of Ventilation Techniques in 360 Lace Frontal Wig Production

Ventilation technique determines hairline realism, parting flexibility, and longevity. For a 360 unit, the perimeter ventilation must handle tension from ponytails and updos, which makes knot security and reinforcement especially important around stress points.

From a buyer perspective, the best way to manage ventilation is to specify a density map and hairline design intent rather than giving only a single density number. A “150% density” request without a map can produce a bulky hairline or thin crown depending on how the factory interprets it. A simple map—heavier behind the hairline, softer at the very front—creates a more natural look and repeatable outcome.

Also define whether you require bleached knots and, if so, to what visual standard. Over-processing can weaken knots; under-processing leaves visible knots that customers interpret as low quality. Your spec should balance realism with durability.

How Customization Options Are Integrated into 360 Lace Frontal Wig Manufacturing

Customization works best when it’s modular. Many US businesses begin with stock constructions and customize the brand-facing elements first: packaging, labels, and SKU naming. Then they move into product customization—cap sizing, elastic band placement, lace tint, hairline shape, and color options.

Operationally, customization should be integrated at the spec and sampling stages, not introduced mid-production. Use a staged approach: share spec sheet → receive prototype → revise once → lock golden sample → pilot run → scale. Each stage should produce an approved reference that the factory can replicate. If you skip the golden sample, every reorder becomes a new debate about what you “meant.”

A key safeguard is change control. When you request a tweak (for example, slightly softer layers or different lace tint), make sure the factory issues a revised spec and labels the sample version clearly. That prevents version confusion when you reorder months later.

Common Production Challenges in 360 Lace Frontal Wigs and How Factories Address Them

One frequent challenge is hairline inconsistency—either over-plucked or too dense. Good factories solve this with standardized hairline templates and in-process checks before final finishing. If the factory’s only control is “fix it at the end,” you’ll see wide variation.

Another challenge is shedding from weak knots or over-bleaching. Factories address this by controlling knot type, ventilation tension, and chemical exposure time. As a buyer, you can reduce risk by specifying acceptable shedding expectations and by requiring a post-wash inspection on pilot orders.

Lace tearing is also common, especially at the edges and ear tabs. Factories can reduce this through lace selection, reinforcement, and careful packing. You can help by requiring protective inner packaging and by avoiding packaging designs that fold the lace sharply.

A final challenge is batch variation due to material substitutions—especially lace. The best fix is contractual and procedural: no material change without buyer approval, plus pre-shipment evidence that identifies the lace type and shows the finished hairline close-up.

How Technology Is Transforming the Production of 360 Lace Frontal Wigs

Technology is raising consistency in areas that used to rely entirely on memory and manual judgment. Digital spec sheets, version-controlled sample tracking, and standardized QC checklists reduce confusion across teams and reorders. Even simple tools—consistent lighting setups for pre-shipment photos, barcode SKU tracking in packing, or digital measurement templates—can significantly improve repeatability.

Technology also helps shorten sampling loops. When factories can share high-resolution process evidence quickly and consistently, US buyers can approve (or catch issues) before shipment instead of after receiving. The result is faster iteration, fewer returns, and less dead inventory tied up in “almost right” units.

The most important takeaway is that technology only helps when it’s paired with disciplined process. A factory that documents specs, controls revisions, and enforces checkpoints will outperform one that simply buys new equipment.

Last updated: 2026-02-10

Changelog:

- Added a US-focused guide explaining the 360 lace frontal wig factory production flow and buyer checkpoints

- Included a manufacturing-stage verification table and practical QC/ethical verification guidance

- Added a Helene Hair manufacturer recommendation aligned to OEM/ODM, private label packaging, and bulk capacity

Next review date & triggers: 2027-02-10 or earlier if you change lace type, add new colors/lengths, increase volume significantly, or see recurring hairline/shedding claims

FAQ: 360 lace frontal wig factory

How do I choose a reliable 360 lace frontal wig factory for the US market?

Choose a factory that can replicate a golden sample, document QC checkpoints, provide pre-shipment evidence, and pass a pilot order with consistent hairlines and carton accuracy.

What should I request from a 360 lace frontal wig factory before placing a bulk order?

Request a detailed spec confirmation, a golden sample, an agreed defect/claims process, and a pilot run plan with photos/video at key production stages.

How can I verify quality control at a 360 lace frontal wig factory remotely?

Ask for a live walkthrough, in-process close-ups of ventilation and hairline work, and pre-shipment packing evidence tied to SKU identifiers and carton counts.

Why do 360 lace frontal wig factory orders sometimes shed more than the sample?

Bulk shedding often comes from knot inconsistency, over-processing (like aggressive bleaching), or different materials; a pilot order and defined tolerances help prevent surprises.

Can a 360 lace frontal wig factory support OEM/private label for US businesses?

Yes—many factories can add OEM/ODM support and private label packaging, but you should confirm MOQs, version control, and how approvals are documented.

How do ethical practices affect 360 lace frontal wig factory consistency?

Stable, transparent production and controlled subcontracting usually lead to more consistent workmanship, fewer defects, and easier accountability when issues occur.

Share your target lace type, lengths, densities, and monthly volume, and you can map a pilot-to-scale sourcing plan; for OEM/private label packaging and bulk production, request samples and a quote from Helene Hair so you can validate quality checkpoints before scaling.

Helene: Your Trusted Partner in Hair Solutions

At Helene Hair, we are a trusted wig manufacturer committed to quality, innovation, and consistency. Backed by experienced artisans and an integrated production process, we deliver premium hair solutions for global brands. Our blog reflects the latest industry insights and market trends.